SPX Marley Geareducer 2800 Series User manual

2800 - 2800S Series Geareducer®

INSTALLATION - OPERATION - MAINTENANCE

Z0927175_C ISSUED 06/2022 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT

user manual

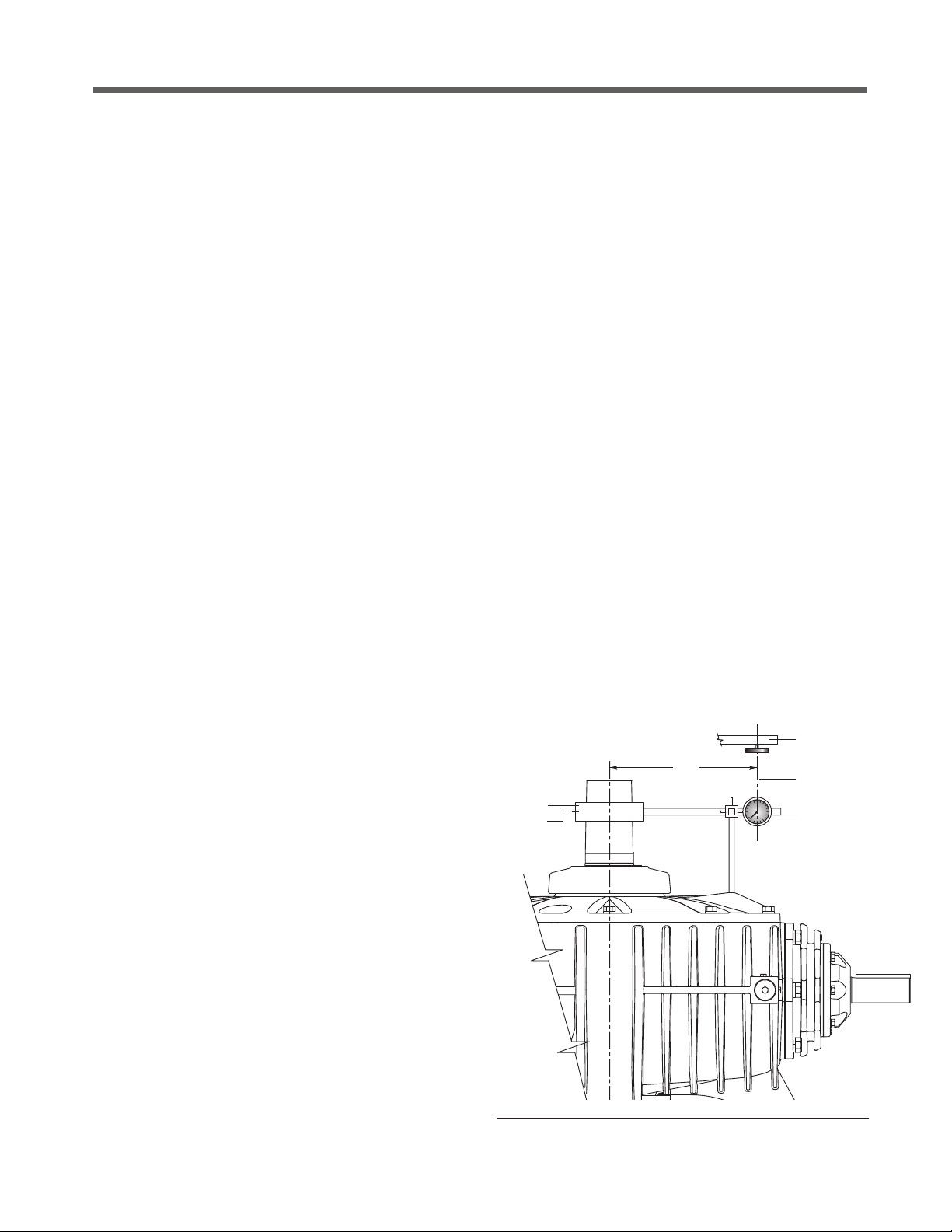

AIR VENT

OIL LEVEL

CHECK AND FILL

VIEW PORT

LOCATION

DRAIN

PLUG

OPTIONAL OIL HEATER

MOUNTING LOCATION

VIBRATION MOUNTING

LOCATION 1/4 - 28 UNF

Maintenance Service Monthly Semi-annually Seasonal Startup or Annually

Geareducer Drive:

