3INSTALLATION

Installation Instructions

CAUTION: BE SURE TO READ!

• Keep this appliance area free and clear of com-

bustibles.

• Do not obstruct the ow of combustion and ven-

tilation air.

• Allow adequate ventilation to unit. Install under

exhaust hood.

• Keep this manual for future reference.

• This installation must conform with local codes

or, in the absence of local codes, with National

Fuel Gas Code, ANSI Z223.1 – latest edition; or

the Natural Gas Installation Code, CAN/CGA–

B149.1; or the Propane Installation Code, CAN/

CGA-B149.2, as applicable.

• The griddle and its individual shuto valve must

be disconnected from the gas supply piping sys-

tem during any pressure testing of that system

at test pressure in excess of ½ psig (3.45 k/Pa).

• The griddle must be isolated from the gas supply

system by closing its individual manual shuto

valve during any pressure testing of the gas sup-

ply piping system at test pressures equal to or

less than ½” psig (3.45 k/PA).

• This unit is serviceable from the front. Do not

install in such a manner that a service person

cannot remove front panels if provided.

• When installed, this appliance must be electrical-

ly grounded in accordance with local codes, or,

in the absence of local codes, with the National

Electric Code, ANSI/NFPA No. 70 – latest edition.

• In Canada, this installation must conform to

C.S.A. Standard C22.2 Canadian Electrical Code.

• The wiring diagram adhesive label is located on

the inside of the control box cover.

• The product must be installed in a room with ad-

equate air supply for complete gas combustion.

• Do not place on or directly against the unit any

objects that would block air openings into the

combustion chamber.

• Suitable for use on combustible oors.

• Clearances from both combustible and noncom-

bustible construction are 0” (0 mm) from side

walls, 10” (254 mm) from rear wall.

• This unit has a exible cord wired into electrical

system.

GENERAL INSTALLATION

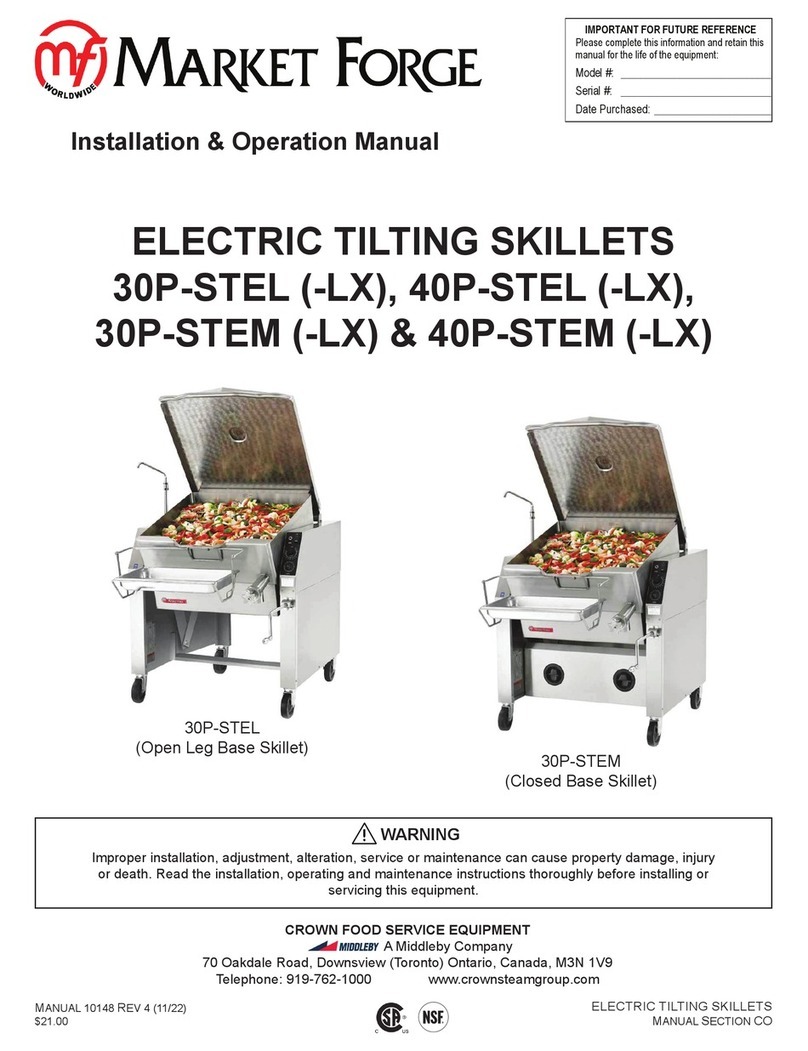

1. Remove carton from skid, being careful not to dent or

scratch nished surface of the unit.

