Manaras Opera MGH Service manual

Installation & Instruction Manual

Installation & Instruction Manual

Commercial & Industrial Very Heavy Duty Worm Gear Operator

Commercial & Industrial Very Heavy Duty Worm Gear Operator

(For sectional doors, rolling doors and grilles)

(For sectional doors, rolling doors and grilles)

MGH

MGH

Electrical Control (BOARD 070E)

Electrical Control (BOARD 070E)

READ AND FOLLOW ALL INSTR CTIONS.

SAVE THESE INSTR CTIONS.

GIVE TO END- SER.

erial #

Model #

Wiring Diagram #

Project #/Name

Door #/Name

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

2

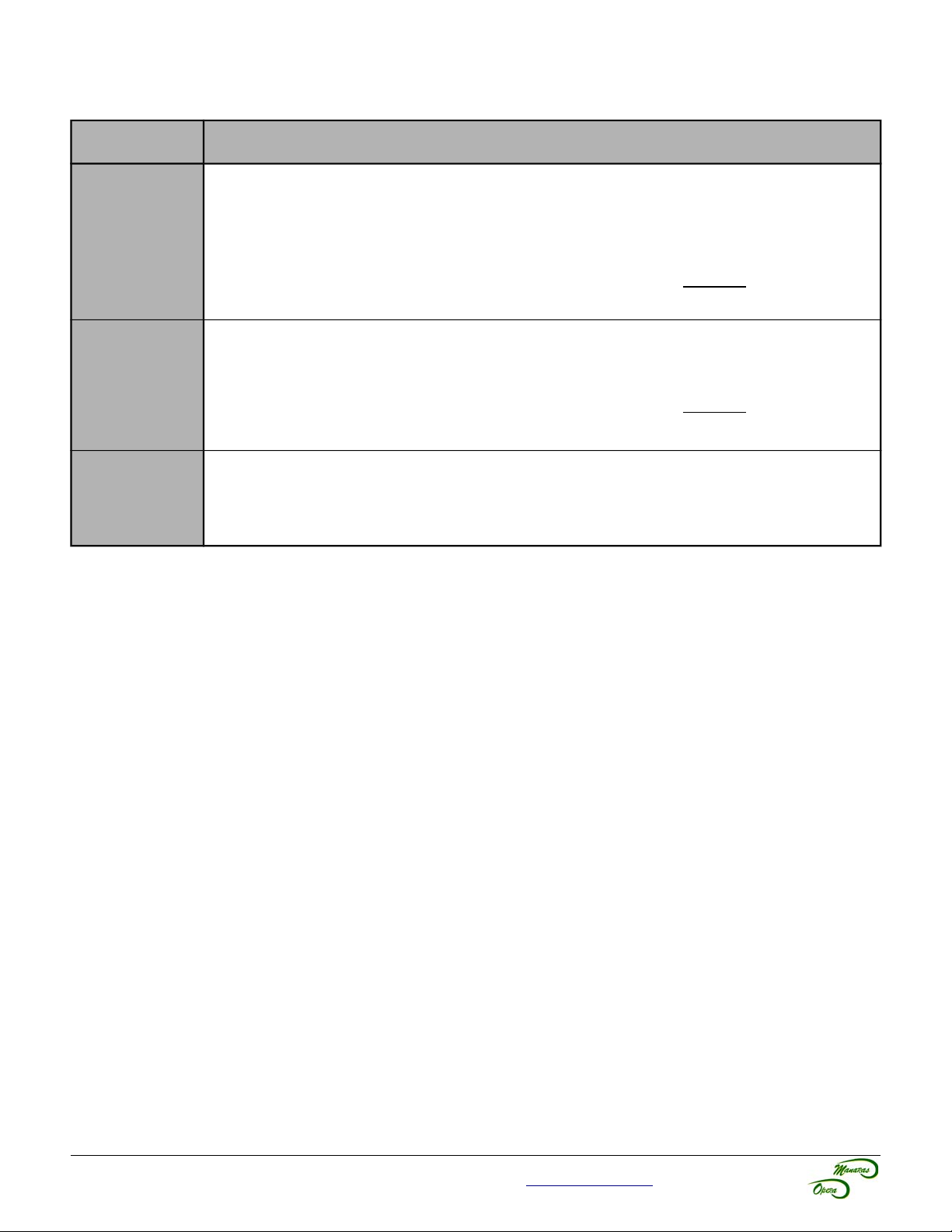

TABLE OF CONTENTS

Installation Instructions............................................................................................................................................... 3

