Manntek SBC User manual

manntek.se

SBC Operating Manual

1" ‑ 6"

2

2018-10-31

Foreword

This operating manual applies to the persons using the Safety Breakaway Couplings.

It is very important to read and understand this operation manual before use of this

coupling. Become familiar with the unit’s operation, applications and limitations. Be

particularly aware of its specic hazards. Store this manual in a clean area and always at

a readily available location. Additional copies at no charge can be obtained through written

requests.

IMPORTANT!!

READ THE COMPLETE DOCUMENTATION

The base for this manual follows the EU-Directives:

Pressure Equipment Directive 2014/68/EU of 15 May 2014

Potentially Explosion Atmosphere Directive 2014/34/EU of 29 March 2014

• Do not make modications that are not authorized by the manufacturer.

• Read and respect all warnings and instructions provided to you.

• Use only original MannTek spare parts for maintenance.

SUMMARY OF REVISIONS

Date of change Description

2015-05-21 1. Edition

2018-10-09 General review & New layout, Updated EU-Directives

2018-10-31 2. Edition - devided in two sizes

3

2018-10-31

Table oF ConTenT

Foreword 2

1 Introduction 4

1.1 Intended use 4

1.2 Product specication 5

1.3 Technical data 5

1.4 Breaking pins 6

1.5 Identication plate e.g. for SBC 2½”- 2½" BSP 7

1.6 Scope of delivery 7

2 General safety rules 8

2.1 Safety instructions 8

3 Transport and storage 10

3.1 Delivery check 10

3.2 Complaints/return of goods 10

3.3 Returning used product 10

3.4 Sample of certicate of decontamination 11

3.5 Storage 11

4 Installation 12

4.1 Initial operation 12

4.2 Installation 12

5 Operation 15

5.1 General notes 15

5.2 Daily visual inspection 15

5.3 Cleaning 15

5.4 Disassembly 15

5.5 Improper use 15

5.6 Maintenance/repair 15

5.7 Miscellaneous 16

6 Maintenance and repair 17

6.1 General information 17

6.2 Maintenance and service instruction 18

6.3 Spare parts and tools 18

6.4 Assembly 19

6.5 Pressure and tightness test 22

7 Applicable documents 23

7.1 Declaration of conformity 23

4

2018-10-31

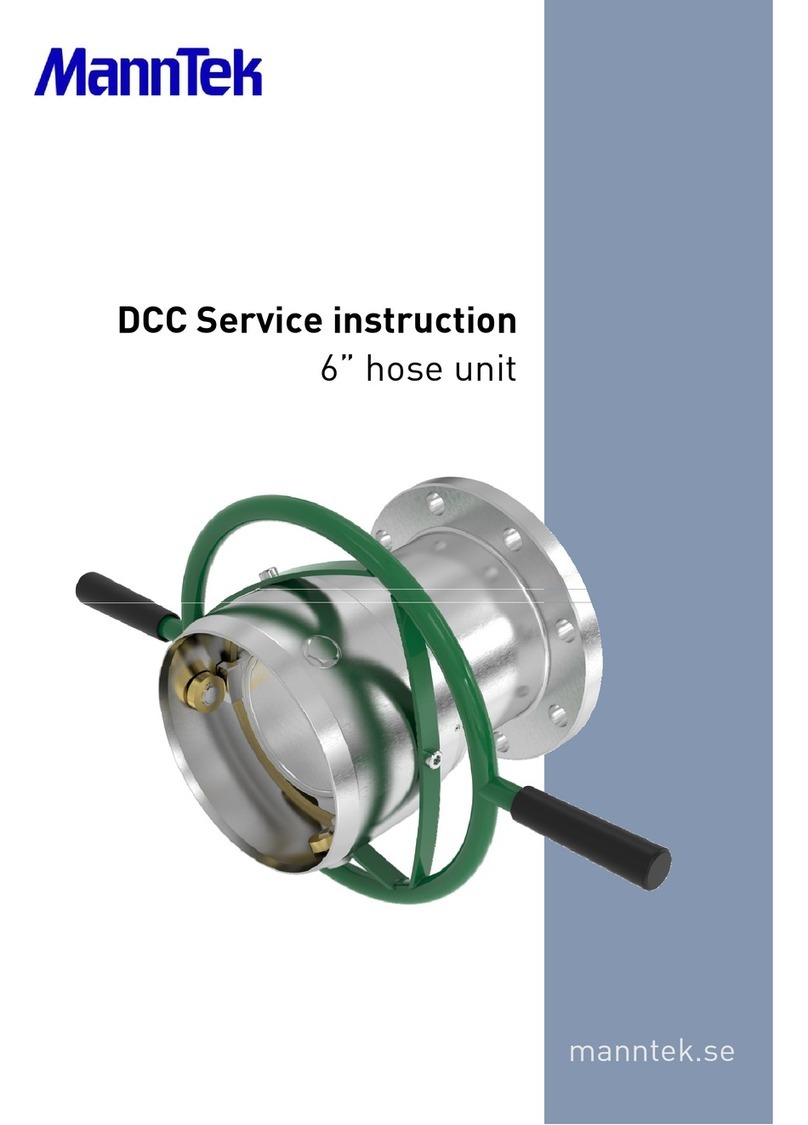

1 InTroduCTIon

1.1 InTended use

The Safety Breakaway Coupling (SBC) acts as a safety component in the supply line of

mobile refuelling systems, preventing damage to the environment whenever the supply

