4 5

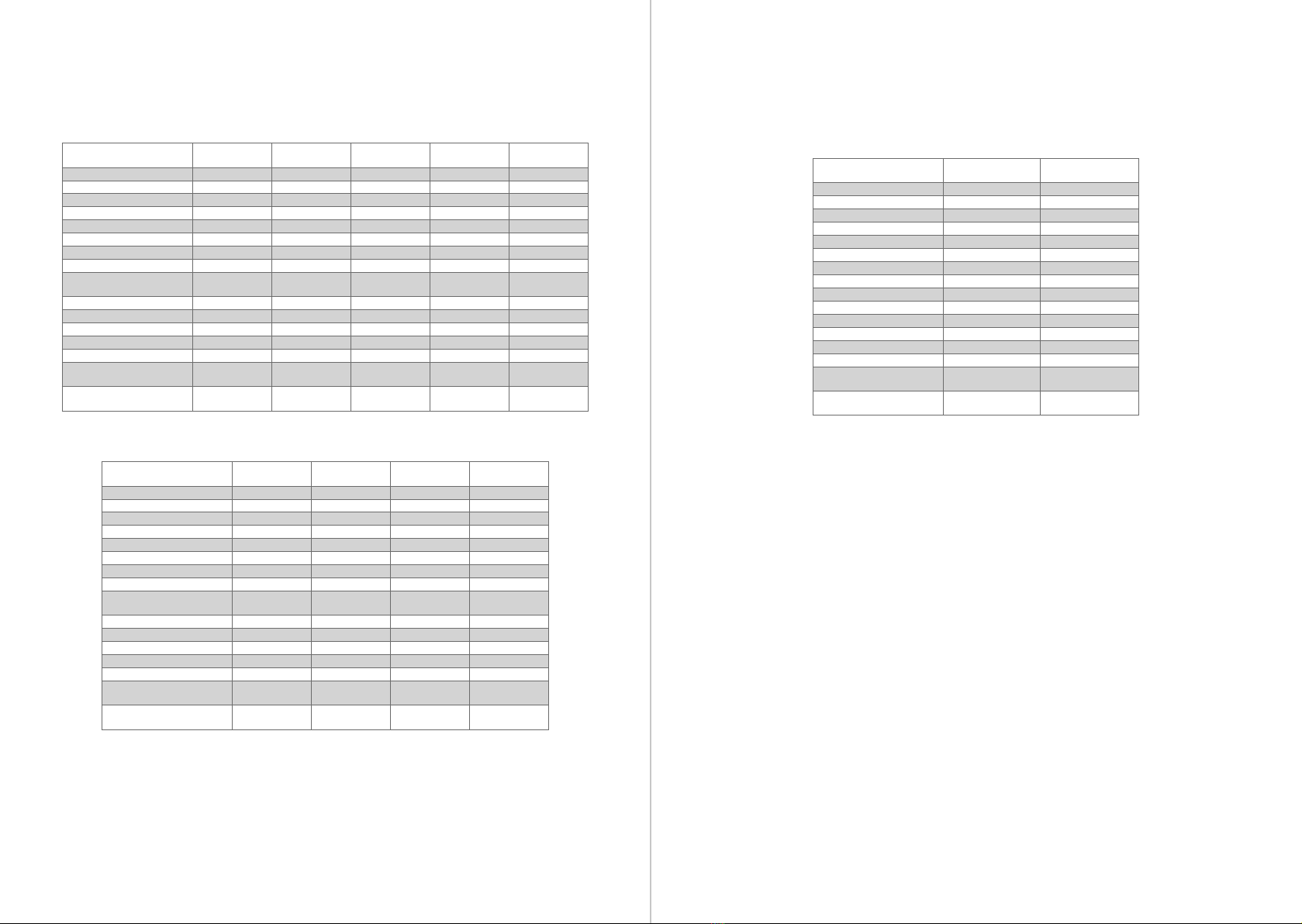

TECHNICAL CHARACTERISTICS

DZ RIO 400 DZ RIO R 500 DZ RIO R 700 DZ RIO 300

CUSTOM MONO

DZ RIO 350

MONO SP

TYPE OF OPERATOR SLIDING SLIDING SLIDING SLIDING SLIDING

MODEL SINGLE-PHASE SINGLE-PHASE SINGLE-PHASE SINGLE-PHASE SINGLE-PHASE

RATED VOLTAGE 127V / 220V 127V / 220V 127V / 220V 127V / 220V 127V / 220V

NOMINAL FREQUENCY 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

RATED POWER 370 W / 515 W 300 W / 286 W 400 W / 450 W 250 W / 260 W 300 W / 480 W

ENGINE ROTATION 1740 1740 1740 1740 1740

NOMINAL CHAIN 3,1 A / 2,25 A 3,05 A / 2,35 A 3,1 A / 2,1 A 2 A / 1,5 A 2 A / 2 A

REDUCTION 1:23 1:23 1:23 1:23 1:23

LINEAR SPEED 13,3m/min ( Z14)

