Manitou JACK DROPPER POST User manual

JACK DROPPER POST SETUP GUIDE

3

JACK DROPPER POST SETUP GUIDE

Thank you for purchasing one of the most innovative hydraulic dropper posts on

the market - the Manitou Jack Dropper Seat Post. Your new seatpost is warranted

for a period of two years from the date of purchase. The warranty is limited to

the repair or replacement of the defective part and is the sole remedy of the

warranty. The warranty applies only to the original owner and is not transferrable.

Proof of purchase is required to validate warranty eligibility. The warranty does

not cover normal wear and tear, routine maintenance, improper installation or

improper use of the seatpost. Modication of the seatpost in any manor shall void

the warranty. shall not be responsible for incidental or individual costs incurred

by the warranty service provider that are not covered by this warranty. The user

assumes the risk of any personal injury or property damage, including damage

to the seatpost, and any other losses, if the seatpost is modied or improperly

used at any time. This warranty gives the consumer specic legal rights and

those rights vary from to This warranty does not aect the statutory rights of the

consumer.

INTRODUCTION

This is a high performance product. It will give you reliable service if installed

properly and regularly maintained by an authorized service center.

Read through these instructions fully and follow them carefully before installing

and/or using your new seatpost. Any questions about the servicing of this fork or

the manual itself should be directed to Hayes Customer Support at:

Hayes

Bicycle

USA

5800 W Donges Bay Road Mequon WI 53092

Phone: 888.686.3472

Email: techsupport@hayesbicycle.com

Hayes

Bicycle

Europe

Dirnismaning 20 a 85748 Garching (b. Munich) Germany

Phone: +49 89 203237450

Email: techsupportEU@hayesbicycle.com

Hayes

Bicycle

Asia

16F, No. 37, Sec. 3 Mincyuan E. Rd. Zhongshan District

Taipei City 10476 Taiwan ROC

Phone: 886-2-2518-1108

WARNING

! !

5800 W Donges Bay Rd

Mequon, WI 53092

manitoumtb.com

888.686.3472

Support: manitoumtb.com/support

MANITOU

For full warranty information please

visit hayesbicycle.com/warranty

WARRANTY

4 5

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

table of contents

SECTION PAGE NUMBER

Before Installing the Seatpost 6

Installation 7

Usage 16

Service 20

FAQ 22

Troubleshooting 24

Exploded View 25

Your Jack Dropper Seatpost must be regularly maintained by a qualied service

technician. If you need assistance locating a qualied service technician, more

information can be found at www.manitoumtb.com. Do not disassemble your

seatpost by yourself Disassembly could cause damage and severe personally

injury as some of the contents are under pressure. Alway wear suitable safety

gloves and safety glasses, when working on your seatpost!

WARNING

! !

Please read the following instructions carefully and install your Jack Dropper

Seatpost according to the steps detailed below. Your Jack Dropper Seatpost is

a precision piece of cycling equipment that requires a specic understanding of

bicycle maintenance and assembly to install. If you are not certain that you have

the appropriate skills or tools to properly install or service this product, please

contact your local bicycle dealer or service provider for assistance.

Jack Dropper Seatpost models use internal cable routing and are designed to be

compatible with bicycle frames that feature such cable routing.

DO NOT DRILL OR MODIFY YOUR FRAME IN ANY WAY. Doing so will void

the Warranty of and in most cases void the warranty of your bicycle.

Modication of your frame in any way may result in frame failure which

could result in injury or death.

If you are unsue whether your Jack Dropper Seatpost is compatible with your

frame, contact your bicycle frame manufacturer or Manitou directly.

Thank you for choosing a Manitou dropper seatpost.

To ensure maximum and enduring performance with your Jack or Jack SL, please

read and follow this manual carefully and keep it for future reference.

If you purchased your seatpost separately, you will nd instructions on how to

install it. Please note that your Jack requires regular maintenance and care - see

the corresponding chapter in this manual.

You can also nd many important and useful tips in our service app or on

www.manitoumtb.com.

Happy trails

Your Manitou team

NOTICE

6 7

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

before installing the seatpost installation

Please be sure that your new Jack Dropper Seatpost will t in your frame. All

Jack Dropper Seatpost models are designed to t either 30.9mm or 31.6mm seat

tube inner diameters in frames, originally designed for internal cable routing.

Improper t may cause slippage, faulty performance, injury or death and may

result in void of warranty.

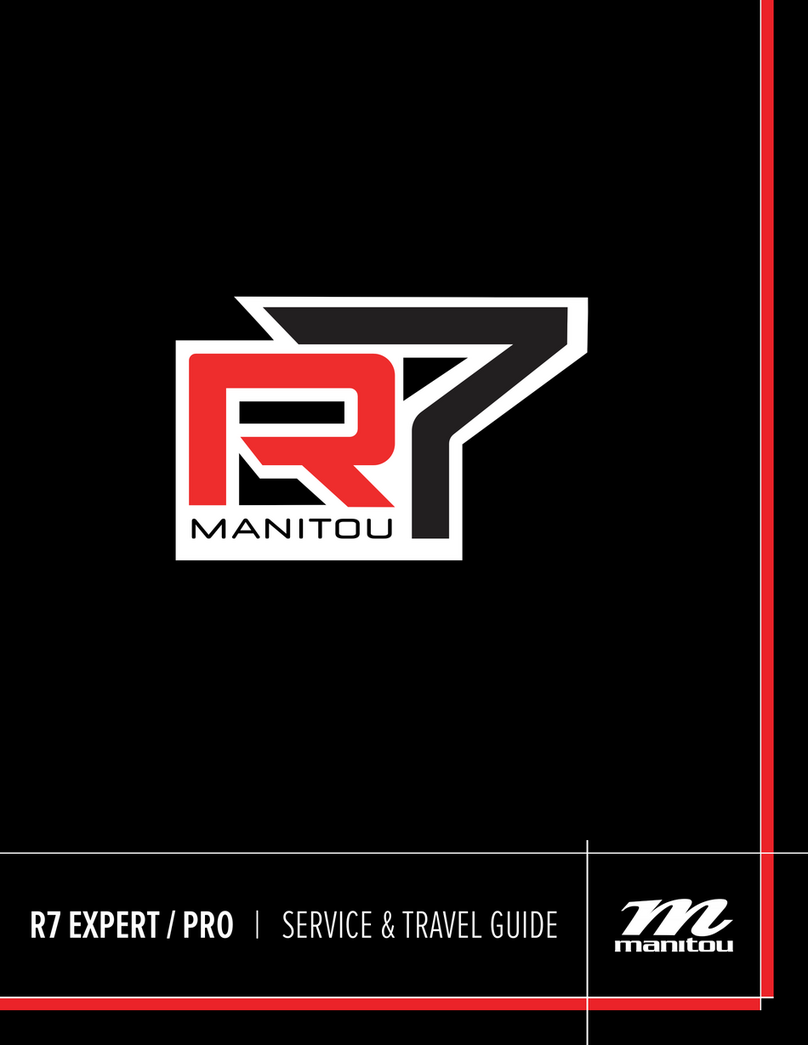

Manitou Underbar Lever remote can be installed with a stand alone clamp on

your handlebar, or an adapter directly on your brake using the Hayes Peacemaker

clamp. Use a maximum torque of 1.5 Nm on the pinch bolt on the clamp. Manitou

Underbar Lever remotes can only be installed on the left side of the handlebar.

Apply a heavy suitable grease on

the lower tube of the post to avoid

galvanic corrosion inside the frame use

friction paste instad of grease only if

the post can not be clamped properly.

Avoid using any paste,that could be

aggressive towards frame and/or post.

Manitou DOES NOT recommend modication or alteration of your frame in any

way. Doing so may void your frame or bicycle’s warranty and may result in frame

failure which could lead to injury or death.

WARNING

! !

Make sure that your seat tube is clean and free of debris and that the inside of

your seat tube is smooth and free of any object that may score the seatpost!

WARNING

! !

WARNING

! !

