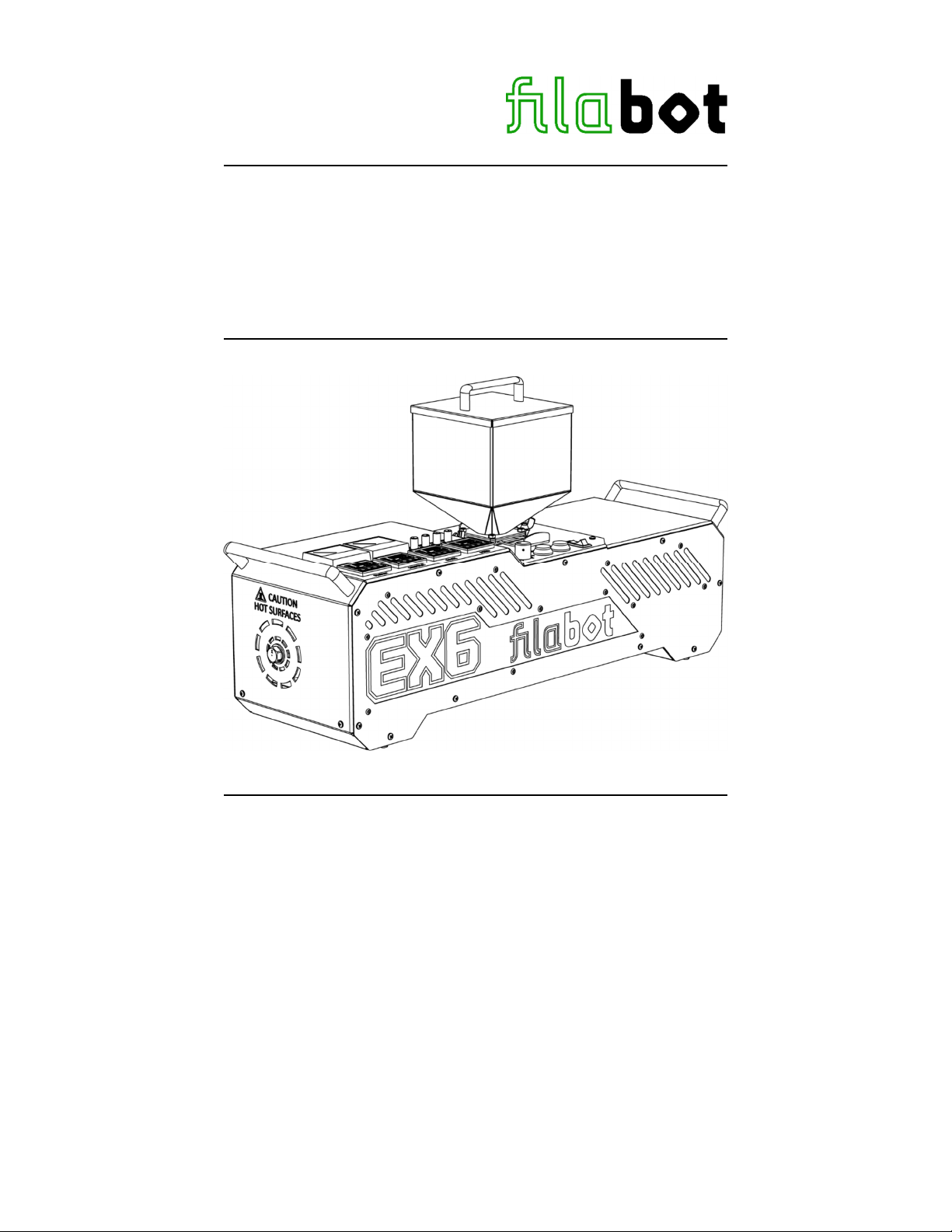

Filabot EX6 User manual

REV.14‐8‐2019

Filabot

Vermont, USA, Earth

1-802-505-6772

Filabot EX6 Extruder

Operation Manual

This manual applies to the Filabot EX6.

