manroland Roland 700 User manual

ROLAND 700

Option

ROLAND InlineInspector

Imprint

Type of document: Option

ROLAND InlineInspector

Product: ROLAND 700

Series: 778

Construction year: 2021

Target group: ●Owner-user of a printing shop

●Operating personnel (Helper ‒Skilled worker: printing machine operator)

Language: EN ‒English

Ref.no.: 80 95A EN H025

Publication status: 08.03.2021

Remarks concerning this manual The instructions of this manual correspond to the technical development of your print-

ing machine at the time of publication of the manual.

All rights reserved, subject to changes any time.

The original manual is written in German. All EC translations are based on the lan-

guage of the original manual.

manroland sheetfed GmbH

Mühlheimer Straße 341

63075 Offenbach am Main

Germany

© Copyright by manroland sheetfed GmbH 2021

All parts of this documentation are protected by copyright.

Any use outside the limits of the copyright is not allowed without the written consent of manroland. This applies, in particular, to the

publication, reproduction and translation of this documentation or parts of it as well as to the storage and processing of its contents

by electronic data processing systems.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Contents

ROLAND 700 ‒Option I

Contents

1 Specifications on the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Documentation of your printing machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Contentofthismanual ............................................... 1

1.2.1 Note for representation of parameters and screen masks . . . . . . . . . . . . . . . . . . . 1

1.2.2 Note on auxiliary equipment (aids, tools, testing and other devices) . . . . . . . . . . . . . 1

2 Safety ......................................................... 2

2.1 Safetynotes ..................................................... 2

2.2 Intendeduse ..................................................... 2

2.2.1 Instructions for the Safety chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.2 Documentation ............................................. 3

3 Sheet inspection system - what is that? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Description ...................................................... 4

4 Centralcontrolconsole ............................................. 5

4.1 Overviewofcomponents.............................................. 5

4.1.1 Central control console with switch cabinet of the sheet inspection system . . . . . . . . . 5

4.1.2 Hazardpoints .............................................. 6

4.1.3 Main switch of the sheet inspection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.4 Useofthemainswitch ......................................... 6

4.2 Software operation of the sheet inspection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 CreatePDF ...................................................... 7

4.4 Typicalfalsealarms ................................................. 7

5 Printingmodule .................................................. 8

5.1 Settingtheclockedblastair ............................................ 8

5.2 Elements of the sheet inspection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Cardboardprinting ................................................. 9

5.4 Sheetguidingelement ............................................... 9

5.4.1 Removing the sheet guiding element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4.2 Removingthebaffleplate ...................................... 10

5.5 Cleaning the sheet inspection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5.1 CleaningtheLEDlamp ....................................... 11

5.5.2 Cleaning the outside of the glass pane of the camera housing . . . . . . . . . . . . . . . 12

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Contents

II ROLAND 700 ‒Option

6 Delivery ....................................................... 13

6.1 Stripinsertingdevice ............................................... 13

6.1.1 Removing the strip inserting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.2 Installing the strip inserting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

A Maintenanceschedule ............................................. 15

A.1 Work not dependent on operating hours (max. 20 000 s/h) . . . . . . . . . . . . . . . . . . . . . . . . 15

A.2 Work not dependent on operating hours (up to 18 200 s/h) . . . . . . . . . . . . . . . . . . . . . . . . 15

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Specifications on the documentation

Documentation of your printing machine 1

ROLAND 700 ‒Option 1

1 Specifications on the documentation

1.1 Documentation of your printing machine

This manual is one part of the technical documentation for your printing press.

1.2 Content of this manual

The manual contains the information required for operating and maintaining this option.

manroland assumes that you read and understood the entire technical documentation that belongs to your

printing machine.

1.2.1 Note for representation of parameters and screen masks

Parameters and screen masks are used for illustration purposes.

Parameter

The values of the parameters represented in the manual (e.g. sheets per hour: 1,000 to 10,000 s/h) - in the text

and in screen masks - are used for illustration purposes. The parameters may deviate depending on the configura-

tion and combination of options of your printing machine.

Screes The screen masks represented in the manual are used for illustration purposes. The machine, components and

ancillary equipment shown may deviate from your printing machine.

