Manitou MARA PIGGYBACK User manual

MARA PIGGYBACK | SERVICE GUIDE

2MARA PIGGYBACK SERVICE MANUAL

5800 W Donges Bay Rd

Mequon, WI 53092

manitoumtb.com

888.686.3472

Support: manitoumtb.com/support

MANITOU

For full warranty information please visit hayesbicycle.com/warranty

WARRANTY

Revised May 26, 2020 11:43 AM

3

MARA PIGGYBACK SERVICE MANUAL

This manual is intended to provide the information necessary for the

250 hour full service of the Manitou Mara PiggyBack shock. We highly

recommend installation and service be performed by a qualied mechanic.

These instructions can be downloaded from the Hayes Performance Systems

website at www.manitoumtb.com

INTRODUCTION

We highly recommend that service to this shock be performed by a certied

bicycle mechanic. Failure to follow instructions presented in this manual

could lead to serious injury or death. Any questions about the servicing

of this shock or the manual itself should be directed to Hayes Customer

Support at:

Phone: 888-686-3472

Email: [email protected]

Suspension shocks by design can contain preload springs, gases and uids

under extreme pressures.Warnings contained in this manual must be

observed to avoid damage to shock,serious injury or even death.

WARNING

! !

4MARA PIGGYBACK SERVICE MANUAL

table of contents

SECTION PAGE NUMBER

Tools And Materials 6

Shock Teardown 6–11

Top Cap Service 12–17

Shaft Service 18-19

Shaft and Air Piston Assembly 20-25

Air Can Service 26-28

Bleed and Fill 29–35

Set-Up Guide 36

Torque Specs 37

IFP Depth Table 38

O-Ring Location 39

Exploded View 40

Torque Specs 32

IFP Depths 33

O-ring Guide 34

Exploded View 35

5

MARA PIGGYBACK SERVICE MANUAL

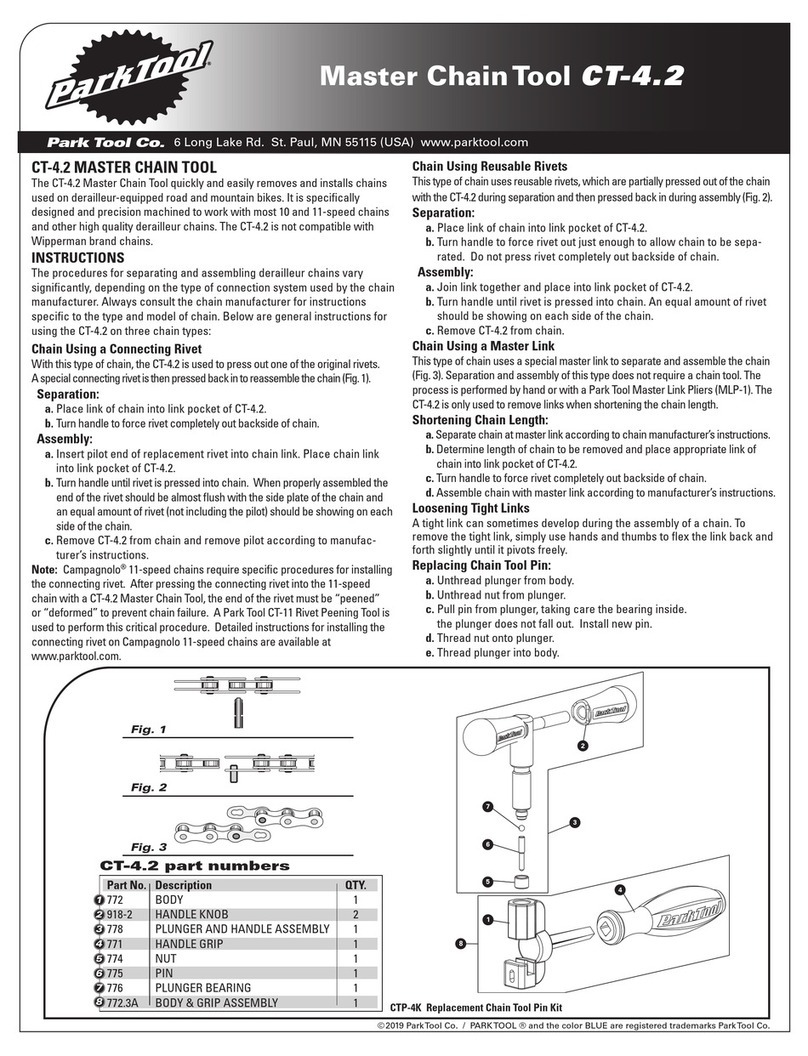

tools and materials

• Safety Glasses

• Nitrile Gloves

• Lint-Free Rags

• Slickoleum™ Grease

• 10-Oz Tub – Manitou Part Number 20-32929

• 5Ml Tube – Manitou Part Number 141-33604-K001

• 5wt Maxima Synthetic shock Oil Manitou Part Number 85-0023

• *For cold weather use Maxima Synthetic All Temperarture 3wt fork oil.

(PN 141-34078-K016)*

• Isopropyl Alcohol

• 3/8 drive socket wrench

• 16mm socket

• Torque wrench

• 21mm crows foot

• Free Hub Tool Park Tool PN FR-1

• Metric hex wrench set

• T-10 Torx wrench

• O-Ring Pick

• Hand Dyno

• Bench mounted vise

• Side cutters

• Small athead screw driver

• Caliper for measuring IFP depth

• Shock Pump

• ½-13 UNC taper tap

• Blue medium strength Loctite

