42

Technical Specifications

Power Output When Used with the 60061/60101 power-supply unit

Input voltage: min. 14 V= / max. 24 V ~

Load: Train operating track 3 amps / 5 amps

Programming track 1.0 amps

Maximum 5,0 amps

Please take note of the specifications in the Help function for this unit so that you can make

full use of the total possible load.

Display resolution: 800 x 480 Pixels with 16 Bit color depth

Possible Connections

Power-supply unit

Programming track

Mobile Station

Feeder track

Network: Ethernet

USB: for a mouse, keyboard, and/or memory stick

Booster: 6015, 6017, or 60174

Feedback Module: S 88

Aux: currently not used

Outlet: Connections for a Central Station (60213/60214/60215), the Terminal 60125 or from the Connect 6021

Input: Connections for a Central Station (60213/60214/60215) as an Auxiliary or Second Unit

SX-Bus: (Currently not used).

Headphones or active speakers (Currently not used).

Technical Note for the Central Station

Only standard, hooded USB sticks with an ferrite core may be plugged into the USB connection.

Digital Protocols:

The following digital protocols are supported:

Märklin Motorola, mfx,

DCC adhering to NMRA/NEM standards.

Software:

Parts of the software for the Central Station are subject to the software license GPL.

You can get the source code for these software parts at no charge from Märklin, either as a CD or by

downloading a CD image from the Märklin home page.

More complete and updated information can be found on our Internet pages “www.maerklin.com“

If an error or defect should occur, do not open the Central Station. Send the defective unit to the Märklin

Service Department or to one of our service stations listed on our Internet page.

Opening this unit cancels any and all warranty claims. The individual and/or firm or customer responsible

for opening the Central Station bears the burden of proof and demonstration that opening the unit did not

cause the defect that has occurred and/or damages.

