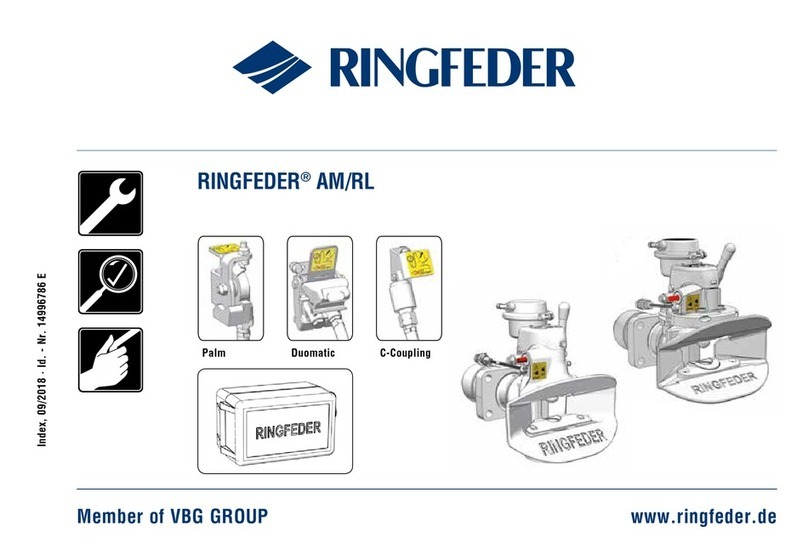

4 of 10 – Version 170815

M

AINTENANCE AND SERVICE INSTRUCTION

Always depressurize the system and rinse off the parts before beginning any

maintenance work. Use protective goggles. Do not handle O-ring seals if the

material appears charred, gummy or sticky.

Use tweezers and wear neoprene or PVC gloves. Do not touch adjacent parts

with unprotected hands. Rinse off the parts once again before starting the “daily

inspection”

D

AILY INSPECTION

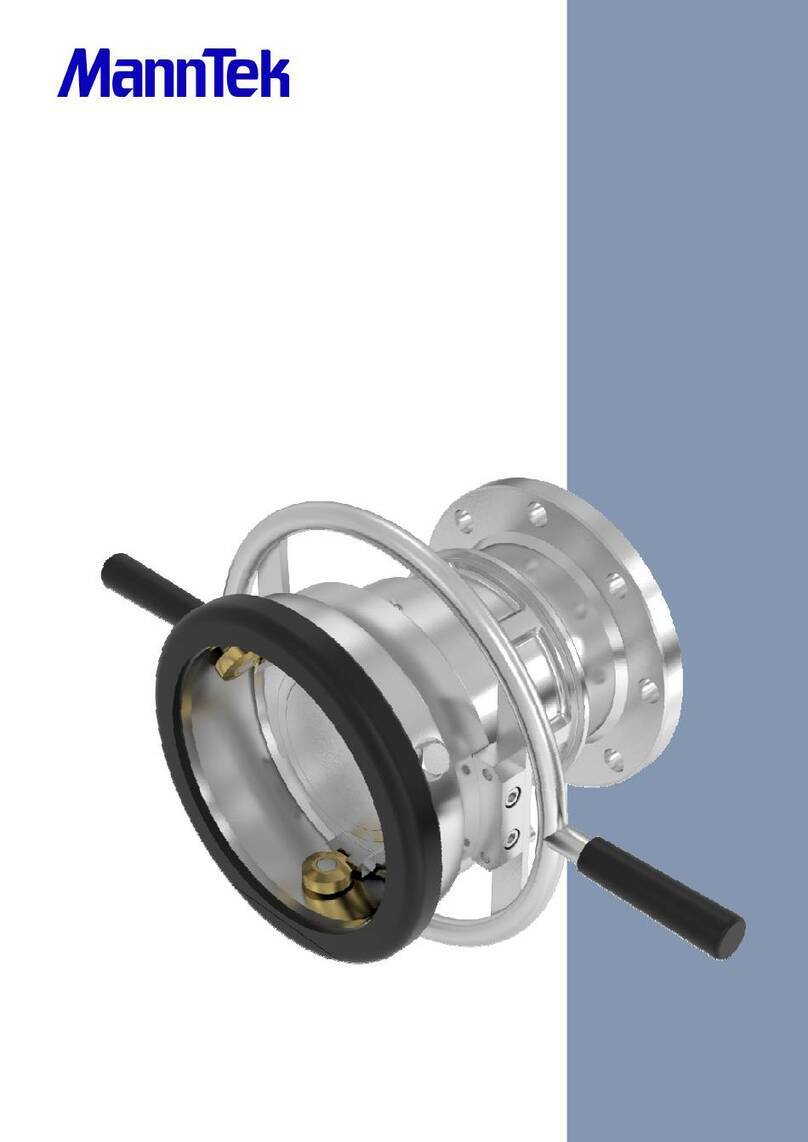

1. Inspect the coupling surface for cleanliness and corrosion.

2. Inspect the O-ring in the house unit connection for serviceability and correct seating

in the grove.

3. Inspect the hose unit swivel for free rotation.

4. Inspect the tank- and hose unit for faultlessness and external signs of seizure.

T

HREE

-

MONTH INSPECTION

1. Exterior cleaning of the coupling halves with a neutral cleanser.

2. Careful “daily inspection” of cleaned units.

O

NCE A YEAR

1. Exchange sealing and washer at least once a year.

2. Refill the hose unit ball bearing grooves with grease

3. Replace worn or damaged components. Repair procedures are straightforward and

no special tools are required.

Check the state of the connection surface and verify that it is clean before proceeding

with the connection.

Couple the repaired unit to a serviceable hose or tank unit as appropriate and check for

correct operation of the valve actuating and bayonet locking mechanism. Couple and

uncouple the unit(s) several times.

U

SE ONLY ORIGINAL

M

ANN

T

EK SPARE PARTS FOR MAINTENANCE

.

Spare part kit (S-S2-xx)

O-ring kit (O-S2-yy)

xx and yy means the material key according to the product catalogue. You will find it

also as the 6

th

to 9

th

sign in the serial number (e.g. S207AxxyyB).