Triex LLC, Barre, VT 05641, USA

1

CAUTION! Read Carefully

HOT MATERIALS & SURFACES Use gloves and eye protection

while operating the EX6 Extruder. The barrel and nozzle are HOT

and melted plastic can stick to the skin and cause serious injury.

HIGH-PRESSURE EXPLOSION Air trapped inside the barrel

becomes highly pressurized during operation and can cause small

explosions out of the nozzle which will throw molten plastic away in

any direction.

TOXIC FUMES Some plastics like PVC can produce dangerously

toxic fumes when they are heated. Always carefully review the

MSDS of any material before using it in the EX6 to avoid dangers to

your health. Always use the EX6 in a well-ventilated area.

In Case of Emergency pull the power cord out of the machine.

Only use the EX6 to extrude thermoplastic polymers. No other use

has been tested or approved by Filabot.

Always STOP the extruder before clearing the feed port or removing

the screw. Never stick anything into the feed port while the screw is

turning as this could damage your system.

The EX6 is designed for indoor use only. Operate in a clean, dry

area.

Check the AC input voltage specified on the S/N Label near the

power inlet. Only use the specified input voltage to operate the EX6

or damage to the components could occur.

Do not use this device if any parts appear missing or damaged.

Do not modify this device without authorization from Filabot.

Contact Filabot with any questions

1-802-505-6772

2

General Specifications

Power Input: 120VAC-13A or 240VAC-6.5A 50/60Hz 1-Phase

1550W MAX - varies with settings

Check S/N Label for proper input voltage

Input Connector Type: IEC 320-C14

Weight: 23kg (50 lbs)

Dimensions: 75.44cm L x 23.11cm W x 21.34cm H(29.7in L x 9.1in

W x 9.75in H) (No Hopper)

Hopper Dimensions: 15.24cm L x 15.24cm W x 21.34cm H (6in L x 6in

W x 8.4in H)

Hopper Volume: 3195.5 cubic cm (195in³)

Total Height: 41.4cm (16.3in) H

(With Hopper)

Temperature Control: 3 PID Controlled Barrel Heat Zones

(aluminum blocks with dual 150W heaters)

1 PID Controlled Feed Throat Heat Zone

2 Manual Speed Controlled Barrel Fans

1 Manual Speed Controlled Feed Throat Fan

1 Manual Speed Controlled Motor Fan

Max Recommended Run Temp: 660°F (350°C)

Drive Control: 0-90VDC PWM Speed Controller with

5A Max Current Limiter

Drive Motor: 1/2 HP 90VDC 4.6A

100 RPM

Torque: 24.3 N*m (215 in-lb)

Gear Ratio 28:1

Grease Lubricated Spur Gearing

Screw: Part # EX6-625

16mm (5/8") Diameter

1/2” Pitch

24 L/D Ratio

17-4 PH Stainless Steel Con. H900

2:1 Compression

Nozzle: Type “X” (7/8"-14 Thread)