• Red high strength Loctite

• Mara Pro complete rebuild kit 142-37512-K032

• Air piston OD seal bullet tool PN 172-32189-K001

• Manitou Clamp Block PN 172-31464

• Manitou shaft seal bullet tool ID of the air piston PN 142-37512-K040

• Air Can / Reservoir Wrench PN 142-37512-K033

• Compression Assembly Pin Spanner HBG PN 142-37512-K031

• Air Piston Seal Pusher Tool PN 172-32189-K001

• Shaft Seal Bullet Tool PN 142-37512-K040

• Manitou Air Can Negative Seal Stop Install Tool 172-32193-K001

• Manitou Air Piston Bushing and Seal Tool 172-32192-K001

• Manitou Rear Shock Air Piston and Seal Tool 142-37512-K041

• Manitou Trunnion Tool 142-37512-K037

6MARA PIGGYBACK SERVICE MANUAL

SHOCKTEARDOWN

1Unscrew air cap, thread on

shock pump to note pressure.

Using the pump’s pressure

release button release all air.

Depress Schrader valve with

a small tool to ensure all air is

released. Remove valve core.

Clamp upper eyelet of shock in

vise. If Trunnion shock, clamp

on trunion mounts. (Use soft

jaws to not damage the shock)

2

3With the shock top cap in a

vise use the air can wrench PN

142-37512-K033 to loosen the

air can on the shock. DO NOT

completely remove the air can

at this point, only loosen one

full turn. Removing the air

can completely at this point

will damage the threads due

to pressure in the negative

chamber.

CAUTION

Do not proceed to the next

step without completely

depressurizing air spring.

7

MARA PIGGYBACK SERVICE MANUAL

4Place shock in a hand dyno

or in a bicycle frame, slightly

compress the shock. At this

point unthread the air can

fully.

Remove air can, bumper, and

spacers (if present). These

may remain in the air can,

locate and save for later re-

assembly.

5

6Remove split ring from the

main air piston.

SHOCKTEARDOWN

8MARA PIGGYBACK SERVICE MANUAL

7With a plastic pick remove

quad-ring seal.

A small side-cutter can be

used to rst partially cut the

large piston ring, then break it

to remove. Be careful not to

damage the groove.

8

9Remove the Piggyback

Reservoir cap by unthreading

it counter-clockwise.

SHOCKTEARDOWN

9

MARA PIGGYBACK SERVICE MANUAL

10 Thread on shock pump, using

the pump’s pressure release

button, release all air. Then

depress Schrader valve with

a small tool a few times to

ensure all air is released.

Remove the valve core.

Use a freewheel removal tool

(example: Park Tool FR-1) to

remove the Reservoir End Cap.

