P-047550-1385 ISSUE 4 © 1998

Installation Instructions for Catalog Series 96DV2(*)-N5

AdaptaBeacon® Signals

EDWARDS

Description

The catalog number 96DV2(*)-N5 AdaptaBeacon signal is a UL

listed small strobe light. The signals are suitab le for indoor or

outdoor (weatherproof) installation and ha ve type 4X enclosure

protection. They are suitable for installation in the Di vision 2

locations listed in Table 1.

These signals are designed for mounting on 1/2" (13 mm) NPT

conduit.

Electrical Specifications

Rated Voltage ................................................. 120V 50/60 Hz

Current ..................................................................... 0.10 Amp

Installation

Install in accordance with the latest edition of the National Elec-

trical Code and local r egulations.

Maintenance

Cleaning

WARNINGS

To reduce the risks of igniting hazar dous atmo-

spheres and electric shock, ensure that power is

disconnected before installing the signal.

To prevent leakage and a potential shock hazard,

when mounting outdoors the signal m ust be

installed with the lens or dome facing directl y up.

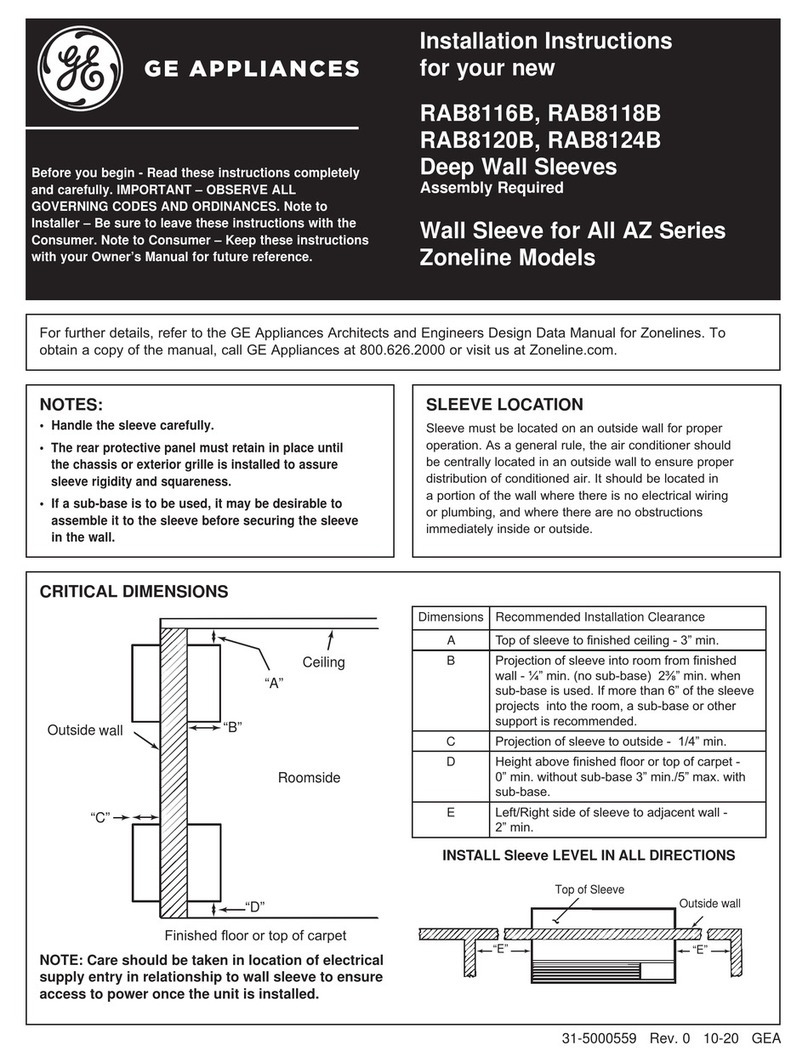

1. Refer to F igure 1. The signals require 1/2" (13 mm) NPT

conduit (not supplied). Route the 18" (457 mm) wire leads

coming from the bottom of the signal mounting base through

the conduit. Thread the conduit into the signal mounting

base.

2. Using wire nuts (not supplied), connect field wiring to signal

wiring. Connect the green ground wire leads using wire nuts

(not supplied). Insert the wires into an appropriate electrical

junction box.

Troubleshooting

If the strobe light fails to operate, make sure there is power to the

signal. If there is po wer and the strobe still f ails to operate , re-

place the strobe tube as directed in the Strobe Tube Replacement

section.

