Manntek DCC Original operating manual

Other Manntek Industrial Equipment manuals

Manntek

Manntek SBC Original operating manual

Manntek

Manntek SBC User manual

Manntek

Manntek SBC User manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek PERC Original operating manual

Manntek

Manntek DCC User manual

Manntek

Manntek SBC Original operating manual

Manntek

Manntek DCC Original operating manual

Popular Industrial Equipment manuals by other brands

Lennox

Lennox 10GCS Series installation instructions

IKA

IKA RW 28 basic operating instructions

Montanari

Montanari MGV34 Series Instructions for installation, use and maintenance

BVA Hydraulics

BVA Hydraulics HG10012 instruction manual

Bayne

Bayne Revolution HD 1999-0520 Operation and parts manual

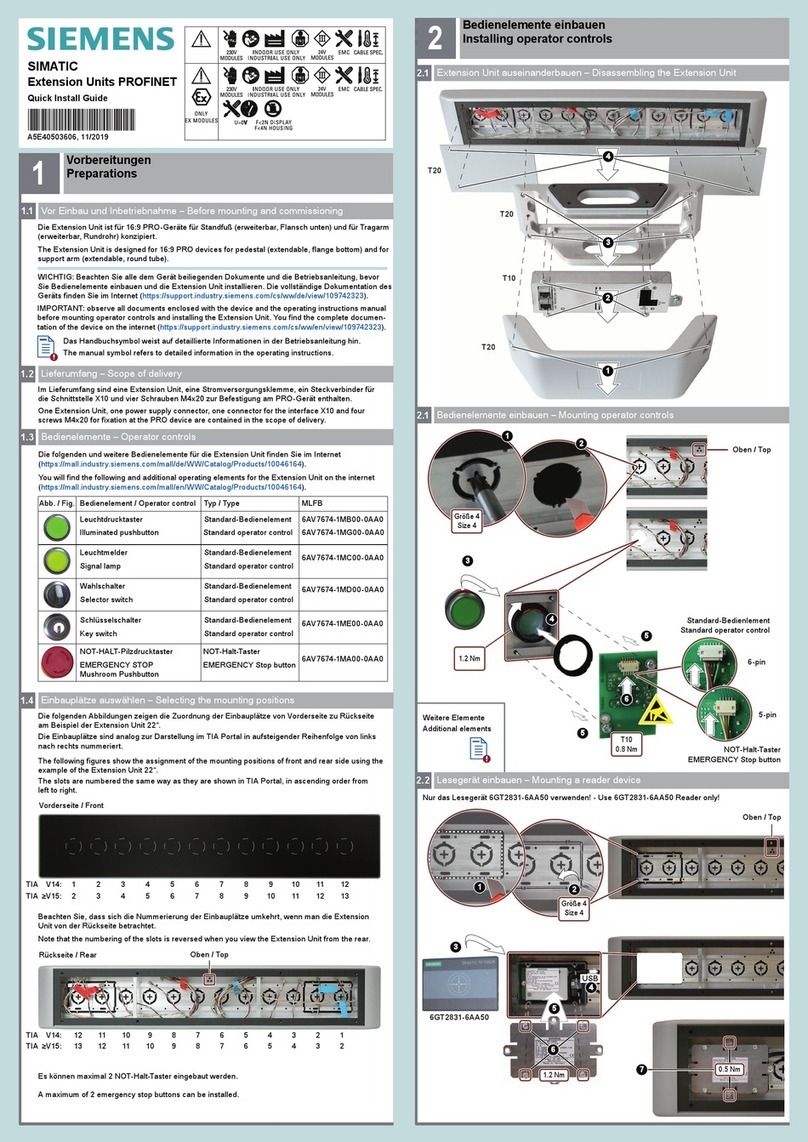

Siemens

Siemens SIMATIC NET CP 1542-5 Equipment manual