1.2.2 Note on auxiliary equipment (aids, tools, testing and other de-

vices)

The aids, tools and testing and other devices described in chapter ’Equipment’ are required in order to

perform the tasks described in this manual correctly. However, not all of this auxiliary equipment is part of

the standard scope of delivery of your printing press. You can order individual items of auxiliary equipment

from manroland by quoting the reference numbers listed. Items of auxiliary equipment listed in this manual

without a reference number, are not part of the standard scope of delivery and cannot be ordered from

manroland. The optional auxiliary equipment available from manroland is indicated as follows in this

manual:

(*) Optional and not included in the standard scope of delivery

22.02.2021 08:18:48 - 778 - 80 95A EN H025

2

Safety

Safety notes

2ROLAND 700 ‒Option

2 Safety

2.1 Safety notes

Function of the warnings

Warnings warn of dangers when handling the product. According to the risk level (degree of danger), the

dangers are classified, designated, described and supplemented by notes to avoid them.

A warning placed at the beginning of a task signalizes that the risk prevails during the entire job.

A warning placed directly before an instruction signalizes that the risk relates to the next step to be taken.

Design of warnings

All warnings are designated by a signal word and a triangular warning symbol. The combination of signal

word and warning symbol determines the risk level (degree of danger).

Note

The warning symbol can be supported by pictographs showing the type of danger or how to avoid it in

order to focus the reader's attention.

DANGER

Designates an imminent danger that is certain to cause serious injury or death.

WARNING

designates an imminent danger that may cause serious injury or death.

CAUTION

designates a potentially dangerous situation that may cause minor injuries.

CAUTION

designates a possible situation during which the machine or an object in its vicinity may be damaged.

CAUTION

Designates a possible situation during which may cause environmental damage.

2.2 Intended use

2.2.1 Instructions for the Safety chapter

The manuals Operation and Maintenance of the printing machine contain detailed instructions for the safety

of the printing machine. These instructions logically also apply to the option described here.

●You must have read and understood chapter 1 Documentation of your printing machine and chapter 2

Safety in the Operation manual and in the Maintenance manual of the printing machine before starting

the tasks described in this manual.

●You must have read and understood the safety notices in the supplied documentation of the manufactur-

ers of the ancillary equipment before starting the tasks described in this manual. These manuals are part

of the technical documentation of your printing machine.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Safety

Intended use 2

ROLAND 700 ‒Option 3

2.2.2 Documentation

Operating manuals contain instructions for the safe, adequate and economical handling of your printing ma-

chine. Carry out all work exactly in accordance with the instructions of the operating manual to avoid dan-

gers, to reduce repair costs and down-times as well as to increase the reliability and service life of your print-

ing machine.

▶You must have read and understood all manuals belonging to the machine before you work on it.

▶You must have read and understood the documentation of the ancillary equipment manufacturers. These

manuals are part of the technical documentation of your printing machine.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

3

Sheet inspection system - what is that?

