Manitou DORADO DH User manual

AMERICAN MADE

MANITOU SUSPENSION

CONGRATULATIONS ON CHOOSING THE LATEST IN SUSPENSION

TECHNOLOGY AVAILABLE, A 2003 MANITOU DORADO FORK BUILT

IN THE USA. This DORADO fork is fully assembled and is ready to

be installed onto your bicycle. It comes equipped with a 1 1/8-inch

threadless steerer tube, AND is only available with a disc brake ver-

sion.

2003 DORADO FORK LINE

DORADO DH . . . . . . . . . . 180 MM TRAVEL / COIL SPRING /

TPC+ DAMPING

DORADO SC. . . . . . . . . . . 130 MM TRAVEL / COIL SPRING /

TPC+ DAMPING

You can also download this manual at www.answerproducts.com.

BICYCLING IS A HAZARDOUS

ACTIVITY THAT REQUIRES THAT

THE RIDER STAY IN CONTROL OF HIS OR HER BICYCLE AT ALL

TIMES. READING THIS MANUAL ENTIRELY AND PROPERLY MAIN-

TAINING YOUR BICYCLE AND SUSPENSION FORK WILL REDUCE THE

POSSIBILITY OF INJURY OR POSSIBLE DEATH. PRIOR TO RIDING

YOUR BICYCLE, YOU SHOULD INSPECT YOUR SUSPENSION FORK TO

ENSURE THAT NO DAMAGE HAS OCCURRED DURING THE COURSE OF

RIDING. DO NOT RIDE YOUR BICYCLE IF THE FORK SHOWS ANY

SIGNS OF BENDING, CRACKING, LEAKING, OR IF IT IS MISSING ANY

OF THE ORIGINALLY SUPPLIED COMPONENTS. ANY FALL FROM

YOUR BICYCLE CAN RESULT IN SERIOUS INJURY OR EVEN DEATH.

FOLLOWING THESE INSTRUCTIONS CAN HELP YOU REDUCE THE RISK

OF BEING INJURED.

IF YOU ARE A MODERATE OR AGGRESSIVE OFF-ROAD RIDER,

OR RIDE AT LEAST THREE TIMES A WEEK OVER ROUGH TERRAIN,

ANSWER RECOMMENDS RETURNING YOUR SUSPENSION FORK

EVERY 2 YEARS FOR A THOROUGH INSPECTION AND UPDATE. TAKE

YOUR FORK TO A MANITOU AUTHORIZED DEALER WHO CAN

ARRANGE FOR SHIPMENT TO ANSWER PRODUCTS, OR YOU MAY

CALL ANSWER AT (661) 257-4411 TO HAVE YOUR FORK

SHIPPED DIRECTLY.

IMPORTANT: The DORADO fork is an off-road fork, and as

such, does not come with proper reflectors for on-road use.

CONSUMER SAFETY INFORMATION

1. Never remove or have the steerer tube or legs (SC version only)

removed from the crown. The steerer tube and legs are press fit

at the factory. Pressing the steerer tube or legs out will perma-

nently damage the crown beyond repair and render it unsafe for

any continued use.

2. Never attempt to thread a threadless steerer tube. Cutting

threads will weaken the steerer tube and cause an unsafe condi-

tion. The only safe thing to do is to obtain the proper

crown/steerer from your dealer.

3. Any other alteration or modification to your fork should be con-

sidered unsafe. Contact Answer Warranty prior to modifying

your fork in any way for safety information.

4. Do not use the DORADO fork if any parts are broken, bent,

cracked, or you suspect may be damaged. Contact your dealer

or Answer Warranty at (661) 257-4411 if you have any ques-

tions concerning the integrity or condition of your fork.

5. Answer Products recommends that you inspect your fork before

every ride for wear and damage. Inspect the crown, inner legs,

outer legs, and dropout areas for cracks or damage.

WARRANTY INFORMATION

Any Answer Products fork found by the factory to be defective in

materials and/or workmanship within one year from the date of pur-

chase (or two years in EU countries) will be repaired or replaced at

the option of the manufacturer, free of charge, when received at the

factory with proof of purchase, freight prepaid. This warranty does

not cover breakage, bending, or damage that may result from crash-

es or falls. This warranty does not cover any fork that has been sub-

ject to misuse or whose serial number has been altered, defaced or

removed. This warranty does not cover paint damage. Any modifica-

tions made by the user will render the warranty null and void. This

warranty is expressly in lieu of all other warranties, and any implied

are limited in duration to the same duration as the expressed warran-

ty herein. Answer Products shall not be liable for any incidental or

consequential damages.