1 General Specifications and Dimensions.........................................................................................................................................................4

1.1 ½ to 1-1/2 HP............................................................................................................................................................................................4

1.2 2 to 5 HP...................................................................................................................................................................................................5

2 Door & Operator Hardware...............................................................................................................................................................................6

2.1 Delivery of Operator..................................................................................................................................................................................6

2.2 Hardware upplied....................................................................................................................................................................................6

3 Operator Installation..........................................................................................................................................................................................7

3.1 Operator Mounting Options.......................................................................................................................................................................7

3.2 Operator Mounting Holes..........................................................................................................................................................................7

3.3 prockets, preader Bar and Drive Chain Installation.............................................................................................................................8

4 Manual Hand Chain and Disconnect Chain...................................................................................................................................................10

4.1 Adjustment of the Manual Hand Chain...................................................................................................................................................10

4.2 Installation...............................................................................................................................................................................................11

4.3 Operating Mode......................................................................................................................................................................................12

5 Limit Switches & Limit Cams: Adjustment & Functionality........................................................................................................................13

5.1 Limit witch Adjustments: Open and Close Cam ettings.....................................................................................................................13

5.2 Limit witch Functionality........................................................................................................................................................................13

5.3 Limit witch Adjustment Using Manual Hand Chain...............................................................................................................................14

6 Electrical Wiring...............................................................................................................................................................................................15

6.1 Low Voltage (Controls) and High Voltage (Power) Connections............................................................................................................16

6.2 Main Power upply Connection..............................................................................................................................................................16

6.3 Wall-Button Connection...........................................................................................................................................................................17

6.4 Optional Accessory Connections............................................................................................................................................................18

7 Electronic Control Board (ECB) – BOARD 070E...........................................................................................................................................21

7.1 General Layout........................................................................................................................................................................................21

7.2 On-Board LED Monitoring tatus...........................................................................................................................................................22

7.3 Electronic Control Board (ECB) Programming.......................................................................................................................................24

8 On-Board Radio Receiver...............................................................................................................................................................................27

8.1 Radio Receiver Components and Compatible Transmitting Devices.....................................................................................................27

8.2 Programming Instructions.......................................................................................................................................................................27

8.3 Radio Control Functions – 1 and 3-Button Transmitters.........................................................................................................................28

9 Operator Start-up.............................................................................................................................................................................................30

10 Clutch Adjustment (if applicable)...................................................................................................................................................................31

ser Instructions........................................................................................................................................................ 32

1 Quick Fix Instructions.....................................................................................................................................................................................33

Maintenance Instructions........................................................................................................................................... 34

1 Preventative Maintenance Schedule..............................................................................................................................................................34

1.1 Mechanical Inspection.............................................................................................................................................................................34

1.2 Electrical Inspection................................................................................................................................................................................35

1.3 Band Brake Maintenance........................................................................................................................................................................36

2 Reducer Maintenance......................................................................................................................................................................................38

3 Troubleshooting Guide....................................................................................................................................................................................39

4 Electrical Drawings..........................................................................................................................................................................................41

4.1 1 Phase Operator with BOARD 070E.....................................................................................................................................................41

4.2 3 Phase Operator with BOARD 070E.....................................................................................................................................................42

4.3 External Wiring with BOARD 070E.........................................................................................................................................................43

5 Mechanical Exploded Views and Replacement Components.....................................................................................................................44

5.1 MGH – ½, ¾, 1, 1-½ HP..........................................................................................................................................................................44

5.2 MGH – 2, 3, 5 HP....................................................................................................................................................................................45

5.3 MGH Brake..............................................................................................................................................................................................46

5.4 MGH Control Box with BOARD 070E.....................................................................................................................................................47

5.5 Replacement Motors, Transformers, olenoids and Resets..................................................................................................................48

Notes............................................................................................................................................................................ 50

Warranty...................................................................................................................................................................... 51

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

3

Installation Instructions

IMPORTANT INSTALLATION INSTR CTIONS

WARNING

TO REDUCE THE RI K OF EVERE INJURY OR

DEATH TO PER ON :

1. READ AND FOLLOW ALL IN TALLATION IN TRUCTION .

2. Install only on a properly operating and balanced door. A door that is operating

improperly could cause severe injury. Have qualified service personnel make repairs

to cables, spring assemblies and other hardware before installing the operator.