1INSTALLING MANITOU UNDERBAR REMOTE LEVER

grease

8 9

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

installation installation

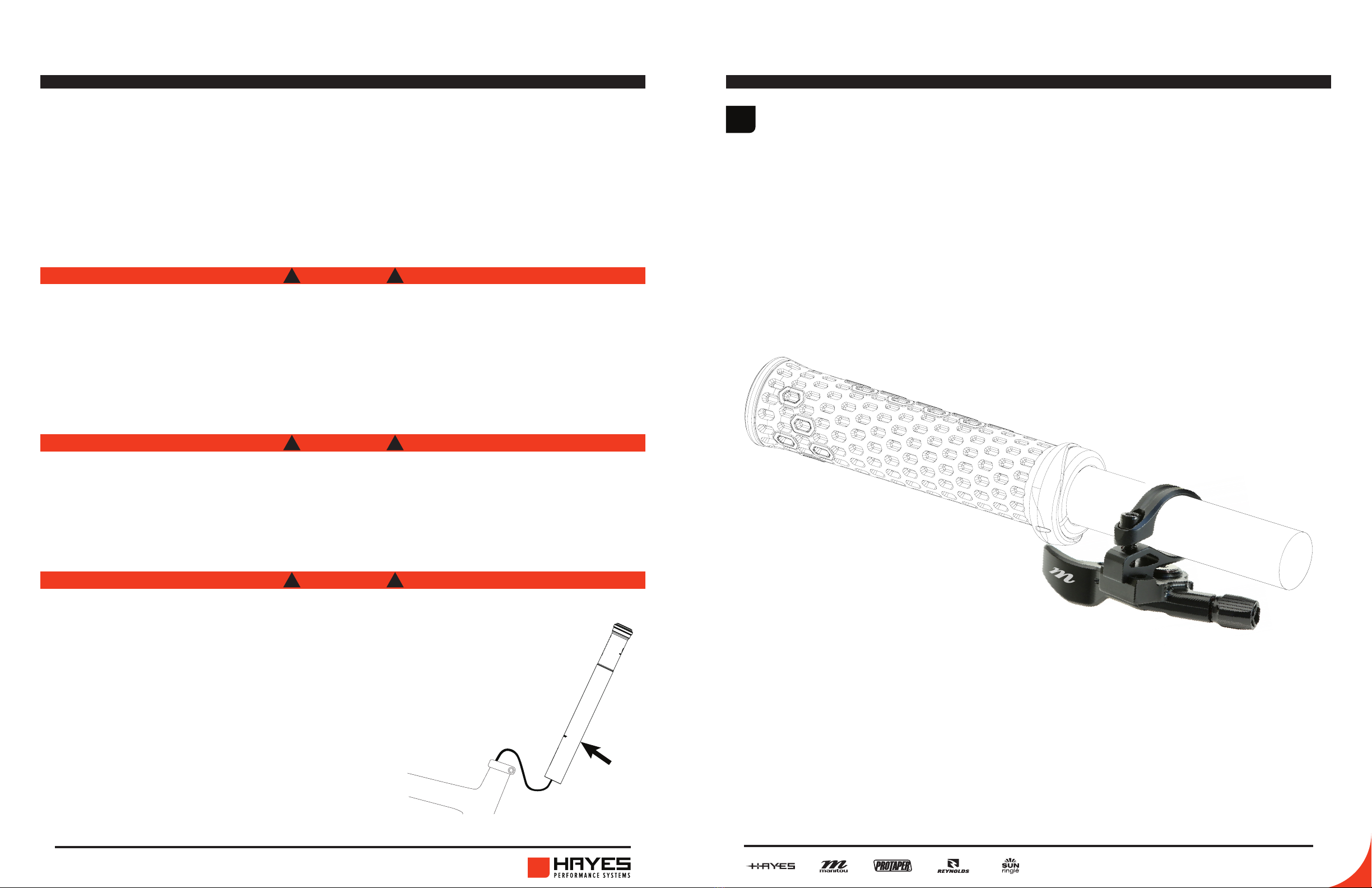

Route the housing through your bicycle frame per your bicycle frame

manufacturer‘s specications.

To determine the correct housing length, place the housing into the tension

adjuster of your remote, and make sure your handlebar can turn a minimum of

90° without stretching the housing.

Do not permanently ax your housing in place. You will need it free to move in a

later step.

Mark the position of your cable housing at the seat clamp, as it protrudes from

the seat tube.

Pull the cable housing out of the seat tube and make another mark 90 mm

downwards. This will be your nal housing length for minimum insertion.

If you insert your post deeper you can cut the housing shorter accordingly to

avoid excessive slack of your housing.

2 2

DETERMINING CABLE HOUSE LENGTH DETERMINING CABLE HOUSE LENGTH (CONTINUED)

9

INSTALLATION

STEP 2: DETERMINING HOUSING LENGTH

Route the housing through your bicycle frame per your

bicycle frame manufacturer‘s specications.

To determine the correct housing length, place the housing

into the tension adjuster of your remote, and make sure your

handlebar can turn a minimum of 90° without stretching the

housing.

Do not permanently ax your housing in place. You will need

it free to move in a later step.

remote lever

cable housing

10

INSTALLATION

STEP 2: DETERMINING CABLE HOUSE LENGTH

Mark the position of your cable housing at the seat clamp, as it

protrudes from the seat tube.

Pull the cable housing out of the seat tube and make another

mark 90 mm downwards. This will be your nal housing length

for minimum insertion.

If you insert your post deeper you can cut the housing shorter

accordingly to avoid excessive slack of your housing.

mark here

cut here

cable housing

90mm

seat clamp Cut the housing to

length with proper cable

cutters.

cable housing

seat clamp

1.

2.

10 11

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

installation installation

The Manitou Jack dropper post uses a specic lightweight dropper post cable and

housing. The cable head replaced the cable end used by other brands to improve

setup and function. If the user desires a standard cable and cable end can be

used.

1. Push the ferrules onto both ends of the cable housing as far as possible.

2. Guide the inner cable through the cable housing from the seat tube towards

the remote lever with the Manitou dropper cable head terminating on the post

side.

3. Insert the inner cable through the remote lever and using the guide on the

bottom side of the post allow 17mm of cable to protrude out of the housing.

Tighten the pinch bolt on the lever too 2 Nm.

