WWW.MARCOUSA.COM

5

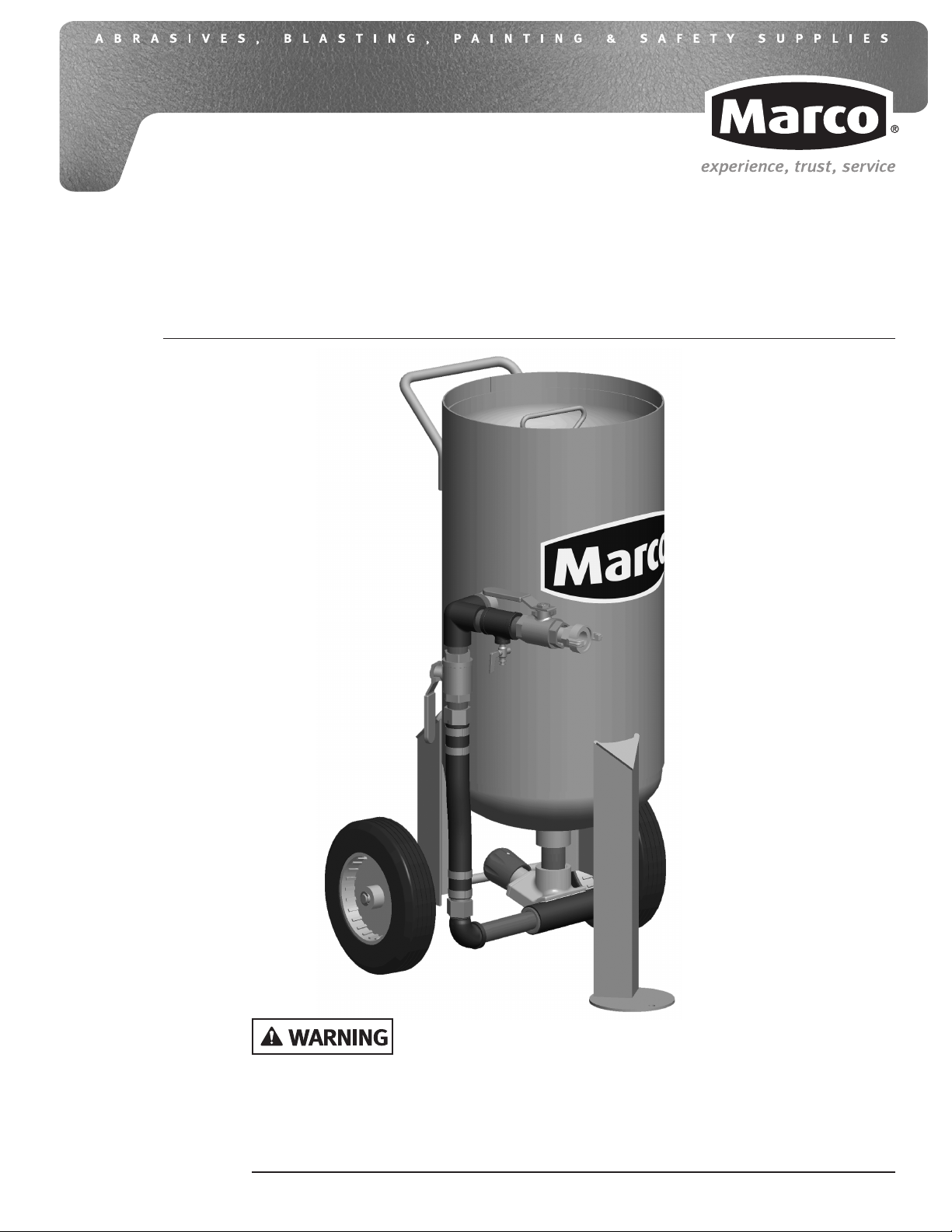

2.0 CUBIC FOOT L-SERIES BLAST MACHINE

Description

Rugged, relentless and reliable is what you get with a Marco 2.0 Cubic Foot L-Series Blast