3. Remove all pull ropes and remove, or make inoperative, all locks (unless

mechanically and/or electrically interlocked to the power unit) that are connected to

the door before installing the operator.

4. Installation of this door operator must be done by a qualified installer.

5. Verify that the operator is correct for type, size of door and frequency of use per the

operator specifications.

6. Install the door operator at least 8 feet (2,44 m) or more above the floor if the operator

has exposed moving parts. Covers or guarding, provided by the manufacturer, must

be installed when the operator is mounted less than 8 feet (2,44 m) above the floor.

7. Do not connect the door operator to the source of power until instructed to do so.

8. Locate the control station: (a) within sight of the door, (b) at a minimum height of

5 feet (1,5 m) above floors, landings, steps or any other adjacent walking surface so

small children cannot reach it, and (c) away from all moving parts of the door.

9. Install the Entrapment Warning Placard next to the control station in a prominent

location.

10. For products having a manual release, instruct the end user on the operation of the

manual release.

11. If you have any questions about the safety of the door operating system, do not install

the operator, contact Manaras-Opera at 1-800-361-2260.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

4

1 General Specifications and Dimensions

1.1 ½ to 1-1/2 HP

UPPLY VOLTAGE...............................115, 230 VAC single-phase, 208, 460, 575 VAC three-phase

CONTROL VOLTAGE............................24 VAC class 2 transformer, 2 amp fuse type ACG

MOTOR.................................................Continuous duty 1/2, 3/4, 1, 1-1/2 horsepower

OPERATOR OUTPUT PEED..............43 RPM

NET WEIGHT (Operator only)...............137 Lbs (62 Kg)

TANDARD WIRING TYPE..................C2 (momentary contact to open/stop and constant-pressure-to-close)

APPLICATION.......................................Very heavy duty worm gear for sectional doors, rolling doors and grilles

DUTY.....................................................25 cycles/hour or >80 cycles/day

Table 1 - Operator Selection Guide ½ to 1-1/2 HP

Maximum Area in Square Feet (general guideline)

Rolling Doors Sectional Doors

HP Insulated

teel

16 ga

teel

teel Grilles

20 ga

teel

Alu. Door

22 ga teel

Alu. Grilles

24 ga

teel

teel

18 ga

ins.

teel

18 ga

20 ga

ins.

Wood

teel 20 ga,

22 & 24 ga

ins.

Alu. teel

22 & 24 ga

Fiber

Glass

½157 236 260 319 358 196 245 314 343 392

¾206 294 358 451 515 270 319 441 490 549

1255 358 446 574 613 294 392 490 564 613

1-½ 353 486 633 625 373 466 549 613

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 1 - MGH Dimensions ½ to 1-1/2 HP

5

1.2 2 to 5 HP

UPPLY VOLTAGE...............................208, 460, 575 VAC three-phase

CONTROL VOLTAGE............................24 VAC class 2 transformer, 2 amp fuse type ACG

MOTOR.................................................Continuous duty 2, 3, 5 horsepower

OPERATOR OUTPUT PEED..............43 RPM

NET WEIGHT (Operator only)...............137 Lbs (62 Kg)

TANDARD WIRING TYPE..................C2 (momentary contact to open/stop and constant-pressure-to-close)

APPLICATION.......................................Very heavy duty worm gear for sectional doors, rolling doors and grilles

DUTY.....................................................25 cycles/hour or >80 cycles/day

Table 2 - Operator Selection Guide 2 to HP

Maximum Area in Square Feet (general guideline)

Rolling Doors Sectional Doors

HP Insulated

teel

16 ga

teel

teel Grilles

20 ga

teel

Alu. Door

22 ga teel

Alu. Grilles

24 ga

teel

teel

18 ga

ins.

teel

18 ga

20 ga

ins.

Wood

teel 20 ga,

22 & 24 ga

ins.