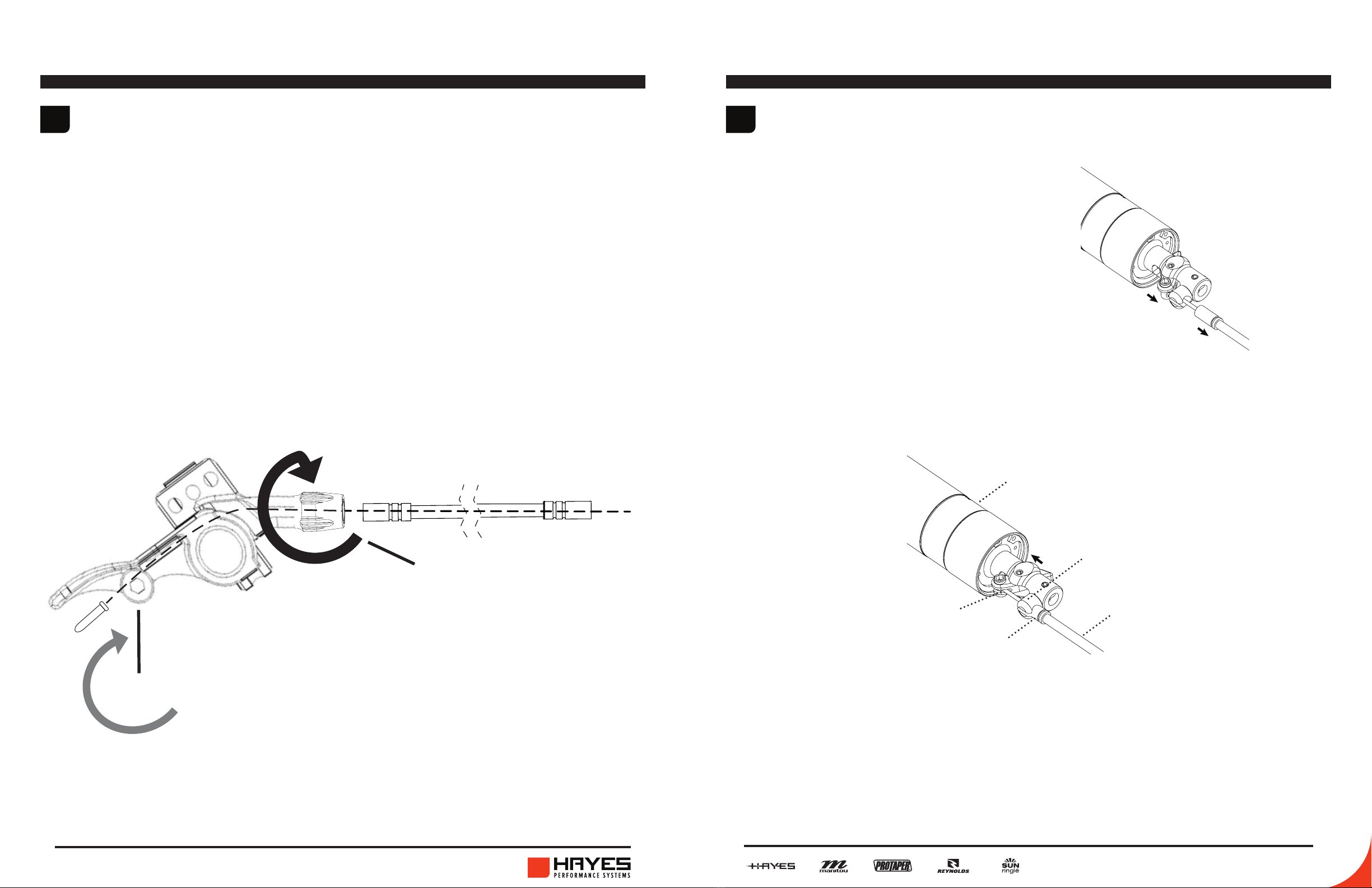

1. Insert the cable head end into the

actuation lever. Gently pull on the outer

housing and move the lever down

to pass the cable end stop with the

ferrule.

2. Guide the inner cable through the slotted cable end stop and push the ferrule f

irmly into the cable end stop by hand.

3. Adjust the tension with the cable tensioner on the lever, so there is no play in

the cable. If the tension is too high, it will permanently activate the post. A low

tension will cause cable play, and the post will not reach its full speed.

4. Cut the inner cable and secure it with an end cap.

3 4

PREPARING INNER CABLE CONNECTING CABLE TO SEATPOST

INSTALLATION

STEP 4: CONNECTING CABLE TO SEATPOST

1. Insert the barrel nut end into the

actuation lever.

2. Gently pull on the outer housing and

move the lever down to pass the cable

end stop with the ferrule.

3. Guide the inner cable through the slotted

cable end stop and push the ferrule

rmly into the cable end stop by hand.

mast

slotted cable stop

cable housing

cable head

12 ferrule

INSTALLATION

STEP 4: CONNECTING CABLE TO SEATPOST

1. Insert the barrel nut end into the

actuation lever.

2. Gently pull on the outer housing and

move the lever down to pass the cable

end stop with the ferrule.

3. Guide the inner cable through the slotted

cable end stop and push the ferrule

rmly into the cable end stop by hand.

mast

slotted cable stop

cable housing

cable head

12

ferrule

adjust cable

tension

2Nm

12 13

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

installation installation

There is only one position for seatpost direction, saddle and saddle clamp

orientation.

Insert the seatpost into your seat tube. When inserting or extending, make sure

you do not pull too hard on the outer housing, as doing so may pull the ferrule

out of the cable stop.

5 5

INSERTING SEATPOST INSERTING SEATPOST (CONTINUTED)

13

INSTALLATION

STEP 5: SEATPOST ORIENTATION

There is only one position for seatpost direction, saddle and

saddle clamp orientation.

rear of bike front of bike

Insert slowly and carefully! When inserting, make sure there are no such things

as pivot points, bent tubes, etc inside your seattube that can interfere with the

seatpost.

WARNING

! !

You should always use a good quality grease on contacting faces between

seatpost and seattube in order to prevent corrosion. Use friction paste only

if proper clamping is impossible with greased components. Contact us before

applying friction paste.

WARNING

! !

Make sure your post does not slip inside the seat tube when sitting on it, before

going out for a real ride.

WARNING

! !

Over-tightening your frame‘s seat clamp might lead to a stuck post and/or

increased wear. Use only as much torque as you need to keep the post in place

during normal riding. It is appropriate for the post to rotate or slip under higher

input forces to prevent overload. Never exceed 5 Nm of torque!

WARNING

! !

14 15

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

installation

All seatpost models must be inserted into the bicycle’s seat tube, so that the

minimum insert line is covered by the seat tube at all times or deeper.

5INSERTING SEATPOST (CONTINUTED)

Insucient seatpost insertion into the bicycle frame‘s seat tube could result in

damage to the seatpost and/or bicycle, causing loss of control, which could lead

to serious injury or death. In case your frame requires more minimum insertion

depth than the post, follow the frame specication.

WARNING

! !

5Nm

Sattelklemme

INSTALLATION

STEP 5: MINIMUM INSERTION DEPTH

All seatpost models must be inserted into the bicycle’s seat

tube, so that the minimum insert line is covered by the seat

tube at all times or deeper.

WARNING: Insucient seatpost insertion into the

bicycle frame‘s seat tube could result in damage to

the seatpost and/or bicycle, causing loss of control,

which could lead to serious injury or death.

In case your frame requires more minimum insertion

depth than the post, follow the frame specication.

MIN INSERT

SEAT CLAMP TORQUE:

Tighten your frame’s seat

collar to a maximum

torque of 5 Nm.

max.

5Nm

15

installation

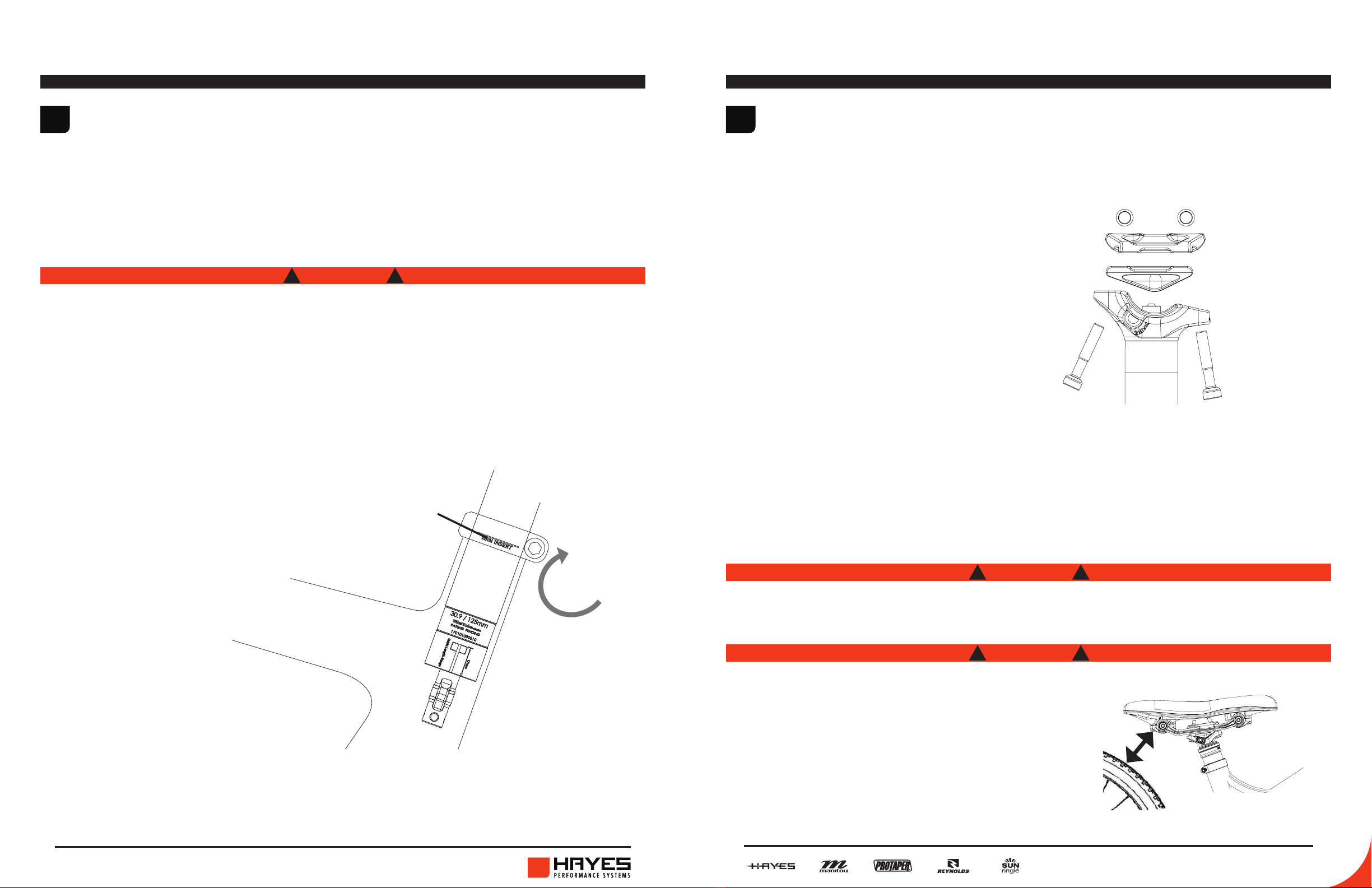

Remove the saddle clamp bolts, barrel nuts, and upper and lower saddle clamps

with a T25 Torx wrench.