17,1 m/min (Z18)

13,3m/min ( Z14)

17,1 m/min (Z18)

13,3m/min ( Z14)

17,1 m/min (Z18)

13,3m/min ( Z14)

17,1 m/min (Z18) 22m/min ( Z22)

MANEUVERS 30 40 60 20 30

DEGREE OF PROTECTION IPX4 IPX4 IPX4 IPX4 IPX4

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C -5° C / +50° C -5° C / +50° C -5° C / +50° C

TYPE OF INSULATION Class B, 130º C Class B, 130º C Class B, 130º C Class B, 130º C Class B, 130º C

LIMIT SWITCH Analog / Digital Analog / Digital Analog / Digital Analog / Digital Analog / Digital

MAX. MASS FROM THE LEAF

OF THE GATE 400 Kg 500 Kg 700 Kg 300 Kg 350 Kg

MAX. DIMENSION OF THE

GATE

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

DZ RIO 350

JETFLEX

DZ RIO 500

JETFLEX

DZ RIO R 600

JETFLEX

DZ RIO R 800

JETFLEX

TYPE OF OPERATOR SLIDING SLIDING SLIDING SLIDING

MODEL THREE PHASE THREE PHASE THREE PHASE THREE PHASE

RATED VOLTAGE 127V / 220V 127V / 220V 127V / 220V 127V / 220V

NOMINAL FREQUENCY 60 Hz 60 Hz 60 Hz 60 Hz

RATED POWER 340 W / 280 W 330 W / 270 W 370 W / 310 W 280 W / 230 W

ENGINE ROTATION 5800 5800 5800 5800

NOMINAL CHAIN 2,4 A / 2,5 A 3,4 A / 2,0 A 3,6 A / 2,1 A 2,8 A / 1,6 A

REDUCTION 1:23 1:23 1:23 1:23

LINEAR SPEED 33 m/min ( Z14)

42,9 m/min (Z18)

33 m/min ( Z14)

42,9 m/min (Z18)

33 m/min ( Z14)

42,9 m/min (Z18)

33 m/min ( Z14)

42,9 m/min (Z18)

MANEUVERS 30 40 50 60

DEGREE OF PROTECTION IPX4 IPX4 IPX4 IPX4

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C -5° C / +50° C -5° C / +50° C

TYPE OF INSULATION Class B, 130° C Class B, 130° C Class B, 130° C Class B, 130° C

LIMIT SWITCH HYBRID HYBRID HYBRID HYBRID

MAX. MASS FROM THE LEAF

OF THE GATE 350 Kg 500 Kg 600 Kg 800 Kg

MAX. DIMENSION OF THE

GATE

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m

DZ RIO PREDIAL 700 DZ RIO PREDIAL 800

JETFLEX

TYPE OF OPERATOR SLIDING SLIDING

MODEL SINGLE-PHASE THREE PHASE

RATED VOLTAGE 127V / 220V 127V / 220V

NOMINAL FREQUENCY 60 Hz 60 Hz

RATED POWER 400 W / 450 W 280 W / 230 W

ENGINE ROTATION 1740 5800

NOMINAL CHAIN 3,1 A / 2,1 A 2,8 A / 1,6 A

REDUCTION 1:23 1:23

LINEAR SPEED 17,1 m/min (Z12) 42,9 m/min (Z12)

MANEUVERS 60 70

DEGREE OF PROTECTION IPX4 IPX4

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C

TYPE OF INSULATION Class B, 130° C Class B, 130° C

LIMIT SWITCH Analog HYBRID

MAX. MASS FROM THE LEAF

OF THE GATE 700 Kg 800 Kg

MAX. DIMENSION OF THE

GATE

HEIGHT = 2.5 m

LENGTH. = 3.0 m

HEIGHT = 2.5 m

LENGTH. = 3.0 m