Alu. teel

22 & 24 ga

Fiber

Glass

2451 613 660 560 620 660

3620 830 890 830 870 910

5* * * * * *

* Consult Factory

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 2 - MGH Dimensions 2 to HP

6

2 Door & Operator Hard are

2.1 Delivery of Operator

Upon delivery of your OPERA jackshaft operator, inspect the unit immediately for any shipping damages. Verify that

you have received all the hardware parts pertaining to your operator model, as listed in Table 3 and shown in

Figure 3. If ordered, other items such as radio controls or other types of optional equipment may be present. If any

item is missing or if there is evidence of damage, call the transport company or your direct supplier.

2.2 Hard are Supplied

Table 3 - Standard Hardware Parts Supplied

No Qty Description

1 1 3-Push-button station (open/close/stop)

2 1 Operator sprocket (1)

Lxxxx

Hxxxx

Gxxxx

3 1 Door sprocket (1)

4 1 #41/#50 Drive chain, 4ft (1) (2)

5 1 #41/#50 Chain link (1)

6 4 5/16-18 x 5/16” et screw HD1-

HBAG

7 2 Key 1/4” x 1-1/2”

8 1 Pocket wheel hand chain, 24ft (3) (4)

9 1 Chain keeper for hand chain (4)

10 1 Disconnect chain, 14ft (3) (5)

11 1 Chain keeper for disconnect chain (5)

12 1 Handle for disconnect chain (5)

13 1 Entrapment Warning Placard

NOTE: Install the Entrapment Warning Placard (shown in Figure 4), next to the control station, visible in the area of

the door.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

(1) Differs according to operator model and door characteristics

(2) 5ft for 42/54/60 tooth door sprocket, 8ft for 72 tooth door sprocket

(3) Quantity = 2 times door shaft height minus 4ft

(4) Only supplied with OMH/OPH/OHJ/OBH/O H/OGH/MGH/GH

(5) Only supplied with OMJ/OPJ/O H/MGH/GH

Figure 3 - Standard Jackshaft Hardware

Figure 4 - Entrapment Warning Placard

7

3 Operator Installation

3.1 Operator Mounting Options

The heavy-duty jackshaft operator line has a dual output shaft and may be wall mounted on either the left hand side

or the right hand side of a sectional door or a rolling door. The heavy-duty jackshaft hoist model comes with a chain

hoist located on the right of the operator. If the application requires that the chain hoist be located on the left of the

operator, it may easily be moved in the field, per the instructions found in section 4, p.10.

This operator is not intended to be installed on horizontal slide doors.

Figure - Right Side or Left Side Wall Mount

(Chain Hoist on Right)

Figure 6 - Right Side Wall Mount

(Chain Hoist on Right)

3.2 Operator Mounting Holes

CA TION

The operator has exposed moving parts and to prevent access to the pinch points, this operator must be installed

at least 8 feet (2,44 m) or more above the floor. Alternatively, covers or guarding, provided by the manufacturer,

must be installed when the operator is mounted less than 8 feet (2,44 m) above the floor.

1. Ensure that the wall or mounting surface provides adequate

support for the operator. The surface must be rigid enough to

prevent any play between the operator and the door shaft.

2. Locate the four mounting holes and the two positive locking

holes, as shown in Figure 7.

3. The optimum distance between the door shaft and the

operator drive shaft is between 12" and 15".

4. ecure the operator to the wall with 1/2” thru-bolts. If the wall

construction prohibits the use of thru-bolts, then sufficiently

sized lag bolts and anchors may be used.

5. Only tighten the bolts after having adjusted the tension of the

drive chain.

6. Ensure that the door shaft and the operator shaft are

parallel.

7. Adjust the drive chain as per instructions found in section

3.3, p.8.

8. ecure the positive locking holes with 1/2” thru-bolts in order

to prevent the operator from moving during the operation,

which keeps the drive chain alignment straight and avoids

abusive wear to the sprockets. Figure 7 - MGH Mounting Holes

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Positive Locking

Holes

8

3.3 Sprockets, Spreader Bar and Drive Chain Installation

The hardware components shown in Figure 8 have been supplied with your operator.

1. Place the door sprocket loosely on the door shaft.

2. Place the operator drive sprocket on the appropriate side of the operator and align it with the drive sprocket of

the operator.

3. Lock the operator and door sprockets in place by inserting the keys and tightening their respective set

screws.

4. Wrap the operator drive chain around the door sprocket and the operator sprocket. horten the drive chain to

the appropriate length. Use the chain link to attach the operator drive chain together.

5. lide the operator to tighten the drive chain and then firmly tighten the mounting bolts.

