DANGER indicates a hazardous

situation which, if materialized, could

result in a serious injury and even in

death.

CAUTION, indicates a hazardous

situation which, if materialized, could

result in material damage or a

moderate injury.

SAFETYINFORMATION

Please pay attention to all Warnings and Cautions in this manual. Failure to do so could result in

serious personal injury and/or equipment damage. It is mandatory to read the entire manual

unpack, install or operate this product.

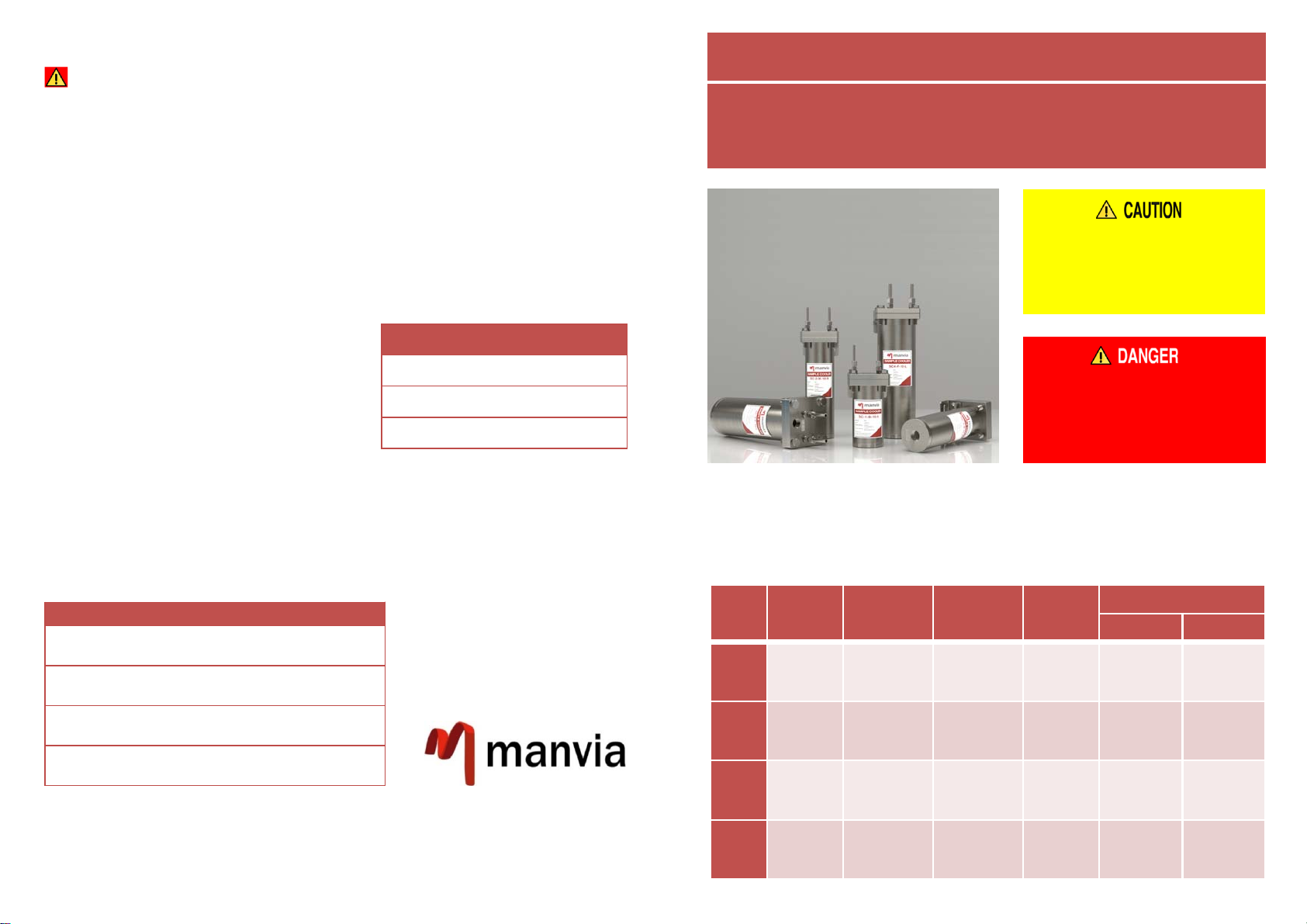

Model Cooling

Area

TubeMaterial

Size

Rating

ShellMaterial

Rating Weight

Optimalflowservice

(cm³/min)