Inspect and tighten all fasteners including oil plug x x

Check for and repair oil leaks x x x

Check oil level x R x

Change oil R R

Make sure vent is open x x

Check driveshaft or coupling alignment x

Inspect and tighten driveshaft or coupling fasteners x

Check driveshaft or coupling bushing / flex elements for unusual wear x

Lube Lines (if equipped)

Check for oil leaks in hoses and fittings x R x

R– Refer to instructions within this manual

Note: It is recommended at least weekly, that the general operation and condition be observed. Pay particular attention to any changes in sound or

vibration that may signify a need for closer inspection.

maintenance schedule

3

operation and service instructions

INITIAL PROTECTION AGAINST CORROSION

As shipped, a Marley Geareducer is protected internally against

corrosion with machine enamel on unmachined parts and with

rust-proofing oil and grease on machined surfaces. These coatings

normally protect the Geareducer against atmospheric corrosion

for storage periods up to six months. However, if oil is added to

the Geareducer, it will dissolve the rust-proofing grease and oil,

requiring the Geareducer to be operated once a week to keep a

protective coating of oil on all interior machined surfaces.

Check Geareducer exterior. If exterior finish has been damaged

during shipment or installation, touch up with epoxy paint as

required. If Geareducer is equipped with a remote dipstick/oil

level gauge and/or drain line, coat any exposed threads at pipe

joints to prevent corrosion.

INITIAL OPERATION

The Geareducer must be filled with oil to the full oil level mark on

theGeareducercasebeforeitisplacedinoperation.SeeChanging

Geareducer Oil section for oil filling instructions.

Geareducers supplied with new towers include oil for the initial

filling. Oil is not furnished with Geareducers supplied as spares

or on replacement orders. Before operating the mechanical

equipment, check to be sure the oil level is at the full mark at the

Geareducer and that the external gauge placard (if equipped) full

mark corresponds with the “Full” level in the Geareducer. Check

any oil lines to be sure there are no leaks.

Be certain that the vent on the Geareducer (and external dipstick/

oil level gauge, if present) is not plugged.

In order to assure long service life, the Geareducer and motor

must be level, and the drive shaft or coupling must be properly

aligned. Refer to the alignment instructions in the Driveshaft or

Coupling User Manual shipped with the cooling tower. Copies

are also available from your local Marley sales representative or

at spxcooling.com.

Note—If the tower is equipped with a two-speed motor, allow a

time delay of at least 20 seconds when switching from high speed

to low speed. Allow a time delay of at least two minutes when

changing direction of fan rotation. Failure to provide these delays

may significantly reduce equipment service life.