3

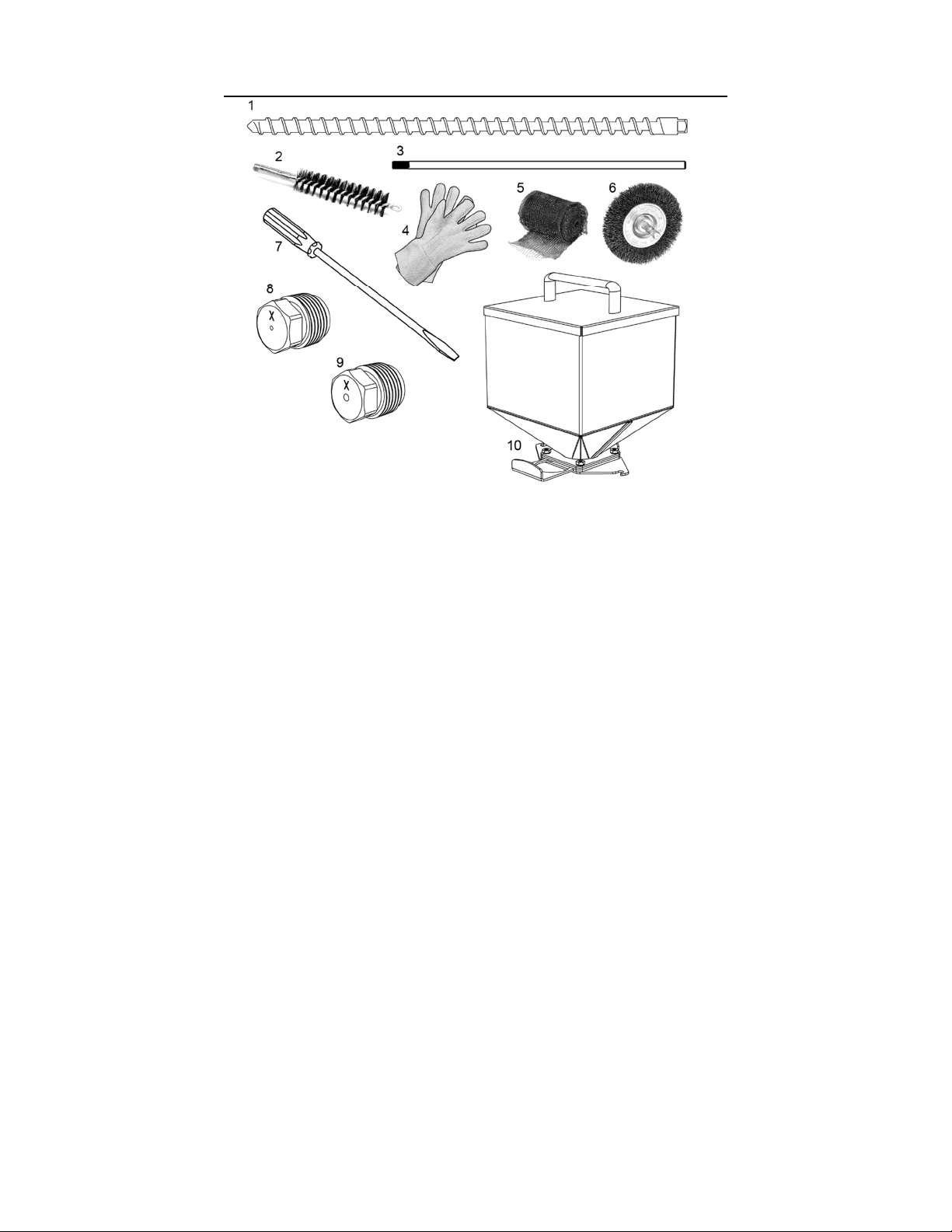

Parts Included

1. Extrusion Screw 5/8” OD 2:1 Comp

2. Brass Bristle Tube Cleaner

3. Tube Cleaner Extension Rod

4. High-Temperature Resistant Terry Cloth Gloves

5. Copper Gauze

6. Brass Bristle Wheel

7. Brass Flared Tip Pry Tool

8. 1.75mm Bore Nozzle

9. 2.85mm Bore Nozzle

10. 195in³ (3.2L) Slide Valve Hopper with Lid

11. 2x 1lb Bags of Extruder Purge Compound

Tools Required:

Non-marring bench vice (with V-block) for holding screw while cleaning

Powered Drill with a chuck that can receive a 5/16” or larger shank

3/4” Wrench (for nozzles)

Automotive grade wheel bearing grease (small amount)

Recommended:

Never-Seize/Anti-Seize thread lubricant (450ºC rated or higher)