hose or pipe bursts during lling or emptying due to a change in location of the tank.

The coupling valves on the tank and on the supply line immediately close whenever the

housing halves Breakaway.

All MannTek products are designed for trouble free

operation in a wide range of applications and operating

conditions. Reliable and safe operation is dependent

upon the correct installation and handling of the

equipment. Regular and appropriate maintenance

is essential to ensure both safety and reliability over

the life of the equipment. Take care that the product

is only used inside the limits of the following product

specication.

There are two kinds of SBCs available. A marine type version is designed for offshore

applications. The specic design requires an installation between two hoses. It is only

possible to release the coupling by axial force.

The length of the hose segments should not

be less than L=a/57,3 x (r+d/2).

L = min. required hose length

a = max. bending angle

r = min. bending radius

d = outer hose diameter

Figure 1: min. required hose length depending

on bending angle shown for hoses according

to EN12115

The second SBC type is an industrial version. Regularly it is connected to a tank or a x

connection point inside a loading station on one side and a hose or a loading arm on the

other side. This makes that the SBC can be released under a pull force angle up to 90º.

5

2018-10-31

1.2 ProduCT sPeCIFICaTIon

Product name: Safety Breakaway Coupling

Sizes: 1", 2", 2½", 3", 4", 5" and 6"

Thread Connection: NPT-Thread ANSI B1.20.1, BSP-Thread ISO 228

Flange Connection: Flange EN 1092, ANSI B16.5, DIN 28459, T.T.M.A., BS 10

Other Connection: MIL-C-10387J, DIN 11850, DIN 11864, DIN 32676, ISO 2852

Material (casting): EN 10213 – 1.4408/1.4409+AT

ASTM A351 – CF-3M or CF-8M EN 1982 – CC491K

EN 1706 – AC-42000/42100-T6

Material (machined): EN 10272 – 1.4401/1.4404+AT

ASTM A479 – S31603 (316L) EN 12164 – CW614N

EN 755-2 – EN AC-5083 or AC-6026/6262-T6

Working pressure: 10 bar / 16 bar / 25 bar / 150 psi / 360 psi

Max test pressure: 16 bar / 25 bar / 40 bar / 240 psi / 540 psi

Temperature range: -20ºC to + 80ºC -Outside this range, between

-54ºC and + 250ºC ask for conrmation

1.3 TeChnICal daTa

Table 1: Nominal Widths, Weight and Dimensions [mm]

Nominal width Breaking Force Connection KG (Stainless steel) D (mm) L (mm)