Description

4ROLAND 700 ‒Option

3 Sheet inspection system - what is that?

3.1 Description

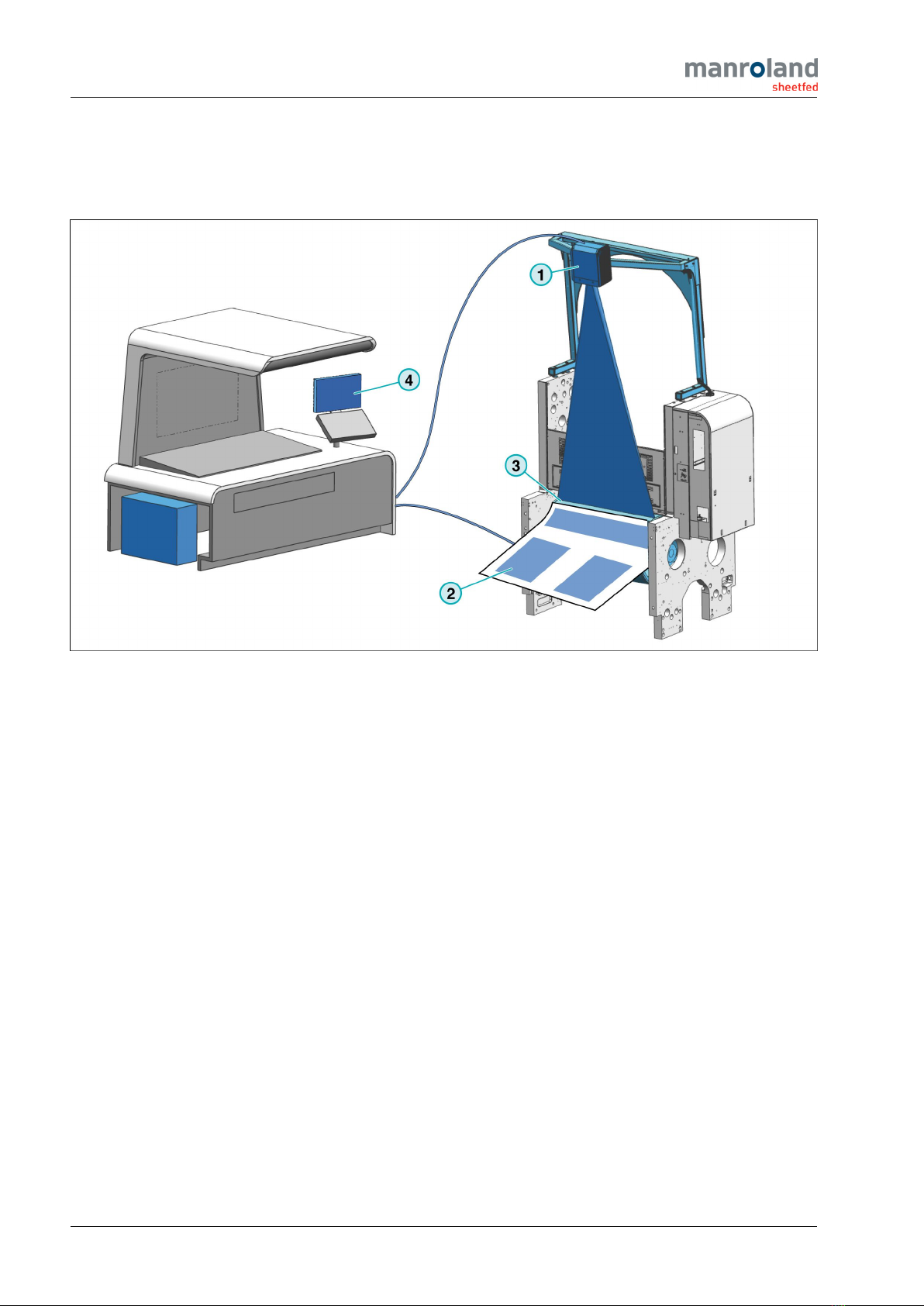

LS-09841-1

During sheet travel, the sheet inspection system checks the printed sheet in the last printing module for pos-

sible faults. These errors could be dirt, scratches, creases, streaks in the printing material or fluctuations in

the printing process.

A camera (1) scans the freshly printed sheet (2) line by line on the impression cylinder (3). The recorded

data are compared in a computer with the reference sheet data. In the event of deviations, a warning signal

sounds and the detected errors are displayed and logged.

During inspection, the printer can analyze the detected faults on the screen (4). The printer can immediately

eliminate faults caused by the printing process.

In the delivery, faulty printed sheets are marked with a stripe.

It is possible to immediately eject the sheets using a sheet ejector (optional).

The sheets can be numbered consecutively (ROLAND InlineNumbering option). In the error log, the num-

bered sheets are assigned to the respective errors.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Central control console

Overview of components 4

ROLAND 700 ‒Option 5

4 Central control console

4.1 Overview of components

4.1.1 Central control console with switch cabinet of the sheet inspec-

tion system

LS-09842-1

1 Switch cabinet of the sheet inspection

system

22.02.2021 08:18:48 - 778 - 80 95A EN H025

4

Central control console

Overview of components

6ROLAND 700 ‒Option

4.1.2 Hazard points

CAUTION

Risk of damage by actuating the main switch. The installed software and the available data may be

damaged or deleted.