Adjust the saddle angle by tightening the two saddle clamp bolts. Tighten both

bolts evenly and alternately to the maximum torque specied on the seatpost.

Ensure that the shaft or thread of the bolts does not contact the post and cause

the bolts to bend.

Jack saddle clamp works with standard rails, oval rails and carbon rails.

To install the saddle, replace the two

saddle clamp bolts, barrel nuts, upper

and lower saddle clamps in the order

they were removed. Ensure that the

rails of your saddle rest in the channel

provided by the upper and lower saddle

clamps before tightening.

6SADDLE INSTALLATION

GREASE SHOULD NOT BE USED ON THE THREADED CONNECTIONS!

WARNING

! !

With seatpost fully dropped and rear

suspension fully compressed, make sure

there is sucient clearence between the

saddle and the tire

WARNING

! !

2Nm

17

INSTALLATION

STEP 7: SADDLE INSTALLATION

Remove the saddle clamp bolts, barrel nuts, and upper and lower

saddle clamps with a T25 Torx wrench (4 mm Allen key on older

models).

To install the saddle, replace the two

saddle clamp bolts, barrel nuts, upper

and lower saddle clamps in the order

they were removed. Ensure that the

rails of your saddle rest in the channel

provided by the upper and lower

saddle clamps before tightening.

Adjust the saddle angle by tightening the two saddle clamp

bolts. Tighten both bolts evenly and alternately to the

maximum torque specied on the seatpost. Ensure that

the shaft or thread of the bolts does not contact the post

and cause the bolts to bend.

REVIVE saddle clamp works with standard rails, oval rails

and carbon rails.

CAUTION: GREASE SHOULD NOT BE USED ON THE THREADED

CONNECTIONS!

CAUTION: With seatpost fully

dropped and rear suspension fully

compressed, make sure there

is sucient clearence between

the saddle and the tire.

36

barrel nut

upper saddle

clamp

lower saddle

clamp

saddle clamp

bolts

Torx T25

barrel nut

upper saddle

clamp

lower saddle

clamp

saddle clamp

bolts

Torx T25

16 17

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

usage

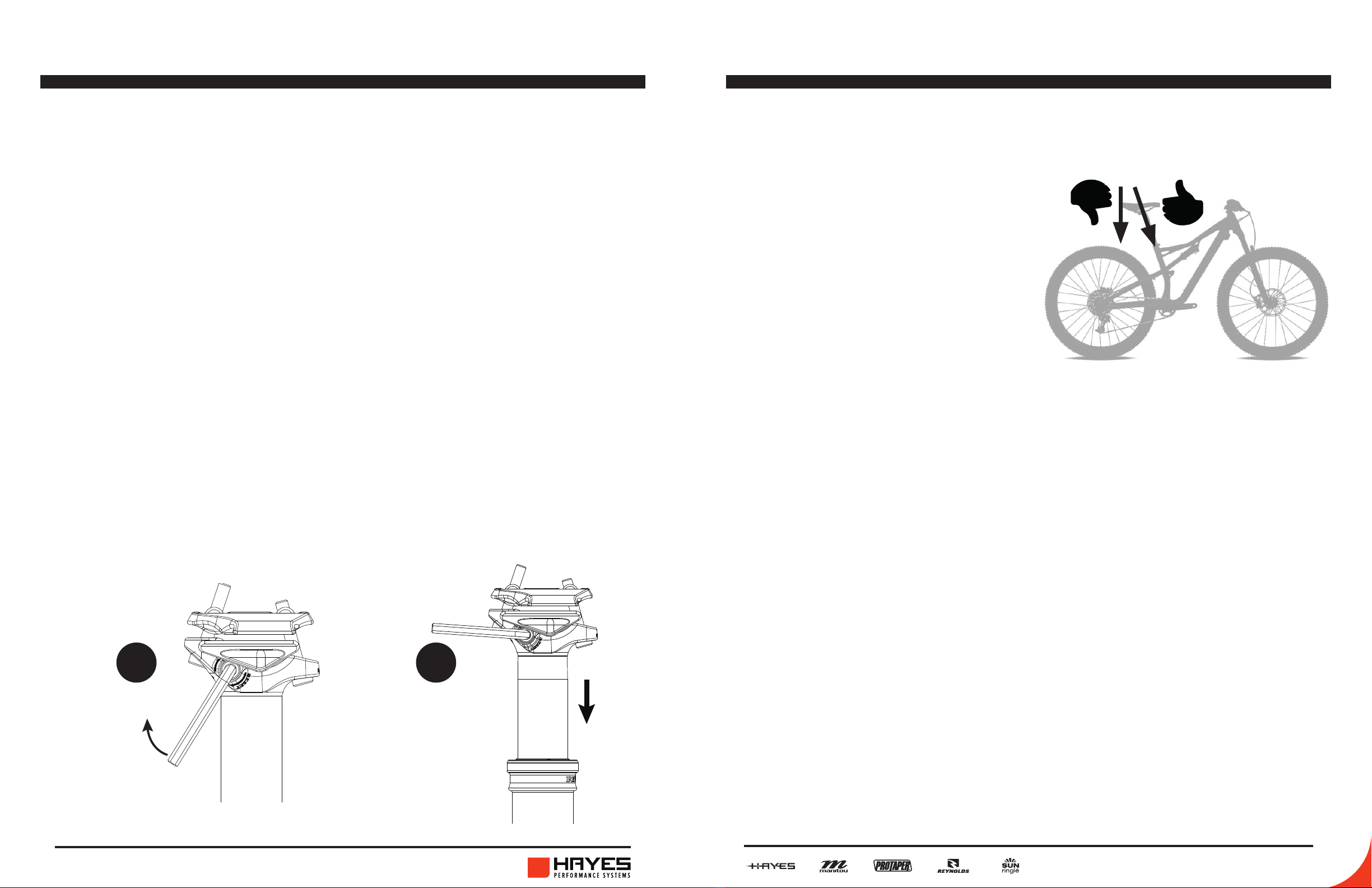

When you receive your post, it will have travelled a long way to reach you. Do a

hydraulic reset using the Jack’s patented reset feature after installing the post

1. Extend the post completely by pushing the remote.

2. Use the included reset lever or a 4 mm Allen key to turn the reset valve

clockwise until you feel a stop.

3. Drop the post by hand completely, while keeping the reset valve open.

4. Release the reset valve, remove hand from saddle.

5. To extend the post, push the remote.

After this procedure, the correct function should be restored completely. Reset,

if necessary, after a few minutes to give the oil a chance to settle down if it still

feels springy.

When your post begins to feel springy, use the reset function. „Springyness“

can be caused by storing your bike upside down or lying on its side. Whenever

possible, store or park your bike upright to avoid having to reset it.

BEFORE FIRST RIDE

18

USAGE

BEFORE FIRST RIDE

When you receive your post, it will have travelled a long way

to reach you. Do a hydraulic reset using the REVIVE‘s patented

reset feature after installing the post:

1. Extend the post completely by pushing the remote.

2. Use the included reset lever or a 4 mm Allen key to turn the

reset valve clockwise until you feel a stop.

3. Drop the post by hand completely, while keeping the reset

valve open.

4. Let go of the saddle once you have released the reset valve.

5. To extend the post, push the remote.

After this procedure, the correct function should be restored

completely. Reset, if necessary, after a few minutes to give the

oil a chance to settle down if it still feels springy.

