2

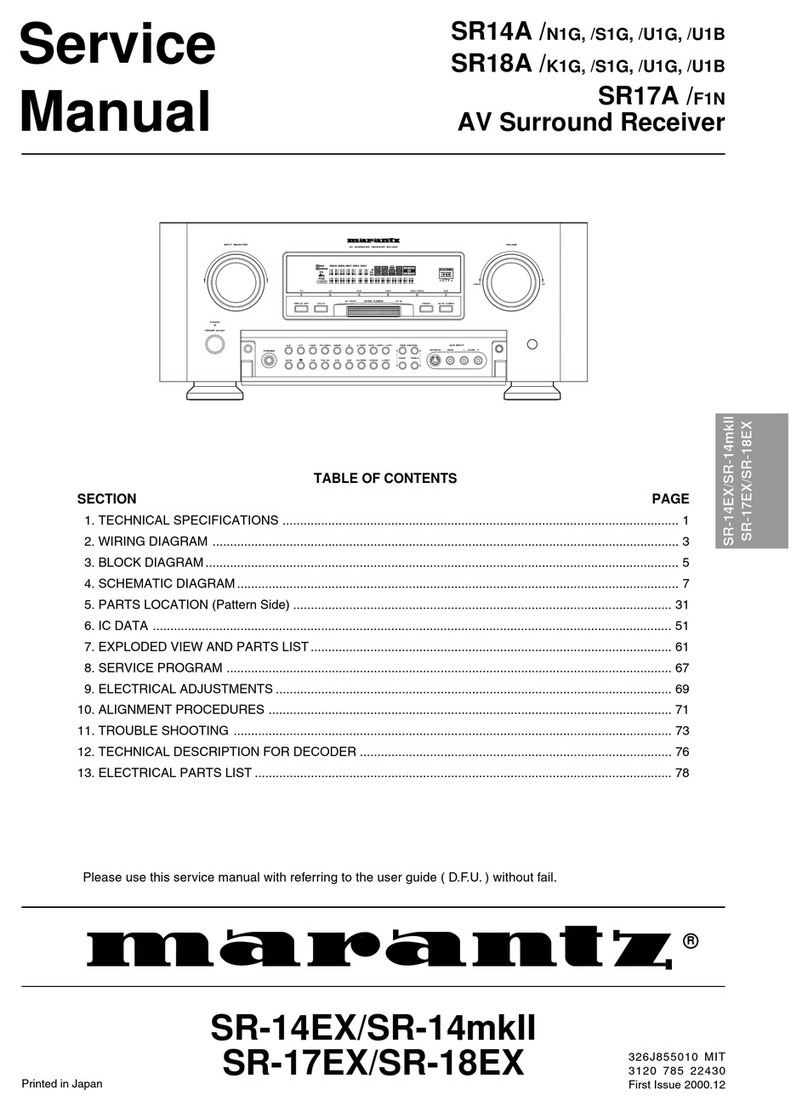

CONTENTS

ABOUT THIS MANUAL.............................................................4

What you can do with this manual ............................................4

Using Adobe Reader (Windows version) ..................................5

SAFETY PRECAUTIONS ..........................................................7

NOTE FOR SCHEMATIC DIAGRAM.........................................8

NOTE FOR PARTS LIST ...........................................................8

TECHNICAL SPECIFICATIONS..............................................10

DIMENSION .............................................................................10

CAUTION IN SERVICING........................................................11

Initializing AV Surround Receiver ............................................11

Service Jig ..............................................................................11

DISASSEMBLY........................................................................12

1. FRONT PANEL ASSY ........................................................13

2. RADIATOR ASSY...............................................................15

3. REG ASSY.........................................................................17

4. PCB RC5_MX ....................................................................18

5. PCB HDMI ASSY ...............................................................19

6. POWER TRANS MAIN ......................................................20

7. AV ASSY ............................................................................22

8. PCB SMPS.........................................................................22

9. PCB SPK............................................................................23

SPECIAL MODE ......................................................................24

1. µcom/DSP Version display mode.......................................25

2. PANEL/REMOTE LOCK Selection mode...........................29

3. Service Related Selection mode .......................................30

BLOCK DIAGRAM...................................................................33

4. DUAL BACKUP MEMORY.................................................45

5. Protection Pass mode........................................................46

6. DM860A Reboot mode.......................................................46

7. NETWORK Initialization mode ...........................................47

JIG FOR SERVICING ..............................................................48

WHEN THE MICROPROCESSOR IS

REPLACED WITH A NEW ONE..............................................50

PROCEDURE FOR UPGRADING

THE VERSION OF THE FIRMWARE ......................................50

1. How to update by DFW......................................................50

2. How to update by DPMS....................................................54

3. How to update by USB Memory.........................................61

ADJUSTMENT.........................................................................70

TROUBLE SHOOTING............................................................75

1. POWER..............................................................................75

2. Analog video ......................................................................76

3. HDMI/DVI ...........................................................................79

4. AUDIO................................................................................81

5. Network/USB......................................................................84

6. SMPS .................................................................................87

LEVEL DIAGRAM....................................................................89

BLOCK DIAGRAM...................................................................95

POWER DIAGRAM..................................................................96

WIRING DIAGRAM..................................................................97

PRINTED WIRING BOARDS...................................................98

SCHEMATIC DIAGRAMS (1/25) ...........................................107

HDMI_ADV3002 ...................................................................107

HDMI_FRONT-HDMI ............................................................108

HDMI_ADV7623....................................................................109

HDMI_SLI11131A..................................................................110

HDMI_DSP............................................................................ 111

HDMI_DIR-PLD.....................................................................112

HDMI_MAIN-DAC .................................................................113

HDMI_DM860A .....................................................................114

HDMI_NET-PHY....................................................................115

HDMI_CPU ...........................................................................116

HDMI_CPU-LEVEL-CHG......................................................117

HDMI_DIGITAL-CNT.............................................................118

HDMI_D-SUPPLY .................................................................119

SPK_SIDE-CNT_SPK...........................................................120

SPK_SIDE-CNT_SIDE-CNT .................................................121

AV_INPUT .............................................................................122

AV_VIDEO.............................................................................123

AV_TUNER ...........................................................................124

FRONT_FRONT....................................................................125

AMP_AMP1...........................................................................126

AMP_AMP2...........................................................................127

SMPS_REG_CNT_SMPS.....................................................128

SMPS_REG_CNT_REG .......................................................129

SMPS_REG_CNT_FRONT-CNT ..........................................130

SMPS_REG_CNT_RC5........................................................131

EXPLODED VIEW .................................................................132

PARTS LIST OF EXPLODED VIEW......................................133

PACKING VIEW .....................................................................134

PARTS LIST OF PACKING VIEW .........................................135

SEMICONDUCTORS .............................................................136

1. IC's ...................................................................................136

2. FL DISPLAY .....................................................................162