11

12 Place a catch basin under the

shock to catch oil. Use the

air can / reservoir wrench

(PN 142-37512-K033) to

unthread the shock reservoir.

(Alternative: use a 30mm

wrench)

SHOCKTEARDOWN

CAUTION

Do not proceed to the next

step without completely

depressurizing reservoir.

10 MARA PIGGYBACK SERVICE MANUAL

13

The shock’s lock-out piston

will be visible at this point,

carefully remove this assembly

and set aside on a lint-free

rag. Be sure to account for

the rubber face seal which

may still be in the top cap

when assembly is removed.

The rubber internal oating

piston (IFP) will be inside the

reservoir. Remove the piston

towards the hex end of the

reservoir, note orientation

and set aside. Removing

the IFP in the other direction

may damage the seals on

the threads. (IFP is replaced

during a full service.)

14

15 Using a small athead screw

driver, gently pry up to remove

the red LSC knob. Be careful

when removing this knob,

underneath are two detent

balls and springs. Pull these

out and set aside, remove the

O-ring used to retain the LSC

knob.

SHOCKTEARDOWN

11

MARA PIGGYBACK SERVICE MANUAL

16 Rotate the HSC so the points

of the star pattern expose the

spanner holes in the adjuster

housing underneath. Using

the Compression Assembly

Pin Spanner (PN 142-37512-

K031), engage the pins

past the HSC adjuster into

the holes in the adjuster

housing. Turn counter-

clockwise to unthread and

remove compression adjuster

assembly.

17

18

SHOCKTEARDOWN

Place the main shock shaft

into the 12mm Manitou clamp

block. Using an eyelet tool

such as a pin wrench or an

adjustable wrench accross the

at turn the top cap counter

clockwise to release the top

cap from the main shock

shaft.

Hold the bottom eyelet in a

vise, and place a drip pan

under the shock. Using a

21mm wrench, remove the air

piston from the damper body.

12 MARA PIGGYBACK SERVICE MANUAL

1

2

3Remove the M1.5 set screw

under the rebound adjustment

knob. Remove the spring

and detent ball. Remove the

rebound adjuster by turning

clock-wise (left-handed

thread). Remove O-ring

and clean the adjuster with

isopropyl alcohol. Install a

new O ring (101-450) and set

aside. *Requires main shaft

to be separated from top cap*

TopCApservice

Remove the lockout lever

assembly by gently sliding it

out. Remove the two O-rings.

Clean the spool with isopropyl

alcohol. Install new O-rings

(the Larger 101-600 close to

the lever, and the smaller 101-

500 near the end.)

Remove the Lock-Out detents

by using an M1.5 hex tool,

and unthread the small set-

screw on the end near the

compression adjuster. Flip

the shock over and tap, or use

a small pointed tool to aid in

removing the spring and ball.

Next, remove the set-screw/

retaining pin near the red

Work/Party lever.

13

MARA PIGGYBACK SERVICE MANUAL

4Remove main shaft O-ring,

air can O-ring and reservoir

O-ring from the top cap.

Thoroughly clean topcap,

spraying isopropyl alcohol into

all ports and passageways.

Allow to air dry or blow out

with clean compressed air.

5

6

Remove valve stem with a

3mm hexwrench.

topcapservice

14 MARA PIGGYBACK SERVICE MANUAL

7Replace O-Ring (101-550-

100), apply small drop of

blue Loctite to the valve stem

threads. Reinstall valve stem

into top cap torque to 2.3-

2.7Nm (20-24 INlbs) Reinstall

valve core.

8

9

Install reservoir O-ring (101-

2600-150), main shaft O-ring

(100-013) and air can O-ring

(101-4100-200).

topcapservice

Grease O-rings, reinstall

Work/Party assembly into the

top cap. Install retention pin,

check for full movement of the

Work/Party lever by adjusting

the depth of the retention pin.

Such that the lever ips just

past the word “WORK”.

15

MARA PIGGYBACK SERVICE MANUAL

10

11

12

Apply a dab of grease to

the O-ring, ramped surface

and thread on the rebound

adjuster. Insert into top cap,

rotate counter-clockwise to

engage the left handed thread.

