4Marland Clutch • 800-216-3515 P-1346-2-MC • 1/18

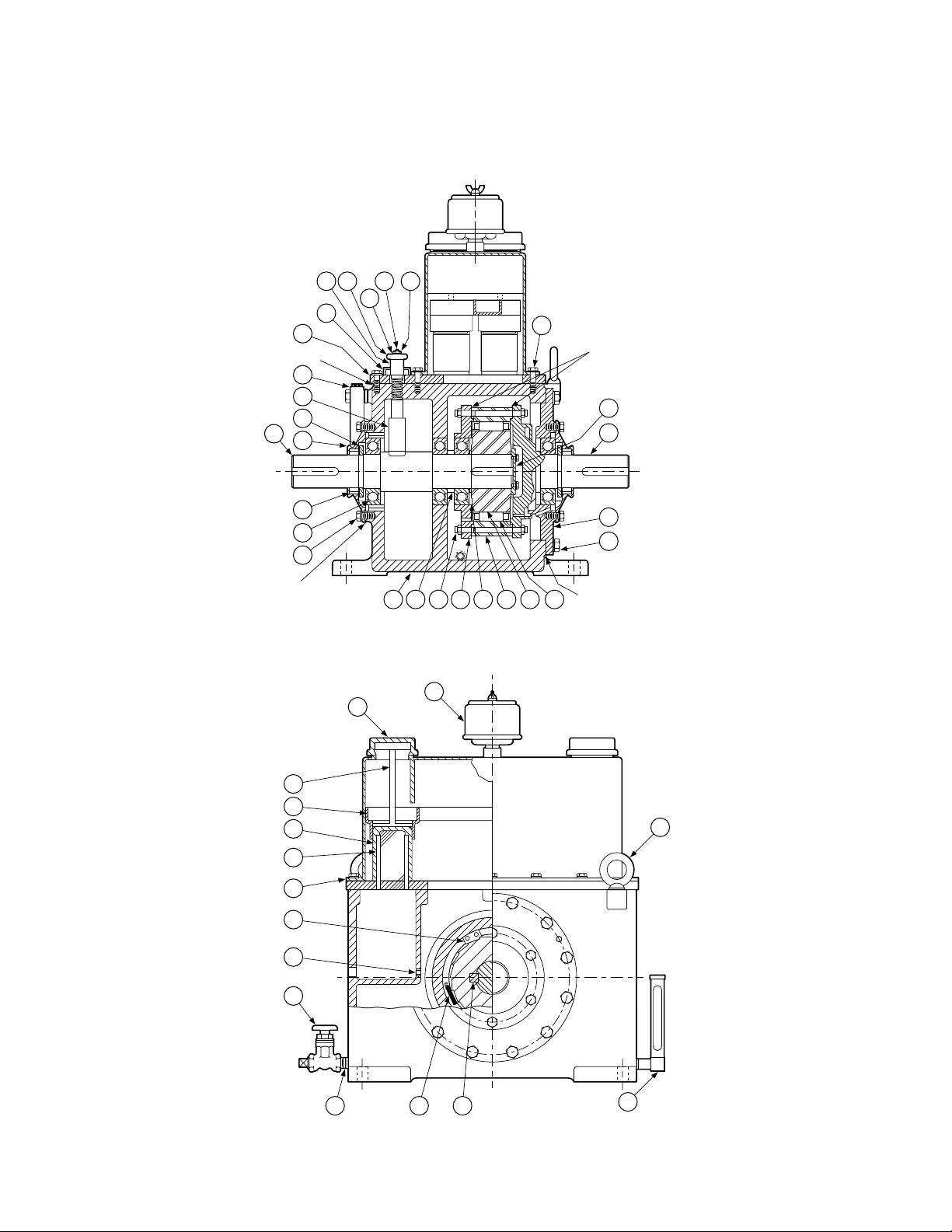

Note: CECON units in sizes 5C and 1M are

furnished with two oil strainer baskets. All

other sizes are furnished with four.

Remove the pipe plugs on housing hood (Part No.

30) and insert the breather-filter using the elbow

fittings provided.

B. Lubricate Couplings

Lubricate the couplings connecting CECON input

and output shafts to the driver and driven shafts

in accordance with the coupling manufacturer’s

instructions. If Marland Clutch has furnished the

couplings, see Coupling Data Sheet enclosed with

this bulletin.

C. Initial Startup

During the initial starting operation, check to

determine if there is any evidence of localized

heating; if the lubrication appears satisfactory; and

whether there is any vibration present due to loose

foundation bolts or misalignment of shafts. If any

correction is necessary, it should be made before

placing the CECON unit into continuous operation.

Note: Oil level may take up to ten minutes at

the maximum intended speed to stabilize.

Lubrication Maintenance

A. Oil Level Gauges

CECON units are provided with 2 oil level sight

gauges. One is located at the end of the clutch

housing to indicate the minimum oil level to be

maintained when the unit is in continuous operation,

or has been operating for at least 10 minutes at the

maximum intended speed. The other oil level gauge

is located at the bottom of the side of the clutch

housing and indicates only the static oil level.

B. Running Oil Level

During operation the CECON unit oil level should be

maintained at or above the minimum running level

as marked for the oil level sight gauge located at

the end of the clutch housing.

When the oil level is below the minimum running

level, sufficient oil should be added to bring the

level up to the indicated minimum running level. To

add oil, remove one of the 2” pipe caps from the

clutch housing hood. It is not necessary to stop the

CECON unit when adding oil.

Important: Running oil level may drop below the

minimum indicated during slow speeds of the input

shaft, such as in starter drives, creep drives, etc.

The static level indicated on the side of the housing

is sufficient for proper lubrication.

C. Renewal of Oil Strainers

Important: Running oil level will drop below the

minimum indicated if oil strainers are clogged.

Strainers may be removed while unit is in operation

by removing the 2” pipe caps at the top of housing

hood. Immediately upon removing a clogged

strainer, wash out sediment from strainer to make it

ready for use.

Improper maintenance methods are often

responsible for dirt and foreign matter getting into

the oil, and subsequently, into the CECON housing.

Keep oil supply and containers, pumps, or funnels

used for filling, clean and free from contamination.

D. Sampling of Oil

To obtain long, trouble-free service from your

CECON unit, it is necessary that the lubricating oil

within the housing be clean and free from sludge

at all times. To be assured of this, make frequent

inspection of the condition of the oil by sampling

a sufficient quantity through the sampling or drain

valve (Part No. 23). Such sampling may be done

while the unit is running and does not require an

interruption of operations.

Visual observation of the running oil level gauge and

oil strainers will provide a further check on oil purity.

The frequency with which the CECON unit

lubricating oil is sampled or replaced is an important

consideration and can only be determined by

individual experience. However, it is considered

desirable to sample the lubrication several times at

weekly intervals after the unit has been placed in

operation. The results of such samplings will dictate

the frequency for future samplings, which could

possibly extend to one month intervals, but in any

event should not exceed three months.

Whenever sampling of the oil indicates

contamination by moisture or foreign matter, such

impurities may be withdrawn from the housing

through the drain valve. If the unit is in operation,

do not withdraw more than 1 quart at a time. The

amount withdrawn should be immediately replaced

with fresh specified oil. Replacement oil may be

added by removing one of the pipe caps or initial oil

fill plug.

E. Changing of Oil

Timing of oil change is determined by the results

of oil sampling. Unless results of oil sampling

suggest otherwise, the oil within the clutch should

be completely changed once a year for continuous

duty applications.