If for any reason warranty work is necessary, return the fork to the

place of purchase. At that time, instructions for repair, return, or

replacement shall be given. Customers in countries other than USA

should contact their dealer or local distributor.

INSTALLATION AND SETUP

INSTRUCTIONS

Ensure that the proper top crown has been delivered on your DORA-

DO first. The steerer tube may need to be cut to length to fit your

bicycle head tube. If you are not familiar with this procedure, or do

not have the proper tools to cut the steerer tube, it is recommended

that you seek a dealer with a qualified bicycle mechanic to perform

installation.

THE STEERER TUBE AND LEGS (SC VERSION)

ARE A ONE TIME PRECISION PRESS FIT AT THE

FACTORY AND CANNOT BE REMOVED FROM THE CROWN. REPLACE-

MENT OF THE ENTIRE CROWN/STEERER ASSEMBLY MUST BE DONE

TO CHANGE STEERER TUBE LENGTHS OR DIAMETERS. REMOVING

AND REPLACING THE STEERER TUBE OR LEGS WILL RESULT IN AN

UNSAFE CONDITION AND SHOULD NEVER BE DONE.

FORK INSTALLATION

1. Remove the old fork from your bicycle.

2. Measure and cut the steerer tube to fit your bicycle head tube.

You generally will want to leave about 10–20 mm excess length

for the DH version.

3. Remove the headset crown race from the old fork and press

onto the DORADO steerer until the race is seated over the

crown.

4. Clean and grease the headset bearings and races.

5. Install the lower bearings (if applicable) on fork crown race.

6. Insert the steerer tube into the head tube of the frame.

7. Install the upper bearings, small spacer ring, and then the top

crown (for DH model).

8. Install the stem cap and bolt. Tighten the bolt to headset manu-

facturer’s specifications.

9. Install the handlebars to the desired height and torque stem

bolts to manufacturer’s specifications. On the DH model, torque

the 5 mm stem clamping system bolts to 60–75 in.-lbs. (7.3–8.5

Nm).

10. Install the brakes and adjust per the manufacturer’s instructions.

11. Install the small side of the hex lock through-axle through the

large opening and wheel. Tighten down the hex lock end bolt

until it is snug. Then tighten the dropout pinch bolts to 40–60

in.-lbs. (4.5–6.8 Nm).

