Manson Engineering Industrial SBC-5926 User manual

SBC-5926

12V In-Car Charger

Dual Input (Solar MPPT & DC)

Operation manual

Keep this manual in a safe place for quick reference at all times.

This manual contains important safety and operation instructions for correct use of the battery charger.

Read through the manual and pay special attention to the markings and labels of the charger,

battery and equipment connected to the battery system.

Pay special attention to these two types of notices used in this manual.

Failure to heed this warning may cause injury to persons and damage to Equipment.

Failure to observe this warning may result in damage to equipment

and improper functioning of the Charger.

WARNING:

●The charger is not designed for any life saving application.

●The charger is designed for in-door use. Protect the charger from ingress of water.

●This charger is made to charge only properly sized lead acid batteries and Lithium Fe PO4 (LFP).

●Don't recharging non-rechargeable batteries.

●Charging other types of battery or under-sized lead acid batteries may cause fire or explosion.

●Install the charger in accordance with all local codes.

●Do not use the charger if it has been dropped or damaged.

●Do not remove casing of the charger, there is no user -serviceable parts inside.

●Do not charge the battery on boats. Remove the battery and charge on shore.

●Never attempt to charge a frozen battery.

●Never attempt to charge a damaged battery.

●Wear protective goggles and turn your face away when connecting or disconnecting the battery.

●Never place the charger on top of a battery.

●Never smoke, use an open flame, or create sparks near battery or charger during normal charging

operation as batteries may give out explosive gas.

●Do not charge batteries in an enclosure (box- in) due to possible explosion of entrapped explosive gas.

●Use of accessory not recommended may cause risk of fire, electric shock.

●Disconnect the mains supply before connecting or disconnecting the links to the battery.

●If the charger does not work properly or if it has been damaged, unplug all DC connections.

Copy Right

All rights reserved.

No part of this publication may be reproduced, or transmitted in any form or by any means without the written

permission from Manson Engineering Industrial Ltd.

Changes in the manual.

Manson Engineering Industrial Ltd. has the right to update and change the content of this manual without

any prior notice and obligation.

Disclaimer

Exclusions for documentation, Indemnity and Product application.

Manson Engineering Industrial Ltd. (Manson)

1) Assumes no warranty to the accuracy, suitability of technical information given in the user manuals or

other documentation.

2) Undertakes no responsibility or liability of losses, damages and related expenses whether specific,

direct, indirect consequential or accidental which might result from the use of information given in this

manual.

3) Shall not be liable to anyone for any special, collateral, incidental or consequential damages in

connection with or from the use of these Manson products. The sole and exclusive liability to Manson,

regardless of the form of action shall not exceed the purchase price of the Manson product.