Compressed air & air blower/duster gun

Heat gun or propane torch

Shop Vacuum Cleaner

Filabot Spooler

Filabot Airpath

Call 1-802-505-6772 or visit Filabot.com for additional/replacement parts

4

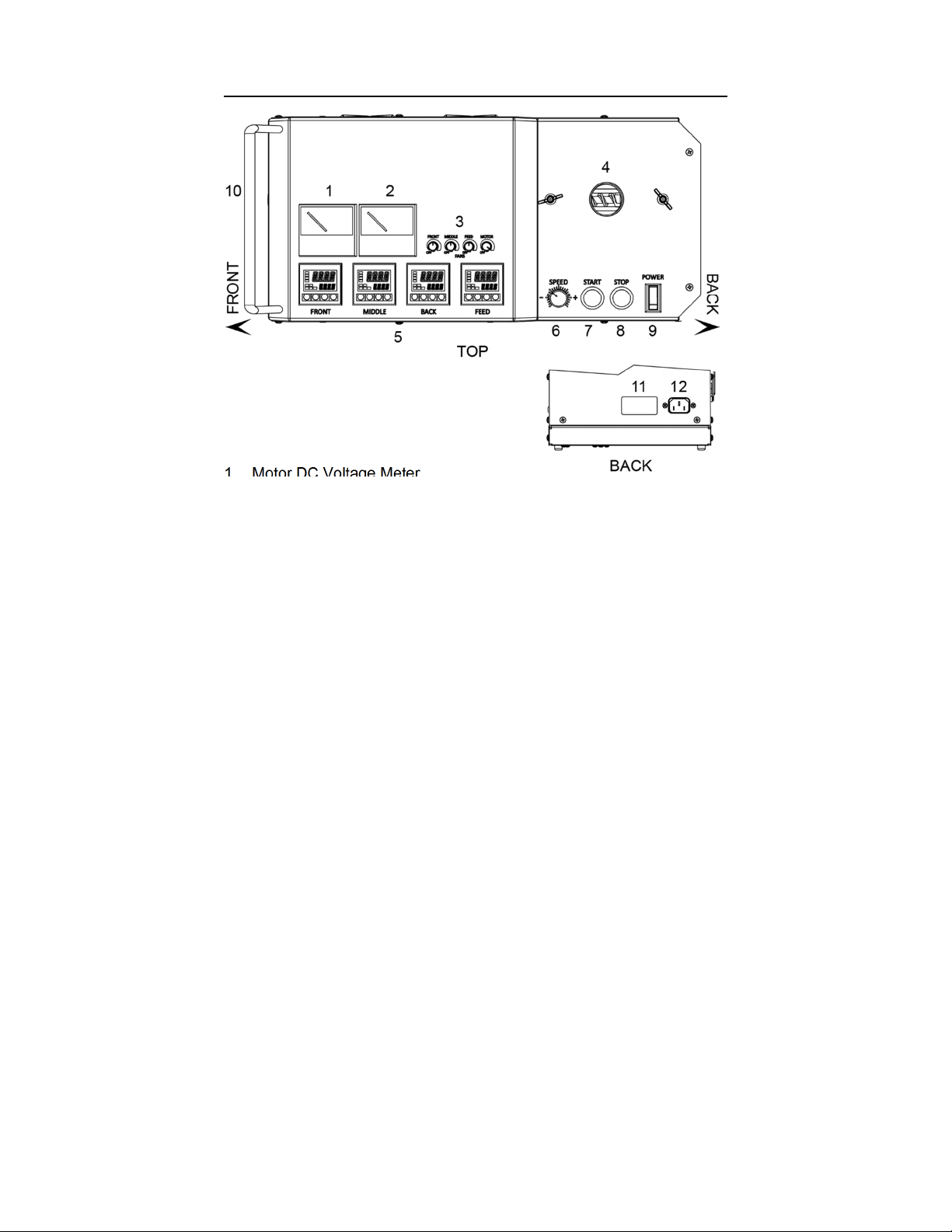

Controls & Inputs

1. Motor DC Voltage Meter

2. Motor DC Amperage Meter

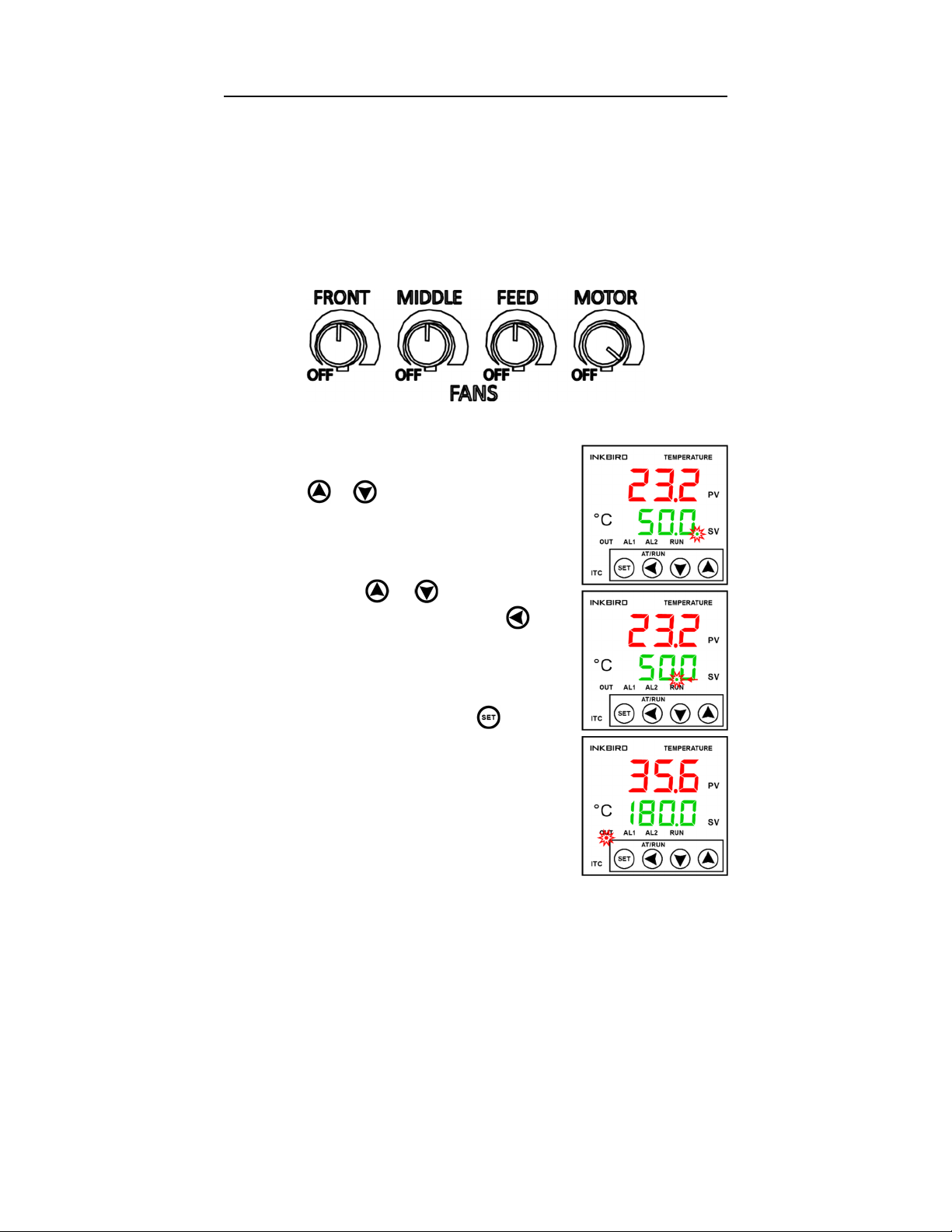

3. Fan Speed Controls (recommended first use settings pictured):

FRONT - Cools barrel between FRONT and MIDDLE heat zones

MIDDLE - Cools barrel between MIDDLE and BACK heat zones

FEED - Cools feed throat

MOTOR - Cools DC motor

4. Feed port for polymer pellets

5. PID Heat Zones

FRONT - Metering section heat zone (nozzle end)

MIDDLE - Compression section heat zone

BACK - Feed/compression section heat zone (feed end)

FEED - Feed port temperature heat zone

6. Motor voltage/speed control knob (0-90VDC)

7. Motor start button

8. Motor stop button

9. Main power switch (thermal breaker)

10. Extrusion nozzle polymer output (front end of the barrel)

11. Serial Number & Voltage Input Label

12. AC Power Input Connector Type: IEC 320-C14

5

First Use & Tuning - Initial Settings

1. Use the EX6 in an open area on a flat, clean surface with plenty of

room to move around the extruder and allow for heat dissipation from

the vents.

2. Plug the machine into a power outlet with the specified input voltage.

3. Turn on the “POWER” switch. All PID Temperature controllers will

turn on, and the "STOP" button will illuminate.