When your post begins to feel springy, use the reset function.

„Springyness“ can be caused by storing your bike upside down

or lying on its side. Whenever possible, store or park your bike

upright to avoid having to reset it.

open

reset-valve

Allen key 4 mm

1st 2nd

drop post

while keeping

reset valve

open

usage

To raise the saddle, push the trigger with unweighted saddle. Once the desired

position is reached, release the trigger. You can set the saddle height innitely in

any position within the post’s travel range.

Your post might need to be manually broken loose if it hasn‘t been used or

adjusted for a long time, since the seals tend to stick to the contacting surfaces.

For this initial „break-away“ just push the remote and then gently push or pull the

saddle until the post starts moving.

TIP: Always store the bike with the dropper not fully extended. This will prevent

the remote from stiening up due to temperature changes (hydro-lock). Dropping

the post about 1/2“-1“ is plenty enough.

DROP AND EXTEND

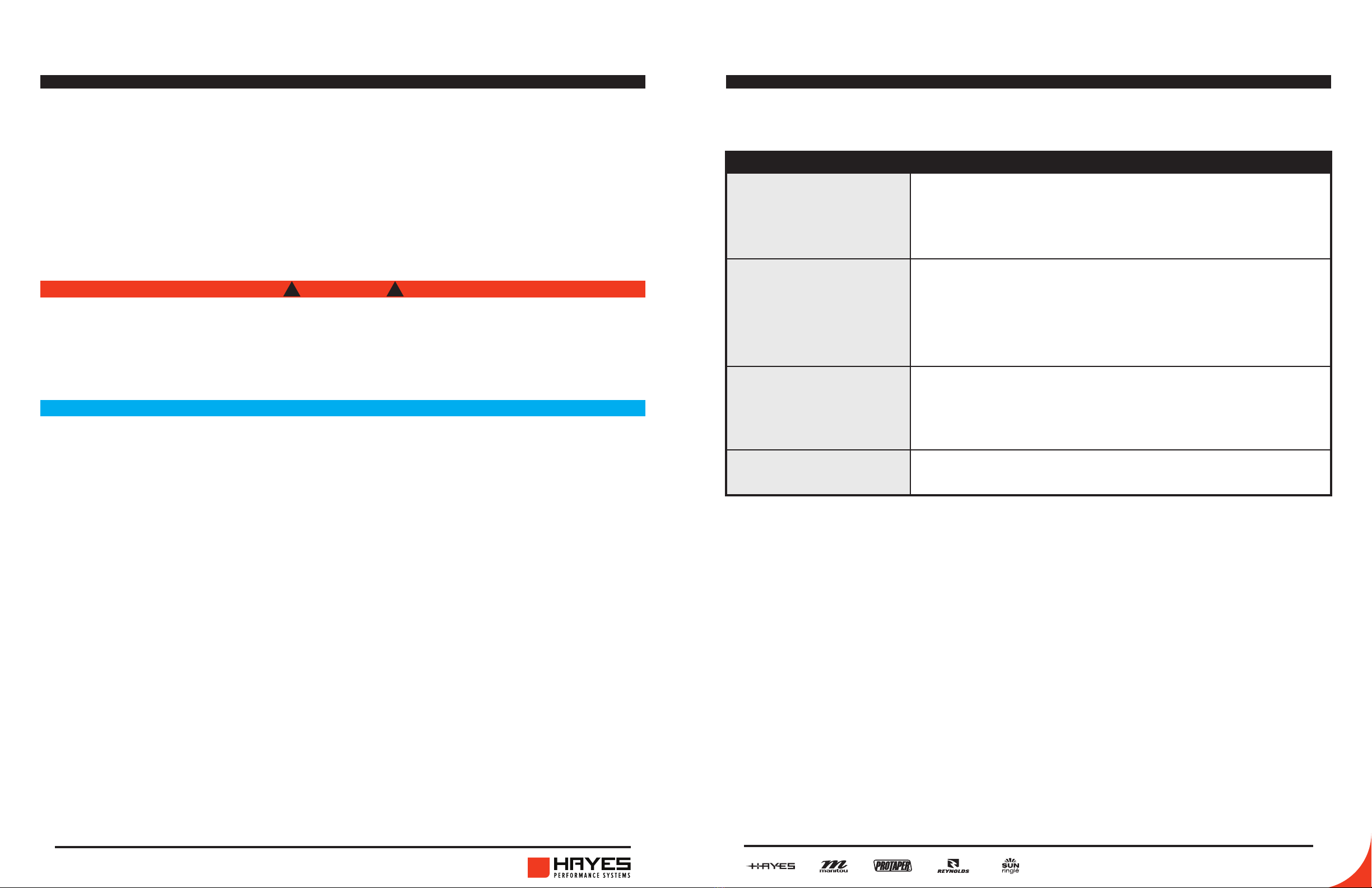

The saddle can be dropped by

(1) Unweighting it

(2) Pushing the trigger

(3) Sitting on the saddle rmly

Ensure smooth action and reduce wear

on pins and bushings inside the post by

applying force only in the direction of the

seat tube axis.

19

USAGE

DROP AND EXTEND

The saddle can be dropped

by (1) unweighting it,

(2) pushing the trigger, and

(3) sitting on the saddle rmly.

Ensure smooth action and

reduce wear on pins and

bushings inside the post by

applying force only in the

direction of the seat tube

axis.

To raise the saddle, push the trigger with unweighted saddle.

Once the desired position is reached, release the trigger.

You can set the saddle height innitely in any position within

the post’s travel range.

Your post might need to be manually broken loose if it hasn‘t

been used or adjusted for a long time, since the seals tend to

stick to the contacting surfaces.

For this initial „break-away“ just push the remote and then

gently push or pull the saddle until the post starts moving.

TIPP: Always store the bike with the dropper not fully extended.

This will prevent the remote from stiening up due to temperature

changes (hydro-lock). Droppening the post about 1/2“-1“ is

plenty enough.

18 19

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

usage

1. Reset the post and then fully extend to maximum length before adjusting air

pressure. Let the post rest for 30 seconds.

2. Remove the saddle clamps.

3. Move the reset lever to upward position using a 4 mm Allen key or the reset

lever.

ADJUSTING RETURN SPEED

Your Jack SL comes with a factory setting of 240~250 psi in air pressure. This

pressure will provide a good balance between return speed and lever force.

However, if you feel your return speed is too slow, you can make your post faster

by increasing air pressure up to a maximum of 290 psi.

Keep your post right side up and fully extended, when adjusting air pressure.

Never operate the air valve, while the post is laying horizontally or upside down

or you will cause suspension uid to leak out of the post under high pressure!

This can cause severe injuries!

WARNING

! !

CAUTION

Safety glasses and gloves must always be worn when adjusting the air pressure,

since the dropper post contains high pressures and suspension uid

20

USAGE

ADJUSTING RETURN SPEED

Your REVIVE comes with a factory setting of 240~250 psi in air

pressure. This pressure will provide a good balance between

return speed and lever force. However, if you feel your return

speed is too slow, you can make your post faster by increasing

air pressure up to a maximum of 290 psi.

CAUTION: Safety glasses and gloves must always

be worn when adjusting the air pressure, since

the dropper post contains high pressures

and suspension uid!

WARNING: Keep your post right side up and

fully extended, when adjusting air pressure.

Never operate the air valve, while the post is

laying horizontally or upside down or you will

cause suspension uid to leak out of the post

under high pressure! This can cause severe injuries!

1. Reset the post and then fully extend to maximum length

before adjusting air pressure. Let the post rest for 30 seconds.

2. Remove the saddle clamps.

3. Move the reset lever to upward position using a 4 mm Allen

key or the reset lever.

usage

ADJUSTING RETURN SPEED (CONTINUED)

4. Remove the valve cap from the valve housing. Do not lose this small plug since

it is essential for proper reset function.

5. Attach the air valve adapter and then attach the shock pump onto the adapter.

Make sure not to overtight the shock connection.

6. Pump the post to desired pressure. We do not recommend pressures lower

than 210 psi, since it can make the post become very slow. Maximum pressure is

290 psi. We recommend to use a high quality shock pump with a 2-step valve to

avoid air loss, when detaching the pump.