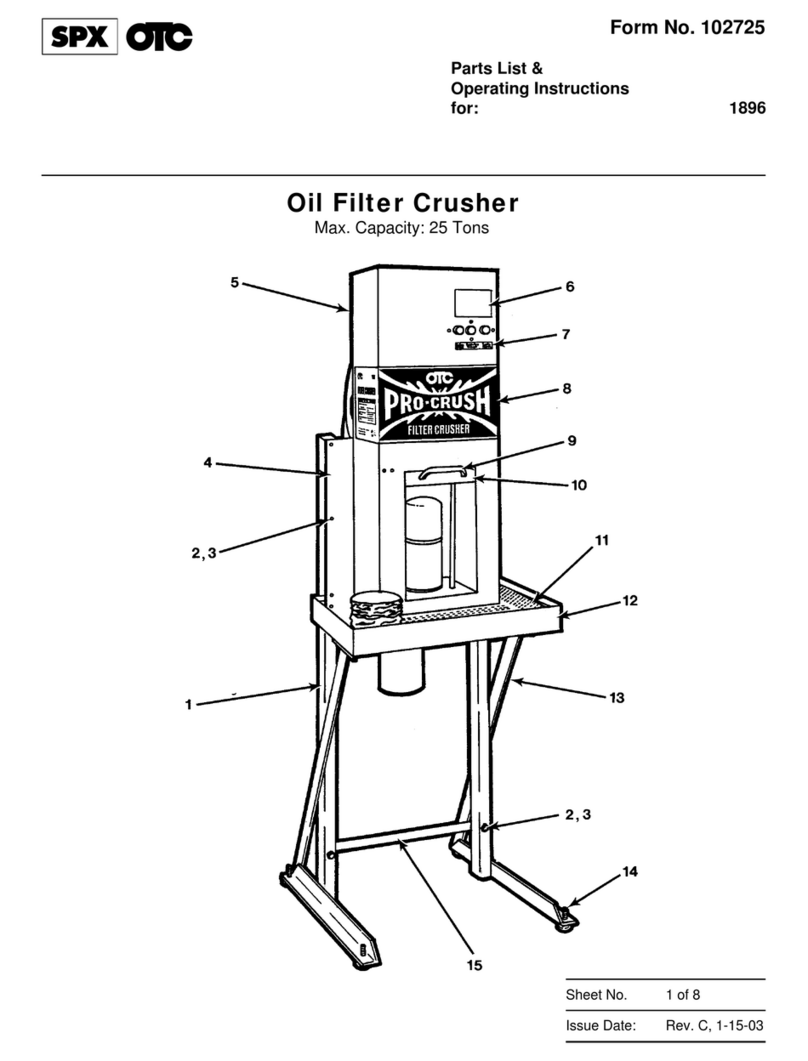

FIGURE 1 Service Fittings

AIR VENT

OIL LEVEL

CHECK AND FILL

VIEW PORT

LOCATION

DRAIN

PLUG

OPTIONAL OIL HEATER

MOUNTING LOCATION

VIBRATION MOUNTING

LOCATION 1/4 - 28 UNF

4

operation and service instructions

SCHEDULED MAINTENANCE

Warning—Make certain that mechanical equipment is inoperable

during periods of maintenance—or during any situation of possible

endangerment to personnel. If your electrical system contains

a disconnect switch, lock it out until the period of exposure to

injury is over.

Monthly—Check Geareducer oil level. Shut down the unit and

allow 5 minutes for the oil level to stabilize. Add oil if required,

noting the addition in your maintenance log. If equipped with an

external dipstick/oil level gauge, small quantities of oil can be

added at that location.

Semi-annually—If using turbine-type mineral oil, change oil—see

Changing Geareducer Oil for instructions. Check that all the

assembly bolts and cap screws are tight, that oil plugs and pipe

connections are in place and free from leaks, and that the vent on

the Geareducer (and external dipstick/oil level gauge, if present) is

clear—a clogged vent can lead to oil leaks. Intermittent operation

and extended periods of downtime can cause condensation of

water in the oil. If using synthetic Marley Gearlube, the oil condition

must be inspected every six months—see Changing Geareducer

Oil for maximizing service life.

Annually—Check mechanical equipment anchor bolts, drive shaft

coupling bolts, and coupling set screws. Tighten as required. Check

Geareducer exterioryearlyandtouch up with epoxy paint if required.

Coat all exposed threads at pipe joints to prevent corrosion.

Every 5 Years—If using synthetic Marley Gearlube, change oil.

To maintain five-year change intervals, use only synthetic Marley

Gearlube. It is recommended to monitor the oil condition every

six months throughout the five-year period per the instructions in

Changing Geareducer Oil.

LUBRICANTS

To ensure maximumperformanceand service life, it is recommended

Marley factory lubricants be used in all Marley Geareducers.

Marley lubricants can be purchased through your local Marley

sales representative.

If lubricants other than Marley factory lubricants are used, they must

not contain any additives (such as detergents or EP additives) which

are adversely affected by moisture and could reduce the service

life of the Geareducer. The responsibility for use of lubricants other

than Marley factory lubricants rests with the customer/owner and

the lubricant supplier.

Seasonal temperature changes may require one viscosity of oil for

summer operation and another for winter operation. Refer to the

tables below for the seasonal selection information.

Table 1 Oil viscosity

Winter or Summer Severe Duty/High Temperature

Air Temperature at Geareducer

Below 110°F (43°C) Above 110°F (43°C)

ISO 150 ISO 220

5

CHANGING GEAREDUCER OIL

Drain the Geareducer oil by removing the drain plug. See

Figure 1 for location. If equipped with an external dipstick/oil

level gauge, remove the drain plug at that location, and drain the

entire system.

When using synthetic oil with extended service intervals remove a

sample for lab analysis and look for evidence of foreign material,

such as water, metal shavings or sludge. If you find unacceptable

condensation or sludge, flush the Geareducer with mineral oil

before refilling.

After inspection is complete, fill the Geareducer with 6.25 gallons

(24 liters) of oil. See Figure 1 for location. If the Geareducer is

equipped with an external dipstick/oil level gauge an additional 3

to 4 quarts of oil will be required. Be certain that the vent on the

Geareducer (and external dipstick/oil level gauge, if present) is

not plugged. Verify that the gauge/drain line is full and that there

aren't any leaks at the connections.