Table of content

Induction P.4

Features P.5

Self Recoverable Protections P.5

Supplied Accessories P.5

Installation Procedure P.6

Battery Type Selection P.7

Solar panel and DC source Dual inputs P.7

Factory Preset Mode, Ignition Feed Mode & Vibration Sensor Mode P.7

To Set Ignition Feed of the charger to AUTO-ON P.8

To Set Ignition Feed of the charger to Manual ON-OFF operation P.8

How to deactivate the Ignition Feed ON mode P.8

Enable build-in vibration sensor P.8

Over ride of Ignition control by vibration sensor P.8

Indicators and Controls P.8-9

Connection P.9

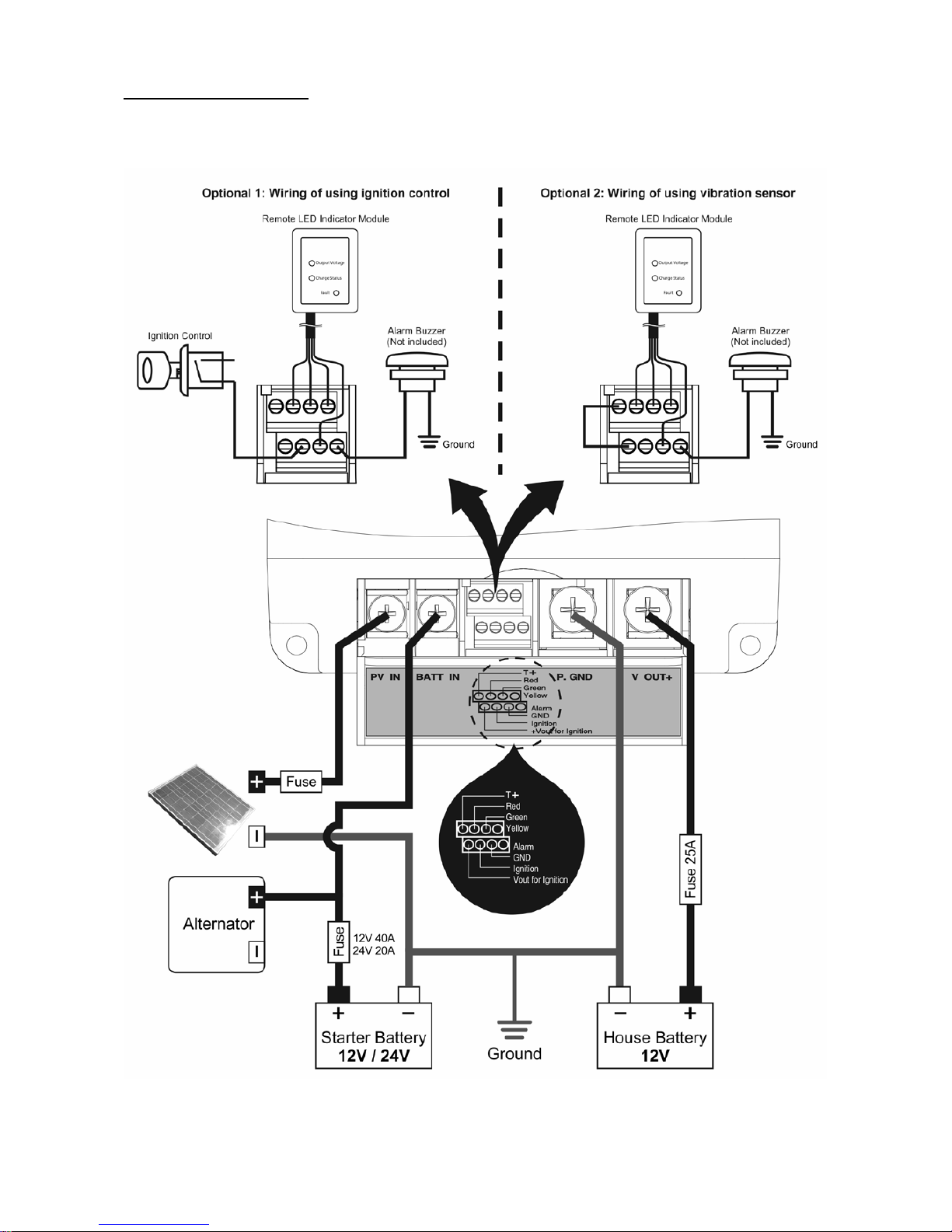

Connect & Wiring Diagram P.10

Specification P.11

Troubleshooting P.12

Figure index

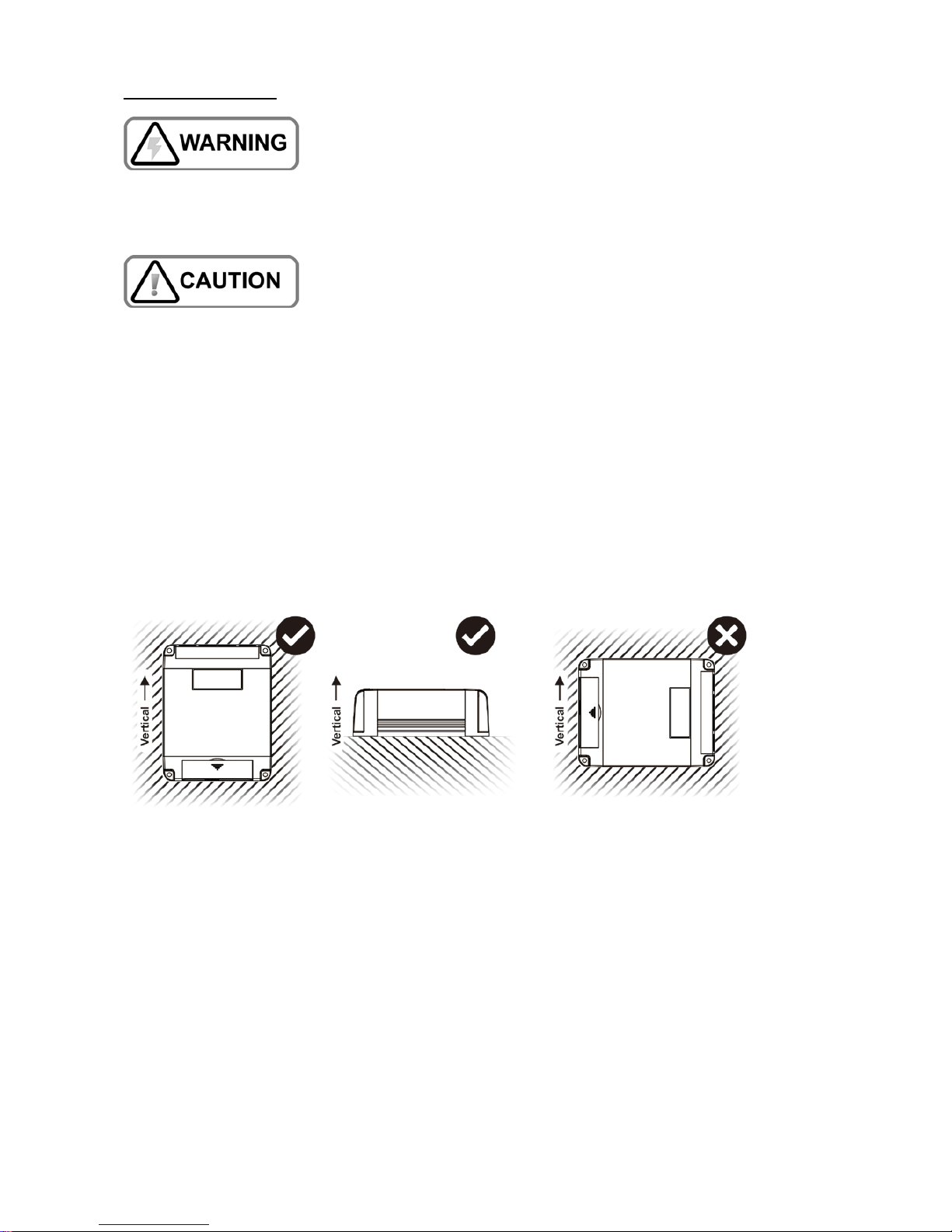

Fig. 1 correct installation direction P.6

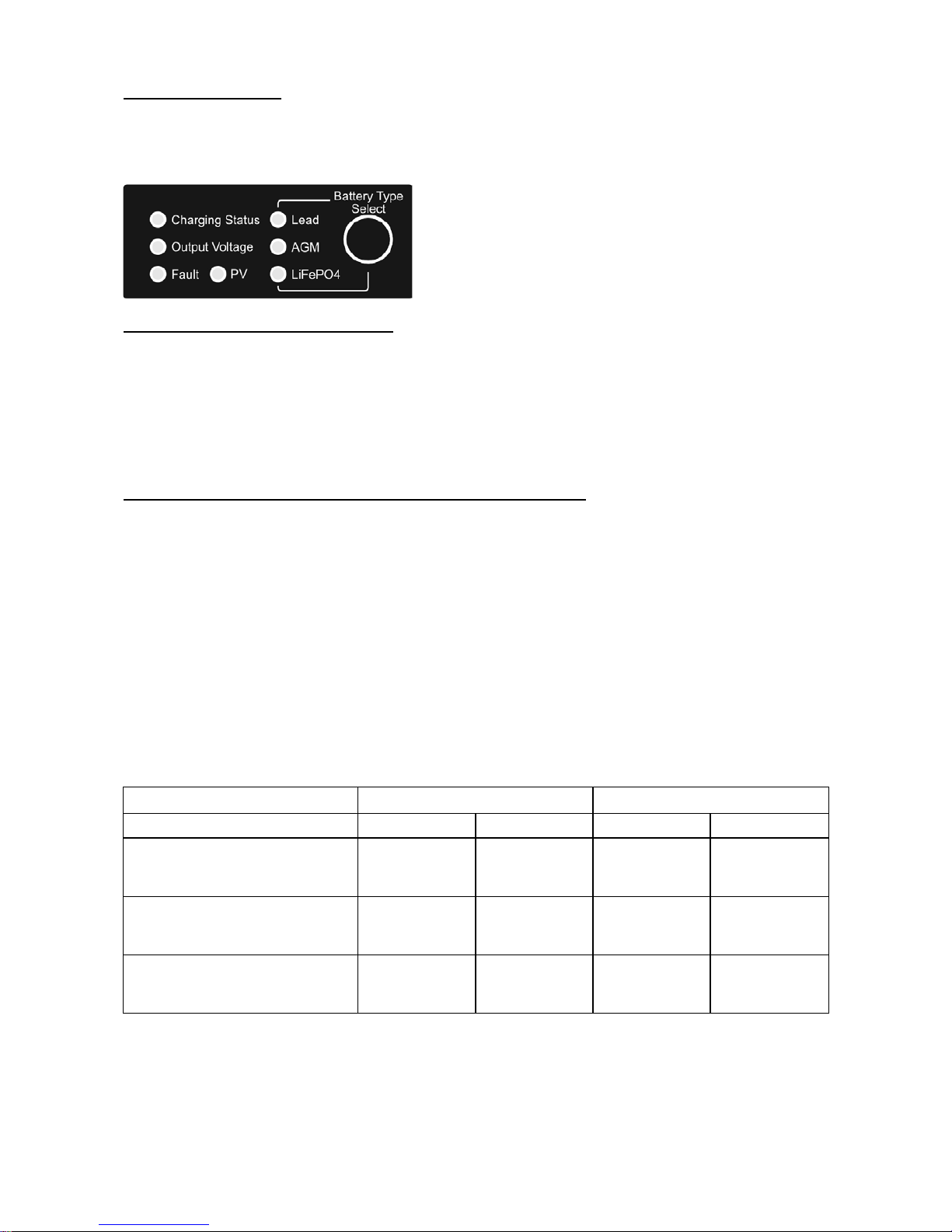

Fig. 2 showing 7 LEDs indicators and one SET button P.8

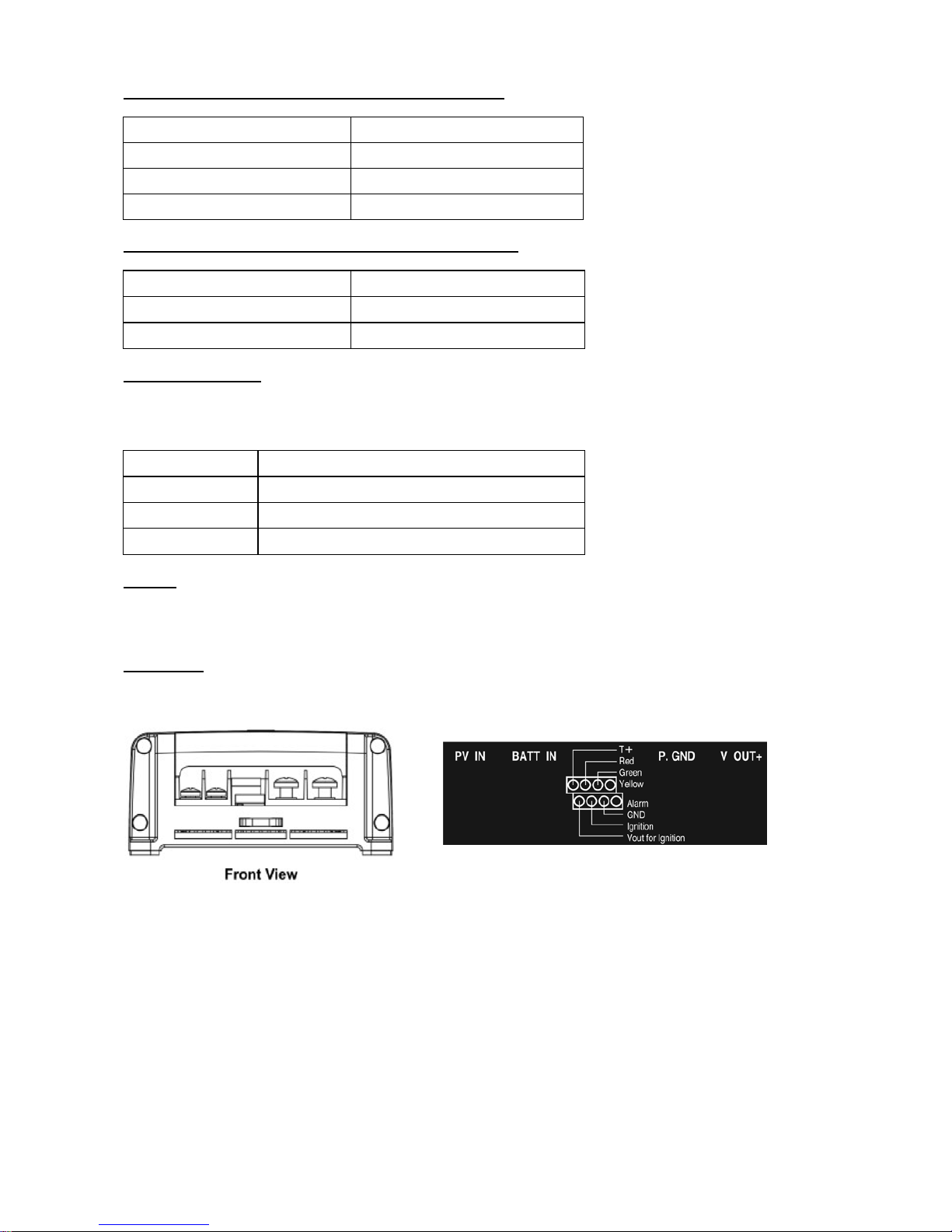

Fig. 3 Terminals & 8PIN connector P.9

Fig. 4 Connection Diagram P.10

Introduction

Especially designed for vehicles with Smart Alternator , Start-Stop ,Regenerative Braking system

The SBC-5926 is designed to address to the issues of wide swing of output voltages from the smart