6. Check the tension on the chain (there should be no more than a 1/4" of slack when the chain is depressed

between the sprockets).

7. Manaras-Opera recommends the use of a chain spreader (sold separately).

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 8 - Hardware Components

Bolt 3/8-16

(To attach chain

spreader)

5

et crew

Door procket

preader Collar

Chain preader

preader Collar

Operator procket

Key

Key

Drive Chain

Washer 3/8

Lock Washer 3/8

Nut 3/8-16

1

2

3

3

4

6

7

Door haft

Operator haft

9

3.3.1 Gear Reducer Breather

CA TION

• To avoid the risk of having high pressure build-up in the reducer (gear box), a reducer breather should

be installed.

•Failure to install the breather may lead to oil leakage from the seal, which will damage the reducer.

All Gear Head operators are supplied with a Reducer Breather. The breather is not mounted at the factory in order to

avoid leakage during handling of the reducer.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Place the breather with the reducer elbow

Unscrew the plug

Plug

Drain

Reducer

Breather

1

2

Breather

Elbow

(facing up)

Tighten the reducer elbow

and angle upwards.

crew the reducer breather

in the reducer elbow.

10

4 Manual Hand Chain and Disconnect Chain

4.1 Adjustment of the Manual Hand Chain

By default, the operator is provided with the chain hoist located on the right hand side. If handling requires the chain

hoist to be on the left side (rolling doors, left operator hood mount), the hoist can easily be transferred from the right

hand side to the left hand side in the field. Refer to Figure 9 and step by step instructions below.

1. Use an Allen key to unscrew and remove the collar.

2. Remove the washer which is located between the collar and the chain guide.

3. Remove the chain guide.

4. Remove the pocket wheel.

5. Transfer these components to the left hand side.

6. Insert the pocket wheel on the hoist shaft up against the spring pin.

7. Insert the chain guide on the hoist shaft.

8. Insert the washer against the chain guide.

9. Insert the collar at the end and use an Allen key to tighten the set screw.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 9 - Changing Chain Hoist from Right to Left

Hoist

haft

Final Position

Hoist on Left Washer

Chain Guide

Collar

pring Pins Pocket Wheel

11

4.2 Installation

4.2.1 Chain Hoist

Before pulling the hand chain through the pocket wheel, pull the limit

cam's retaining bracket back. Turn the cams to the center of the limit

shaft to be sure that they are not being mechanically driven through

their normal limit switch end positions.

1. Run the hand chain through the pocket wheel and through

the chain guide, see Figure 10.

2. Allow both ends of the chain to hang down toward the

ground until both ends are approximately 2 feet (0.6 m) from

the floor. Cut the hand chain if necessary.

3. Connect both ends of the hand chain together.

4.2.2 Disconnect Chain

1. Link the disconnect chain to the hook located at the

extremity of the operator's disconnect mechanism, see

Figure 11.

2. Install the handle under the chain keeper to facilitate

handling of the chain.

3. Under the handle, make a knot in order to fasten the end of

the chain.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 11 - Disconnect Chain

Handle

Disconnect

Mechanism from

Operator

Disconnect Chain

Knot

Figure 10 - Hand Chain Installation

Chain Keeper

12

4.3 Operating Mode

This operator has a floor level hoist engagement lever to:

–disconnect the door from the electrical motor

–release the brake

–engage the manual hoist mechanism, see Figure 12

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 12 - Hoist Engagement and Hoist Operation

Pull the handle and

attach the disconnect

chain to the chain

keeper for manual

operation.

Release the tension from

the disconnect chain to

return to electrical mode.

Chain Keeper Disconnect Chain

Handle

2. Manual Mode 3. Storage

PULL

PULL

STORE

STORE

Pull chain on either side

to operate door.

Follow the 3 steps shown below to

attach the chain (when not in use)

to the chain keeper.

1. Engagement 4. Return to Electrical Mode

13

5 Limit S itches & Limit Cams: Adjustment & Functionality

WARNING

To reduce risk of EVERE INJURY or DEATH to persons:

•Do not attempt to make limit switch adjustments unless power has been electrically disconnected.

5.1 Limit S itch Adjustments: Open and Close Cam Settings

This operator is equipped with the ACC -CAM® feature, for precise and quick one-handed limit setting adjustments.

To adjust the limit cams, see Figure 13.