Alternate procedure:

If the cooling tower has an external oil gauge and drain line

equipped with a three-way valve below the oil level gauge. See

Figure 2.

1. Remove pipe plug. Turn valve control stem clockwise to open

drain.

2. With Geareducerdrained, thethree-way valve turnedclockwise,

and the pipe plug removed, connect fill source (usually a hose

to a pump, to the three-way valve).

operation and service instructions

Pump oil through the hose. Check oil level occasionally by

turning the valve control stem counterclockwise and allowing

the oil level in the sight glass to stabilize. Continue filling until

full level mark is reached.

3. With the oil level at the full mark turn the valve control stem

counterclockwise to close the drain and open the valve to

the sight glass. Remove the oil filling line and reinstall pipe

plug in the three-way valve.

REPAIR AND OVERHAUL

The Model 2800 Geareducer is assembled using specialized

tools and fixtures. Bearings and gear sets are unique and not

available from other sources. Geareducers can be repaired in the

field—however, major repairs require the use of a fully equipped

machine shop. Refer to the Field Repair section of this manual

for further instructions.

If your Geareducer ever needs repair or replacement, Marley

recommends returning the unit to a Marley factory service center.

Contact your Marley sales representative to discuss course of

action. The Marley Order Number on your cooling tower will be

required if the Geareducer is shipped back to the factory for repair.

Obtain a “Customer Return Material” tag from the Marley sales

representative in you area.

To find your Marley sales representative call 800 462 7739 or

visit at spxcooling.com.

OIL LEVEL CHECK

OIL GAUGE

AND DRAIN LINE

OIL GAUGE

VENT

OIL LEVEL

GAUGE

DRAIN PLUG

THREE-WAY

VALVE

FIGURE 2 Service Fittings

6

FIGURE 3

parts list

BEARING

RETAINER

PINION

CAGE

CAP

DOWEL PIN

407

GEAREDUCER

CASE

VIEW PORT

BOTTOM CAP

204

206

205

404

306

304

VENT

406

201

CASE COVER

WATER

SLINGER

DOWEL PIN

027

101

008

303

305

403

301

401

302405

104

103

105

104

402

PINION

CAGE

VIBRATION INSTRUMENT

MOUNTING LOCATION

1/4"-28 UNF 106

307

101

504

203

405

2800S ASSEMBLY

PINION

CAGE

CAP

7

1 Complete Geareducer Assembly

100 Spiral Bevel Gear Set

008 Ring Gear Hub

101 Set of Matched Spiral Bevel Gears, including integral pinion shaft with key

Gear Ratios as follows: 5.07:1 5.46:1 6.15:1 6.82:1 7.90:1

027 Ring Gear Attaching Hardware

103 Pinion Key

104 Lock Nut

105 Lock Washer

106 Oil Slinger

200 Fan Shaft Set

201 Fan Shaft

202 Fan Key

203 Ring Gear Hub Key

204 Fan Retention Washer

205 Fan Retention Cap Screw

206 Fan Retention Lock Washer

Pinion Shaft Bearings

301 Head Tapered Roller Bearing

302 Tail Tapered Roller Bearing

Fan Shaft Bearings

303 Lower Tapered Roller Bearing

304 Upper Tapered Roller Bearing

Shim Packs

305 Fan Shaft Shims

306 Retainer Shims

307 Pinion Cage Shims

O-Rings

401 Pinion Cage O-ring

402 Pinion Cage Cap O-ring

403 Bottom Cap O-ring

404 Water Slinger O-ring

Seals

405 Pinion Shaft Oil Seal

406 Fan Shaft Seal

407 Fan Shaft Wear Sleeve

Miscellaneous

500 Oil Heater Element (not shown)

504 Magnet

PARTS LIST

parts list

8

field repair

GENERAL

Geareducers can be repaired in the field—however, major repairs

require the use of a fully equipped machine shop. When field repair

or replacement of parts is necessary, the following procedure is

recommended for the disassembly and assembly of the unit. If any

O-ring, oil seal or gasket is to be reused, care should be taken

not to damage it during disassembly. Parts which contain O-rings

or seals should not be jerked or twisted past a shoulder or edge.

These parts are marked with an asterisk (*) in the description

below. O-rings, oil seal and gaskets should be carefully inspected

for damage before being reinstalled. Marley recommends that new

O-rings and oil seals be installed during a major overhaul.

