LED light. This saves the value.

Press the “L DISP” button to light up the “POWER”

label.

oPress the “SET” button to illuminate its LED light

oPress the “DECR or INCR” buttons to set the

plasma power (Watts) by decreasing or

increasing the Power in the left display above.

oWhen the correct power appears in the display,

press the “SET” button again to extinguish the

LED light. This saves the value.

Press the “R DISP” button on the right side to illuminate

the “GAS1” label.

oPress the “SET” button to illuminate its LED light

oPress the “DECR or INCR” buttons to set the O2

(or Ar) flow rate, (% of 100 sccm), by

decreasing or increasing the value in the right

display above.

oWhen the correct flow value appears in the

display, press the “SET” button again to

extinguish the LED light. This saves the

value.

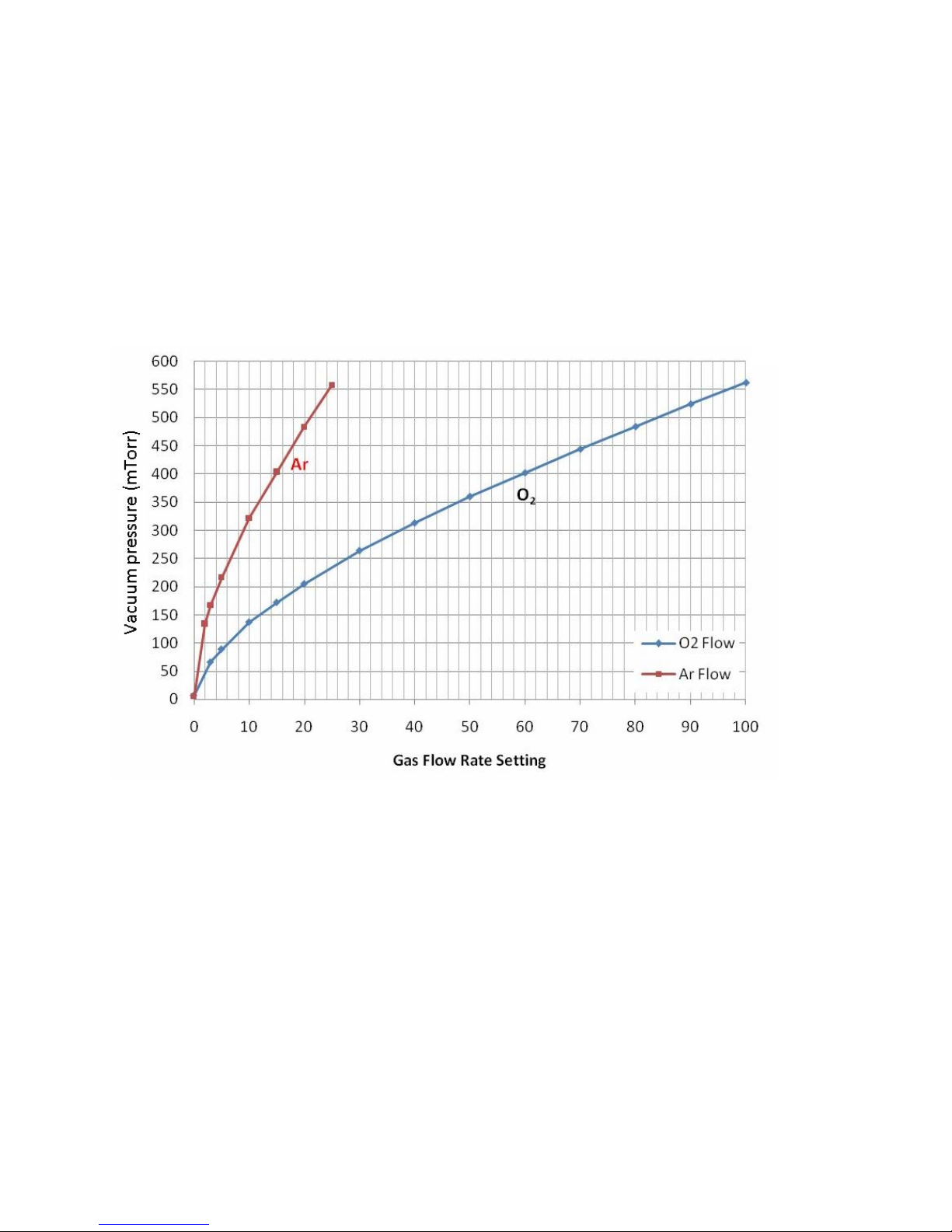

oConsult the percent O2(Ar) flow vs pressure chart

in Appendix B to determine the proper flow value

for your process pressure. The actual values may

drift somewhat over time as the vacuum pump oil

becomes contaminated, so some variance from

the table may be required as experience dictates.

4) RUNNING THE PROCESS

•Press the “START” button in the