Turn until it lightly bottoms.

Reinstall spring and detent

ball.

topcapservice

Replace the O-Ring (101-

1600-0180) on the HSC

Piston. Replace the O-Ring

(100-018) on the compression

cartridge body (above threads

at the ange). Grease both

O-Rings.

Install the compression

assembly into the top cap.

Use the compression assembly

Pin spanner tool (142-37512-

K031) and torque to 5.7Nm

(50 in-lb).

16 MARA PIGGYBACK SERVICE MANUAL

13

14

15

topcapservice

Lightly grease O-ring (PN 100-

016 ) and install on the HSC

compression adjuster.

Use this procedure to install

detent and spring for lockout,

rebound and LSC knob. Install

detent spring using a tool and

a dab of grease to help hold

the spring in place. Repeat

procedure with detent balls.

Reinstall LSC knob by pushing

straight down to not disrupt

the detent balls.

17

MARA PIGGYBACK SERVICE MANUAL

16 Remove the O-ring (101-2300-

150) from the lock-out piston

assembly. Remove face seals

if still in place. Clean assembly

with Isopropyl alcohol. Install

new piston O-ring and new

face seal(s). O-ring type face

seals (2pc) (101-700-110) or

gure 8 type seal (08-37751)

depending on the seal gland

available. Lockout will be

installed at the time of oil ll.

Note: Use grease to hold face

seals in place.

17 Remove O-ring (100-021)

from the reservoir end cap.

Clean end cap with Isopropyl

alcohol. Install new O-ring

and apply grease. Set aside

on a clean, lint free rag

until needed after the oil ll

process.

Topcapservice

Faceseals

18 MARA PIGGYBACK SERVICE MANUAL

Clamp the main shaft in the

12mm Manitou Clamp Block

(PN 172-31464) Remove

the piston nut from the shaft

with a 16mm socket wrench.

Carefully slide the shims and

piston onto a small tool like

an O-ring pick or screw driver

to preserve the sequence of

components. Carefully set

aside.

1Remove the rebound needle

(inner piece with rounded

head) from the main shaft by

gentle pulling it up. Be aware

of the spring and two small

washers at the bottom of the

rebound needle.

Remove O-ring (101-600)

from the rebound needle.

Clean needle with Isopropyl

alchohol. Replace the O-ring

(101-600) on the rebound

shaft. DO NOT grease this

O-ring! Function and assembly

is better without grease.

2

3

Shaftservice

19

MARA PIGGYBACK SERVICE MANUAL

4

5If the service warrants

replacement of bushings

within the air piston, use a

½-13 UNC bottoming tap and

the Manitou clamp block to

remove the bushings. (See

Manitou Air Piston Bushing

and Seal Tool instructions for

information)

SHaftservice

Remove inner shaft O-ring.

20 MARA PIGGYBACK SERVICE MANUAL

1Place the air piston into the

rst pocket of the service

block. Grease the outside

of the bullet tool and place

it on top of the piston. Use

the Air Piston Seal Pusher

Tool (PN 172-32189-K001) to

install the glide ring onto the

air piston. Note If bullet tool is not

available see “50 hour air can and piston

service guide” for alternative method of

replacing the seals. If using this method

the air piston will need to be installed on

the main shaft. It is recommended this

would be done after the full service is

complete. Please skip to step 5 if using

the alternative method

2

3

Grease new air piston quad

seal (08-30017) and use the

seal pusher to install onto the

air piston.

shaftandairpistonassembly

Install the Split Ring (08-

30718) onto the air piston.

Table of contents

Other Manitou Bicycle Accessories manuals

Manitou

Manitou Axel Super 2004 User manual

Manitou

Manitou SIX User manual

Manitou

Manitou MATTTOC PRO User manual

Manitou

Manitou BLACK COMP 80/100 User manual

Manitou

Manitou Circus Expert User manual

Manitou

Manitou JACK DROPPER POST User manual

Manitou

Manitou DORADO DH User manual

Manitou

Manitou LUXE COMP User manual

Manitou

Manitou DORADO User manual

Manitou

Manitou R7 EXPERT User manual