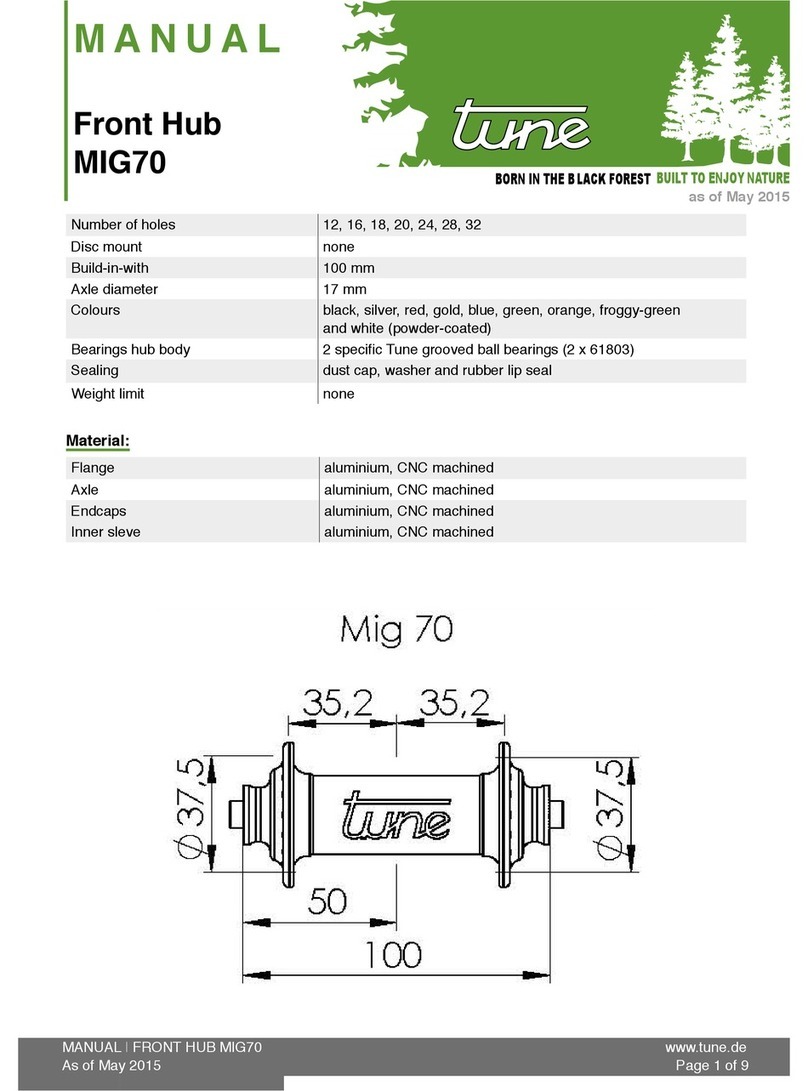

UPPER TRIPLE CLAMP SIZING – DORADO DH

To fit a variety of bike head tube sizes, there are two distinct upper

triple clamps. The flat upper triple clamp is the small size and fits

head tubes between 130 mm and 160 mm in length. The drop upper

triple clamp is the large size and fits head tubes between 155 mm

and 185 mm in length. Both clamps must fully engage the aluminum

bulges on the outer tubes without extending beyond the small taper

line with the upper and lower clamps. All triple clamp bolts must be

torqued to 60–75 in.-lbs. (7.3–8.5 Nm).

HEX AXLE INSTALLATION

The hex axle used on DORADO forks is unique in that it allows

the legs to be locked together once the pinch bolts have been tight-

ened. To install the hex axle, simply slip the axle into the dropout,

small axle hex side first into the large dropout hex. Thread in the set

bolt into the small hex side and snug slightly. Push the fork up and

down a few times to center the axle and hub and then tighten all

pinch bolts to 40–60 in.-lbs. (4.5–6.8 Nm).

ATTACHMENT OF THE BRAKE CABLE

Failure to properly route and securely attach the brake cable to the

fork can cause serious injury or death. Included with the fork is a

small black cable guide that can be attached to the fork guard

depending on how you attach the cable. The best method we’ve

found is to attach the cable so that it runs down the outside of the

left fork leg. Just make sure that you do not attach the cable to the

fork any other place than on the fork guard, as this will cause the

cable to bind and possibly crimp as the fork is compressed. The

cable should be routed through the guides located on the upper car-

bon tubes but should be free to slide.

HANDLEBAR INSTALLATION – DORADO DH

The DORADO DH comes equipped with an integrated handlebar

upper triple clamp system. This provides additional steering stiffness

as well as puts the handlebars straight every time. All handlebar

bolts should be torqued to 50–60 in.-lbs. (5.7–6.8 Nm). All triple

clamp bolts and steerer tube bolts should be torqued to 60–75 in.-

lbs. (7.3–8.5 Nm).

SPRING SETUP – MEASURING SAG

You’ll need a tape measure, a pencil and a piece of paper.

1. Measure the distance from the front axle’s centerline to the bot-

tom of the lower crown without anyone sitting on the bike and

write this distance down. (Remember the exact locations of the

two points because you’ll need to use them later.)

2. Have the rider sit on the bike and measure the distance between

the same two points as in step one. It’s important to be in the

normal riding position (weight centered) with your feet on the

pedals.

3. Subtract the second measurement from the first. The resulting

measurement is the static sag.

SAG MEASUREMENT CHART

FORK MODEL FORK TRAVEL SAG

DORADO SC 130 mm 25 to 32 mm

DORADO DH 180 mm 40 to 45 mm

RIDE KITS

Each DORADO fork comes with two medium rate springs installed. In

addition, one firm spring and one soft spring have also been pack-

aged with the fork. Using the recommended sag measurements list-

ed above, adjust the spring stack as necessary. If there is too much

sag, replace a single spring at a time with a firmer one; if too little

sag, replace with a softer one. If additional adjustments are required,

ride kits can be purchased from Answer under the following part

numbers:

MODEL DH MODEL SC

SPRING RATE PART NO. SPRING RATE PART NO.