alternator, braking regenerative EURO 5/6 vehicles in fully charging the house battery. It is suitable for use

with all old alternator system and distant house battery.

The built-in vibration sensor makes it possible to use the charger by just connecting to the starter battery

terminal without touching the car’s electrical /electronic wiring thus avoiding any possible excuse of revoking

the car’s warranty.

The digital control and auto-select design of SBC-5926 make it automatically adapt to 12V or 24V input

alternator/ battery system.

This is an automatic dual input solar & alternator-battery charger for charging 12V house battery banks of

lead acid , AGM type II and Lithium Fe Po4 batteries.

The built in Solar charge controller is of Maximum Power Point Tracking (MPPT) technology which

maximizes the PV power from your 12V up to 20 Amp or 400 Watt solar panels to your house battery.

In 12V alternator /battery system the house battery is charged by both Solar and alternator /battery

simultaneously to maximize the free solar energy.

**In 24V alternator /battery system the house battery is charged by Solar only when the car’s

alternator/battery stops charging operation.

Multistage Charging Process

This is a select (battery type) and forget charger designed for fast and accurate recharge of your deep cycle

house battery. The smart multistage charging enables the charger to be connected permanently to your

battery banks without the worry of over charging or drying out the electrolyte.

Also with both inputs permanently connected, you can be rest assured of charging your batteries whenever

you are on the move or when the sun shines on your solar panel.

Lead Acid Based Battery

A 3 Stage Bulk, Absorption & Float charging profile with maximum constant charging current at the Bulk

Stage and a Constant Voltage with decreasing charging at the Absorption Stage and a reduced voltage Float

Charge for maintenance when battery is full.

LiFePO4 (LFP) Battery

A 2 Stage charging is specially for the LiFePO4 battery and charging current stops at the end of Absorption

Stage.

There are 3 alternator charging modes available, Factory Preset Mode, Ignition Feed Mode, and Vibration

Sensor Mode. When the Vibration Sensor detects vibration from car’s engine, it triggers charging by

alternator.

P.4

Features

●Dual input from car battery with alternator input and Solar panel.

●Auto select for 12V or 24V car system.

●Design all alternators, conventional, smart alternators, start-stop & regenerative braking.

●3 DC Charge Modes to select:

Vibration Sensor Mode.

