3

2. SAFETY RULES

WARNING! To reduce the risk of injury or death read and follow all instructions. Save these instructions.

Carefully follow all the instructions specified herein. Failure to do so could cause equipment damage and/or personal

injury.

Swing-4000 is designed to operate swing gates. Use the operator only for its intended purpose, any other use is pro-

hibited.

The manufacturer assumes no liability for damage or injury to persons or property which occur as a result of incorrect

use of the operator.

Prior to operator installation verify the gate operates smoothly.

Installation must be performed in accordance with the standards EN12453 and EN 12445. For countries, which are not

EC members, these requirements are to be met.

Verify the gate conforms to EN12604 and EN 12605 standards (see gate documentation). For countries, which are not

EC members, the above mentioned requirements shall be met in order to obtain appropriate safety level.

Mechanical units of the gate shall conform to EN12604 and EN 12605 standards.

Make sure that the installation site meets the climatic conditions of the operator.

Do not install the operator in premises where there are flammable substances or other hazardous environments, as this

may cause an explosion or fire.

Use tools specified in «Tools» section hereof during assembly, installation and adjustment of the operator.

When performing operation at height, use a stable support.

The operator is not designed for installation at height over 2,5 m.

Always wear protective gloves and eye protection when drilling.

To fasten the product, use the hardware supplied with the operator or the corresponding one.

Always disconnect electrical power prior to installation, cleaning or maintenance of the operator.

If the operator is to be used with the gate having a built-in pass door it is required to install an additional safety device

preventing operator actuation when the pass door is open.

Make sure no objects will get jammed between movable and stationary parts of the operator.

Use only DoorHan accessories, as other manufacturers accessories may cause the automatic system to malfunction.

DoorHan Company assumes no liability for unstable operation of the automatic system when using safety devices and

accessories produced by other than DoorHan manufacturers without the approval of DoorHan.

Never leave operator motor disengaged as it may cause uncontrolled movement of the gate leaves and as a result their

damage.

Never use the operator if it needs to be repaired or adjusted. Incorrect operator or door installation may cause severe injury.

The manufacturer assumes no liability for incorrect installation or damage occurred during operation.

Since the operator has no power cord with a plug it shall be connected to the mains supply via automatic switch with

a minimal distance of 3 mm between the neighbouring contacts. It is recommended to use a 6 А double-pole circuit

breaker.

Before starting the operator make sure there are no foreign objects in the operator working zone.

Do not make any changes to the automatic system that are not specified in this manual.

Remove the product packaging and dispose of it. Do not leave packaging materials within reach of children.

Never allow children to play in the gate area while the operator is in operation. All remote controls, as well as stationary

control buttons, must be inaccessible to children.

Walk or drive through only when the gate is fully opened and the operator is on stop.

The contents of the instructions may not serve as a basis for any kind of claims.

The manufacturer reserves the right to make any changes to the product construction, structure, components and ac-

cessories without notice.

Having installed the operator verify all the mechanisms are correctly adjusted, safety devices and manual release func-

tion properly.

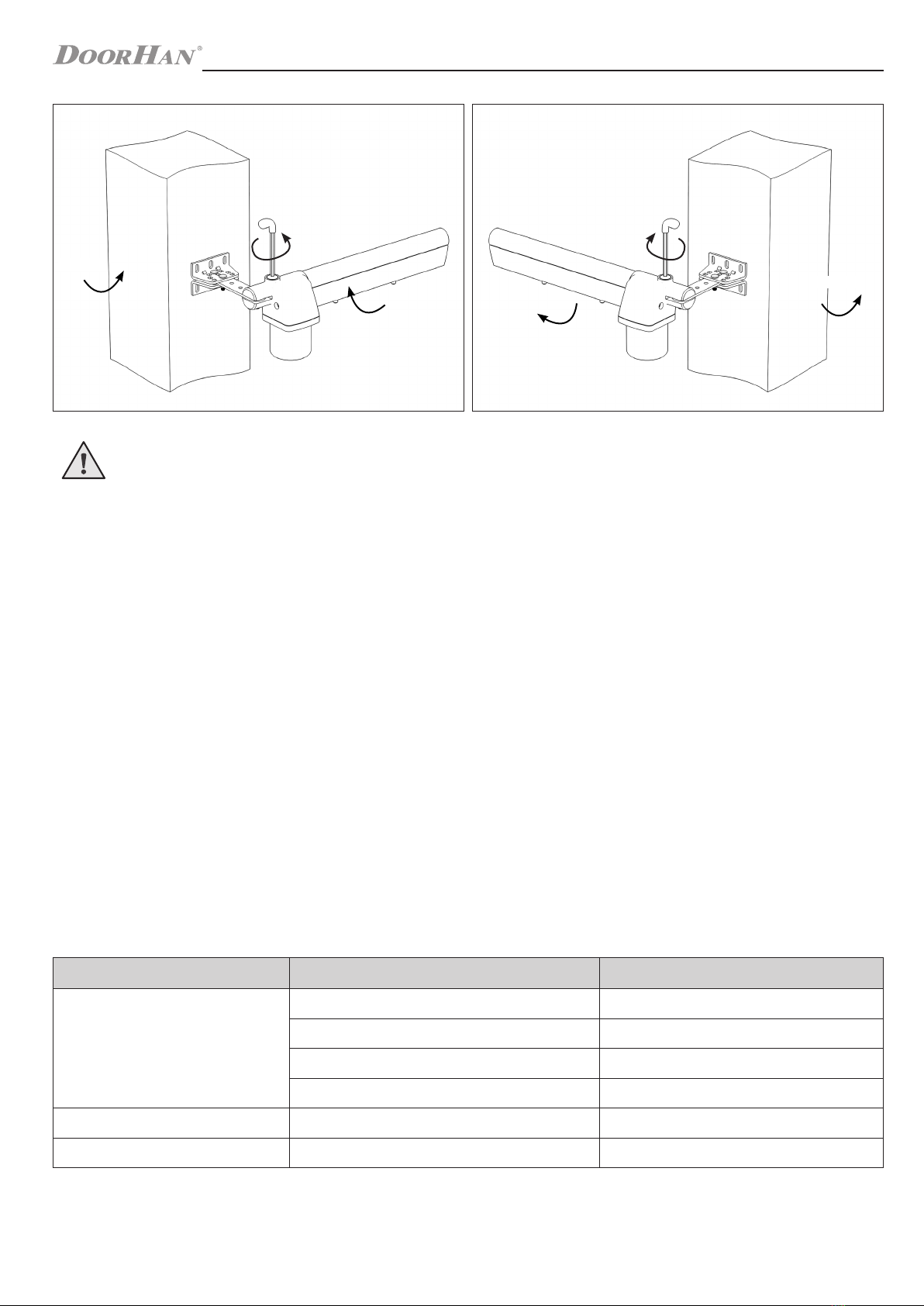

WARNING! Always install mechanical stops to limit the travel of gate leaves if the operator has no limit switches (option).

SAFETY RULES