4. Set the Fans to these recommended base settings:

5. Set the PID controllers to within ±30°C of your expected operating

temperatures.

a. To program the set temp, press the

or key once, and the decimal

point will flash at the first selected

digit:

b. Use the and keys to adjust the

selected digit value. Use the key

to select the next digit:

c. Once the set temp is adjusted to the

desired value, press the key twice

to set the value. The “OUT” indicator

will turn on when power to the

heaters for that zone is switched on:

NOTE: Some smoke caused by remaining oils

from manufacturing is normal during the first

startup. If smoke continues or increases after

tuning, contact Filabot.

6

First Use & Tuning - Self-Tuning PID Function

6. Run the self-tuning PID function on all 4 controllers at the same time.

Be sure the measured temp “PV” is at least 30°C cooler than your

set temp "SV" before starting self-tuning function. Doing this

increases the accuracy of the calculated PID parameters. If

temperatures reach the set temp before self-tuning can be started,

set all temperatures low and turn all fans to full speed until

temperatures decrease. Return set temps to your previous setting,

then begin self-tuning the controllers:

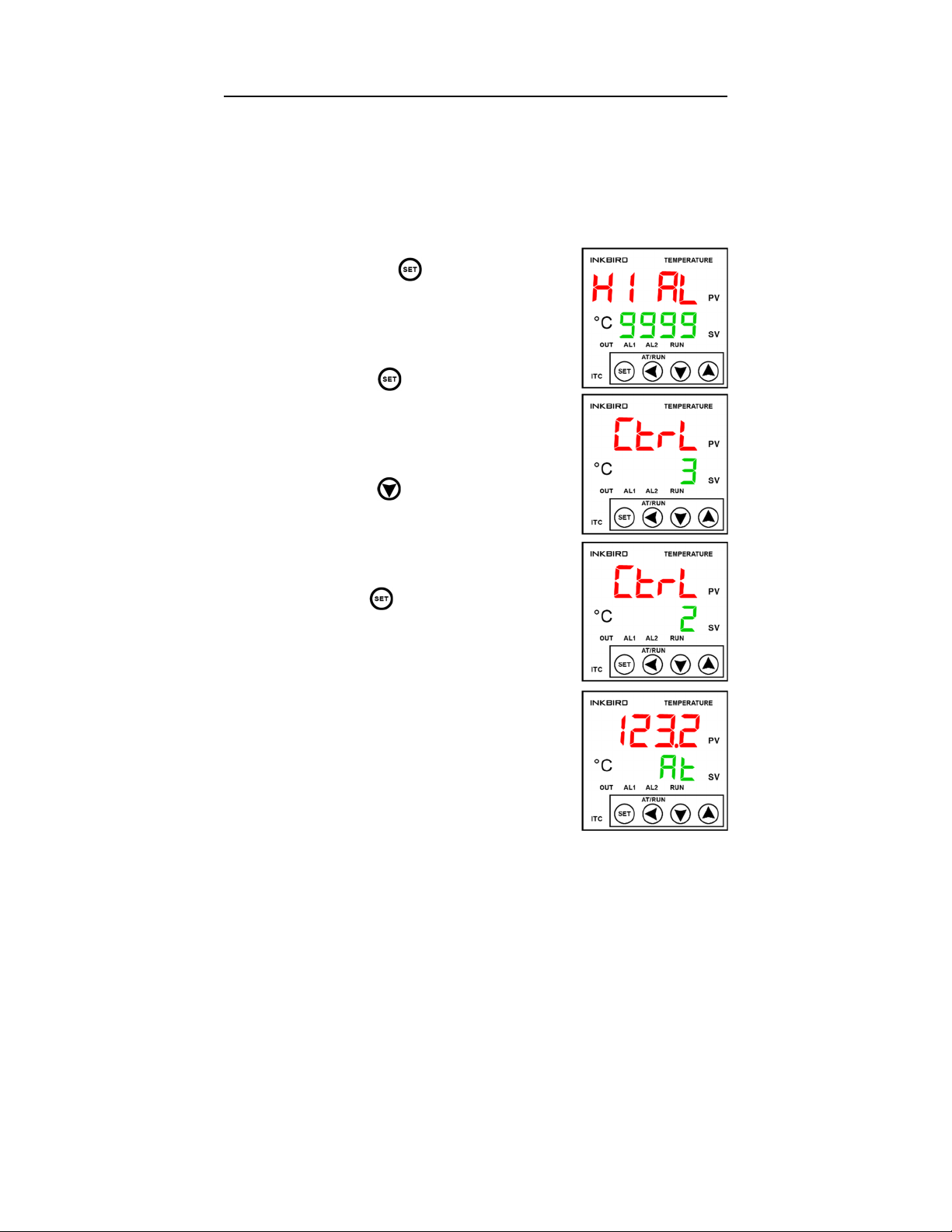

a. Hold the key until the display

shows “HI AL 9999”:

b. Press the key 5 times until the

display shows “CtrL 3”:

c. Press the key once to change the

value to “2”:

d. Hold the key to scroll back to the

main display. “PV” will display the

current temp, and "SV" will flash

between “At” and your set temp while

the auto-tuning function is running:

NOTE: While the auto-tuning function is running,

temperatures will overshoot the set temp

significantly. This is normal during the tuning

process which can take around ½ hour. After the

“At” function completes, wait until the temperatures

stabilize at their set temp before beginning to

extrude. To ensure the PID controllers perform at

their highest accuracy, we recommend re-tuning

whenever operating at a temperature more than 30°C higher or lower than

the temperature the previous tune was set at. For advanced users, the full

Inkbird manual can be found on the EX6 page at Filabot.com.

7

First Use & Tuning - Installing the Screw

7. After all the PID controllers have finished auto-tuning, turn the

“SPEED” adjustment knob to the lowest setting (all the way CCW)

and press the “START” button. The “START” button will illuminate.

8. Turn the “SPEED” knob up (CW) slowly until the voltmeter reads

about 10 volts. The motor will turn slowly now. This will allow the