7. Remove pump and adapter from the post.

8. Clean your post from any excessive suspension uid.

9. Reinstall all previously removed parts in the order they were removed.

Instead of using the air adapter, you can also remove the reset axle and attach

the pump directly.

21

USAGE

ADJUSTING RETURN SPEED

4. Remove the valve cap from the valve housing.

Do not lose this small plug since it is essential for

proper reset function.

5. Attach the air valve adapter and then attach the shock

pump onto the adapter. Make sure not to overtight the

shock connection.

6.

Pump the post to desired pressure. We do not recommend

pressures lower than 210 psi, since it can make the post become

very slow. Maximum pressure is 290 psi. We recommend to

use a high quality shock pump with a 2-step valve to avoid air

loss, when detaching the pump.

7. Remove pump and adapter from the post.

8. Clean your post from any excessive suspension uid.

9. Reinstall all previously removed parts in the order they

were removed.

Instead of using the air adapter, you can also remove the reset

axle and attach the pump directly.

air valve

adapter

Allen key 1.5 mm Allen key 2 mm

OR

Allen key 4 mm

20 21

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

SERVICE

MAINTENANCE

You can expect reliable service from this high-performance product if properly

installed and regularly maintained by an authorized Manitou service center or a

qualied service technician.

For assistance locating a qualied service technician, visit www.manitoumtb.com.

Besides routine maintenance, the operator must check the seatpost every time it

is used to ensure proper operation.

Your new seatpost is warranted for a period of two years from the date of

purchase. The warranty is expressly limited to the repair or replacement of the

defective part and is the sole remedy of the warranty.

Do not disassemble your seatpost by yourself unless you are a skilled and

authorized technician! Failure to follow these warnings and instructions will

immediately void your warranty!

WARNING

! !

CAUTION

When working on the seatpost, gloves and safety glasses must always be worn!

As some of the components are under high pressure, disassembling the seatpost

may cause damage and severe personal injury.

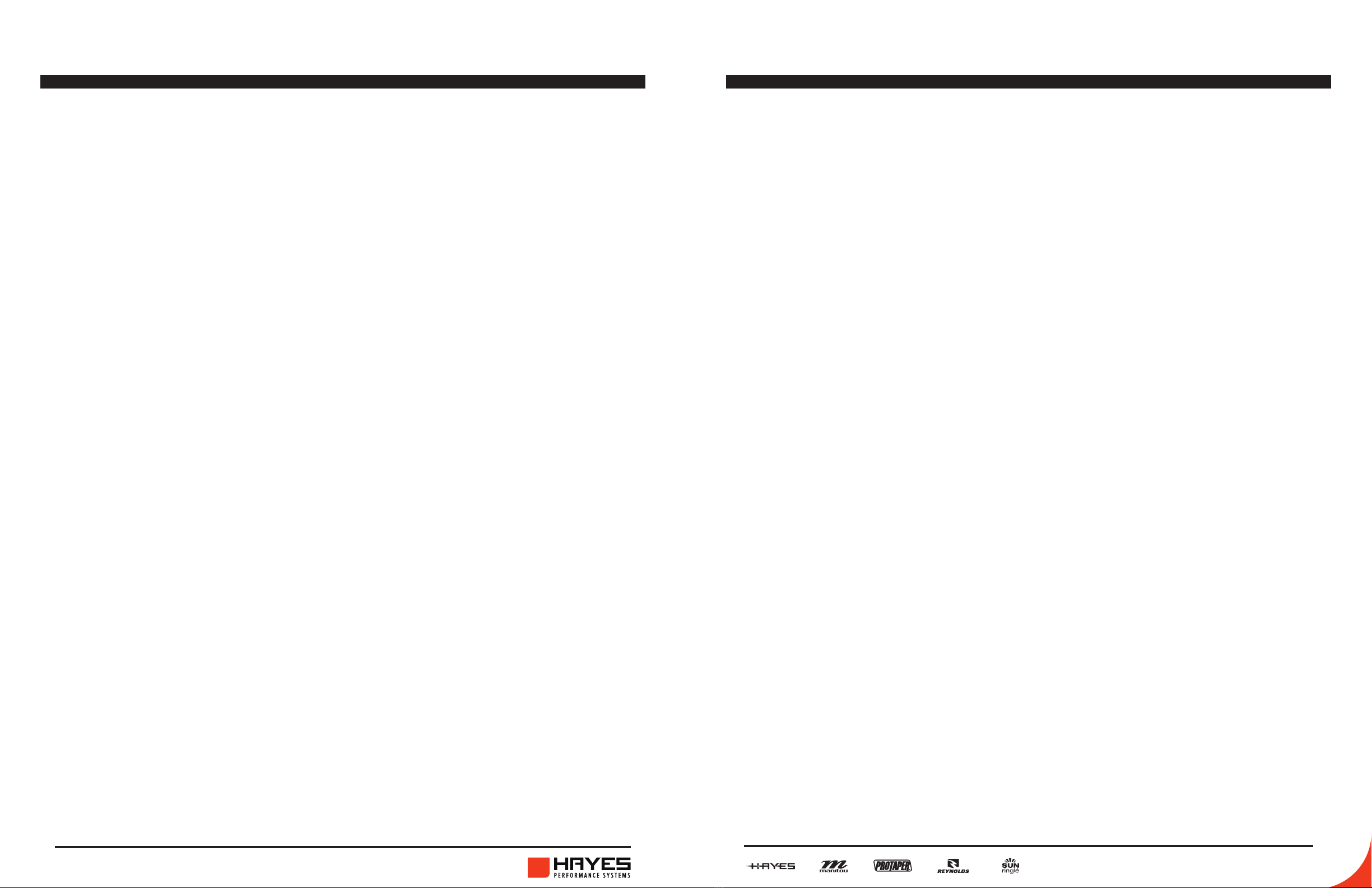

SERVICE INTERVALS

BEFORE EVERY RIDE

• CHECK SADDLE CLAMPS FOR PROPER FIT

• INSPECT THE POST FOR DAMAGE

• CHECK FUNCTION

AFTER EVERY RIDE

• GENTLY WIPE OFF DIRT & WATER (NO POWER WASH!)

• MAKE SURE NO WATER ENTERS THE FRAME DURING WASHING (HUMIDITY CAN

CAUSE CORROSION)

• STORE BIKE IN A DRY PLACE

MINIMUM EVERY 12

MONTHS OR AFTER 100

HOURS OF OPERATION*

• LOWER TUBE SERVICE**

UPON NEED • FULL CARTRIDGE SERVICE**

MAINTENANCE

SERVICE

*whichever comes rst

** Complete maintenance plan, instructions and video tutorials can be

found on www.bikeyoke.com!

Before longer periods of non-use (>1 month), be sure to carry out a service on

the lower tube unit to prevent corrosion damage due to humidity.

Depending on the amount of use and riding conditions, a shorter maintenance

interval may be necessary in order to ensure a smooth function of your Manitou

seatpost!

22 23

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

faq

IS THERE A WEIGHT LIMIT ON THE JACK DROPPER POST?

Our Jack / Jack SL has a maximum rider weight of 115kg (253lbs).

CAN I USE OTHER REMOTES THAN MANITOU?

We support all commonly available cable dropper remotes. To provide full return

speed and smooth drop feel, your remote should have a least 10 mm of cable pull

for Jack and at least 5 mm of cable pull for Jack SL.

CAN I MOUNT SADDLES THAT HAVE CARBON RAILS AND/OR HIGH-

OVAL RAILS TO MY POST?

Our Jack droppers are compatible with standard 7x7 mm and oval rails 7x9 or

7x10 mm made from carbon or alloy.

CAN I CLAMP MY MANITOU SEATPOST IN THE ASSEMBLY STAND?

We recommend to clamp only the lower tube unit with care.

CAN I GET SPARE PARTS FOR MY JACK?

We have all important spare parts available in our online shop, at our distributors

and listed Manitou dealers. Other parts are available on demand.

IS THERE ANYTHING I NEED TO CONSIDER WHEN LOWERING MY POST?

Before pushing the remote lever, slightly unweight your saddle. Always apply the

drop force along the seat tube direction!

faq

MY POST SLIGHTLY COMPRESSES UNDER LOAD. IS THAT NORMAL?

A small amount of compression movement is absolutely normal and harmless,

and can be up to 1-2 mm.

WHAT DO I HAVE TO CONSIDER WHEN INSTALLING THE SADDLE?