Soft 85-4946 Soft 85-4534

Medium 85-4947 Medium 85-4538

Firm 85-4948 Firm 85-4539

Extra Firm 85-4949

DAMPING ADJUSTMENTS –

DORADO FORKS

With DORADO forks, since the fork features an upside-down design,

the damping system is also reversed. As a result, compression

damping adjustment is now located at the bottom of the right leg

and rebound damping is on top of the right leg.

COMPRESSION DAMPING ADJUSTMENT – TPC PLUS

For TPC Plus-equipped DORADO forks, a turn of the knob located on

the bottom of the right leg is all that is needed to adjust compression

damping. Turning the knob clockwise (as you are looking at the fork

from the bottom) increases compression damping, while turning it

counterclockwise decreases compression damping.

REBOUND DAMPING ADJUSTMENT – TPC PLUS

Rebound adjusters on DORADO forks are located on the top of the

right fork leg. Turning the knob clockwise (as you are looking from a

rider’s position) increases rebound damping, while turning it coun-

terclockwise decrease rebound damping.

BEFORE EACH RIDE

IMPORTANT: The DORADO should not be used if any parts

appear to be or are damaged. Contact your local dealer or

Answer Products for replacement parts.

IMPORTANT: Before every ride you should:

1. Ensure that the through-axle is properly adjusted and tight.

2. Wipe the inner legs and clean and check the entire fork for any

obvious damage.

3. Check the headset for proper adjustment.

4. Ensure that the front brake cable is properly routed and check

brake adjustment.

BREAK-IN

Your new fork is designed to break in during your first few rides

(about 20 hours total riding time). Prior to break-in, you may notice

your fork feels tight and slightly sticky. Following the break-in period,

your fork will feel much smoother and react to bumps much better

than when you first put it on your bike. After 20 hours, you may

want to recheck your compression and rebound to fine tune the fork

completely.

MAINTENANCE

IMPORTANT:

1. Use of dirt guards is recommended to keep your DORADO fork

performing at its optimum for extended service cycles and

maintaining maximum life of the fork.

2. Use of this fork without dirt guards will require frequent serv-

ice intervals to maintain performance and normal life of the

fork.

3. Warranty will be void if fork is found to show that dirt guards

were not in place and frequent service was not performed.

Your DORADO fork requires periodic maintenance, cleaning and

inspection performed by a qualified service technician. This is

because moisture and contamination may build up inside the fork

depending on the severity of riding conditions.

If you have any questions regarding your 2003 Manitou DORADO

suspension fork in the U.S., contact the Answer Customer Service

Department at (661) 257-4411. For information outside of the U.S.,

contact your authorized Manitou dealer or distributor. You can also

log on to www.answerproducts.com and download this manual or

see detailed instructions on how to service your suspension fork.

Thank you again for choosing a 2003 Manitou DORADO suspension

fork.

DEALER SERVICE ADDENDUM

INTRODUCTION When servicing the fork, take the time to

inspect all parts for excessive wear or damage. There are basically

three aspects of a fork that will require attention:

1. Lubrication of stanchions (inner legs) and bushing inspection

2. Spring stack

3. Damping system

LUBRICATION OF STANCHIONS (INNER LEGS) AND

BUSHING INSPECTION The outer leg bushings need to be serv-

iced approximately every 40 hours of riding (depending on conditions

– extreme conditions may require a more frequent service schedule).

The method used to determine if your fork requires the lubrication

system to be cleaned and serviced is if stiction (binding as you com-

press the fork) develops. If you feel any stiction, remove the inner

legs per the instructions below and inspect the bushings for signs of

excessive wear. Pay close attention to the bushing contact surface,

which can be damaged by contamination in severe conditions.

Replace any worn or damaged parts that are discovered.

SPRING STACK Inspection and service of the spring stack should

be performed after 80 hours of riding. The spring stack may require

servicing if there is an audible rubbing sound coming from the left

side of the fork during compression. The spring stack can be removed

and serviced using the instructions below.

DAMPING SYSTEM The damping system on your DORADO fork

needs to be serviced approximately every 40 hours. The DORADO fork

uses a sealed gas free hydraulic damping system. The damping oil

and foam compensator (if installed) should be removed at this time

and replaced with 5WT fork oil as described in the instructions below.