Ignition Feed Mode with Automatic or Manual Control setting.

Factory Preset Mode (charging function always on).

●Suitable for standard Lead Acid, AGM and Lithium Fe PO4 battery.

●3 Stage charge for Lead Acid based batteries.

●Specific 2 Stage charge for LiFePO4 battery.

Self Recoverable Protections

Input & Output reverse polarity.

Input Under Voltage.

Input & Output Over Voltage.

Over Load.

Charger Over Temperature and cooling fan jammed.

Supplied Accessories

●Remote LED Indicator Module (with 2M cable) like the unit front panel.

●4 heavy duty electrical eye connectors.

●One plastic wire guide.

●Double side sticker tape for the Remote Indicator Module.

P.5

Installation Procedure

Do NOT install this unit in the vehicle engine bay.

This is a fan cooled electronic device not for use in high temperature, corrosive and dusty environment which

will drastically shortens the life and performance of the charger.

This charger is designed only for internal mounting and away from direct sunlight, heat and rain. Allow at

least 80mm of space at both ends for ventilation.

We recommend wiring by a qualified automobile electrician to ensure local safety and on-board standard are

followed

1. To provide the best cooling effect, mount the unit in vertical position with the terminal end facing

downwards due to the top front exhaust design.

2. First install the charger as close to the house battery as possible via a fuse.

3. Check the LED indicators by a few presses on the Select Button.

4. Before connect input to DC Alternator, check on type of alternator of car, for new car with smart

alternator select ether Vibration Sensor Mode or Ignition Feed Mode.

*see table “Summary of 3 operation modes” on next page for detail

Fig.1 correct installation direction

P.6

Battery Type Selection

1. Press and hold the only Set Button for about 5 seconds until the LED flashes.

2. Light quick presses will move the LED from Lead--> AGM--> LiFePO4--> Lead.

3. Stop at the chosen battery type and wait till LED stops flashing to confirm your selection.

Solar panel and DC source Dual inputs

The charger support 12V Solar panel and DC source inputs. Both inputs can be connected simultaneously to

the charger or either one. Charger uses Solar energy as priority source to charge battery to maximize the

usage of Solar panel. The PV LED and charging output will be switched ON whenever the Solar panel has

sufficient energy for charging. The PV LED will ON to indicate Solar panel has sufficient energy and is being

used for charging. During Solar panel being used, no matter single input or dual inputs configure, the Ignition

Control and the Vibration Sensor have NO effect on output ON/OFF control.

*The allowable maximum power rating of solar panel is 400 Watt with maximum 30V Open Circuit voltage.

Factory Preset Mode, Ignition Feed Mode & Vibration Sensor Mode

There are three operation modes for the charger:

1. The charger comes in with the factory default mode:

Ignition control and Vibration Sensor are deactivated, it starts operation

when output and inputs are set up.

This mode will limit the input voltage range to protect over discharge of car’s battery.

This mode is not recommended for modern cars.

2. The Ignition Feed Mode requires wiring connection to the car’s electrical circuit, charger only

operates when car’s ignition has tuned on.

3. The Vibration Sensor Mode over rides the Ignition Feed Mode. It turns on the charger when

vibration is detected, vibration can come from the car’s engine and road.

**Use of vibration sensor does not touch the car’s electrical circuit and avoid problem in car’s

warranty.