2. Inspect unit carefully for shipping damage. File clam

with carrier immediately if damage is found.

3. Remove screws holding unit to skid.

4. Transfer unit to desired position and make level and

steady by adjusting feet to compensate for oor ir-

regularities. Bolt the ange feet to the oor.

5. Raise skillet cover to full open position. Raise skillet

by turning crank clockwise. Check to make sure burn-

ers and carryover tube are in position and securely

seated.

6. Lower skillet by turning hand crank counterclockwise

until fully seated on frame. Skillet is equipped with

interlock switch, which does not permit burners to ig-

nite until skillet is lowered to less than 10o o normal

horizontal cooking position.

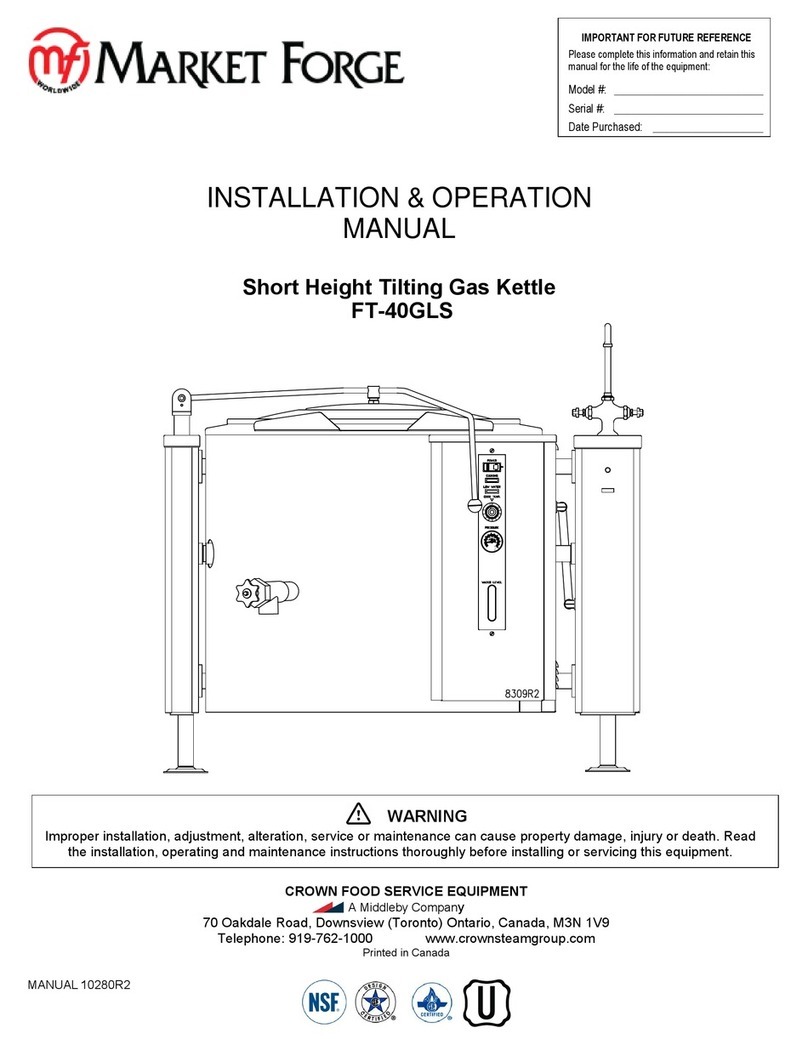

7. Gas service conditions:

DO NOT CONNECT GAS LINES. Only qualied in-

staller or service person should make the instal-

lation.

a. This unit is factory-adjusted for gas consump-

tion of 93,000 BTU/Hour (on 30 gallon units) or

126,000 BTU/Hour (on 40 gallon units) at the

pressure indicated. Please read rating plate on

top of control box. If this plate is marked for a dif-

ferent gas than that supplied, notify your dealer

immediately.

b. Use new 3/4 I.P.S. iron or steel pipe comply-

ing with ANSI Standard for wrought-steel and

wrought-iron Pipe B36- latest edition, properly

threaded, reamed and free from chips, oil and

dirt. If pipe dope is used, apply a moderate

amount, leaving two end threads bare. Gas con-

nection is on the rear of the right console. Pipe in

a gas shut-o valve accessible to the operator.

c. Natural gas units are equipped with a pressure

regulator factory-adjusted to give 3.5” (89mm)

water column manifold pressure. The supply

pressure must be at leaset 7” (178mm) water

column pressure.