DISASSEMBLY

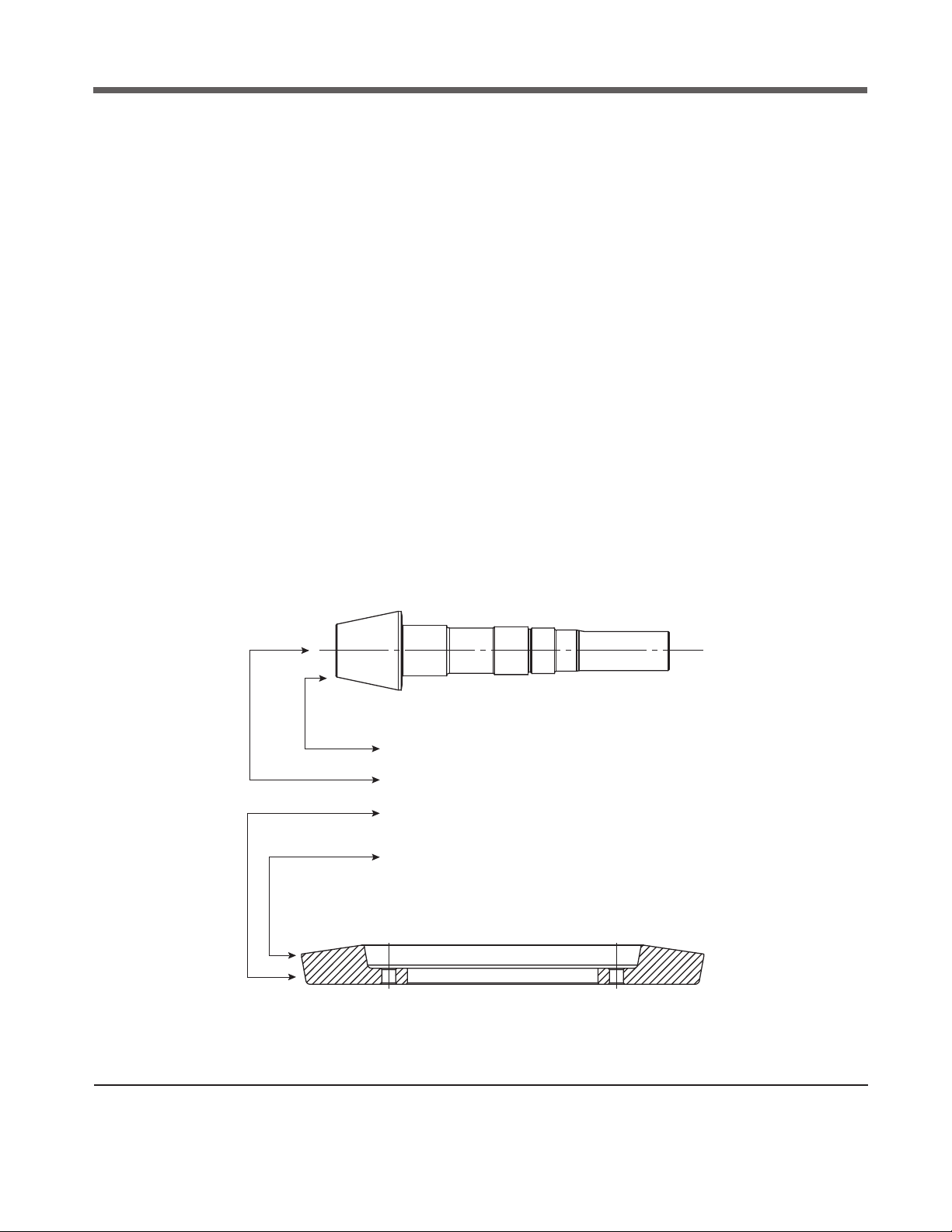

Part numbers and references—refer to Figure 3.

1. Drain oil.

2. Remove outer ring of bolts in pinion cage and remove pinion

subassembly*.

Note—The thickness of the shim pack (307) is important in

resetting the gears. The shim pack should either be saved or

carefully measured with a micrometer. If the gears are to be

replaced, record the pinion setting distance that is etched on

the pinion gear. See Figure 4.

3. Remove water slinger*.

4. Remove bearing retainer and shim pack (306) from top of

case.

Note—The thickness of this shim pack is important in

the endplay setting of the gears. The shim pack

should either be saved or carefully measured with a

micrometer.