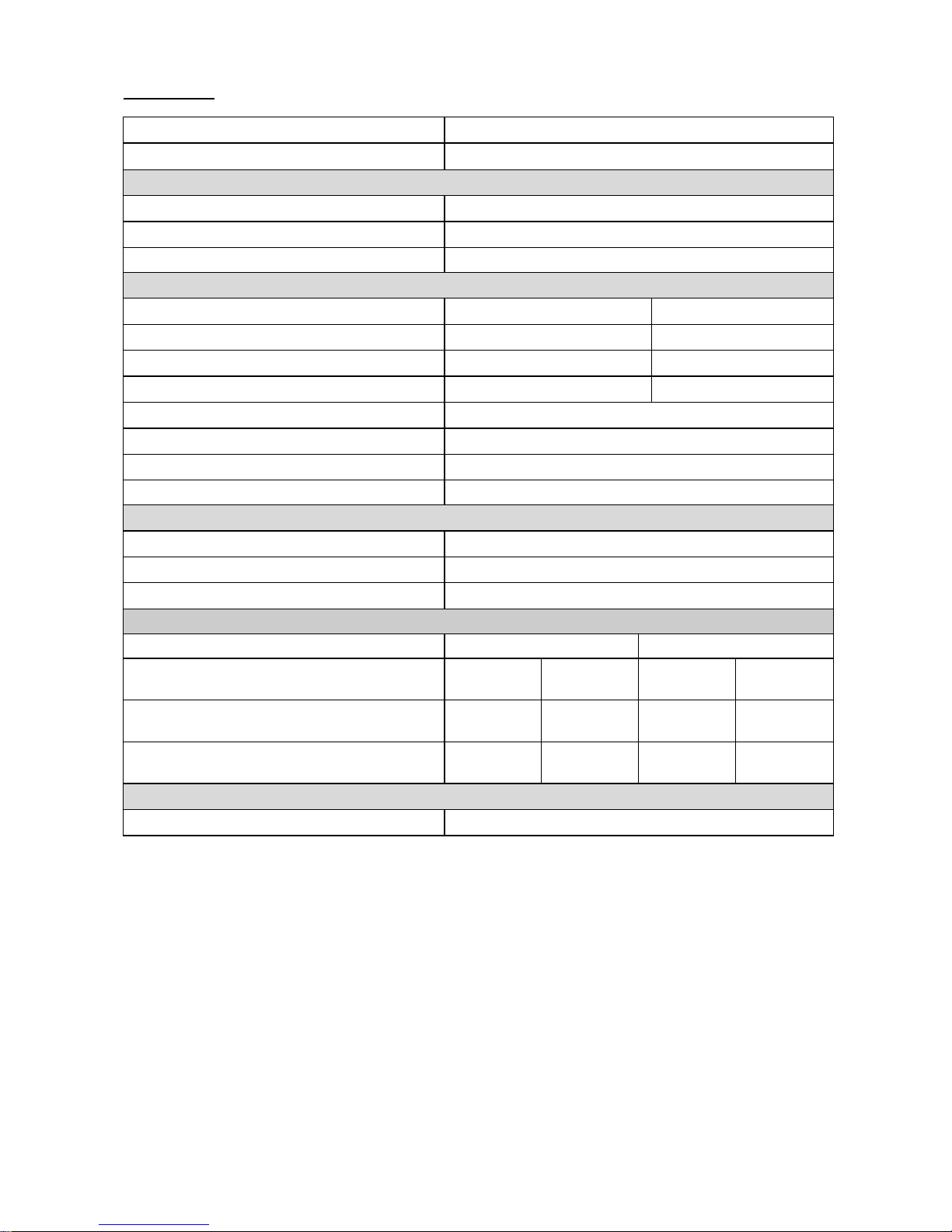

Summary of 3 operation modes

CHARGE MODE

12V CAR

24V CAR

CHARGE ON

CHARGE OFF

CHARGE ON

CHARGE OFF

Vibration Sensor Mode

when sensor is triggered by vibration

from car

11-16V

<9V

22-32V

<18V

Ignition Feed – Automatic Mode

connect to Ignition switch when

Ignition is on

11-16V

<9V

22-32V

<18V

Factory Preset Mode

Vibration Sensor & Ignition Feed

Inactive

12.8-16V

<12.2V

25.6-32V

<24.4V

The Ignition Feed and Vibration Sensor modes are suitable for Constant Voltage Alternators, Smart

Alternators, Start Stop, Euro 5 and 6 engines, cars with Regenerative Braking.

P.7

To Set Ignition Feed of the charger to AUTO-ON

Connect the Ignition Pin (in Fig.4: Terminals & 8 Pin Connectors diagram) to the car’s hot wire (that is the

wire that has a positive dc 9 to 32V when car’s ignition is turned on).

The charger only operates when the car is running, and charger stops charging once ignition is off.

To Set Ignition Feed of the charger to Manual ON-OFF operation

You can wire up a push switch with one end to the Vout for Ignition Pin and the other to Ignition Pin, see

Fig.4 Terminals & 8 Pin Connectors diagram. Shorting both pins will turn on the charger, disconnect will turn

off the charger.

How to deactivate the Ignition Feed mode

The Ignition Feed Mode will stay with the charger it has been activated once, even if the charger is taken out

from the system and re-installed in another car. That is once the Ignition Feed Mode has been activated,

charger will only be turned on when there is a positive voltage (+9V to +32V) at the Vout for Ignition Pin,

otherwise the charger stays in off mode.

Reset charger to factory default state with Ignition Feed in deactivated mode, such that the charger will start

charging the house battery as soon as input and output connections are made.

To deactivate the Ignition Feed mode:

1. Disconnect any wire to the Ignition Pin in the charger.

2. Press and hold Set Button for about 15 seconds until 3 battery type LED flash.

3. Release button to complete the deactivation of the Ignition Feed Mode.

Enable build-in vibration sensor

The built-in vibration sensor is enabled by connecting the T+ pin to Vout for

Ignition pin. The vibration sensor is in standby mode with output is OFF (no

charging). When sensor is triggered by vibrations which cause it to go the

active mode and after 8 seconds of further vibrations. The output will be

switched ON for about 100 seconds continuously.

Any further vibration during the 100 seconds active mode, will extend the

output ON for another 100 seconds. The output will be switched OFF if no

more vibration within 100 seconds of last vibration.

Over ride of Ignition Feed by Vibration Sensor

Built-in vibration sensor when enabled dominates the control of output and over rides all other Modes

including the Ignition Feed. That is only vibration can make the charger start charging with output ON.

To disable the Vibration Sensor: Take out the connection between the T+pin from Vout for Ignition pin.

Indicators and Controls

Fig. 2 showing 7 LEDs indicators and one SET button

P.8

Charging Status LED for LEAD ACID Battery - 3 Stages

Charging status LED

Charging stage

Fast flashes

Bulk charge

Slow flashes

Absorption

Solid

Float

Charging Status LED for Lithium Fe PO4 Battery - stages

Charging status LED

Charging stage

Fast flashes

Bulk charge

Slow flashes

Absorption

Output Voltage LED

This LED shows the voltage level at the V OUT terminal, it is the battery voltage when there is no Load

connected to the battery.