1. Pull the cam's retaining bracket back.

2. Turn the cams for limit adjustment: turning cams toward the center of the limit shaft increases door travel or

turning the cams toward the limit switch decreases door travel.

5.2 Limit S itch Functionality

Open Limit S itch and Advanced Open Limit S itch

When activated, the Open Limit witch will stop the operator while the door is travelling in the upward direction.

hould be adjusted accordingly to stop door in fully open position. The microprocessor has a built-in program that

replaces the Advanced Open Limit witch.

Close Limit S itch and Advanced Close Limit S itch

Close Limits are not present on operators with an ECB. In it's place, the microprocessor has a built-in patented

Advanced Close Time feature. While the door is travelling downwards and once the Advanced Close Limit witch is

activated, the door will stop after 200 milliseconds. The distance travelled varies according to the speed of the door.

The value is fixed and cannot be re-programmed or adjusted.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 13 - Limit Cam Adjustment

Open Cam

Adv. Close

Limit witch

Open Limit

witch

Close Cam

Cam

Retaining

Bracket

Increase

Door Travel

Decrease

Door Travel

Open ide Close ide

14

5.3 Limit S itch Adjustment Using Manual Hand Chain

Table 4 - Limit Switch Adjustment Procedures

Limit Switch Adjustment Procedures

Open Limit

1. Using the hoist, manually raise the door to a nearly opened position or desired open

position.

2. Pull the cam-retaining bracket from the Open side, see Figure 13, and rotate the Open

cam manually until it activates the Open Limit witch sufficiently so that a “click” can be

heard.

3. Release cam-retaining bracket and make sure that the bracket engages in the slots of

both cams.

Advanced

Close Limit

1. sing the hoist, manually lower the door to approx. 6” above the ground.

2. Pull the cam-retaining bracket from the Close side, see Figure 13, and rotate Close cam

manually until it activates the Close limit switch sufficiently so that a “click” can be heard.

3. Release cam-retaining bracket and make sure that the bracket engages in the slots of

both cams.

Limit Switch

Fine

Adjustment

1. Limit switch fine adjustment HOULD be done after the main power supply is connected

to the operator. Refer to section Operator tart-up, Table 9, p.30.

Note: One (1) notch on cam is equal (=) to about ½” of the door travel.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

15

6 Electrical Wiring

WARNING

To reduce risk of EVERE INJURY or DEATH to persons:

•All electrical wiring should be done by a qualified professional and in accordance to local

electrical codes.

•Always shut OFF the main power before performing any electrical intervention.

•Use proper wire gauge for incoming power line and for accessory connections.

•Install operator main circuit breaker next to operator for easy access for power shut-off.

•Use separate knockouts on operator control box for accessories and main power cables.

•Always separate low and high voltage wires.

•Operator should be properly grounded to the building ground and to the main power

supply ground lug.

•Always use suitable and appropriate rating circuit breakers for operator protection.

•Compare available power supply voltage to voltage on operator name plate prior to

electrical connection. Failure to connect appropriate power supply voltage may cause

serious damage to the operator.

NOTICE

•THE OPERATOR MU T BE ADEQUATELY PROTECTED AGAIN T OVERCURRENT AND HORT-

CIRCUIT.

•PLEA E REFER TO LOCAL ELECTRICAL CODE.

•PLEA E REFER TO NATIONAL ELECTRIC CODE (NFPA 70) ARTICLE 430 ECTION IV (430,51 /

430,52 / 430,53).

•PLEA E REFER TO CANADIAN ELECTRIC CODE (C A 22,1) ECTION 28-200 / 28-206.

Guideline to determine the branch-circuit rating of the protective device [A]:

Time Delay Fuse: 1,75 x FLA

Non-Time Delay Fuse: 3,0 x FLA

A fuse that does not exceed the next higher standard ampere rating shall be permitted.

Example: If FLA = 3,8A

•Time Delay Fuse: 1,75 x 3,8A = 6,65A → tandard fuse to use: 10A

•Non-Time Delay Fuse: 3,0 x 3,8A = 11,4A → tandard fuse to use: 15A

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

FLA = Full Load Amp

16

NOTICE

•The installer MU T test for proper connection and functionality of the operator and its accessories

before leaving the job site.

•The installer should also perform a demonstration for the end-user.