Periodically clean the AdaptaBeacon lens surf ace, to maintain

optimum light visibility . The lens may be cleaned with a soft

cloth or sponge using water or a mild detergent solution. Ensure

that the lens is completely dry before assembling the signal.

Strobe Tube Replacement

CAUTION

To prevent damage to the lens, do not use abrasive

materials or cleaners.

Refer to Table 2 for the requir ed strobe tube.

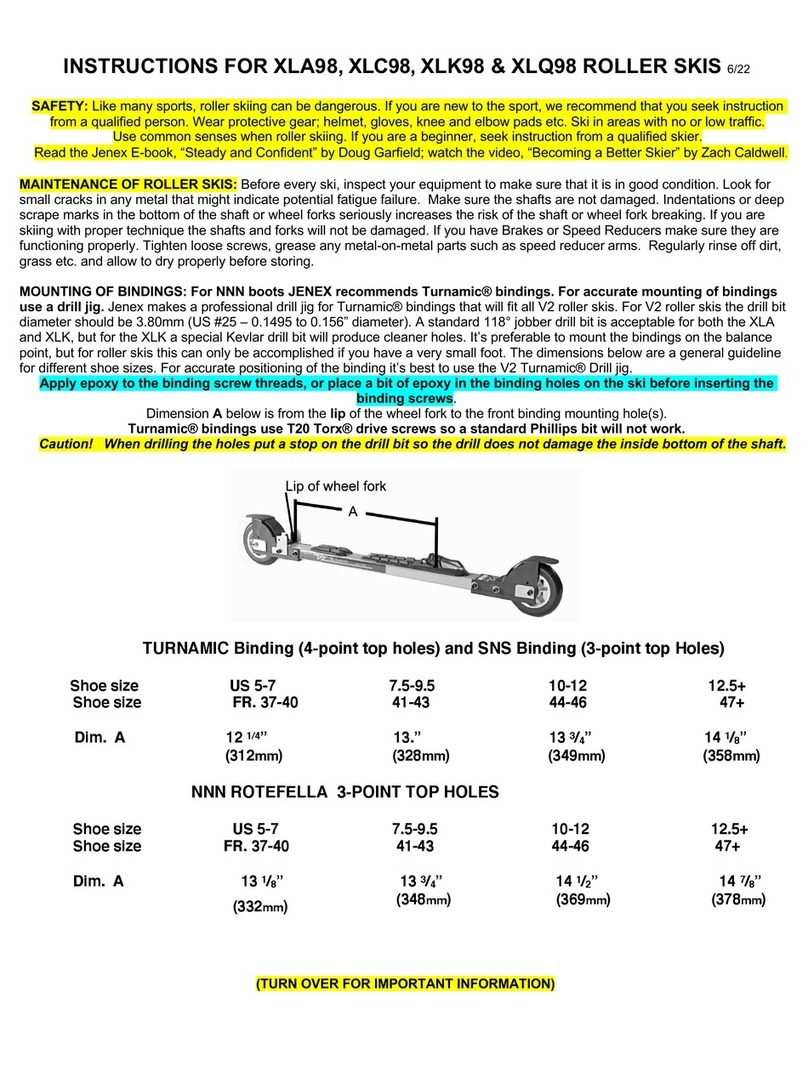

1. Refer to Figure 2. Remo ve the scre w in the clamp ring,

remove ring, and set aside. Carefully lift the lens straight up

and off the signal mounting base, being careful not to damage

the strobe tube or lens gasket. If the lens adheres to the gasket

on the signal base do not force apart by hand b ut car efully

pry the lens off using a thin blade scre wdriver.

*The letter in this position signif ies the color of the supplied lens. A - amber, B - blue, C - clear, G - green, M - magenta or R - red.

WARNINGS

To reduce the risks of igniting hazar dous

atmospheres and electric shock, ensure that power

is disconnected before installing the signal.

Do not

connect power until installation has been

completed and unit is tightl y assembled and

secured.

To prevent leakage and a potential shock hazard,

use care when disassembling the signals to

prevent tearing of the gaskets.

CAUTION

To prevent damage to the strobe tube, handle the

strobe tube only by the base.

2. Grasp the strobe tube by its base and pull straight up from its

socket. Install the new strobe tube by aligning the connector

on the base of the tube with the mating soc ket. Carefully

press down into the soc ket.

3. Assemble the signal.

4. Turn on power and verify that the strobe operates.