DN25 - 1" 3,2 kN 1" Thread 1,7 74 126

1" Flange 4,2 115 132

DN50 - 2" 13 kN 2" Thread 2,6 114 178

2" Flange 7,3 165 178

DN65 - 2½" 22 kN 2½" Thread 7,4 140 251

2½" Flange 13,2 191 214

DN80 - 3" 33 kN 3" Thread 8,5 174 279

3" Flange 15,1 210 222

DN100 - 4" 52 kN 4" Thread 15,5 211 320

4" Flange 20,7 254 239

DN125 - 5" 81 kN 5" NPT male 32 269 362

5" Victaulic 31 269 341

DN150 - 6" 92 kN 6" Thread 46,8 304 400

6" Flange 57,6 318 384

6

2018-10-31

Table 2: Materials

Component Material no. Standard Operating

temperature

Housing Check

valve

1.4404 EN 10270-1.4401+AT -54°C to 250° C

1.4409 EN 10213-1.4409+AT

CW614N EN 12164-CW614N -54°C to 200° C

CB491K EN 1982.CB491K-GS

5083 EN 755- AW-5083

-54°C to 100° C

6262 EN 755- AW 6262-T6

42100 EN 1706-AC-42100-T6

Spring 1.44.1 EN10270-1.4401 -54°C to 250° C

Table 3: Seals

Component Material Standard2Operating temperature1

O-ring

NBR Perbunan TM , Buna N -38° C to 80° C

EPDM Buna AP -54° C to 120° C

FFKM Kalrez TM , Chemraz TM -15° C to 260° C

FKM Viton TM -20° C to 200° C

1.4 breakIng PIns

Mann Teknik AB delivers breaking pins according to customer specication. Standard

pins are available for different applications. The breaking force should be specied for the

weakest component

Without any specication we supply our couplings with bolts according to the following

table.

Table 4: Internal pressure reduces the force needed to release the coupling.

Breakin

Force at DN25 DN50 DN65 DN80 DN100 DN125 DN150

0 bar

6 bar -0,7 kN -1,1 kN -2,6 kN -3,8 kN -5,7 kN -7,9 kN -11,1 kN

10 bar -1,1 kN -1,9 kN -4,4 kN -6,3 kN -9,5 kN -13,2 kN -18,6 kN

16 bar -1,9 kN -3,1 kN -7,0 kN -10,1 kN -15,2 kN -21,2 kN -29,8 kN

25 bar -2,9 kN -4,9 kN -11,0 kN -15,9 kN -23,7 kN -33,1 kN -46,5 kN

37,5 bar -4,4 kN -7,3 kN -16,5 kN -23,8 kN -35,6 kN -49,7 kN -69,8 kN

40 bar -4,8 kN -7,8 kN -17,6 kN -25,4 kN -38,0 kN -53,0 kN -74,5 kN

150 psi -1,2 kN -2,0 kN -4,5 kN -6,5 kN -9,8 kN -13,7 kN -19,2 kN

300 psi -2,4 kN -4,0 kN -9,1 kN -13,1 kN -196 kN -27,4 kN -38,5 kN

1For temperature stability of the seal material used must be considered separately for each individual case

2 Kalrez, Viton = Registered Trademarks of DuPont; Chemraz = Registered Trademark of Green Tweed

7

2018-10-31

Our standard specication was made for LPG hoses with a minimum burst pressure at

100 bar. For other applications you can specify the breaking force depending on the burst

pressure of your hose.

Table 5: Recommended breaking force for different hose burst pressures:

Burst pressure hose DN25 DN50 DN65 DN80 DN100 DN125 DN150

30 bar 4 kN 7 kN 11 kN 18 kN 28 kN 40 kN

40 bar 6 kN 10 kN 15 kN 24 kN 37 kN 54 kN

48 bar 7 kN 12 kN 18 kN 28 kN 45 kN 65 kN

60 bar 3,0 kN 9 kN 15 kN 23 kN 36 kN 56 kN 81 kN

68 bar 3,2 kN 92 kN

80 bar 12 kN 20 kN 30 kN 48 kN 75 kN 108 kN

100bar 4,8 kN 13 kN 22 kN 33 kN 52 kN 81 kN 117 kN

600 psi 6 kN 10 kN 15 kN 24 kN 39 kN 56 kN

1200 psi 3,1 kN 12 kN 21 kN 31 kN 49 kN 78 kN 112 kN

Table 6: Max. spill under disconnection at max working pressure:

