EFA cutters Translation of the original operating instructions-EN

Table of contents

1. Introduction and general information______________________________________________________ 2

1.1 Information on the operating instructions ______________________________________________________ 2

1.2 User group _____________________________________________________________________________ 2

1.3 Scope of supply__________________________________________________________________________ 3

1.4 Intended use ____________________________________________________________________________ 3

1.5 Claims for defects, liability, warranty__________________________________________________________ 4

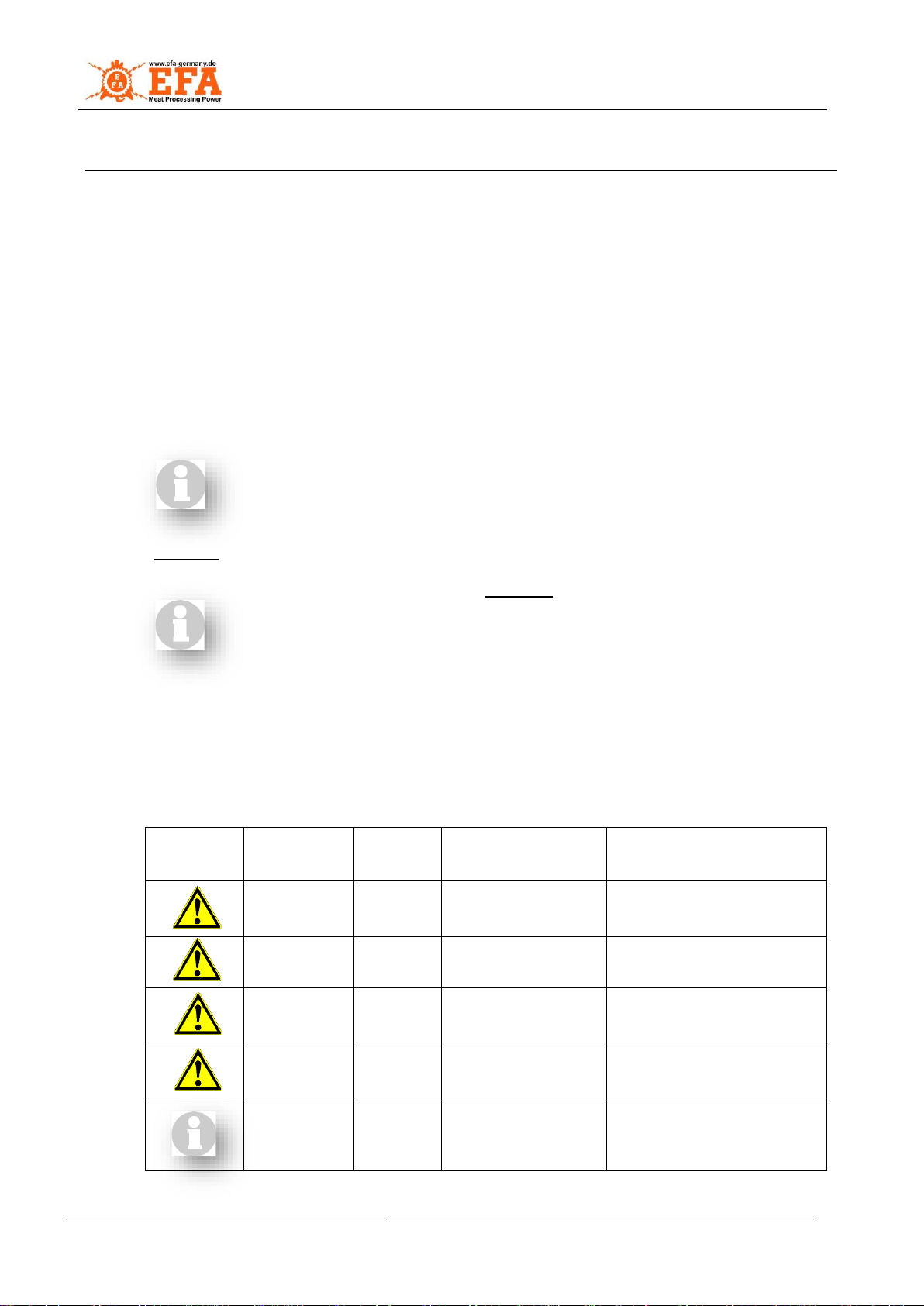

2. Safety______________________________________________________________________________ 5

2.1 Safety instructions________________________________________________________________________ 5

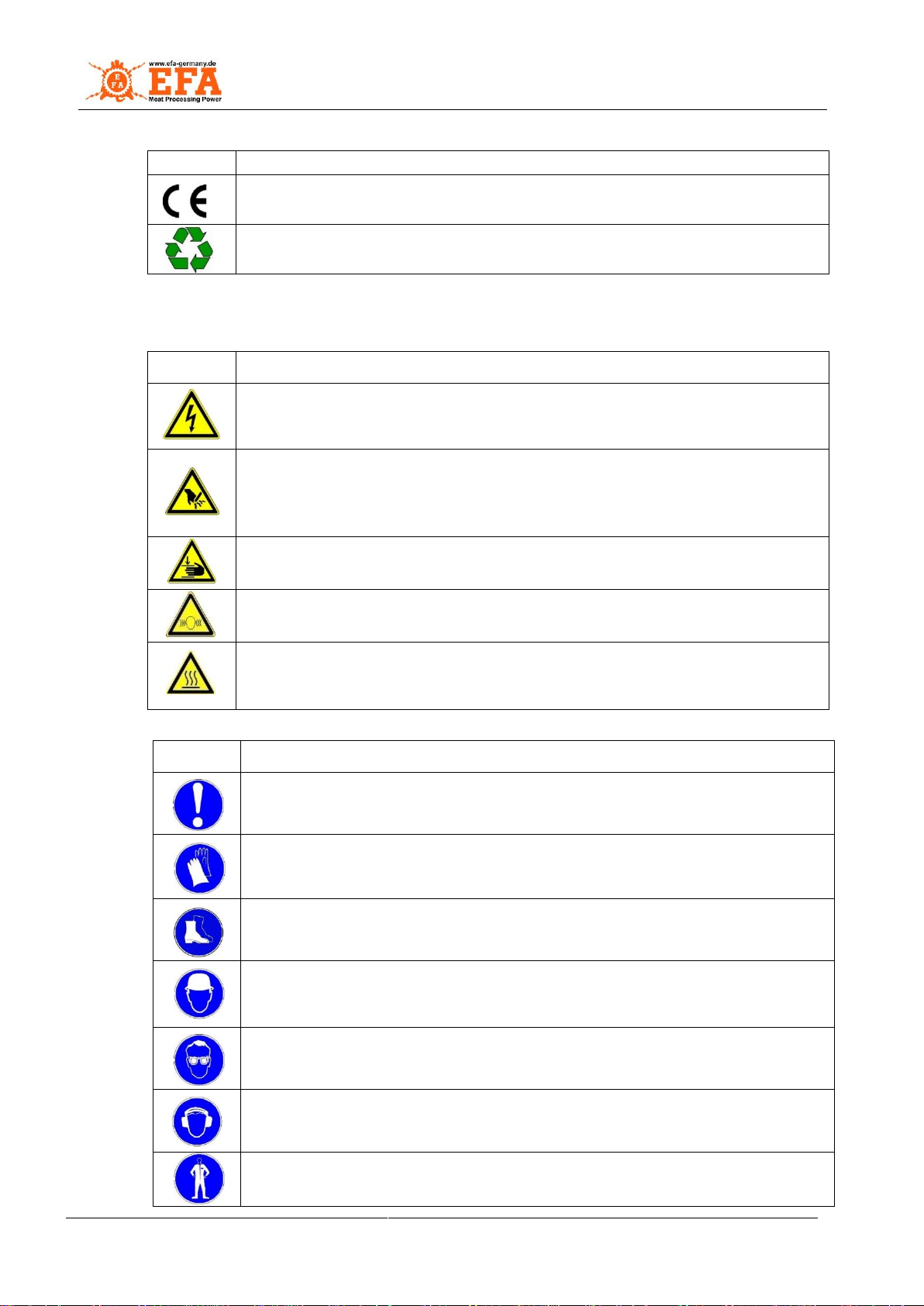

2.1.1 Other safety signs __________________________________________________________________ 6

2.1.2 Warning sign ______________________________________________________________________ 6

2.1.3 Mandatory instruction sign____________________________________________________________ 6

2.1.4 Prohibition sign ____________________________________________________________________ 7

2.2 Personal protective equipment in the following lifecycle phases_____________________________________ 7

2.3 Conduct at the workplace __________________________________________________________________ 7