FIGURE 4 Gear Match Numbers and Setting Data

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE RING GEAR. (EXAMPLE CO-43)

PINION SETTING DISTANCE. (EXAMPLE 4.860)

BACKLASH (NORMAL) AT WHICH THE GEARS WERE

LAPPED. (EXAMPLE .010)

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE PINION GEAR. (EXAMPLE C0-43)

THE PINION SETTING DISTANCE IS THE DISTANCE

THE END OF THE PINION SHOULD BE FROM THE

CENTERLINE OF THE RING GEAR SHAFT.

9

5. Drive dowel pins down into case.

6. Remove bolts, pry case cover off and lift fan shaft assembly

out of the case.

7. Turn case over and remove bottom cap and shim pack (305).*

Note—The thickness of this shim pack is important in setting the

backlash. This pack should be saved or carefully measured with

a micrometer.

8. Remove bearing cups (303 and 304) from the Geareducer

case and cover.

9. Remove fan shaft seal from upper bearing retainer and wear

sleeve from water slinger.

PINION CAGE DISASSEMBLY

1. Remove pinion cage cap* from pinion cage.

2. Remove O-ring* (402).

3. Remove locknuts and lockwasher (104 and 105) then press

pinion shaft (101) out of pinion cage. This will free tail bearing

cone (302). Remove O-ring* (401) from pinion cage.

4. Press oil slinger (106) and head bearing cone (301) from

the pinion shaft.

5. Press bearing cups (301 and 302) out of pinion cage.

FAN SHAFT DISASSEMBLY

1. Remove ring gear (101) from the ring gear hub

(008).

2. Press fan shaft (201) through lower bearing cone (303) and

ring gear hub (008).

3. Remove lower fan shaft key (203).

4. Press fan shaft (201) through upper bearing cone (304).

ASSEMBLY

Before assembling a new pinion gear in the pinion cage, check

match numbers on pinion gear and spiral bevel ring gear to be

certain that they are a matched set. Gears are lapped in matched

sets at the factory and should not be separated. Numbers are

etched on both the pinion and ring gear as illustrated in Figure 4.

All parts that are to be reused should be thoroughly cleaned

before being reinstalled. It is recommended to replace all bearing

assemblies.

PINION CAGE SUBASSEMBLY

1. Place oil slinger (106) on pinion shaft. It is recommended to

heat the slinger on an induction (bearing) heater so that it

may be slid over the shaft.

2. Press head bearing cone (301) on pinion shaft making sure

oil slinger and bearing are against gear.

3. Press bearing cups (301 and 302) into pinion cage.

4. Lower pinion cage on pinion shaft, until head bearing cone

and cup mate.

5. Press tail bearing cone (302) on pinion shaft until it mates

with its bearing cup. Do not over engage. Pinion cage should

rotate freely.

6. Install locknuts and lockwasher (104 and 105). Tighten nuts

on bearing cone until 8 to 15 in·lbƒ (904-1695 mN·m) of

bearing preload is obtained. Bearing preload is the resistance

in the bearings to shaft rotation measured in in·lbƒ required

to rotate the shaft at uniform velocity. Preload is necessary

to ensure gear mesh stability and to maximize bearing life.

Bend tab(s) on lockwasher to secure locknut in place.

7. Install O-ring (401) in groove on pinion cage.

8. Press pinion shaft seal (405) into pinion cage cap.

9. Install pinion cage cap onto pinion cage by gently sliding over

pinion shaft (without key) taking care not to damage pinion

shaft seal.

10. Tighten pinion cage cap screws to 25 ft·lbƒ (34 N·m).

11. Record the pinion setting distance that is etched on the pinion

gear. See Figure 4.

INSTALLATION OF FAN SHAFT

1. Press ring gear hub (008) and the upper and lower bearing

cones (303 and 304) on the fan shaft (201). Install ring gear

(101) on ring gear hub and tighten cap screws to 115 ft·lbƒ

(156 N·m).

2 Install the bottom cap using old shim pack or make up

equivalent thickness shim pack (305). Torque bolts to

45 ft·lbƒ (6 N·m).

3. Align and tap lower fan shaft bearing cup (303) into position.

4. Install fan shaft assembly in case.

5. Align and tap upper fan shaft bearing cup (304) into position.

Apply a bead of sealant to the cover flange inboard of the

bolt holes. Install cover on case. Install dowel pins in cover

and drive flush with top of cover.