square tang of the screw to align with the square socket at the back

of the barrel.

9. Apply a very thin layer of grease to all 5 flat surfaces of the square

tang on the back of the screw. Be careful not to leave excess grease

on the edges of the tang to minimize grease getting on the barrel

walls while inserting the screw. Check that there is a thin layer of

grease on the square tang at every screw change.

10. Insert the screw, square end first, into the end of the barrel. Push the

screw into the barrel until it stops and begins to turn slowly with the

motor. The tip of the screw should be recessed about 1/2” from the

end of the barrel when the screw is fully inserted.

CAUTION! The barrel is HOT! To prevent burns, always use gloves

when working with the screw and nozzles. Use the provided brass pry

tool or another blunt object to push the screw back.

It should take minimal force to insert the screw fully. DO NOT tap the

screw in as this could jam the screw in the barrel. There could be debris

in the barrel or square socket that is stopping the screw. See “Cleaning”

for more information.

Turn off the machine and contact Filabot if any part of the machine

appears damaged.

11. Apply a thin layer of anti-seize lubricant to the nozzle threads and

screw the nozzle into the end of the barrel. The nozzle should be

snug but not tight, approximately 200 in-lbs (230 kg-cm).

8

Extruding

Even when starting with the recommended settings, adjustments to

screw speed and temperature will be necessary due to variables in the

environment such as ambient temperature and humidity.

1. Set the PID temperature controllers to the expected operating

temperatures. Refer to “First Use & Tuning – Initial Settings” (p. 5).

2. Install the screw. Refer to “First Use & Tuning – Installing the Screw”

(p. 7). NOTE: The screw may be installed at any barrel temperature

however it is recommended that the nozzle is installed at operating

temperature in case of the residual polymer in the threads which

could prevent the nozzle from screwing in fully and sealing.

3. Install the hopper on the feed port and add the polymer pellets to the

hopper. Make sure the slide valve on the base of the hopper is open.

4. Start the extruder and set the speed to about ¼ or 25 volts.

5. Once the polymer begins to extrude from the nozzle, feed the strand

to the spooling unit and begin making fine adjustments.

6. Begin by adjusting the screw speed up to your desired output rate.

This speed may have to be adjusted up or down depending on the

output consistency and how quickly the filament is cooled.