▶Only in an emergency is the operator allowed to actuate the main switch in order to cut off the

current of the sheet inspection system.

▶Only specially trained and authorized expert personnel from manroland or our sales/service part-

ner is allowed to actuate the main switch of the sheet inspection system.

CAUTION

Risk of distorted inspection results. The inspection system interprets foreign bodies in the inspec-

tion area as errors.

▶Prevent objects and body parts from entering the visual range of the camera.

4.1.3 Main switch of the sheet inspection system

K1169

Switching the sheet inspection system on or off in

dangerous situations.

Note

The main switch must always be in the posi-

tion ON.

4.1.4 Use of the main switch

Note

An actuation of the main switch causes the immediate standstill of the sheet inspection system without

a data backup. It does not affect the printing press.

Procedure

CAUTION

Risk of data loss. Risk of data loss when the main switch is actuated.

▶Actuate the main switch in an emergency only.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Central control console

Software operation of the sheet inspection system 4

ROLAND 700 ‒Option 7

K1169

▶In a dangerous situation, actuate the ’main

switch’ of the sheet inspection system.

◁The sheet inspection system will be switched

off.

◁Data that is not saved is lost.

4.2 Software operation of the sheet inspection system

Note

Information about operating the software is located in the instruction manual of the manufacturer.

4.3 Create PDF

Note

Follow the PDF specification and the checklist for creating a PDF –see Manufacturer's Operating

Instructions.

4.4 Typical false alarms

The following typical false alarms can occur by misinterpretation of the sheet inspection system.

Fault due to unsuitable reference sheet

If the sheet inspection system signals a larger number of faults at the start of the inspection, the cause often

is an unsuitable reference sheet. In this case you will have to read in a new reference sheet.

Note

For more information, see the manufacturer's operating manual.

Fault at the sheet tail edge

When printing cardboard starting from 130 N/mm, it is possible that the sheet tail edge lifts off from the im-

pression cylinder.

Redefine the area to be inspected to ignore the lift-off of the sheet tail edge.

Note

For more information, see the manufacturer's operating manual.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

5

Printing module

Setting the clocked blast air

8ROLAND 700 ‒Option

5 Printing module

5.1 Setting the clocked blast air

Note

The blast air prevents the deflection of the sheet tail edge onto the baffle plate or the inspection lamp,

as well as the formation of corrugation with thin printing materials (<150 g/m²)