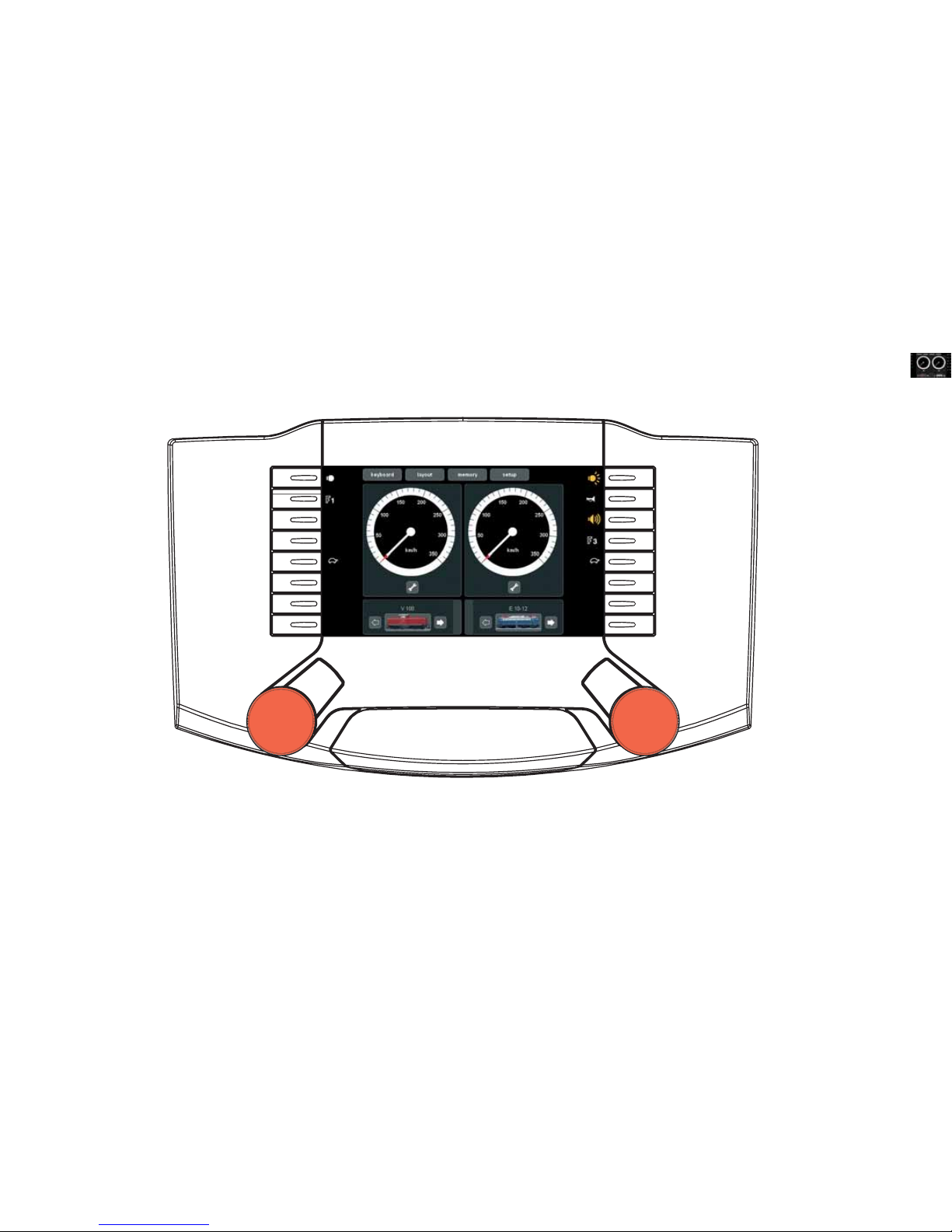

Introduction

The fourth generation of Märklin multi-train control systems is now ready with this “Märklin Digital“.

The most important component is the Central Station, which is responsible for the generation of the

correct control data, which carries out the coordination of the components connected to it, and which

also offers an easy-to-use manageable operating surface. Trouble-free operation with this complex

system is only ensured when you use only tested Märklin system components. Märklin‘s manufacturer‘s

warranty therefore becomes invalid if you use any other make of product with the Central Station.

The operator is thereby responsible for damages arising from the use of other makes of products.

Adhere to the techniques and principles presented in this instruction manual when connecting your

layout to the Central Station. The use of other circuits can easily lead to damage to the electronic

components. It is therefore best if you refrain from “expensive“ experiments. The Central Station is

not a toy. Make sure that this device is also used by children only as a controller for a model railroad.

We hope you will have a lot of enjoyment using the Central Station with your model railroad layout.

With this Central Station you have a device that offers you extensive possibilities for controlling your

model railroad. We recommend that you work through the examples presented in this handbook.

You will thereby have a much greater level of reliability in using the Central Station.

Your Märklin Service Team

Notes for the Central Station

Do not expose the Central Station to moisture.

This Märklin product is not watertight. Malfunctions can occur if there is high humidity or if moisture

gets inside the housing. The corrosion of the internal mechanism and electronics can lead to irrepara-

ble damages.

Do not expose the Central Station to shock.

If this controller is exposed to blows or strong vibrations, the result can be continuous malfunctions.

Do not expose the Central Station to extremes of temperature.

Sudden changes in temperature can cause moisture to condense inside the housing. In order to avoid

condensation buildup, you should keep the Central Station protected andl you should protect it during

transport before you change to a location with much higher or lower temperature.

Do not use force when operating the buttons and control knobs on the Central Station.

Do not use force when operating the buttons and control knobs on the Central Station.

Safekeeping

Do not keep the Central Station in locations where the following unfavorable conditions prevail:

High humidity or bad ventilation.

Temperatures over 50° Centigrade / 122° Fahrenheit (such temperatures can occur for example in direct

sunlight) or under -10° Centigrade / 14° Fahrenheit.

Humidity over 60%.

The humidity must not be greater then that for Central Europe.

Cleaning

Remove lint and dust with a soft, dry or slightly moist cloth. Never use alcohol, thinners or other

strong cleansers.