6. Install cap screws and tighten to 45 ft·lbƒ (61 N·m).

field repair

10

field repair

7. Install bearing retainer using old shim pack (306) or equivalent

thickness and tighten cap screws to 45 ft·lbƒ (61 N·m).

8. Measure fan shaft end play with a dial indicator on a surface

normal to the plane of rotation. Lift shaft axially with no more

than 500 lbƒand rotate slowly until all movement stops.

Zero the dial indicator. Lower shaft (zero lifting load) and

rotate shaft until axial movement stops. End play will be

read directly from the dial indicator. Adjust the fan shaft

bearings to .001-.003"(.025-.076mm) end play. The end

play is adjusted by adding or removing shims (306) under

the bearing retainer.

9. Once proper and play is obtained install fan shaft oil seal in

upper bearing retainer.

INSTALLATION OF PINION CAGE

1. Find the difference between the pinion setting distance of

the old gear and the new pinion gear and adjust the old shim

pack (307) or make a new shim pack to compensate for the

different setting distances.

Example:

Pinion setting distance of old gear 6.505

Pinion setting distance of new gear 6.500

Difference .005

Remove .005 from shim pack.

2. Engage pinion gear tooth with “X” marked on end between

ring gear teeth marked with “Xs”. Care must be taken not to

damage the pinion gear teeth by forcing them into the ring

gear teeth.

3. Install pinion cage subassembly into case and tighten cap

screws to 75 ft·lbƒ (102 N·m).

GEAR SETTING PROCEDURE

The proper mounting of the gear set is essential to obtain long

life and smooth operation of the gears. The pinion and ring gears

were positioned approximately in the preceding steps. The correct

gear position is determined by the gear backlash.

1. With the “X” marked tooth on the pinion gear engaged

between the two “X” marked teeth on the ring gear, check

the backlash with a dial indicator as shown in Figure 5. Lock

the pinion shaft against rotation. The amount of movement

of the fan shaft, measured at a distance equal to the outside

radius (9.5") of the ring gear is the backlash. Obtain backlash

setting by adjusting ring gear axially by removing or adding

shims (305) at bottom bearing cap.

Note—To maintain the previous fan shaft bearing endplay

adjustment, a corresponding shim (306) adjustment must be made

at the bearing retainer.

Example: Removing .003" shims at the bottom bearing cap

requires the addition of .003" shims at the bearing retainer to

maintain correct bearing adjustment.

Recheck the backlash to make sure it is within the proper limits.

3. After the equivalent backlash setting has been obtained with

the marked teeth in mesh, check the backlash at two other

points on the ring gear (points approximately 120° apart). If

necessary, adjust shim stack-up at bottom bearing to result

in all three measurements being within a range of -.003" to

+.006" of the primary marked reference. An attempt should

be made to obtain a primary reading close to the reference

value while still meeting the tolerance for the other two

measurement locations.

FINAL ASSEMBLY

1. Remove bottom cap and apply a bead of sealant to the bottom

cap flange inboard of the bolt holes. Reinstall the bottom

bearing cap and tighten the cap screws to 45 ft·lbƒ (61 N·m).

2. Install wear sleeve (407) on water slinger.

3. Install O-ring (404) in water slinger.

4. Apply assembly grease to fan shaft and install water slinger

ensuring slinger is fully seated into the bearing retainer.

5. Replace air vent and all pipe plugs.

6. Fill with lubricant selected from Table 1.

TOP VIEW

OF INDICATOR

POINT OF MEASUREMENT

OUTSIDE RADIUS OF GEAR

DIAL INDICATOR

SET SCREW

COLLAR

9.5"

FIGURE 5 Gear Backlash Measurement

11

Z0927175_C | ISSUED 06/2022

COPYRIGHT © 2022 SPX TECHNOLOGIES

In the interest of technological progress, all products are subject to design

and/or material change without notice.