Nominal diameter DN25 DN50 DN65 DN80 DN100 DN125 DN150

Max. spill at WP 0,05 l 0,1 l 0,2 l 0,4 l 0,6 l 1,2 l 2,0 l

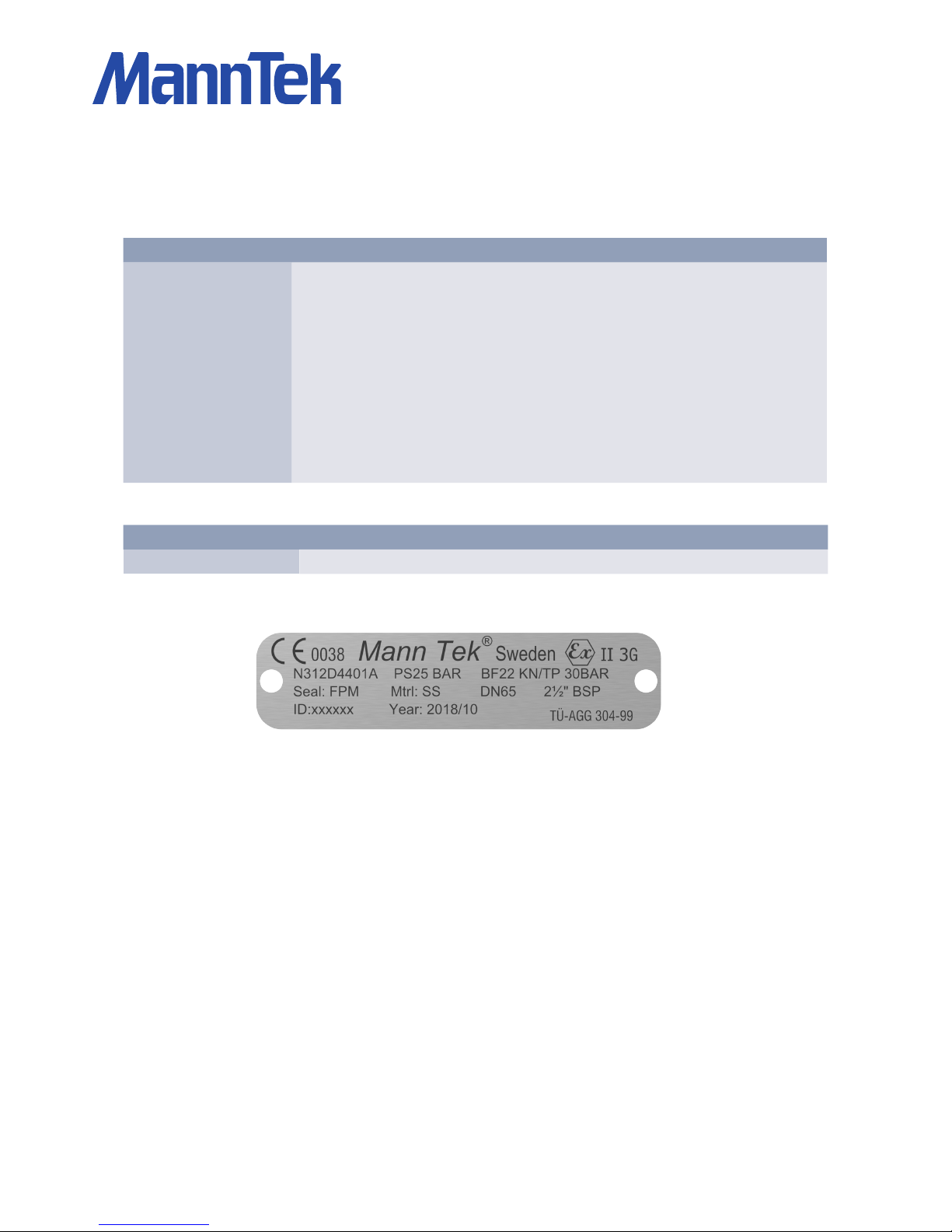

1.5 IdenTIFICaTIon PlaTe e.g. For sbC 2½”- 2½" bsP

Industrial Type Marine Type

Article no: N312D4401A* N312M4401A*

Working Pressure PS: 25 bar 25 bar

Max Test Pressure PT: 30 bar 30 bar

Breaking Force BF: 22 kN 22 kN

Seal: FPM (Viton) FPM (Viton)

Mtrl: Stainless Steel Stainless Steel

Size: DN65 – 2½“ DN65 – 2½"

*For key of article no. please ask for explanation list.

1.6 sCoPe oF delIvery

1 pcs N312D4401A Safety Breakaway Coupling

In case of ange connection gaskets and bolts to mount the coupling into the application is

not part of the delivery. For NPT thread use PTFE tape for sealing (see chapter 4.2).

8

2018-10-31

2 general saFeTy rules

Before you install any MannTek equipment it is essential to check that the material and

performance specications are acceptable for your specic application. The pressure

ratings and primary materials of the construction are clearly indicated on the identication

plate of each MannTek product. A drawing showing the materials of construction relating

to each individual component is available upon request. The technical department at

MannTeknik AB is always happy to provide guidance on material suitability. Our data

is taken from published chemical resistance information as well as our own application

experiences. Specication checks should always be carried out before the product is

supplied, but if unsure, ask! Especially if you are using the products outside the specied

temperature range, ask for conrmation regarding your application.