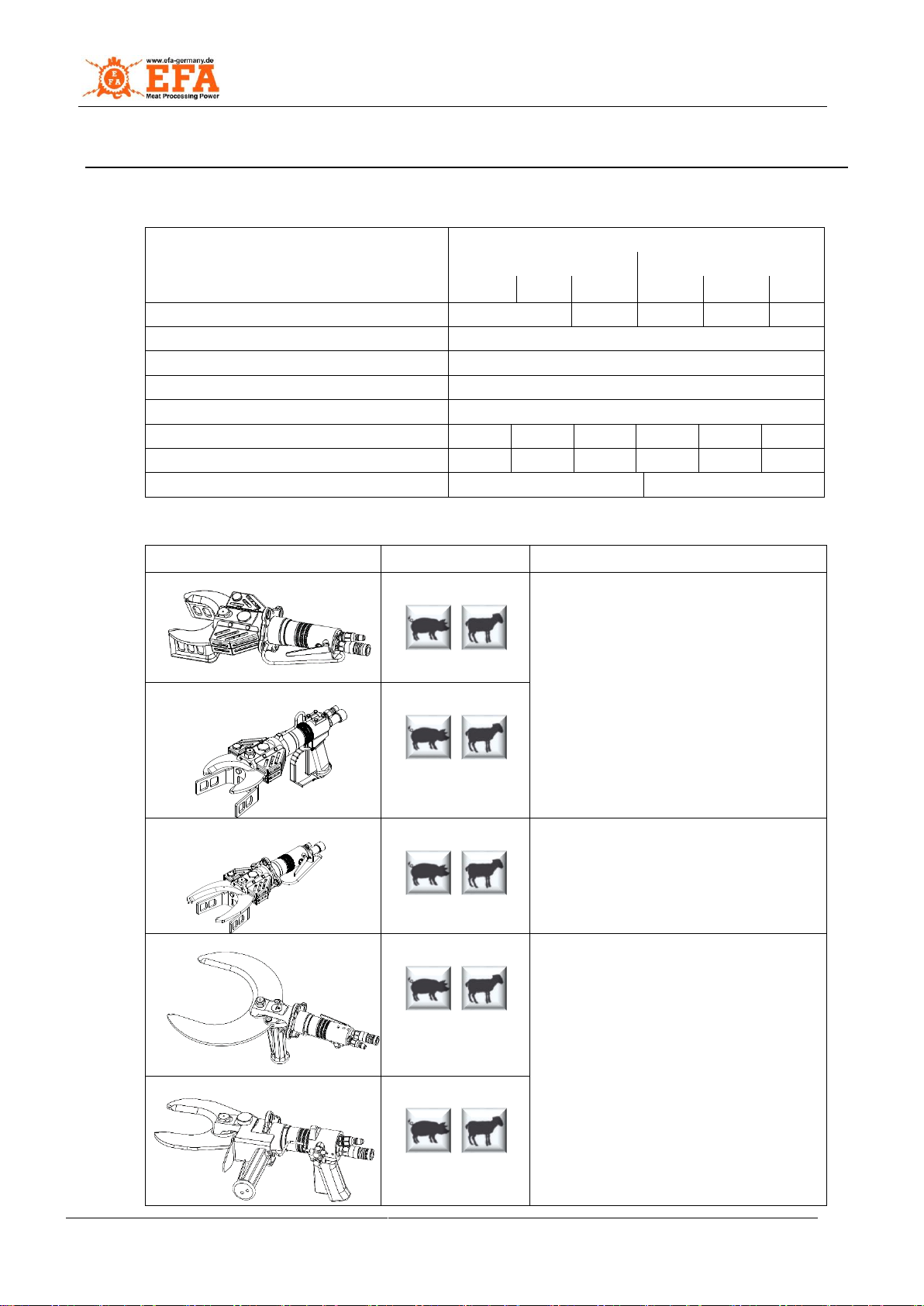

3. Technical description__________________________________________________________________ 8

3.1 Dimensions _____________________________________________________________________________ 9

3.2 Nameplate_____________________________________________________________________________ 12

4. Transport and storage ________________________________________________________________ 13

5. Connection and start-up ______________________________________________________________ 14

5.1 Initial start-up___________________________________________________________________________ 14

5.1.1 Spring balancer___________________________________________________________________ 14

5.1.2 Hydraulic unit_____________________________________________________________________ 15

5.1.3 Coupling and uncoupling the cutter____________________________________________________ 15

6. Handling___________________________________________________________________________ 16

6.1 Switch operation ________________________________________________________________________ 16

6.2 Working with the cutter ___________________________________________________________________ 17

6.2.1 Operational safety_________________________________________________________________ 17

7. Assembly__________________________________________________________________________ 18

7.1 Knife change___________________________________________________________________________ 18

7.1.1 Replacing the knives _______________________________________________________________ 18

7.1.2 Checking the knife play _____________________________________________________________ 19

7.1.3 Knife installation __________________________________________________________________ 19

7.1.4 Hydraulic unit_____________________________________________________________________ 19

8. Service and maintenance _____________________________________________________________ 20

8.1 Daily cleaning after completion of the slaughtering______________________________________________ 20

8.1.1 Cleaning the cutter ________________________________________________________________ 20

8.2 Daily maintenance of the cutter_____________________________________________________________ 21

8.2.1 Lubrication_______________________________________________________________________ 21

8.2.2 Knife play________________________________________________________________________ 21

8.3 Extended maintenance (after about 100 operating hours) ________________________________________ 21

8.3.1 Hydraulic unit_____________________________________________________________________ 21

8.3.2 Sharpening the knives______________________________________________________________ 22

8.3.3 Repair by customer service__________________________________________________________ 22

8.3.4 Return __________________________________________________________________________ 22

9. Waste disposal –recycling ____________________________________________________________ 23

9.1 Disassembly and disposal_________________________________________________________________ 23