Hex Axle – Removal (Figure 1)

To remove the front wheel,

loosen the four dropout pinch

bolts (1) using a 5 mm hex

wrench. Loosen the button head

screw (2) on the right side of

the fork (while facing the fork)

using a 6 mm hex wrench. Push

the axle through the dropouts

from right to left.

Hex Axle – Installation

Reverse the steps above. Torque the button head screw to 15–20 in.-

lbs. (1.7–2.3 Nm). Torque the pinch bolts to 40–45

in.-lbs. (4.5–5.1 Nm).

Triple Clamp Removal (Figure 2)

Loosen the five pinch bolts (1)

using a 4 mm hex wrench and

slide the outer leg down through

the assembly.

Triple Clamp Installation

(Figure 2)

Wipe the aluminum sleeves (2)

on the outer legs and inside of

each triple clamp (3) with iso-

propyl alcohol. Position the

lower clamp on the flat surface

of the leg sleeves; the inside of the clamp must have full surface con-

tact with the sleeve. Torque the pinch bolts to 60–75 in.-lbs. (7.3–8.5

Nm).

Coil Spring Removal (Figure 3)

Use a 20 mm socket to remove the bottom right leg (facing the fork)

end cap (1). Pull the spring

stack (2) consisting of

one MCU, two springs and

connectors out of the

fork leg.

Coil Spring Service, Ride

Kit Installation (Figure 3)

Replace the spring in the

sequence shown, coating

the spring with a liberal amount of Maxima spring grease. Install the

end cap. Torque the end cap to 60–70 in.-lbs. (6.9–7.90 Nm).

Inner Leg Removal (Left Leg, Figure 4)

Remove the coil spring (see above) prior to removing the compression

rod. Unscrew the top cap (1)

with a 1 1/16" socket. Pull the

shaft out of the inner leg until it

stops; do not force. Clamp the

shaft using soft jaw blocks

(Answer tool P/N 064615). Using

a 1 1/16" socket, unscrew the top

cap off of the compression rod

(2). Pull the inner leg downward

from the outer leg.

Seal System Removal and

Bushing Replacement

(Figures 5 and 6)

There are two seals that make up

the sealing system on the bottom

of the outer carbon legs: an outer

(dust) seal to prevent contamina-

tion from the outside, and an

internal (oil) seal to retain lubri-

cation grease inside the fork. The

seals should be replaced if exces-

sive grease is found to be leaking

out of the fork or if on inspection,

excessive contamination is found

inside the outer leg. The seals

must also be removed if it

becomes necessary to replace the

bushings.

Remove the outer (dust) seal (1)

as shown (2). Pry out the metal circlip (3) and then the lower (oil)

seal (4). Discard both seals and circlip; they cannot be reused once

removed.

The bushings should be inspected for signs of wear (discoloration) or

tears on the surface. Bushings can be replaced using tools and

instructions found in Answer bushing removal and installation tools

PN 85-3909 and 85-3911.

Seal System Installation (Figure 7 and 8)

The two seals must be identified and

oriented before installation:

1. The oil seal is installed first

and is rubber on the outside

diameter. It is installed so that

the lip is pointing to the inside

of the outer leg. Install using

Answer seal installation tool

P/N 064000 (1).

2. Install the circlip into

the machined groove in the

outer leg.

3. The dust seal is installed last

and has metal on the outside

diameter. It is installed so that

the lip is pointing to the out-

side and metal surface towards

the circlip. Use the installation

tool to tap the seal into place.

The dust seal will be flush with

the rim (2) of the outer leg

when the seal system installa-

tion is complete.

Before reinstalling the inner leg

after servicing, liberally apply

Motorex grease to the upper and

lower outer leg bushings (3). Lightly

grease the inner legs before inser-

tion.

12

132

21

FIGURE 3

12

FIGURE 2

FIGURE 1

FIGURE 4

12 3 4

FIGURE 5

FIGURE 6

1

23

FIGURE 7

FIGURE 8

Damping System (Right Leg) Service – Leg Removal

(Figure 9)

It is recommended that the

right leg be removed before

service. Remove inner leg from

outer leg as follows:

1. Pull the rebound damper

adjuster knob (1) out of

the damper nut.

2. Remove the damper nut

(2) with an 8 mm hex

wrench.

3. Pull the inner leg (3) out

of the outer leg (4).