Machine. From quick touch-ups to complete jobs, the 2.0 Cubic Foot L-Series Blast Machine

is up to the task. Compact design, welded handle, and rugged solid core tires makes this

machine highly mobile and easy to move around your job site. The industry proven Two Hole

Junior Metering Valve provides the operator with precise metering capabilities, reliable flow,

reduced media usage and increased productivity. Equipped with the KwikFire 153 Remote

Control Handle, you gain "instant on, instant off" control over your media flow and improved

performance. An optional moisture separator will provide dryer air; reducing clogs in the

abrasive flow.

Features:

• Built in accordance with ASME Pressure Vessel Code - proven industrial grade durability

• 125 psi operating pressure - allows for a wider range of media and surface profile options

• Durable powder-coated finish - better protection against the elements

• KwikFire 153 Remote Control Handle - gives "instant on, instant off" control over your media

• Bantam Metering Valve - virtually infinite control over abrasive for precise mixture ratio

• Triangular Filler Plug Handle - provides an easy grip during pressurization

• Concave head - makes filling easier with less media spilled on the ground

• Stable tripod design - three point design resists tipping on irregular surfaces

• Solid rubber tires - puncture proof and durable for reliable performance

• Welded handle - makes for easy transport to, from, and around your work site

• Dimensions - 21"W x 24"L x 39"H / Weight - 126 lbs

Operational Requirements

The following may cause safety hazards or reduced performance:

• Improper installation and/or maintenance of components

• Failure to place blast machine on a secure, flat surface

• Improper air supply pressure (minimum 30 psi, maximum 125 psi)

• Incorrect lifting / transporting of blast machine or incorrect or worn lifting devices

• Use of media too coarse for nozzle orifice

• Use of media coarser than 20 mesh may cause clogging in the Bantam Metering Valve