Procedure

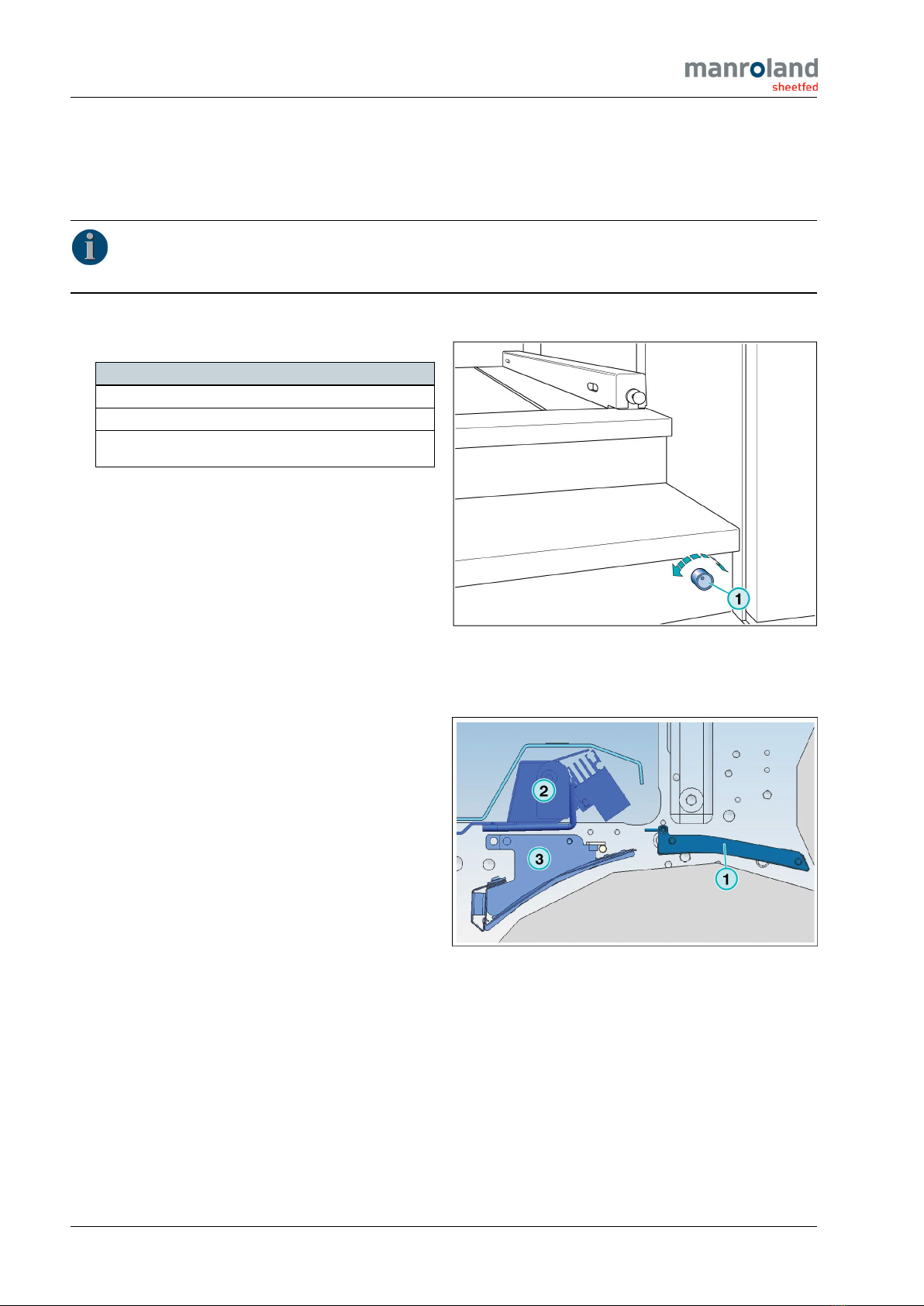

05-09047-2

▶Set the blast air with rotary button (1).