Singlefase Condensing

heattransfer

SC‐10.11m²

1.2ft²

316SS

1/4”ODx0.049”

245bar@540⁰C

304SS/316SS

30bar@200⁰C

5kg

11.02lb 1,000 700

SC‐20.22m²

2.4ft²

316SS

1/4”ODx0.049”

245bar@540⁰C

304SS/316SS

30bar@200⁰C

7kg

15.43lb 1,800 1,100

SC‐30.35m²

3.8ft²

316SS

3/8”ODx0.065”

215bar@540⁰C

304SS/316SS

30bar@200⁰C

11kg

24.25lb 3,500 2,000

SC‐40.44m²

4.8ft²

316SS

3/8”ODx0.065”

215bar@540⁰C

304SS/316SS

30bar@200⁰C

12kg

26.46 lb 5,000 2,000

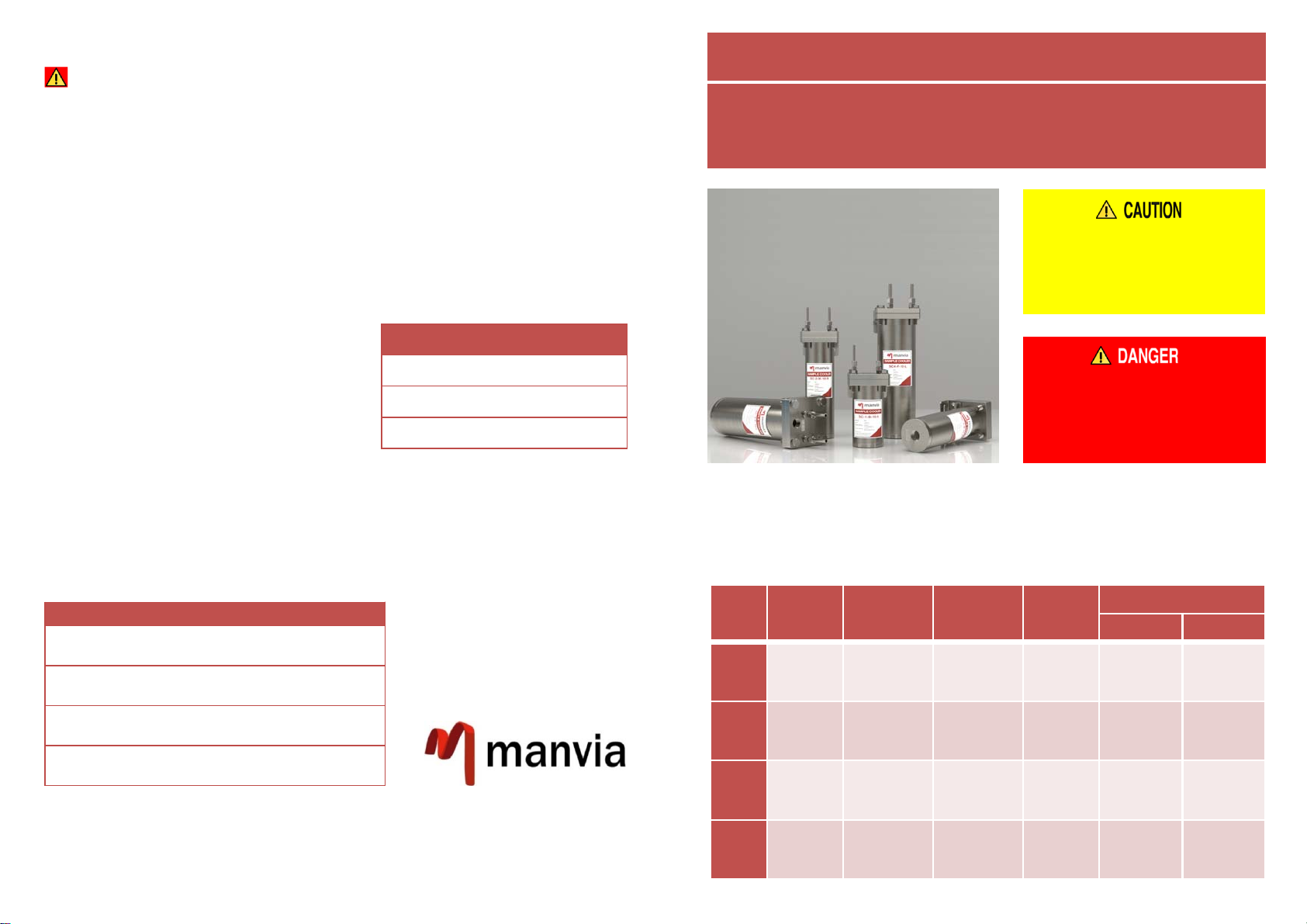

INSTALLATION,OPERATION&

MAINTENANCEMANUAL

MANVIASAMPLECOOLERSSCSERIE

SCSERIECOOLERSSPECIFICATION

MAINTENANCE

Remove scale by circulating an inhibited sulfamic acid

cleaning solution through the cooling water side.

Replace used gaskets with new ones. After

reassembly, pressurize shell and visually inspect for

water leaks. Recommended bolts torque 80 Nm.

Replace gaskets showing visible leaks. Keep spare

shell gaskets on hand for this need

STANDARDWARRANTY

Manvia warrants products manufactured by it and supplied

hereunder to be free from defects in workmanship and, to

the extent materials are selected by Seller, to be free from

defects in materials, in each case for a period as defined in

the table below:

Model Description WarrantyPeriod

SC–1 Steam & Water Sampling

Products and Systems

Twelvemonthsfrom

dateofshipment

SC–2 Steam & Water Sampling

Products and Systems

Twelvemonthsfrom

dateofshipment

SC–3 Steam & Water Sampling

Products and Systems

Twelvemonthsfrom

dateofshipment