Alternately tighten the clamping bolts to the torque specied on the dropper post.

IMPORTANT: Do not grease the saddle clamp bolts.

CAN I LIFT MY BIKE ON THE SADDLE?

It is acceptable for Manitou droppers to carefully lift the bike on the saddle.

IS IT OKAY TO USE T-BAR LIFTS WITH MY MANITOU SEATPOST?

Manitou generally advises against using t-bar lifts. In addition to the obvious risk

of scratching the post‘s coating, the multitude of lift variants result in incalculable

loads on the post, which can lead to possible late eects. Any use of our

seatposts on t-bar lifts is expressly at the user‘s own risk and voids the warranty.

FOR MORE ANSWERS AND QUESTIONS CHECK OUT OUR WEBSITE.

24 25

JACK DROPPER POST SETUP GUIDE JACK DROPPER POST SETUP GUIDE

ISSUE POTENTIAL CAUSE SOLUTION

Remote lever

does not return

Actuator lever (#48) or plunger (#32)

are seized

Properly clean and grease actuator lever and

plunger (use thick grease, not suspension grease)

Seized inner cable due to corrosion Replace inner and outer cable

Remote lever is

hard to push

Riding in low temps, then going back

inside will let oil expand and cause

extensive pressure inside inner chamber

Use 4mm Allen Key to engage reset function ->

pressure will equalize. Advise to drop the post

before storing the bike after coming back from

rides in cold temps to avoid this happening again

Oil betwen piston shaft (#29) and push

rod (#30) -> defective seal (#53)? Full rebuild and replacement of defective seal

Sticky or ow

movement

Water or dirt or corrosion inside lower

tube or lack of grease Lower tube service

Foam ring (#45) clogs breathing holes at

bottom of post

Clean or replace foam ring, if neccessary perform

lower tube service

Pressure is too low Reset pressure to 260 psi

Cable tension too low Increase cable tension

Seat collar torque too high Check seat collar (max 5Nm)

Post clamped too close to collar Move post out of seattube by 2mm

Outside temperature too low Post should normally work ne until as low as -10°

C (with original oil)

Air leakage Schrader valve or O-rings (#17 or #18)

not tightened or defective

Tighten or replace schrader valve and/or full

cartrideg rebuild with replacement of defective parts

Oil leakage Defective O-ring #53 or defective lower

seal head assembly Full rebuild with replacement of defective parts

Post sinks owly

under load

Defective O-rings #16, #21, #24 or #27 Full rebuild with replacement of defective parts

Cable tension too high Reduce cable tension

Outer housing endcap is diocated (after

post adjustment in frame) Relocate the outer housing endcap in ist seat

Post owly

extends by

itself

Defective O-rings #16, #21, #24 or #27 Full rebuild with replacement of defective parts

Cable tension too high Reduce cable tension

Outer housing endcap is diocated (after

post adjustment in frame) Relocate the outer housing endcap

Post requires

frequent resets

Post is early version without microvalve

(#54)

This is normal, if the post is stored and/or actuated

upside down Upgrading with new inner tube (#22)

and microvalve will make the post less prone to air

ingestion

Reset lever

does not return

Reset axle (#8) is seized Make sure set screw (#5) is not clamping the axle,

remove, clean and grease reset axle

Pressure is too low Set pressure to 260 psi

TROUBLESHOOTING EXPLODED VIEW

33

open with heat

46

19

27

5

Torque 4.5Nm

1

51

23

22

39

37

6

53

11

10

21

3

8

52

54

42

26

thread-lock strong, open with heat

55

12

20

13

29

torque 6Nm

44

40

45

50

49

41

4

7

57

36

43

48

34 7

32

24

BikeYoke REVIVE

47

17

30

25

upwards

38

28

lip must face

18

31

2

14

16

9

15

35

thread-lock medium

NOTE:

running change:

#41 + #42 = old

#57 = new

torque 4Nm

POS part name qty.

1barrel nut M5 2

2REVIVE upper saddle clamp 1

3REVIVE lower saddle clamp 1

4saddle clamp bolt M5x30 2

5set screw M3x0.5x3 1

6o-ring 5x1 1

7set screw M4x0.7x5 2

8REVIVE lever axle 1

9o-ring 6x1 1

10 REVIVE lever 1

11 REVIVE upper tube 1

12 valve plug 1

13 o-ring 3.5x1 1

14 valve core 1

15 REVIVE valve 1

16 o-ring 2x1.5 1

17 o-ring 13x2/11.5x2 1

18 o-ring 8x1.5 1

19 REVIVE seal head 1

20 spring pin 3x12 1

21 o-ring 8x2 1

22 inner tube 1

23 o-ring 7x2.5 1

24 backup-ring 1

25 main piston 1

26 valve spring 1

27 o-ring 2x1.5 NBR90 1

28 main valve 1

29 piston shaft 1

30 push rod 1

31 o-ring 4x1 1

32 shaft cap 1

33 o-ring 17x2 1

34 shaft bushing 1

35 lower seal head 1

36 u-cup 1

37 wiper /spring loaded wiper 1

38 upper stanchion bushing 1

39 lower tube 1

40 guiding pin 6

41 lower stanchion bushing 1

42 lower stanchion bushing washer 1

43 lower sealhead circlip 1

44 o-ring 18.64x3.53 1

45 foam cover 1

46 o-ring 24x2 1

POS part name qty.

47 actuator housing 1

48 actuator lever 1

49 cable stop 1

50 actuator circlip 1

51 spring pin 3x10 2

52 barrel nut 1

53 o-ring 2.5x1.5 1

54 Microvalve 1

55 reset lever 1

56 air adapter (not pictured) 1

57 lower bushing (IGUS) 1

Cartridge fluid volumes:

125mm = 35ml

160mm = 41.5ml

185mm = 46ml

213mm = 60ml

BikeYoke recommends 96% Mobil DTE 10 Excel 15 with 4% r.s.p. No Stick Slip.

Other suspension oils with similar viscosity will work, but may differ in performance.

Recommended grease:

r.s.p. Slick Kick

r.s.p. Soft grease

SRAM Butter

KS Post Paste

Buzzy's Slick Honey

Don´t use spray-on lubricants!

33

open with heat

46

19

27

5

Torque 4.5Nm

1

51

23

22

39

37

6

53

11

10

21

3

8

52

54

42

26

thread-lock strong, open with heat

55

12

20

13

29

torque 6Nm

44

40

45

50

49

41

4

7

57

36

43

48

34 7

32

24

BikeYoke REVIVE

47

17

30

25

upwards

38

28

lip must face

18

31

2

14

16

9

15

35

thread-lock medium

NOTE:

running change:

#41 + #42 = old

#57 = new

torque 4Nm

POS part name qty.

1barrel nut M5 2

2REVIVE upper saddle clamp 1

3REVIVE lower saddle clamp 1

4saddle clamp bolt M5x30 2

5set screw M3x0.5x3 1

6o-ring 5x1 1

7set screw M4x0.7x5 2

8REVIVE lever axle 1

9o-ring 6x1 1

10 REVIVE lever 1

11 REVIVE upper tube 1

12 valve plug 1

13 o-ring 3.5x1 1

14 valve core 1

15 REVIVE valve 1

16 o-ring 2x1.5 1

17 o-ring 13x2/11.5x2 1

18 o-ring 8x1.5 1

19 REVIVE seal head 1

20 spring pin 3x12 1

21 o-ring 8x2 1

22 inner tube 1

23 o-ring 7x2.5 1

24 backup-ring 1

25 main piston 1

26 valve spring 1

27 o-ring 2x1.5 NBR90 1

28 main valve 1

29 piston shaft 1

30 push rod 1

31 o-ring 4x1 1

32 shaft cap 1

33 o-ring 17x2 1

34 shaft bushing 1

35 lower seal head 1

36 u-cup 1

37 wiper /spring loaded wiper 1

38 upper stanchion bushing 1

39 lower tube 1

40 guiding pin 6

41 lower stanchion bushing 1

42 lower stanchion bushing washer 1

43 lower sealhead circlip 1

44 o-ring 18.64x3.53 1

45 foam cover 1

46 o-ring 24x2 1

POS part name qty.

