Revision 1.0 Page iii

Table of Contents

1Introduction ...........................................................................................................................1

1.1Firmware Revision.................................................................................................... 1

1.2TMP100 Features..................................................................................................... 1

1.3TMP100 Accessories................................................................................................ 2

1.4Quick Install.............................................................................................................. 2

2Installation .............................................................................................................................2

2.1Unpacking the Box ................................................................................................... 2

2.2Choosing a Mounting Location ................................................................................. 2

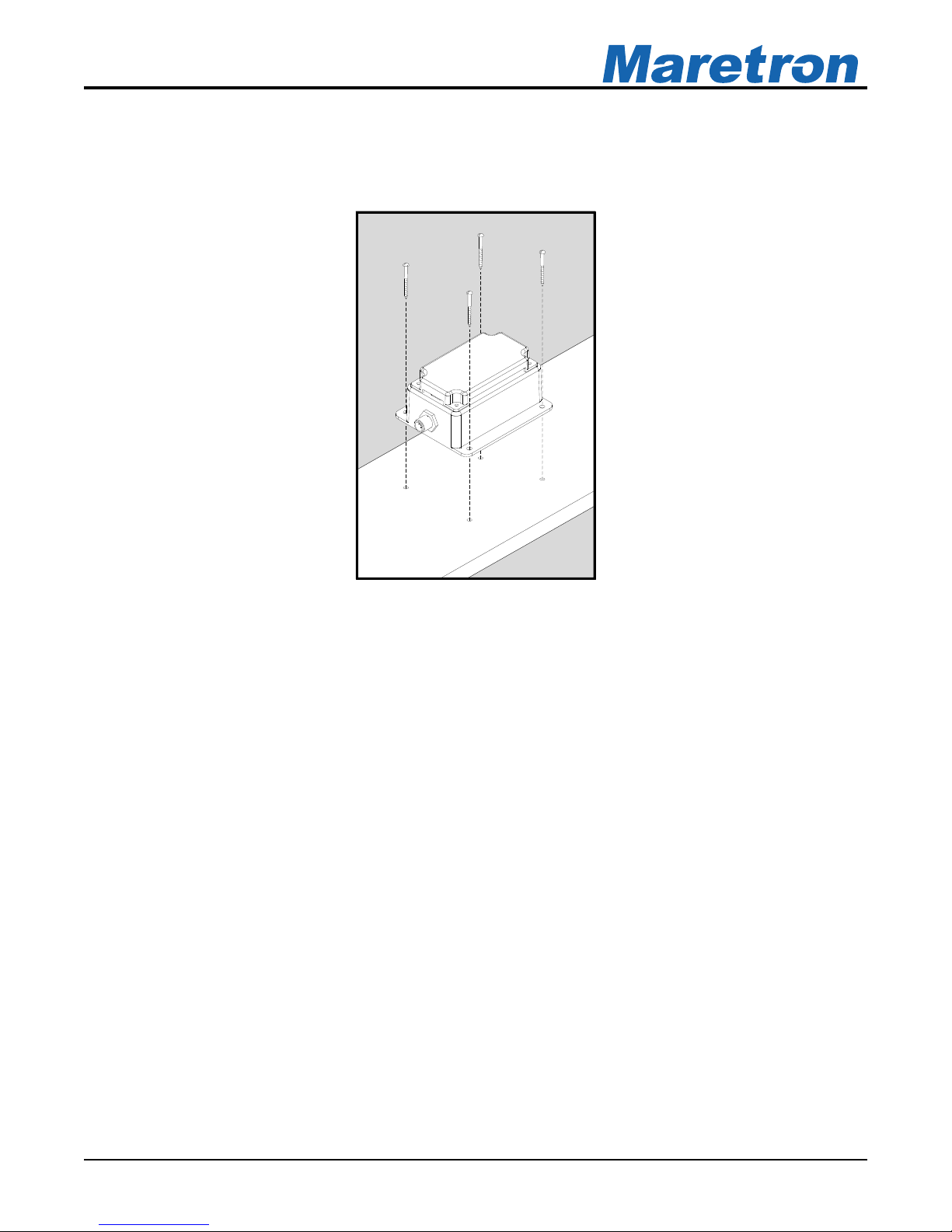

2.3Mounting the TMP100 .............................................................................................. 3

2.4Connecting the TMP100........................................................................................... 3

2.4.1NMEA 2000®Connection............................................................................... 3

2.4.2Temperature Probe Connections................................................................... 4

2.4.2.1Exhaust Gas Temperature (EGT) Probe.......................................... 5