SC–4 Steam & Water Sampling

Products and Systems

Twelvemonthsfrom

dateofshipment

All rights reserved. All product and company names are

property of their respective owners. This document

contains proprietary information. No part of this

document may be photocopied or reproduced without the

prior written consent of Manvia S.A. Sucursal España.

COOLERSSPARE PARTS

Part#Name

CL2O Cover "O" Ring for SC‐1andSC‐2

CL3O Cover "O" Ring for SC‐3andSC‐4

START‐UP

DANGER:To avoid the risk of burns, it is essential that a full flow of cooling water is present before

opening the sample inlet valve. Always close the sample inlet valve before turning off the cooling water.

Sample pipework becomes very hot under normal working conditions, and will cause burns if touched.

Follow this procedure for safe operation:

Open the cooling water inlet valve and outlet valve (if installed) first, and ensure that a full flow can

be seen at the cooling water outlet.

Gradually open the sample inlet valve and regulate the flow to achieve a cooled sample at desired

temperature.

Allow the sample to run for a while before collection or adjust flow to analyze in continuous systems.

When enough liquid has been collected close the sample inlet first, and then the cooling water

inlet/outlet valves. In continuous analyzer systems ensure the temperature is within allowable range.

After closing the sample inlet valve the sample OUT connection may drip in manual sampling systems

for a few minutes while the coil drains.

MA‐SC‐SERr00