LED status

Battery Voltage Level

Fast Flashes

Battery Voltage lower than 12.5V

Slow Flashes

Battery Voltage between 12.5V and 13.6V

Solid

Battery Voltage higher than 13.6V

PV LED

The PV LED is lit when PV panel with over 14.4V output voltage is connected. This is a good way to check

for open circuit in the solar connection. PV LED is off at night.

Connection

After both input and output are connected, the charger will have output after 10Sec.

Fig.3 Terminals & 8PIN connectors

1 Vout for Ignition:12 Voltage signal. Short this pin to Ignition pin to enable ignition control of unit.

Short this pin to T+ to enable vibration sensor.

*This pin is for Ignition and Vibration sensor only. Don’t connect to other devices.

2 Ignition: Connect this pin to ignition car ignition to make the charger operate in sync with

vehicle ignition control.

3 GND: Ground pin for remote module. Connect to remote control black wire.

4 Alarm: Alarm output pin. 12V 50mA for external alarm.

5 Yellow: Connect to remote module yellow wire.

6 Green: Connect to remote module green wire.

7 Red: Connection to remote module Red wire.

8 T+: Vibration sensor enable pin. Connect to Vout for Ignition pin to enable Vibration

sensor. P.9

Connect & Wiring Diagram

Individual fuse/ breaker is required to be close to starting battery (charger input) and close to house battery

(charger output wire). Fuse at the solar panel to the rating of the short circuit current of the solar panel.

Fig.4 Connection Diagram

P.10

Specification

Rated output power

20A at 13.8VDC

Efficiency

≥90%

Input Voltage

DC Input Voltage Range

9 - 16VDC (12VDC Input) / 18 - 32VDC (24VDC Input)

Max. Solar Panel Open Circuit Voltage

30VDC

No load input current

<25mA

Output (Charge) Voltage

Battery Type

Absorption

Float

Lead

14.4V

13.3V

AGM

14.7V

13.6V

LiFePO4

14.8V

Stop

Alarm Output

12V / 50mA

Size(L x W x H)mm

130 x 188 x 55mm

Weight

Approx. 870g

Operating Temperature

-10 to +40ºC (Ambient Temperature)