Do not assume that a MannTek product supplied for one specic application

automatically will be suitable for other similar applications. Many variables

affect the performance of materials. If you wish to use a MannTek product for a

different application than the one originally specied, check with Mann Teknik

AB to ensure compatibility before installation. Please remember, the application

details should include all media transferred through the coupling. Not just the

primary transferred media. As with all equipment, a check should be made

to ensure that the installation fulls the requirements of applicable prevailing

industry, local, national and international standards. Particular attention should

be paid to pressure ratings, safety factors and the position of upstream and

downstream afliated closures.

2.1 saFeTy InsTruCTIons

Proper seal and wetted metal parts material selection is critical for safe

operation. To assure maximum life for the service intended, use only those

materials, sealing and lubricant compatible with the uids being handled. Please

note material being supplied and make certain that it is suited for the intended

service. This is important in the food processing industry.

The Safety Breakaway Coupling assembly does not eliminate possible

exposure to hazardous substances. In case of an emergency release some

product between both pistons will spill out. The conditions of handling and use

are beyond our control, and we make no guarantee, and assume not liability

for damages or injuries related to the use of this coupling assembly. It is the

responsibility of the user to comply with all applicable federal, state, and local

laws and regulations.

Do not handle O-ring seals if their material appears charred, gummy or sticky.

Use tweezers, wear gloves and protective goggles in appropriate material,

consult the material safety data sheet (MSDS) of your product. Do not touch

adjacent parts with unprotected hands.

9

2018-10-31

Piping systems must always be depressurised and drained before attempting

disassembly and removal of any MannTek product.

Authorized and qualied personnel must carry out all assembly and

maintenance operations. The installation must be equipped with suitable

controls that prevent an increase of pressure beyond the maximum allowed limit

(this is the responsibility of the installer/user).

Failure to do so could result in serious personal injury, property damage, leakage or

unexpected separation.

For a safe operation, read also the installation and operating instructions in this

manual (see chapter 4 and 5) and ask for our service instructions.

10

2018-10-31

3 TransPorT and sTorage

The product may only be transported or stored when absolutely clean. Suitable sealing

must be used for the openings to ensure no damage occurs to the surfaces/sealed

areas. The seals may only be removed by trained personnel. The storage location must

guarantee adequate protection from corrosion or extreme temperatures.

3.1 delIvery CheCk

• Check for any transportation damage. If so report this immediately to the forwarder.

• Check that the products and quantities are in accordance with the delivery note.

3.2 ComPlaInTs/reTurn oF goods

• If returning goods, please contact MannTeknik AB to receive a Complaint Report

form.

• Complete the form with as much details as possible.

• Return the goods with the Complaint Report attached on the outside of the

package!

3.3 reTurnIng used ProduCT

• If returning used goods, please contact MannTeknik AB to receive a Complaint

Report form.

• Complete the form with as much details as possible.

• Rip this page out and ll in the Certicate of Decontamination.

• Return the goods with the Complaint Report and the Certicate of Decontamination!

11

2018-10-31

REPAIR SERVICE

To comply with Health & Safety Regulations, all returned valves must be accompanied by a

Certicate of Cleanliness and a Data Sheet for the last product carried.

CERTIFICATE OF DECONTAMINATION

We certify that the following couplings/valves have been cleaned prior to

despatch and are free of any harmful substances:

Qty:…………Part no:…………………..Serial no:…………………………..

Qty:…………Part no:………………….. Serial no:…………………………..

Qty:…………Part no:………………….. Serial no:…………………………..

Qty:…………Part no:………………….. Serial no:…………………………..

YES NO

Free al all liquid _____ _____

Air blown _____ _____

Couplings/Valve dismantled _____ _____

The last known product the coupling/valve was in contact with:……………………

Data sheet of last product attached………………….Yes/No

Company Name/Address:………………………………………………………………

Signature of Supervisor:………………………………………………………………..

Company Stamp:

3.4 samPle oF CerTIFICaTe oF deConTamInaTIon

Make a copy of this page, ll in the required information and send it back together with the

goods.

3.5 sTorage

Store coupling in a dry, dust free, dark place, in ambient temperature.

12

2018-10-31

4 InsTallaTIon

4.1 InITIal oPeraTIon

The correct installation of all MannTek products is essential to ensure safe and satisfactory

operation. Checks should be made to ensure that the tting of MannTek products does

not interfere with the correct operation of afliated equipment (i.e. isolation valve, excess

ow valves, etc). Before securing the ange or thread connection to mating equipment

(i.e. hose, loading arm and storage tank), ensure that no foreign objects, dirt, grit, etc. are

present in the coupling.

All ange and thread connections should be made without imparting excessive strain to the

equipment and pressure checked according to our recommendations in chapter 6.4 table

8 prior to use. All gaskets and sealing materials used to make the permanent connection

should be of suitable material and able to operate at least up to the maximum parameters

of the MannTek equipment.

Each MannTek product is designed to take reasonable external loads associated with

good handling practice but is not designed to accept continuous excessive load values

associated with maladjustment or poor installation. Continuous excessive strain will equate

to increased component wear and possibly premature failure if not corrected.

When MannTek equipment is used with hoses, attention should be paid to hose length

to ensure correct handling characteristics. Hoses should be of sufcient length to ensure

operation well within the stipulated hose minimum bend radius up to the maximum

operation envelope. If the ow velocity exceeds 5.25 m/s additional measures are

necessary due to static electricity. This could be hoses with increased conductivity, charge

inhibiting additives, earth bonding.

In case of emergency release liquid will spill out between both halves, depending on

pressure and size. The maximum spill is mentioned in chapter 1.5 table 6. The operator

has to take care to protect the staff against spillage and provide a drain tray if necessary.

Once all the above elements are satisfactory, an installation check should be carried out to

prove the system.

4.2 InsTallaTIon

When installing MannTek equipment to new pipe work, tanks, etc. ensure the system is

free from debris that may be transferred through the coupling. Where the hose or loading

arm assembly is the primary static dissipation or earth route, the electrical continuity value

of the assembly shall be checked to ensure regulatory compliance. Special attention

should be paid to the balancing of loading arms. The weight of the coupling plus transfer

media should be taken into account at the specication stage. It is usual for loading arm

balance settings to account of weight variations due to differences in the full/empty cycle.

13

2018-10-31

The MannTek product can be installed directly in the product line and is ready for use after

removing the transport protection. The installation is as follows:

a. Remove the packaging and the tread/ange protection

b. Check the coupling for damages before mounting.

c. To prevent damages during mounting a suitable wrench should be used for the

intended bolts and nuts.

Use always a tting wrench to mount

the coupling to a hose, a pipe or a

tank. Tighten the tting using the

wrench on the respective side where

the connection is made.

Torque forces should never

be transferred via the

SBCoupling.

d. Ensure that the product line is empty and all valves are closed before you connect

the coupling into the line.

Flange connection

e. Table 7: Tightening torque for bolts:

Metric Inch

Size 8.8 Size A193 B7

M8 24 Nm 5/16 -18 UNC 16 lbf-ft

M10 50 Nm 3/8 -16 UNC 29 lbf-ft

M12 85 Nm 1/2 -13 UNC 70 lbf-ft

M16 210 Nm 5/8 -11 UNC 139 lbf-ft

M20 410 Nm 3/4 -10 UNC 243 lbf-ft

M22 550 Nm 7/8 -9 UNC 389 lbf-ft

M24 700 Nm 1 -8 UNC 582 lbf-ft

f. Bolt tightening sequence.

14

2018-10-31

NPT Thread Sealing

Sealing NPT threads can be an exasperating experience if certain techniques are not

followed.

The following tips will help alleviate many common problems in thread sealing:

g. Always use some type of sealant (tape or paste) and apply sealant to male thread

only. If using a hydraulic sealant, allow sufcient curing time before system is

pressurized.

h. When using tape sealant, wrap the threads in a clockwise motion starting at the rst

thread and, as layers are applied, work towards the imperfect (vanishing) thread.