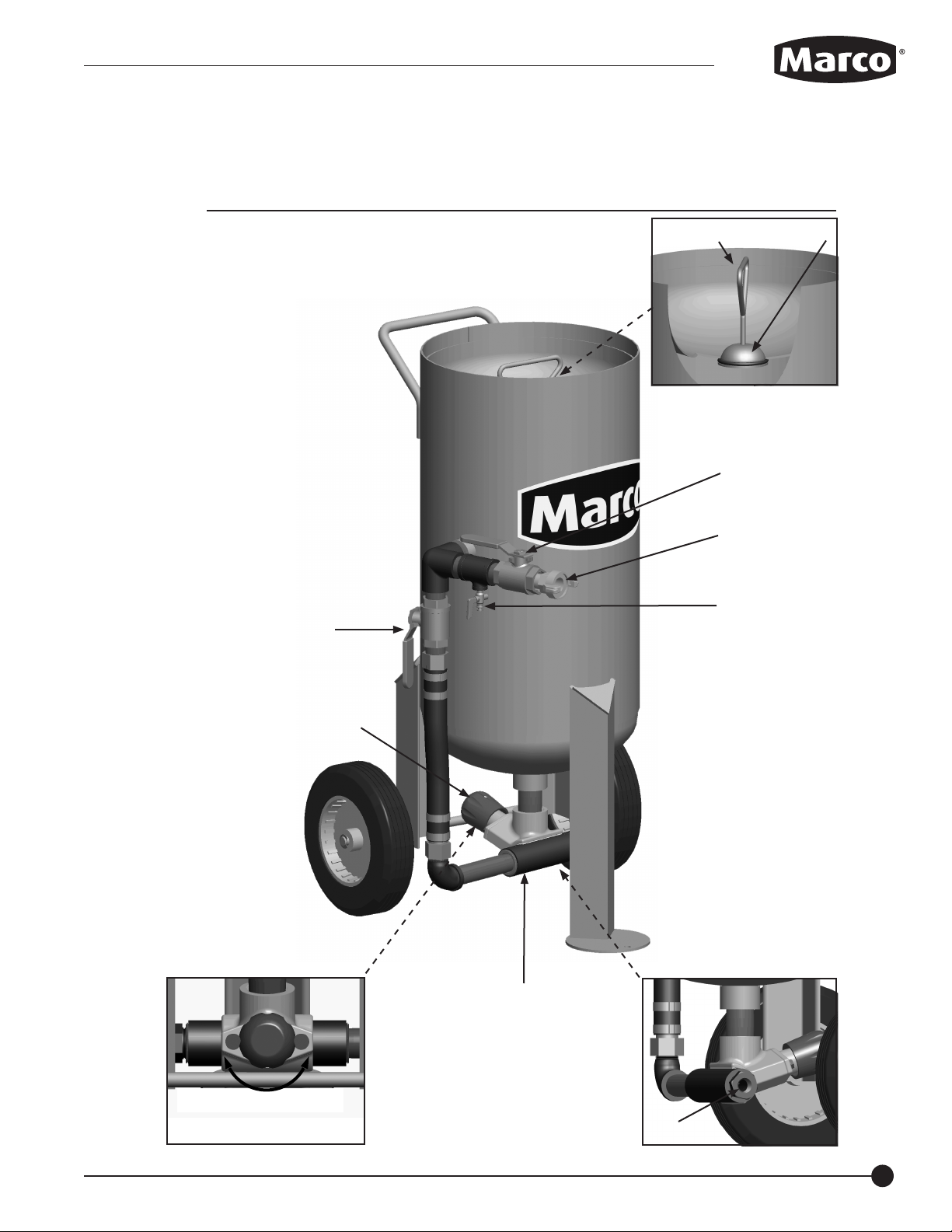

Operating Instructions (Figure 2)

Before using:

• Inspect Blast Machine for damage. Replace any damaged components before use.

• Inspect Filler Plug O-ring (2) and Filler Plug (1) for damage

• Test all Ball Valves (3, 8) for binding by turning to the fully open position and back to the

fully closed position. Replace immediately if damaged.

• Test Petcock (5) for binding by turning the handle 180 degrees (from the 9 o’clock to

3 o’clock position). Set Petcock (5) handle to a closed (9 or 3 o'clock )position.

• Test Bantam Metering Valve (6) by twisting Control Knob (7) one full turn clockwise then

counter-clockwise. Close Bantam Meter Valve by turning control knob clockwise until the

valve seats .

• Attach Blast Hose to Bantam Metering Valve (a).

• Attach KwikFire 153 to Blast Hose and install Blast Nozzle on KwikFire 153 (fig.7).

• Test KwikFire 153 Remote Control System by rotating Control Lever to the operating position

and release. If the Control Lever does not return to the closed postition, remove system from

service and inspect KwikFire 153 for damage before returning system to service.

• Fill Blast Machine with media.

• Attach Air Hose to 2-Lug Hose Fitting (4).

Ensure the surface is stable

and is sufficient to support the

weight of a Blast Machine full

of media. Unstable surfaces

and surfaces that cannot

support the gross weight of a

full blast machine could cause

the blast machine to tip over.

Failure to comply with the

above warning could result in

death or serious injury.

Never weld, grind or drill

on the blast machine (or any

pressure vessel). Doing so

will void ASME certification

and manufacturer’s warranty.

Welding, grinding or drilling

on the blast machine (or any

pressure vessel) could weaken

the vessel causing it to burst.

Failure to comply with the

above warning could result

in death or serious injury.

(ASME Pressure Vessel Code,

Section VIII, Division 1)

Inspect all equipment for

wear or damage before and

after each use. Failure to

use Original Equipment

Manufacturer repair parts and

failure to immediately replace

worn or damaged components

could void warranties and

cause malfunctions. Failure to

comply with the above warning

could result in death or serious

injury.

2.0 Cubic Foot L-Series Blast Machine

Never use the filler plug to lift

or move the blast machine.