Geareducer

USER MANUAL

SPX COOLING TECH, LLC

7401 WEST 129 STREET

OVERLAND PARK, KS 66213 USA

spxcooling.com

This manual suits for next models

1

Table of contents

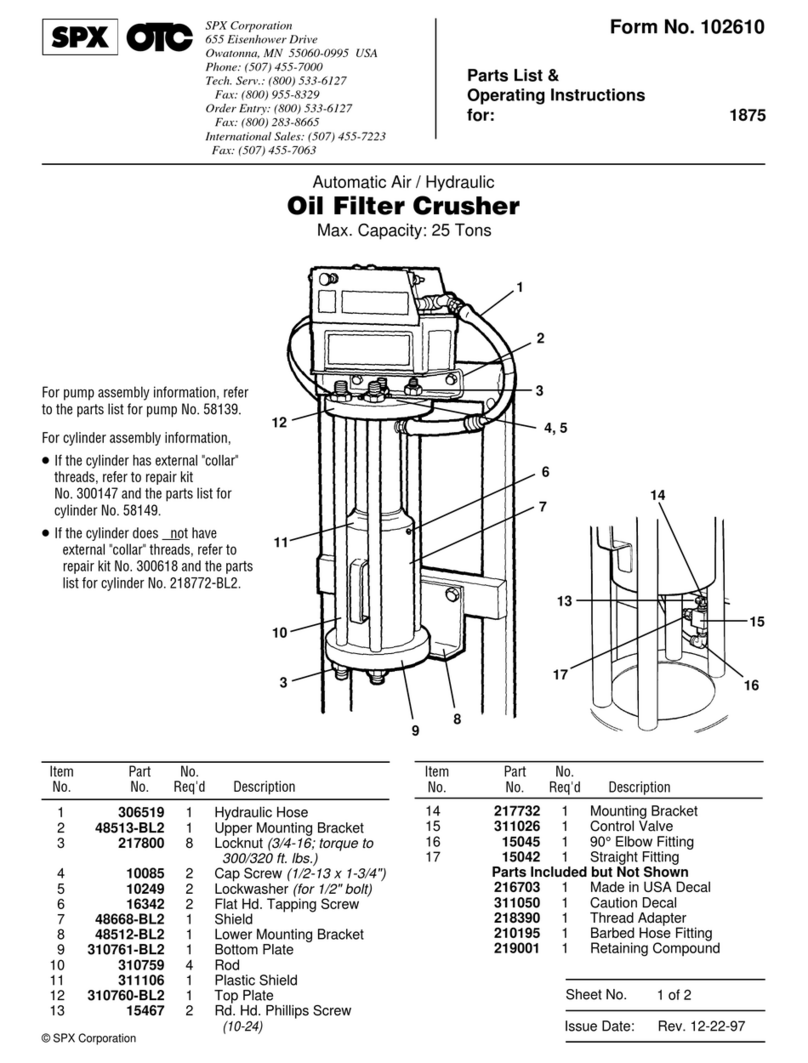

Other SPX Industrial Equipment manuals

SPX

SPX Marley Geareducer 34.4 Series User manual

SPX

SPX APV ParaFlow User manual

SPX

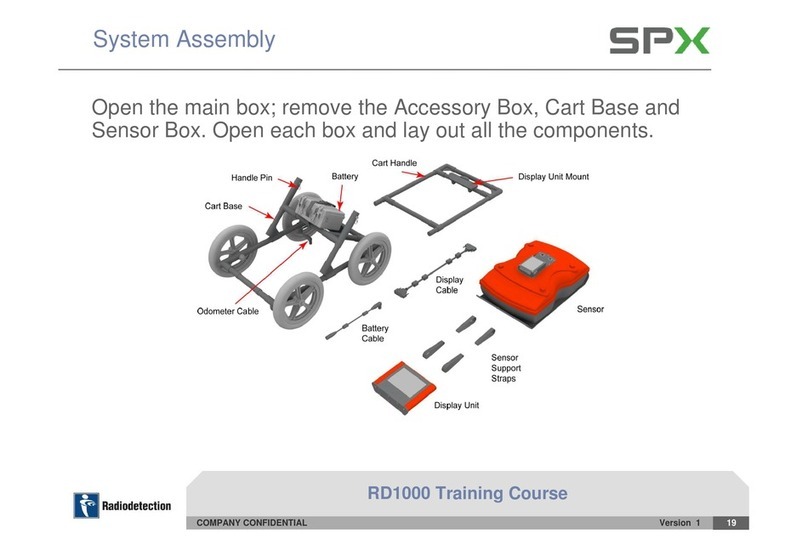

SPX RD1000 User manual

SPX

SPX Hankison Trip-L-Trap 505 User manual

SPX

SPX CUES ACCUPOINT MS611 User manual

SPX

SPX Power Team HNS150A User manual

SPX

SPX APV Cavitator User manual

SPX

SPX Waukesha Cherry-Burrell Votator II User manual

SPX

SPX Marley Geareducer 32.2 Series User manual

SPX

SPX OTC PRO-CRUSH 1896 User manual