Technical data

Turning to the left = more blast air

Turning to the right = less blast air

Turning to the right up to the stop = Blast air is switched

off

5.2 Elements of the sheet inspection system

05-09840-4

1 Sheet guiding element

2 Inspection lamp

3 Baffle plate with blast tube

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Printing module

Cardboard printing 5

ROLAND 700 ‒Option 9

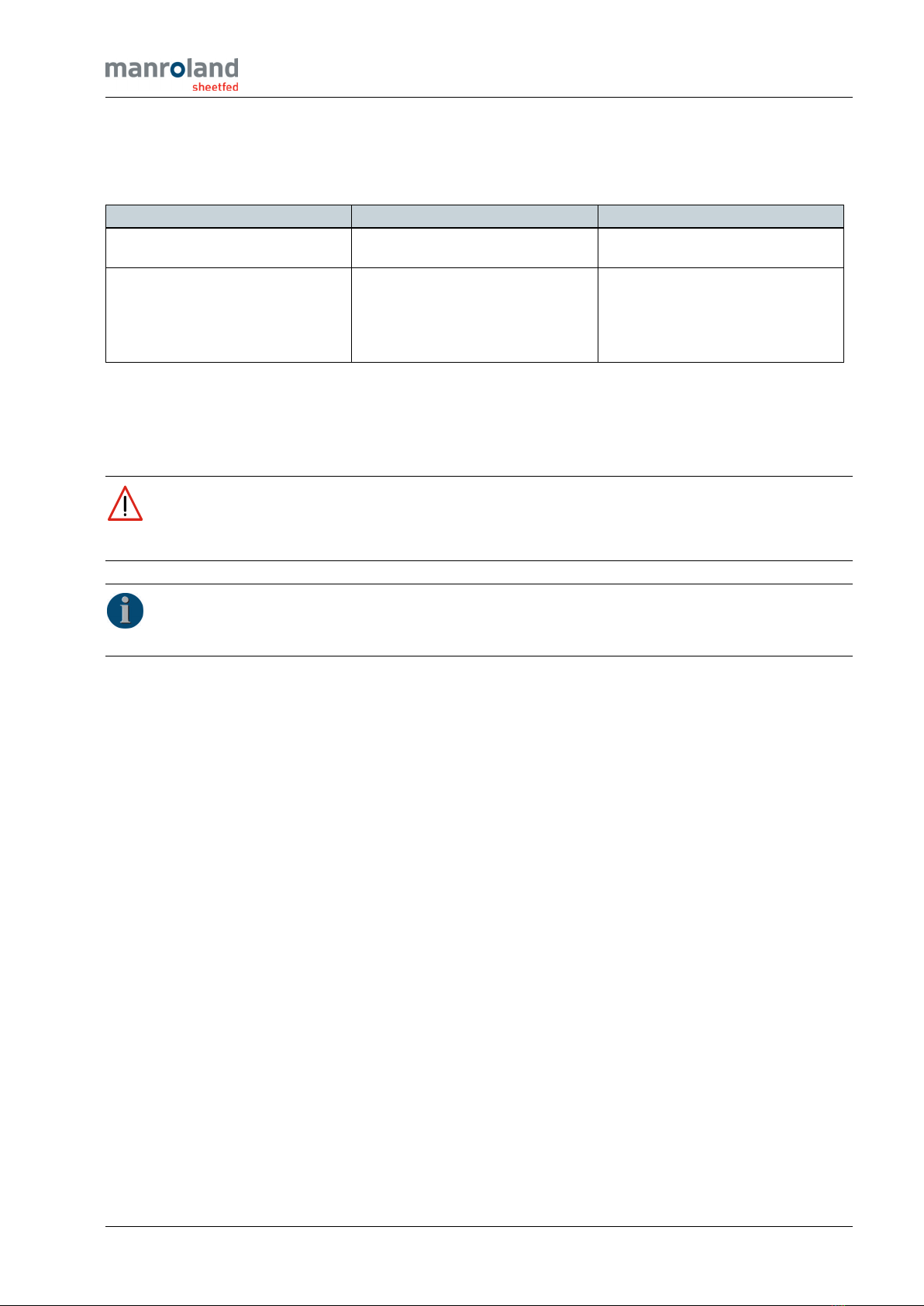

5.3 Cardboard printing

If necessary in cardboard printing, you can remove various elements to improve the printing result.

Elements to be removed Inspection restrictions ICP restrictions

●Baffle plate with blast tube ●for UV intermediate dryer

●for printing material <150 g/m² -/-

●Sheet guiding element

and

●Baffle plate with blast tube

●for UV intermediate dryer

●for printing material <150 g/m²

●for UV intermediate dryer

●for inspection

Note

The inspection lamp must be switched

off.

5.4 Sheet guiding element

5.4.1 Removing the sheet guiding element

DANGER

Risk of personal injuries. Risk of injuries if this work is performed by a single person.

▶Always perform this task together with a second person.

Note

If you want to wash the impression cylinder manually, it will be necessary to remove the sheet guiding

element.

Procedure

1. Lock the printing machine with the ’Stop-Safe’ key - see the manual Operation.

2. Open guard 9.8 over the impression cylinder.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

5

Printing module

Sheet guiding element

10 ROLAND 700 ‒Option

05-09839-1

3. Fold the retaining frame (1) open.

Option: UV final drier

◁The inspection lamp and the baffle

plate can be seen.

05-09845-2

4. Pull the locking mechanism (1) (A+B-side) out-

ward in the direction of the arrow and swing it

down in the direction of the arrow.

5. Reach into the intended cutouts (2) and pull the

sheet guiding element (3) evenly and parallel

out of the machine.

Note

For installing the sheet guiding ele-

ments, proceed in the reverse order.

Final tasks

▶Close guard 9.8 over the impression cylinder.

5.4.2 Removing the baffle plate

Material

Socket wrench, width across flats 10

Note

If possible, carry out this task together with a second person.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Printing module

Cleaning the sheet inspection system 5

ROLAND 700 ‒Option 11

Procedure

1. Lock the printing machine with the ’Stop-Safe’ key - see the manual Operation.

05-07076-1

2. Open guard 9.8 over the impression cylinder.

05-08090-1

3. Turn the threaded spindle (1) (B-side) out up to

the stop.