Recommended Cable Size

Cable Length

Recommended SAE

1 – 5 Meters

8AWG

5 – 9 Meters

6AWG

Operating Mode

12V CAR

24V CAR

Vibration Sensor Mode

Charge ON

11-16V

Charge OFF

<9V

Charge ON

22-32V

Charge OFF

<18V

Ignition Feed – Automatic Mode

Charge ON

11-16V

Charge OFF

<9V

Charge ON

22-32V

Charge OFF

<18V

Factory Preset Mode

Charge ON

12.8-16V

Charge OFF

<12.2V

Charge ON

25.6-32V

Charge OFF

<18V

Recommended PV Panel Size

PV Panel Size

400Watt with maximum 30V open circuit voltage

P.11

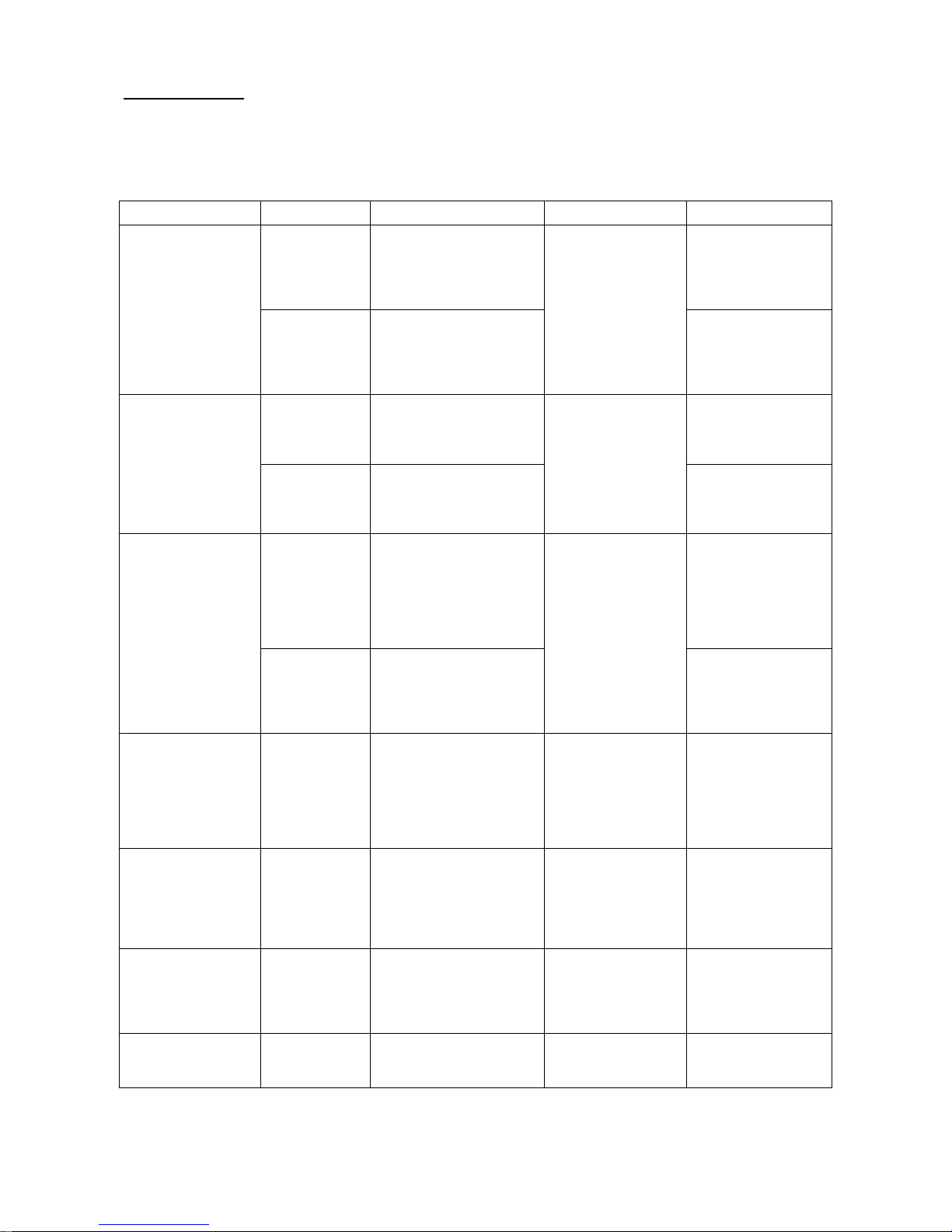

Trouble Shooting

The Fault LED is solid on when a protection is triggered and output of the charger is off. When the cause of

the fault has been clear up, Fault LED becomes off and charger returns to normal operation. Almost all the

protections are by software design and self recoverable, once the cause of fault has been dealt with. There

are two layers of protection for Input and Output Over-Voltage, the first layer is by software and the second

layer by hardware as a double insurance to protect the charger and the connected devices.

Problem

Indication

Possible Causes

Suggested Solution

Recovery Condition

Low Voltage

Disconnect (LVD)

Ignition Control is not

set to Auto ON

Fault LED ON

12V battery system:

Input voltage <12.8V for

20s.

Check the starter

battery voltage.

Use correct size cable

between charger and

starter battery.

12V battery system:

Automatic recovery

when input voltage

rises above 13.4V for

60s.

Fault LED ON

24V battery system:

Input voltage <25.6V for 20s

24V battery system:

Automatic recovery

when input voltage

rises above 26.8V for

60s.

Low Voltage

Disconnect

(LVD)

Ignition Control is set

to

Auto ON

Fault LED ON

12V battery system:

Input voltage <9V for 5s

Check the starter

battery voltage.

Use correct size cable

between charger and

starter battery.

12V battery system:

Automatic recovery

when input voltage

rises above 11V for 5s.

Fault LED ON

24V battery system:

Input voltage <18V for 5s

24V battery system:

Automatic recovery

when input voltage

raise above 22V for 5s.

Output Over Voltage

Protection (Output

OVP)

Two layers of

protection

First layer by software

Second layer by

hardware

Fault LED ON

Software OVP:

Output terminal voltage >set

absorption Voltage +0.6V

for 2s.

Disconnect any load to

battery and check

battery voltage.

If no load connected to

battery in first place.

Check battery voltage

if over set absorption

voltage, disconnect

battery.

Software OVP:

Automatic recovery

when the voltage on

output terminal is

reduced below

absorption Voltage

+0.3V for 3s.

Fault LED ON

Hardware OVP:

Output terminal voltage

>17.0V.

FUSE will blow.

Hardware OVP:

Does not automatic

recovery

Required to replace the

blown FUSE.

Input Over Voltage

Protection (Input OVP)

Two layers of

protection

First layer by software

Second layer by

hardware

Fault LED ON

PV LED may

also be on at the

same time.

Software input OVP:

Charger output will be

shutdown when input DC

voltage higher than 32V.

Check input battery

voltage is not higher

than 32V.

Software Input OVP:

Automatic recovery

when the voltage on

input terminal is

reduced below 31.5V

for 5s.

Input Over Voltage

Protec

tion (Input OVP)

by hardware.

All LEDs OFF

including the

FAULT LED.

Hardware Input OVP:

The FUSE will blow when

input terminal

voltage higher

than 33.5V.

Find out about the

Input source condition

& spec such as

voltage surge etc.

Before replacing with

the new fuse.

Hardware input OVP:

Does not automatic

recovery

Required to replace the

blown

FUSE.

Over Temperature

Protection (OTP)

Fault LED ON

Charger internal

temperature is too high.

Check input & exhaust

ends have no

blockage and

a minimum 10mm

clearance.

Automatic recovery

when charger

temperature reduce to

normal level.

FAN fault

Fault LED ON

FAN not working

Check for objects

jamming fan or Fan is

out of order.

Remove objects which

jamming

the fan .

REV.3 20180928

7673-5926-0562

P.12

Table of contents

Other Manson Engineering Industrial Automobile Accessories manuals

Manson Engineering Industrial

Manson Engineering Industrial SBC-5925 Installation manual

Manson Engineering Industrial

Manson Engineering Industrial SBC-6104 User manual

Manson Engineering Industrial

Manson Engineering Industrial SDC-6203 User manual

Manson Engineering Industrial

Manson Engineering Industrial SDC–5203 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction