For more information visit www.marcobeveragesystems.com

FRIIA C, FRIIA CS & FRIIA C HANDS-FREE

FRIIA COLD, FRIIA COLD/SPARKLING & FRIIA COLD HANDS-FREE

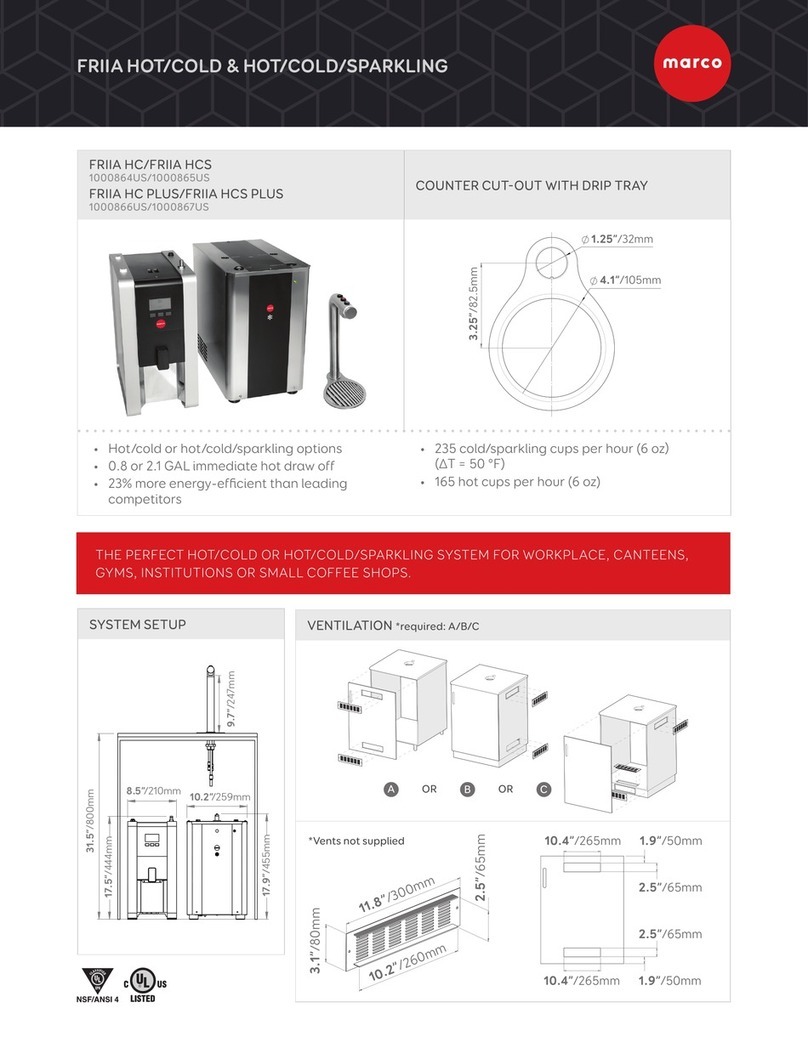

COUNTER CUT-OUT WITH DRIP TRAY

FRIIA C 5001860US

FRIIA C Tall 5001863US

FRIIA C Hands-Free 5001857US-C

FRIIA CS 5001862US

FRIIA CS Tall 5001865US

Power

1401482

1400820

Cold/Sparkling

Water

2301251

4”/100mm

For drip-tray only

1.25”/32mm

3.25”/82.5mm

6.6”/168mm

369

437

600

600

100 min.

275

200

Applies to model(s) 1000850# & 1000851# (where # is blank, or one or more alphanumeric characters)

DRAWN BY

DWG NO.:

PANEL REMOVAL

DESCRIPTION:

PJT

20-08-14

187

C.O.

FRIIA Assembly (in cabinet)

31.5”/800mm

12”(Hands-free)

11.4” (Cold/Sparkling)

17.9”/

455mm

10.2”/259mm

13.5”/

345mm

(Tall)

VENTILATION REQUIREMENTS

FRONT VENTILATION: Ventilation grilles cut out of standard cabinet door.

SIDE VENTILATION: Ventilation grilles cut out of standard 600mm

cabinet. Grilles may be fitted on either side as long as they ventilate

into an open unobstructed area.

BASE VENTILATION: Ventilation grilles cut in base panel and base

plinth, a grille must also be cut out at the top of the cabinet.

• At least 2 x vents 260mm/10.2” w x 65mm/2.5 h

• The cabinet may be ventilated in many ways provided there are cut

outs placed near the base and another near the top of the cabinet

to take advantage of natural circulation.

UNPACKING INSTRUCTIONS

• The chiller must be handled only in a vertical position. Transporting

the appliance in a horizontal position can cause severe damage to

the refrigerator.

• Remove the exterior and interior packing. Packing materials

(especially any plastic bags) should be stored out of the reach

of children, as a potential source of danger. When disposing

packaging parts, please follow current regulations on the matter,

separating carton from plastic parts.

• Always check that the equipment that is delivered corresponds to

the model indicated in the accompanying document.

• The equipment is shipped in a cardboard box. Once the packaging

has been removed, check the equipment has not been damaged in

transit; if damage is found, notify the carrier.

ELECTRICAL INSTALLATION PROCEDURE

When installing the machine, always observe the local regulations and

standards. The appliance is supplied with a moulded power cord. A

suitable mains power supply socket should be available within easy

access of the appliance so that it can be disconnected easily after install.

The standard machines are supplied with a UK 3-pin plug. For

EU models a 2-pin CEE-7 plug will be supplied. US models will be

supplied with the suitable plug. A suitable mains power supply socket

should be available within easy access of the appliance so that it

can be disconnected easily after install. The wires from the font are

terminated in a Mini Fit connector which will plug into a similar Mini Fit

connector mounted on the top lid of the undercounter boiler.

PLUMBING INSTALLATION PROCEDURE

• Ensure that the equipment is installed according to local plumbing

& water regulations.

• Fit a stop valve on a cold water line and attach a 3/4” BSP male

fitting, (eg. 3/4” x 1/2” 311 or washing machine type stop valve).

Suitable fittings are supplied with the kit to attach to 3/8”

Compression or 3/8” John Guest.

• Connect water supply lines following the installation drawings,

as per installation guide.

• In case filter systems are used verify that they satisfy the

requirements of the legislation in force.

• If the filter is new, turn on water and flush at least 10 liters

(2.5 gallon) through the filter before to connect it to the cooler;

if the filter is a used one, connect water inlet to the chiller.

• To ensure that the maximum value of pressure of 3 Bar is not

exceeded the chiller integrates a pressure reducer.

• Turn on the water to flush any impurities, dust etc from the inlet hose and

water pipe. Allow several litres through. Especially for new installations.

OPERATING THE CHILLER/CARBONATOR FOR THE

FIRST TIME

• Before connecting the appliance to the power source, let it stand upright

for approximately 2 hours. This will reduce the possibility of a malfunction.

• Check that all installation procedures have been carried out.

• Ensure water inlet is open.

• Before supplying power to the unit check water and Carbon Dioxide

lines do not leak.

• Plug the chiller into a suitable socket switch ON/OFF switch on the rear

of the chiller to ON position. The “Power ON Status” light will light-up.

• When the unit is on, the carbonation pump starts to fill. The

carbonation device stops when it reaches the maximum level.

• Once water and CO2 are connected, open the vent on top of the

Chiller by pulling the ring. This operation allows the escape of any air

bubbles present inside, which would affect the carbonation adversely.

• On the pressure reducer knob, adjust CO2 pressure to a value

between 50 and 65 PSI (350 and 450 kPa) (3.5 - 4.5 bar). This value

depends on the temperature of the water and on the ambient

temperature. The temperatures correspond to the CO2 pressure.

• To enable filling the lines, open the two lines in the following order:

cold sparkling water and cold natural water, until the flows appear

regular and without the presence of air, in each case deliver and

discharge at least 5 litres of water from each line.

• At this point you can dispense water.