Material

Socket wrench, width across flats 10

◁The UV-drier protective housing is

unlocked.

4. Take UV-dryer protective housing (2) in the

direction of the arrow out of the machine.

5.5 Cleaning the sheet inspection system

5.5.1 Cleaning the LED lamp

Material

Lintfree cloth

Preliminary operations

1. Lock the printing machine with the ’Stop-Safe’ key - see the manual Operation.

2. Open guard 9.8 over the impression cylinder.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

5

Printing module

Cleaning the sheet inspection system

12 ROLAND 700 ‒Option

Procedure

▶Clean the LED lamp.

Material

Lintfree cloth

Note

If you determine that the output of the LED lamp decreases, contact our sales/service partner.

Final tasks

▶Close guard 9.8 over the impression cylinder.

5.5.2 Cleaning the outside of the glass pane of the camera housing

Material

Lintfree cloth

Procedure

▶Clean the outside of the glass pane of the camera housing.

Material

Lintfree cloth

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Delivery

Strip inserting device 6

ROLAND 700 ‒Option 13

6 Delivery

6.1 Strip inserting device

6.1.1 Removing the strip inserting device

Preliminary operations

1. Lock the printing machine with the ’Stop-Safe’ key - see the manual Operation.

2. Open guard 40 in front of the sheet removal zone.

Procedure

10-07722-2

1. Pull off both connectors (1) from the strip in-

serting device.

2. Carefully lift strip inserting device (2) in the

direction of the arrow out of the delivery.

Final tasks

▶Close guard 40 in front of the sheet removal zone.

6.1.2 Installing the strip inserting device

Preliminary operations

1. Lock the printing machine with the ’Stop-Safe’ key - see the manual Operation.

2. Open guard 40 in front of the sheet removal zone.

Procedure

10-07723-2

1. Carefully lift the strip inserting device (1) onto

the fixing plate at the delivery until it engages.

2. Connect the two connectors (2) to the strip

inserting device.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

6

Delivery

Strip inserting device

14 ROLAND 700 ‒Option

Final tasks

▶Close guard 40 in front of the sheet removal zone.

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Maintenance schedule

Work not dependent on operating hours (max. 20 000 s/h) A

ROLAND 700 ‒Option 15

Appendix

A Maintenance schedule

A.1 Work not dependent on operating hours (max. 20 000 s/h)

Interval Maintenance tasks Page

Once per week Cleaning the LED lamp 11

Once per month Cleaning the outside of the glass pane of the camera housing 12

A.2 Work not dependent on operating hours (up to 18 200 s/h)

Interval Maintenance tasks Page

Once per week Cleaning the LED lamp 11

Once per month Cleaning the outside of the glass pane of the camera housing 12

22.02.2021 08:18:48 - 778 - 80 95A EN H025

Index

16 ROLAND 700 ‒Option

Index

C

Cleaning

LEDlamp........................... 11

Clocked blast air

Setting .............................. 8

D

Description

Sheet inspection system . . . . . . . . . . . . . . . 4

E

Elements of the sheet inspection sys-

tem ................................... 8

F

False alarm

Sheetfrontedge...................... 7

Sheetrearedge ...................... 7

H

Hazard points

Mainswitch.......................... 6

I

Installation

Strip inserting device . . . . . . . . . . . . . . . . . 13

M

Main switch

Hazardpoints ........................ 6

Sheet inspection system . . . . . . . . . . . . . . . 6

Usage .............................. 6

R

Removal

Sheet guiding element . . . . . . . . . . . . . . . . . 9

Strip inserting device . . . . . . . . . . . . . . . . . 13

S

Setting

Clockedblastair...................... 8

Sheet front edge

Falsealarm.......................... 7

Sheet guiding element

Removal ............................ 9

Sheet inspection system

Description .......................... 4

Mainswitch.......................... 6

Sheet rear edge

Falsealarm.......................... 7

Strip inserting device

Installation.......................... 13

Removal ........................... 13

U

Usage

Mainswitch.......................... 6

Table of contents