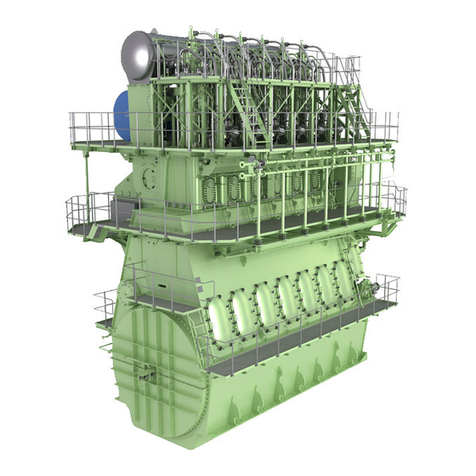

MAN B&W S50MC-C8

MAN B&W Index

Subject Section

MAN Diesel

Subject Section

S

Sequence diagram for Controllable Pitch

Propeller ..............................................................16.02

Sequence diagram for Fixed Pitch Propeller ...........16.01

Servo oil system for VBS type CP propeller ..............5.18

SFOC calculations .....................................................2.09

SFOC calculations, example ....................................2.10

SFOC for high efficiency turbochargers ....................2.07

SFOC guarantee ........................................................2.08

SFOC, engine configurations related to ....................6.01

SFOC, reference conditions and guarantee .............2.08

SFOC, with constant speed ......................................2.09

SFOC, with fixed pitch propeller ...............................2.09

Shaftline earthing device ...........................................5.17

Shop test .................................................................19.05

Shop trials ...............................................................19.01

Shut down for AMS and UMS – Class and MAN Diesel

requirements ............................................................18.04

Shut down system ...................................................16.01

Side mounted PTO/RCF, space requirement ............4.02

Silencer, exhaust gas ..............................................15.04

Slow down and shut down system, alarm ..............18.04

Slow down for UMS – Class and MAN Diesel

requirements .......................................................18.04

Slow down system .............................................16.01/03

Slow turning before starting ....................................16.01

SMG/CFE Generators ...............................................4.03

Soft blast cleaning, turbocharger cleaning ..............15.02

Space requirement ....................................................5.02

Space requirements and overhaul heights ................5.01

Space requirements for side mounted PTO/RCF......4.02

Spare parts ..............................................................19.01

Spare parts, additional parts ...................................19.07

Spare parts, unrestricted service ............................19.06

Spare parts, wearing parts ......................................19.08

Spark arrester, exhaust gas .....................................15.04

Specific Fuel Oil Consumption (SFOC) .....................1.04

Specific fuel oil consumption, ME versus MC

engines .................................................................2.06

Specification for painting of main engine ................19.02

Specified maximum continuous rating (M) ................2.04

Spray shields, fuel oil and lubricating oil pipe ...........7.04

Standard tools for maintenance, list of ...................19.10

Standard tools, dimensions and masses ................19.10

Start of engine, temperature at ...............................12.08

Starting air compressors .........................................13.02

Starting air receivers ................................................13.02

Starting air system ....................................................1.06

Starting air system, manoeuvring diagram..............16.01

Starting air systems, components for .....................13.02

S

Starting air valve ........................................................1.06

Starting and control air pipes ..................................13.03

Starting and control air systems..............................13.01

Static converter, frequency........................................4.03

Stuffing box ...............................................................1.06

Stuffing box drain oil system ...................................10.01

Supply system, cylinder lubricating oil ......................9.03

Symbols for piping .........................................................A

System control units, MAN B&W Alpha

Cylinder Lubricators ..............................................9.02

System, cylinder lubricating oil .................................9.01

System, engine control ............................................16.01

System, exhaust gas ...............................................15.01

System, exhaust gas for main engine ...............15.03/04

System, fire extinguishing for scavenge air space ..14.07

System, fuel oil ..........................................................7.01

System, jacket cooling water ..................................12.05

System, jacket water ...............................................11.03

System, lubricating and cooling oil ...........................8.01

System, MAN B&W Alpha Cylinder Lubrication ........9.02

System, manoeuvring ................................................1.06

System, manoeuvring, on engine ............................16.01

System, scavenge air .............................................. 14.01

System, scavenge air box drain ..............................14.06

System, scavenge air cooler cleaning .....................14.05

System, seawater ....................................................12.01

System, seawater cooling .......................................12.02

System, shut down ..................................................16.01

System, starting air .................................................16.01

System, stuffing box drain oil ..................................10.01

Systems, control and starting air.............................13.01

Systems, monitoring and instrumentation ..............18.01

Systems, starting air ................................................13.01

Systems, turbocharger cleaning ..............................15.02

T

Tank, deaerating ......................................................12.07

Tank, lubricating oil ....................................................8.06

Telegraph system ...............................................16.01/03

Temperature at start of engine ................................12.08

Temperature control valve, lubricating oil ..................8.05

The MC/MC-C Tier II Engine .....................................1.01

Thermostatic valve, central cooling .........................11.03

Thermostatic valve, jacket water .............................12.07

Thermostatic valve, seawater ..................................12.04

Thrust bearing ...........................................................1.06

Tool panels ..............................................................19.11

Tools ........................................................................19.01

Tools, dimensions and masses of ...........................19.10