If the system that the connection being made to cannot tolerate foreign matter (i.e.

air systems), leave the rst thread exposed and apply the tape sealant as outlined

above.

i. When using paste sealant, apply to threads with a brush, using the brush to work

the sealant into the threads. Apply enough sealant to ll in all the threads all the way

around.

j. When connecting one stainless steel part to another stainless-steel part that will

require future disassembly, use a thread sealant that is designed for stainless

steel. This stainless-steel thread sealant is also useful when connection aluminium

to aluminium that needs to be disconnected in the future. These two materials

gall easily, and if the correct sealant is not used, it can be next to impossible to

disassemble.

k. When connecting parts made of dissimilar metals (i.e. steel and aluminium), standard

tape or paste sealant performs satisfactorily.

l. For sizes 2” and below, tape or paste performs satisfactory. When using thread tape,

four wraps (covering all necessary threads) are usually sufcient.

m. For sizes 2 1/2” and above, thread paste is recommended. If thread tape is used,

eight wraps (covering all necessary threads) are usually sufcient. Apply more wraps

if necessary.

n. Over-tightening threads can be just as detrimental as insufcient tightening. For sizes

2” and below, hand tighten the components and, with a wrench, tighten 3 full turns.

For sizes 2 1/2” and above, hand tighten the components and, with a wrench, tighten

2 full turns.

o. For stubborn to seal threads, apply a normal coating of thread paste followed by a

normal layer of thread tape.

p. For extremely stubborn to seal threads, apply a normal coating of thread paste

followed by a single layer of gauze bandage followed by a single layer of gauze

bandage followed by a normal layer of thread tape.

When this procedure is done, the connection becomes permanent. Extreme

measures will be necessary to disconnect these components. All other

measures to deal the threads should be explored prior to use of this technique.

The start-up may take place only when the MannTek product has been mounted as

instructed and the necessary function tests and leak tests have been conducted by the

approved authorities (see chapter 7).

15

2018-10-31

5 oPeraTIon

5.1 general noTes

Operators are obliged to provide qualied and trained personnel familiar with the handling

of supply pipes, safety couplings, any uid being pumped as well as its danger potential.

Such staff must also be familiar with the applicable safety regulations and the regulations

of the employer’s liability association. The pull cable must be shorter than the supply line

and must always be tight and attached in such a way that the safety breakaway coupling

can be safely triggered.

5.2 daIly vIsual InsPeCTIon

All couplings should be briey inspected at the start of each day’s operation. Check for dirt,

seal damage and any obvious physical damage (such as impacts, etc.).

5.3 CleanIng

Check the seal of the connections before every cleaning. In case the coupling is used for

materials that harden, stick, etc., the coupling has to be cleaned of residues after every

use. Before dismantling, the coupling always has to be cleaned with a suitable cleaning

agent (regardless of the product carried).

5.4 dIsassembly

When the coupling should go into service there is a danger that the uid will spurt out.

Special protective measures such as personal protection equipment must therefore be

adopted. Always ensure the system is cleaned in the proper manner. After cleaning,

remove any residue from the cleaning agent.

How to disassemble:

a. Wear suitable personal safety equipment.

b. Make sure that the coupling is depressurised and empty.

c. Clean coupling before disassembly (use cleaning agent suitable for the

pumped uid).

d. Unscrew coupling always with a tting wrench.

5.5 ImProPer use

The equipment should never be used in the case of visible damage or where there is prior

knowledge of damage that may lead to malfunction.

5.6 maInTenanCe/rePaIr

Maintenance should be done regularly; at least once in the year. Maintenance and repair

of the equipment may be carried out only by MannTeknik AB or by companies/technicians

authorized by MannTeknik AB (see chapter 6).

16

2018-10-31

5.7 mIsCellaneous

The operator is solely responsible for the installation, operation, and maintenance of the

coupling. Mann Teknik AB accepts no responsibility for damages due to faulty installation,

faulty handling, as well as negligent or incorrect maintenance.

17

2018-10-31

6 maInTenanCe and rePaIr

6.1 general InFormaTIon

The SBCoupling consists of two housing halves with a check valve in each. The housings

are held together by three breaking bolts during normal operation. The two check valves

support each other during normal operation and keep the conduit open.

Positioning body halves

1 Body (half)

2 Coupling ange

3 Thread connection

4 Piston

5 Spring

6 Breaking bolt

In case the tank wagon rolls away or someone forgot to disconnect the supply line before

the truck drives off, the SBC is activated as follows:

Before the supply line is stressed by undue external forces the breaking pins become

destroyed. The coupling halves are separated from each other and the spring-loaded

check valves instantaneously close both ends of the line. On the industrial version one

half of the coupling remains rmly connected to the tank wagon while the other half of the

coupling remains connected to the supply line. The marine type is always placed between

two hoses. The pull force is only working in axial direction. After releasing both halves

remain at the end of each hose. This prevents the outow of liquids or gases from both

product carrying ends of the line.