6.1 Lo Voltage (Controls) and High Voltage (Po er) Connections

1. Route the power line wires either from

the right or from the left of the control

box, as shown in Figure 14.

2. Route all low voltage control wires, as

shown in Figure 14. KEEP LOW

VOLTAGE WIRE EPARATE FROM

LINE VOLTAGE WIRE .

3. U E COPPER CONDUCTOR ONLY.

6.2 Main Po er Supply Connection

Single-Phase (115/230V) Three-Phase (208/230-460-575V)

Correct motor rotation: witch the BLUE and ORANGE

motor wires on the power board.

Correct motor rotation: witch ANY TWO incoming lines

(phase) on the power terminal block.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Line 3

Line 2

Line 1

Power Terminal Block

NEUTRAL

LIVE

Power Terminal Block

Figure 14 - Low Voltage (Controls) and

High Voltage (Power) Connections

Control

Power

17

6.3 Wall-Button Connection

WARNING

•Wall controls must be mounted in clear view of the door, far enough from the door, or positioned such

that the user is prevented from coming in contact with the door while operating the controls and at least

5 feet (1,5 m) above the standing surface.

•Keep low voltage wires separate from line voltage wires.

•Use copper conductors only.

Push-Button Station (PBS) Connection

Figure 1 - STATION 020 / 084

3-PBS Open / Close / Stop Figure 16 - STATION 041 / 049 / 0 6 / 076 / 078

3-PBS Open / Close / Stop

Figure 17 - STATION 079

3-PBS Open / Close / Stop with Key Lock-out

Figure 18 - STATION 080

3-PBS Open / Close / Stop with Key Lock-out and Light

Figure 19 - STATION 001 / 081

1-PBS Open Figure 20 - STATION 010 / 082

2-PBS Open / Close

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

18

6.4 Optional Accessory Connections

NOTICE

•Photo cells must be installed facing each other across the door's path within 6” (15 cm) of the plane of

the door and the beam no more than 5-3/4” (14,6 cm) above the floor.

•Keep low voltage wires separate from line voltage wires.

•Use copper conductors only.

6.4.1 Electric Photo Cells / Photo Eyes (Non-Monitored)

Through Beam Type

Figure 21 - PHOTO 008A/B Figure 22 - PHOTO 01 / 016 / 04 / 0 0 / 0 1 / 0 9

Reflective Type

Figure 23 - PHOTO 018 Figure 2 - PHOTO 038

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 24 - PHOTO 060

19

6.4.2 Reversing Edge Device (Non-Monitored)

NOTICE

•If the door is controlled by any device other than a constant pressure push-button station on close,

including a timer-to-close, a reversing edge must be connected.

Installation

Pneumatic Sensing Edge

1. Place the air switch in position, refer to Figure 26.

2. Place the air hose in position.

3. Use a coil cord or take-up reel to connect the air

switch to the operator terminals. Install electric

wires according to Figure 27 or Figure 28.

4. Connect one end of the air hose to the air

switch.

5. Place the air plug in the other end of the air

hose.

Electric Sensing Edge

1. Place the junction box in position, refer to Figure 26.

2. Place the sensing edge in position.

3. Use a coil cord or take-up reel to connect the

sensing edge wires to the operator terminals.

Install electric wires according to Figure 29.

4. Connect the sensing edge to the junction box.

5. N/A

Figure 27 - AIRSWITCH 001 / 007 Figure 28 - AIRSWITCH 009

Figure 29 - Electric Reversing Edge

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

Figure 26 - Reversing Edge

20

6.4.3 Pull Cord & Key S itch

Figure 30 - PULLCORD 001 / 003 / 004 / 007

Figure 31 - KEYSWITCH 010 / 01

Figure 32 - KEYSWITCH 019

6.4.4 Vehicle Loop Detector

Figure 33 - Vehicle Loop Detector

6.4.5 Other Accessories

Additional accessories are available, such as:

•Universal Auxiliary Output Module

•External Mid- top witch

•External Timer Defeat witch

Please contact your dealer or our inside sales department at 1-800-361-2260 for further information.

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information

2-Position Key S itch 2-Position Key S itch & Stop Button

Recommendation: Put Control Board on C2

or E2 Mode (constant-pressure-to-close)

Twist the two (2) leads (wires) a

minimum of 6 twists/foot

Table of contents

Other Manaras Opera Gate Opener manuals