4. Remove the leg guard.

Damping System (Right Leg) Service – Leg Disassembly

(Figure 10)

Oil is removed from the

inner leg (3) by removing

the rebound and com-

pression assemblies to

ensure that all old oil is

removed from the sys-

tem. The compression

damping assembly (2) is

located at the bottom

(dropout) end and the

rebound assembly (1) is at the top.

1. Rebound Assembly Removal – With the rebound assembly end of

the leg pointing up (to minimize spilling damping oil), unscrew

the end cap and slowly pull out the assembly over a drip pan.

Pour out and discard the damping oil.

2. Compression Damping Assembly Removal – Unscrew the screw

holding the adjuster knob and remove the knob. Loosen the 13

mm adjuster needle lock nut (Figure 11, #1). Unscrew the end

cap using a 20 mm socket and slowly pull out the assembly over

a drip pan. A piece of black foam (compensator) may come out

as part of some production models.

Damping System (Right Leg) Service – Leg Assembly

(Figures 11, 12 and 13)

The damping system contains no air and when replacing damping oil,

must be bled to remove all air.

1. Install the rebound damper

assembly and torque the end cap

to 60–75 in.-lbs. (7.3–8.5 Nm).

2. Hang the leg vertical at a 45º

angle as shown in Figure 11. Place

a drip pan under the leg.

3. Fully extend the rebound damping

assembly shaft and fill with 5WT

Maxima fork oil (Answer PN 85-

3814) up to the bottom of the

inner leg threads. Cycle the

rebound damper shaft several

times, covering the open end of the leg with a rag. Allow the leg

to sit for two minutes to allow any air bubbles in the system to

rise to the top.

4. On the compression damping assembly, remove and discard the

foam compensator if one was there during damper removal. A

replacement is found in

tune-up kit PN 85-4953.

Remove the 13 mm

adjuster needle locknut

(1). Unscrew the needle

(2) until it is loose from

the assembly, but do not

remove.

5. Insert the compression damp-

ing assembly with its foam

compensator (if applicable)

wrapped tightly around the

shaft into the leg. Oil will be

displaced during this step. Be

sure that the foam does not

bunch up against the leg cap

and is fully inserted into the

leg. Screw in the assembly and

torque to 60–75 in.-lbs.

(7.3–8.5 Nm) using a

20 mm socket.

6. Install the adjuster needle and

13 mm lock nut and torque

to 10–15 in.-lbs. (1.1–1.7 Nm).

7. Install the compression adjuster knob.

8. Inspect the damper bleed process by compressing the rebound

shaft to the bottom out bumper. This is to ensure that the foam

compensator did not bind up internally to limit the travel. If it

does not fully compress, the system must be re-bled.

9. Fully extend the damper shaft and install the inner leg into the

outer leg. Lubricate the bushings and inner leg as specified

under Seal System Installation.

10. Install the damper nut using an 8 mm hex wrench and torque to

15–30 in.-lbs. (1.7–3.4 Nm).

11. Push the rebound damper adjuster knob into the nut until it

snaps in place.

Disk Brake Adapters (Figure 14)

There are three disk brake

caliper adapters included with

the DORADO forks:

(1) International Standard

(2) Post Mount – 6" Disk

(3) Post Mount – 8" Disk

DORADO SC (Single Crown) Fork

Service (Figure 15)

Service procedures for the DORADO SC

fork are the same as for the DH model

except for the method used to remove

the left inner leg. Leg removal is

accomplished by removing the 6 mm

button head cap screw (1) on top of

the crown and pulling the inner leg

out. Re-torque the screw to 15–30 in.-

lbs. (1.7–3.4 Nm) upon assembly.

321

4

FIGURE 9

FIGURE 10

132

12

123

1

FIGURE 11

FIGURE 14

FIGURE 13

FIGURE 12

FIGURE 15

1 Foam Compensator

This manual suits for next models

1

Table of contents

Other Manitou Bicycle Accessories manuals

Manitou

Manitou JACK DROPPER POST User manual

Manitou

Manitou Mezzer Pro User manual

Manitou

Manitou Axel Super 2004 User manual

Manitou

Manitou MARA PIGGYBACK User manual

Manitou

Manitou XVERT R User manual

Manitou

Manitou Jack SL Dropper Seat Post User manual

Manitou

Manitou DORADO EXPERT 37MM User manual

Manitou

Manitou 2001 MARS User manual

Manitou

Manitou R7 EXPERT User manual

Manitou

Manitou MATTTOC PRO User manual