7. Measure the filament at points along its length after it is cool to

determine the consistency of output. If the output is not consistent,

you will see significant variances in the diameter of the filament. If

this is the case, adjustments to screw speed and temperature will

need to be made.

8. When extruder output consistency is within the desired range, adjust

the spooling unit’s speed to control the diameter of the filament.

-Turn up the spooling unit speed to decrease the diameter

-Turn down the spooling unit speed to increase the diameter.

Refer to the Troubleshooting section for general extrusion issues.

Refer to our online resources at Filabot.com for demonstrations of

polymer extrusion and more details on what you should look for with

regards to output.

9

Cleaning

Caution! Parts of the extruder get hot! Wear gloves and eye protection!

It is recommended to thoroughly clean the extruder after use, or right

before the next use, for the most consistent extrusion. Polymer melt on

the screw due to heat creep after shutdown can cause issues when

restarting the extruder. Leave the extruder temperature zones on during

cleaning.

1. Shut off the slide valve on the hopper if pellets are remaining.

Remove the hopper from the feed port. NOTE: Larger pellets can

jam the slide valve from closing all the way however the flow of

pellets will still be cut off, and the hopper can be removed. Have a

container ready to release the pellets into after the hopper is

removed.

2. Either run the extruder until the feed port is empty or use a vacuum

cleaner to remove the remaining pellets. Continue running the

extruder until polymer stops extruding from the nozzle.

3. If you are using a filter nozzle, stop the extruder, remove it, and

replace it with a standard nozzle with a minimum hole size of 1.5mm.

Purge damages the filter. Fill the feed port approximately halfway

with extruder purge compound while continuing to run the extruder.

Do not change the temperatures to run purge. You may need more

or less depending on the polymer used. NOTE: Use high temp purge

for temps over 300°C. It is possible to remove and clean the screw

without using purge material, but the process can be significantly

more difficult and is not recommended.

4. Continue running the extruder until purge stops extruding from the

nozzle, or add more if the residual polymer is still visible in the purge.

NOTE: Running the extruder “dry”

with no polymer in the feed will

cause excess wear on the screw

over time. Avoid running the

extruder while empty for more

than a few minutes at a time.

5. After all the purge has been

extruded, stop the extruder and

remove the nozzle.

6. Use the brass pry tool to push the

screw forward out the end of the

barrel by prying on the screw

flights visible in the feed port.

10

Cleaning - Continued

7. Pull the screw the rest of the way out of the front of the barrel using

gloves, then clamp the back of the screw in a non-marring vice with a

v-block for cleaning. NOTE: Clean the screw while it is still hot.

Always use a smooth, non-marring vice and v-block to secure the

screw. Damage to the screw from the use of an improper vice could

cause wear issues or prevent the screw from fitting in the barrel.

8. Clean the remaining material from the screw using a power drill with

the brass bristle wheel. If present, large pieces of material may need

to be scraped off first. NOTE: Always use soft metal tools (brass,

aluminum, etc.) to remove material from the screw to prevent

marring of the surface which can decrease the life of the screw and

cause extrusion issues. Use a heat gun or propane torch if the screw

cools and cleaning becomes difficult.

9. Screw the brass bristle tube cleaner onto the tube cleaner extension

rod and wrap two layers of copper gauze around the brass bristle

tube cleaner (wrap the gauze counter-clockwise with the extension

rod pointing toward you).

10. Secure the end of the extension rod in the power drill chuck and

make sure the drill is turning clockwise.

11. Insert the brass bristle tube cleaner into the end of the barrel, while

spinning, and continue until the end of the tube cleaner is visible in

the feed port. Remove the tube cleaner, while spinning, and repeat if

necessary. Avoid inserting the tube cleaner past the feed port as this

could push debris into the square socket which receives the screw.

12. Use compressed air in the feed port to blow any remaining debris out

the end of the barrel. Check if the barrel looks clean by shining a

light in the feed port and looking into the end of the barrel.

Refer to our online resources at Filabot.com for cleaning demos.

Table of contents

Other Filabot Industrial Equipment manuals