Marquette Hellige GmbH MicroSmart V 2.xx Page 1

Servicing Instructions 227 470 35 B - 97.12

Contents

1 Documentation and nomenclature of Marquette Hellige instrument part Nos ........... 4

1.1 Configuration of instrument part No ............................... 4

1.2 Configuration of the PCB part Nos ................................. 4

1.3 Instrument status documentation (nominal status) ....................... 5

2Descriptionoftheunit................................................ 6

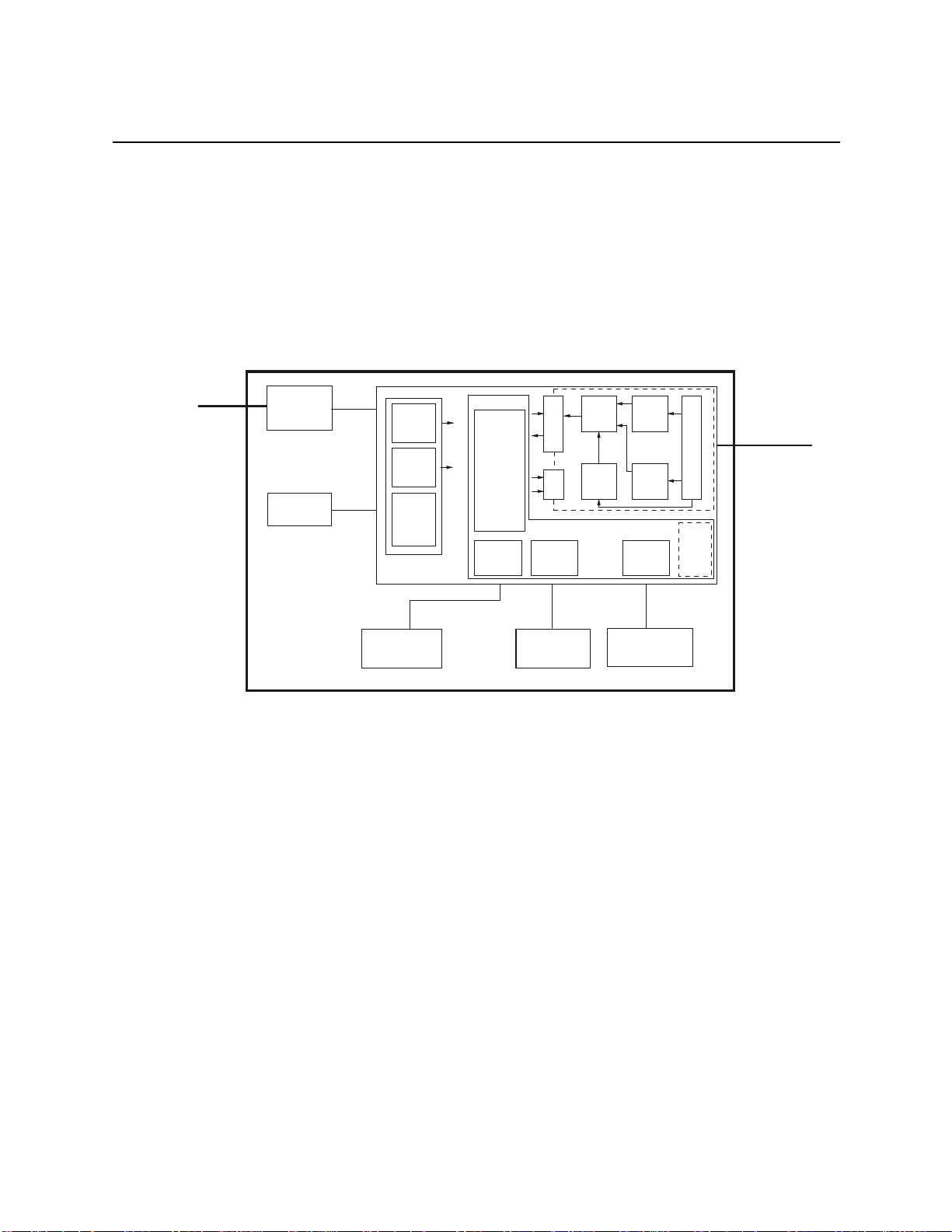

2.1 Block diagram, total unit ....................................... 7

2.2 Mechanical structure .......................................... 8

3Descriptionofthefunction ............................................ 8

3.1 Power supply module .......................................... 8

3.1.1 System inlet .......................................... 8

3.1.2 Extended range power supply .............................. 9

3.2 Battery .................................................... 9

3.3 Printed circuit board (PCB) MicroSmart ............................ 10

3.3.1 Voltage supply and monitoring ............................ 11

3.3.2 Computer .......................................... 15

3.3.3 ECG recording and pre-processing ......................... 19

3.3.4 Drive electronics and display ............................. 24

3.4 Internal interfaces ........................................... 28

3.4.1 Interface, power supply ................................. 28

3.4.2 Interface, display ..................................... 29

3.4.3 Interface, thermal array ................................. 30

3.4.4 Interface, motor ...................................... 32

3.4.5 Interface, photoelectric barrier ............................ 32

3.4.6 Interface, keyboard .................................... 33

3.4.7 Interface, ECG input ................................... 34

3.5 External interfaces ........................................... 35

3.5.1 Line inlet ........................................... 35

3.5.2 Patient input ........................................ 35

3.5.3 IR interface ......................................... 36

3.6 Delimitations .............................................. 37

4Unittestfunctions ................................................. 38

4.1 General .................................................. 38

4.2 Key test and loudspeaker test .................................... 39

4.3 Display test ................................................ 39

4.4 Motor test ................................................. 39

4.5 Recording test .............................................. 40

4.6 IR test (MicroSmart MC only) ................................... 40

4.7 Recording the results ......................................... 40