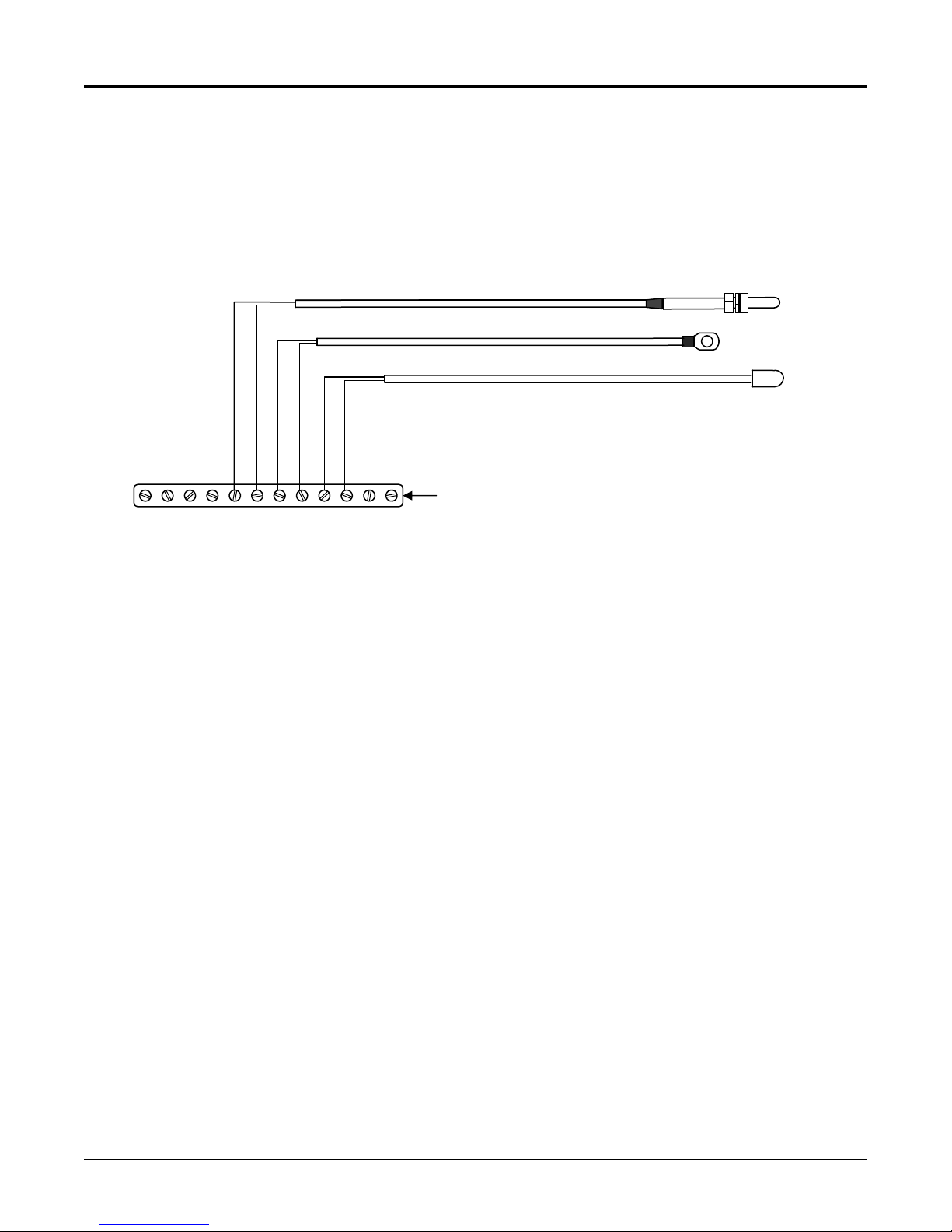

2.4.2.2Thermistor Type Probes (Ring/Under Bolt, Ambient Air, or

Immersion Probe) .......................................................................................... 5

2.4.3Checking Connections................................................................................... 6

2.5Configuring the TMP100........................................................................................... 6

2.5.1Channel #0 - #1 Source................................................................................. 6

2.5.2Channel #2 - #5 Source................................................................................. 7

2.5.3Channel #0 - #5 Instance............................................................................... 7

2.5.4Channel #0 - #5 Label ................................................................................... 7

2.5.5Advanced Configuration…............................................................................. 7

2.5.5.1NMEA 2000®PGN Enable/Disable .................................................. 7

2.5.5.2Restore Factory Defaults ................................................................. 7

2.5.5.3Installation Description… ................................................................. 8

3Maintenance..........................................................................................................................8

4Troubleshooting ....................................................................................................................8

5Technical Specifications........................................................................................................9

6Technical Support ...............................................................................................................10

7Installation Template ...........................................................................................................11

8Maretron (2 Year) Limited Warranty....................................................................................12

Table of Figures

Figure 1 – Mounting the TMP100 .............................................................................................. 3

Figure 2 – NMEA 2000®Connector Face Views ....................................................................... 4

Figure 3 – Exhaust Gas Temperature Probe Connection Diagram ........................................... 5

Figure 4 – Ring/Under Bolt, Ambient Air, or Immersion Temperature Probe Connection

Diagram.............................................................................................................................. 6

Figure 5 – Mounting Surface Template ................................................................................... 11