Maintenance tasks, to put the released coupling back into service, may be

performed only by trained personnel from an authorised professional workshop.

All measures necessary for inspection, maintenance and repair must be carried

out in accordance with the national regulations of the country where the system

is installed.

1

324

5

6

18

2018-10-31

Sealing-kit

3 O-rings

An assembly drawing is following with the kit

and each O-ring is marked with the respective

position number.

In case of failure or Breakaway order the SBC-

SEAL SET and carry out repairs according to

the assembly instructions in chapter 6.4.

Breaking-bolt-kit

3 Breaking bolts.

In case of failure or Breakaway order the SBC-

BOLT SET and carry out repairs according to

the assembly instructions.

Attention: Do not forget to specify the proper

size and breaking force!

Tool for SBC

A special tool for the piston guide of the SBC

can be ordered from MannTek.

O-ring tools

Special tools to remove the O-rings can be

ordered from MannTek.

6.2 maInTenanCe and servICe InsTruCTIon

Always depressurise the system and rinse off the parts before beginning any

maintenance work. Use protective goggles. Do not handle O-ring seals if the

material appears charred, gummy or sticky.

Use tweezers; wear gloves and protective goggles in appropriate material,

consult the material safety data sheet (MSDS) of your product. Do not touch

adjacent parts with unprotected hands. Rinse off the parts once again before

starting the “daily inspection”

6.3 sPare ParTs and Tools

19

2018-10-31

6.4 assembly

1 After release

When the coupling should go into service

there is a danger that the uid will spurt out.

Special protective measures such as personal

protection equipment must therefore be

adopted. Always ensure the system is cleaned

in the proper manner. After cleaning, remove

any residue from the cleaning agent.

a. Wear suitable personal safety

equipment.

b. Make sure that the coupling is

depressurised and empty.

c. Clean coupling before

disassembly (use cleaning agent

suitable for the pumped uid).

d. Unscrew coupling with a tting

wrench.

2 Visual inspection

Screw out the destroyed parts of the breaking

bolts. Check for dirt, seal damage and any

obvious physical damage (such as impacts,

etc.).

If you have a “Non Closure” coupling continue

item 10.

3 Disassemble

Unscrew the three screws that lock the spindle

steering.

4 Disassemble

The piston is sticking out on the other side,

therefore place the coupling half on distances

for easier maintenance. In newer versions the

spindle steering is xed with screws which have

to be removed rst. In older versions you need

only to press down the steering and turn it free.

Release it carefully.

Piston guide is spring loaded. Risk of

injury.

Using our special tool makes work easier and

therefore increases safety.

20

2018-10-31

5 Detail parts after disassembling

Take out all the parts from the body

1. Spindle steering

2. Spring

3. Body

4. Piston

5. Spring cap and PTFE-bushing

6 Piston O-ring

Replace the O-ring (pos.3 ) on the piston with

a new greased O-ring. Have an equal pressure

around the O-ring. The O-ring must be pressed

into the groove on the piston.

Use only grease which is suitable for O-ring

material.

For mounting the new O-ring use MannTek

spare parts only. Special tools are helpful for a

good t of the O-ring.

7 Mounting piston

The piston is bigger in diameter than the three

brackets for the piston guide.

Introduce the piston as shown. Put it into a

relaxing position in the valve seat. Take care,

the piston is sticking out on the other side.

8 Reassemble coupling halves

Fit the spring with spring cap and spindle

steering with PTFE-bushing. Press down the

spindle steering and turn, to x it in its position.

9 Locking the spindle steering

Fit the screws into the given holes in the body

and xate the spindle steering by mounting

the three locking screws. Use Loctite® 243 for

locking the screws.

Mount back the at seal.

10 Outer body O-ring

Replace the O-ring (pos.15 ) on the body with a

new greased O-ring.

Use only grease which is suitable for O-ring

material.

12 3 4 5

Other manuals for SBC

3

Table of contents

Other Manntek Industrial Equipment manuals

Manntek

Manntek DCC Original operating manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek SBC User manual

Manntek

Manntek PERC Original operating manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek CBC User manual

Manntek

Manntek SBC Original operating manual

Manntek

Manntek DDC Original operating manual

Manntek

Manntek DCC Original operating manual

Manntek

Manntek SBC Original operating manual