47 actuator housing 1

48 actuator lever 1

49 cable stop 1

50 actuator circlip 1

51 spring pin 3x10 2

52 barrel nut 1

53 o-ring 2.5x1.5 1

54 Microvalve 1

55 reset lever 1

56 air adapter (not pictured) 1

57 lower bushing (IGUS) 1

Cartridge fluid volumes:

125mm = 35ml

160mm = 41.5ml

185mm = 46ml

213mm = 60ml

BikeYoke recommends 96% Mobil DTE 10 Excel 15 with 4% r.s.p. No Stick Slip.

Other suspension oils with similar viscosity will work, but may differ in performance.

Recommended grease:

r.s.p. Slick Kick

r.s.p. Soft grease

SRAM Butter

KS Post Paste

Buzzy's Slick Honey

Don´t use spray-on lubricants!

33

open with heat

46

19

27

5

Torque 4.5Nm

1

51

23

22

39

37

6

53

11

10

21

3

8

52

54

42

26

thread-lock strong, open with heat

55

12

20

13

29

torque 6Nm

44

40

45

50

49

41

4

7

57

36

43

48

34 7

32

24

BikeYoke REVIVE

47

17

30

25

upwards

38

28

lip must face

18

31

2

14

16

9

15

35

thread-lock medium

NOTE:

running change:

#41 + #42 = old

#57 = new

torque 4Nm

POS part name qty.

1barrel nut M5 2

2REVIVE upper saddle clamp 1

3REVIVE lower saddle clamp 1

4saddle clamp bolt M5x30 2

5set screw M3x0.5x3 1

6o-ring 5x1 1

7set screw M4x0.7x5 2

8REVIVE lever axle 1

9o-ring 6x1 1

10 REVIVE lever 1

11 REVIVE upper tube 1

12 valve plug 1

13 o-ring 3.5x1 1

14 valve core 1

15 REVIVE valve 1

16 o-ring 2x1.5 1

17 o-ring 13x2/11.5x2 1

18 o-ring 8x1.5 1

19 REVIVE seal head 1

20 spring pin 3x12 1

21 o-ring 8x2 1

22 inner tube 1

23 o-ring 7x2.5 1

24 backup-ring 1

25 main piston 1

26 valve spring 1

27 o-ring 2x1.5 NBR90 1

28 main valve 1

29 piston shaft 1

30 push rod 1

31 o-ring 4x1 1

32 shaft cap 1

33 o-ring 17x2 1

34 shaft bushing 1

35 lower seal head 1

36 u-cup 1

37 wiper /spring loaded wiper 1

38 upper stanchion bushing 1

39 lower tube 1

40 guiding pin 6

41 lower stanchion bushing 1

42 lower stanchion bushing washer 1

43 lower sealhead circlip 1

44 o-ring 18.64x3.53 1

45 foam cover 1

46 o-ring 24x2 1

POS part name qty.

47 actuator housing 1

48 actuator lever 1

49 cable stop 1

50 actuator circlip 1

51 spring pin 3x10 2

52 barrel nut 1

53 o-ring 2.5x1.5 1

54 Microvalve 1

55 reset lever 1

56 air adapter (not pictured) 1

57 lower bushing (IGUS) 1

Cartridge fluid volumes:

125mm = 35ml

160mm = 41.5ml

185mm = 46ml

213mm = 60ml

BikeYoke recommends 96% Mobil DTE 10 Excel 15 with 4% r.s.p. No Stick Slip.

Other suspension oils with similar viscosity will work, but may differ in performance.

Recommended grease:

r.s.p. Slick Kick

r.s.p. Soft grease

SRAM Butter

KS Post Paste

Buzzy's Slick Honey

Don´t use spray-on lubricants!

33

open with heat

46

19

27

5

Torque 4.5Nm

1

51

23

22

39

37

6

53

11

10

21

3

8

52

54

42

26

thread-lock strong, open with heat

55

12

20

13

29

torque 6Nm

44

40

45

50

49

41

4

7

57

36

43

48

34 7

32

24

BikeYoke REVIVE

47

17

30

25

upwards

38

28

lip must face

18

31

2

14

16

9

15

35

thread-lock medium

NOTE:

running change:

#41 + #42 = old

#57 = new

torque 4Nm

POS part name qty.

1barrel nut M5 2

2REVIVE upper saddle clamp 1

3REVIVE lower saddle clamp 1

4saddle clamp bolt M5x30 2

5set screw M3x0.5x3 1

6o-ring 5x1 1

7set screw M4x0.7x5 2

8REVIVE lever axle 1

9o-ring 6x1 1

10 REVIVE lever 1

11 REVIVE upper tube 1

12 valve plug 1

13 o-ring 3.5x1 1

14 valve core 1

15 REVIVE valve 1

16 o-ring 2x1.5 1

17 o-ring 13x2/11.5x2 1

18 o-ring 8x1.5 1

19 REVIVE seal head 1

20 spring pin 3x12 1

21 o-ring 8x2 1

22 inner tube 1

23 o-ring 7x2.5 1

24 backup-ring 1

25 main piston 1

26 valve spring 1

27 o-ring 2x1.5 NBR90 1

28 main valve 1

29 piston shaft 1

30 push rod 1

31 o-ring 4x1 1

32 shaft cap 1

33 o-ring 17x2 1

34 shaft bushing 1

35 lower seal head 1

36 u-cup 1

37 wiper /spring loaded wiper 1

38 upper stanchion bushing 1

39 lower tube 1

40 guiding pin 6

41 lower stanchion bushing 1

42 lower stanchion bushing washer 1

43 lower sealhead circlip 1

44 o-ring 18.64x3.53 1

45 foam cover 1

46 o-ring 24x2 1

POS part name qty.

47 actuator housing 1

48 actuator lever 1

49 cable stop 1

50 actuator circlip 1

51 spring pin 3x10 2

52 barrel nut 1

53 o-ring 2.5x1.5 1

54 Microvalve 1

55 reset lever 1

56 air adapter (not pictured) 1

57 lower bushing (IGUS) 1

Cartridge fluid volumes:

125mm = 35ml

160mm = 41.5ml

185mm = 46ml

213mm = 60ml

BikeYoke recommends 96% Mobil DTE 10 Excel 15 with 4% r.s.p. No Stick Slip.

Other suspension oils with similar viscosity will work, but may differ in performance.

Recommended grease:

r.s.p. Slick Kick

r.s.p. Soft grease

SRAM Butter

KS Post Paste

Buzzy's Slick Honey

Don´t use spray-on lubricants!

33

open with heat

46

19

27

5

Torque 4.5Nm

1

51

23

22

39

37

6

53

11

10

21

3

8

52

54

42

26

thread-lock strong, open with heat

55

12

20

13

29

torque 6Nm

44

40

45

50

49

41

4

7

57

36

43

48

34 7

32

24

47

17

30

25

upwards

38

28

lip must face

18

31

2

14

16

9

15

35

thread-lock mediu m

torque 4Nm

16F, No. 37, Sec. 3

Mincyuan E. Rd.

Zhongshan District

5800 W. Donges Bay Rd.

Mequon, WI 53092

Dirnismaning 20 a

85748 Garching (b. Munich)

Germany

16F, No. 37, Sec. 3

Mincyuan E. Rd.

Zhongshan District

GLOBAL HEADQUARTERS &

HAYES BICYCLE GROUP USA

HAYES BICYCLE GROUP EU

HAYES BICYCLE GROUP ASIA

facebook.com/ManitouMTB

instagram.com/ManitouMTB

#ScienceofSmooth

Table of contents

Other Manitou Bicycle Accessories manuals

Manitou

Manitou DORADO User manual

Manitou

Manitou 2001 MARS User manual

Manitou

Manitou Circus Expert User manual

Manitou

Manitou MARA PIGGYBACK User manual

Manitou

Manitou XVERT R User manual

Manitou

Manitou DORADO EXPERT 37MM User manual

Manitou

Manitou Mara Pro User manual

Manitou

Manitou Axel Super 2004 User manual

Manitou

Manitou DORADO DH User manual

Manitou

Manitou SIX User manual

Popular Bicycle Accessories manuals by other brands

Specialized

Specialized Elite CylcoComputer user manual

Sigma

Sigma BC 16.16 manual

Playcore

Playcore Dero Setbacks installation instructions

VDO Cyclecomputing

VDO Cyclecomputing x3dw instruction manual

Cateye

Cateye RAPID X2 manual

buratti meccanica

buratti meccanica Clorofilla Trail Use and maintenance manual