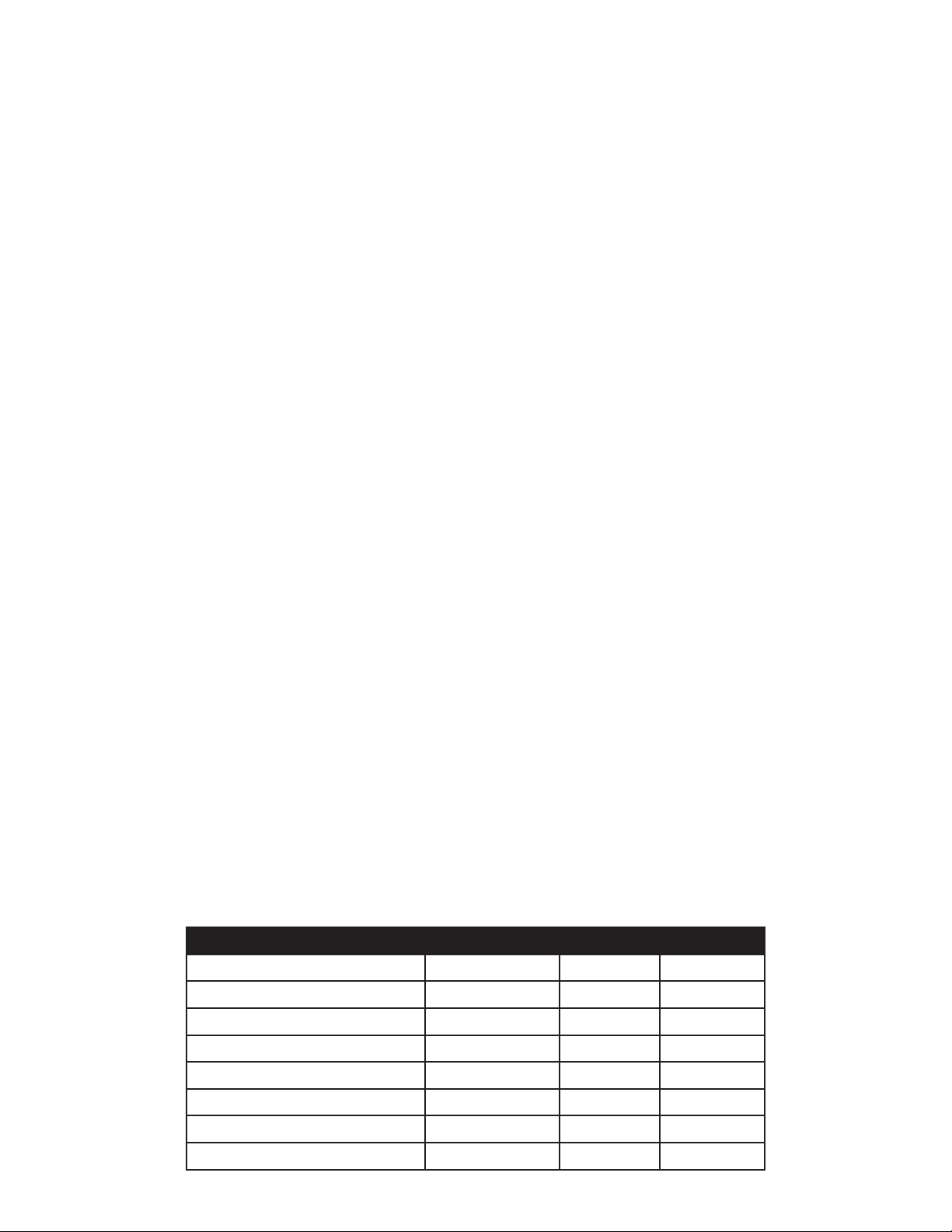

QTY.DESCRIPTION

FILE NAMEDET.

1

FRAME ASSM, 600CM-PC-BLACK

WU591.iam1

6

HCS 3/8"-16NC X 1.5 ZINC

WR150.ipt2

10

FLAT WASHER, 3/8"

WR103.ipt3

20

LOCK WASHER, 3/8 ZINC PLATED

WR211.ipt4

20

HEX NUT, 3/8-16- 00123

WR108.ipt5

2

YOKE BEARING, 600CM-PC-BLACK

WU733.iam6

8

CB 3/8-16- 00122

WR107.ipt7

1

HANDWHEEL ASSM, 600CM-PC-BLACK

WU657.iam8

1

SHAFT ASSM, DRIVE, 600CM

R5362.iam9

2

SEAL, GREASE DRUM RING

WX1100.ipt10

2

CONE BEARING-TIMKEN LM67048-400CM 400CM-PL 400UT-PL

WX1102.ipt11

1

DRIVE PINION - 600CM

R5360.ipt12

1

HUB, SPROCKET, 600CM

WX1280.iam13

1

TILT PINION SHAFT, 600CM

R5676.ipt14

1

TILT PINION-600CM

R5359.ipt15

1

LEVER, BRAKE ASSM, 600CM-PC-BLACK

WU708.iam16

2

SOCKET SET SCREW 5/16-18 X 5/16

WR1042.ipt17

1

SPROCKET

WX1261.ipt18

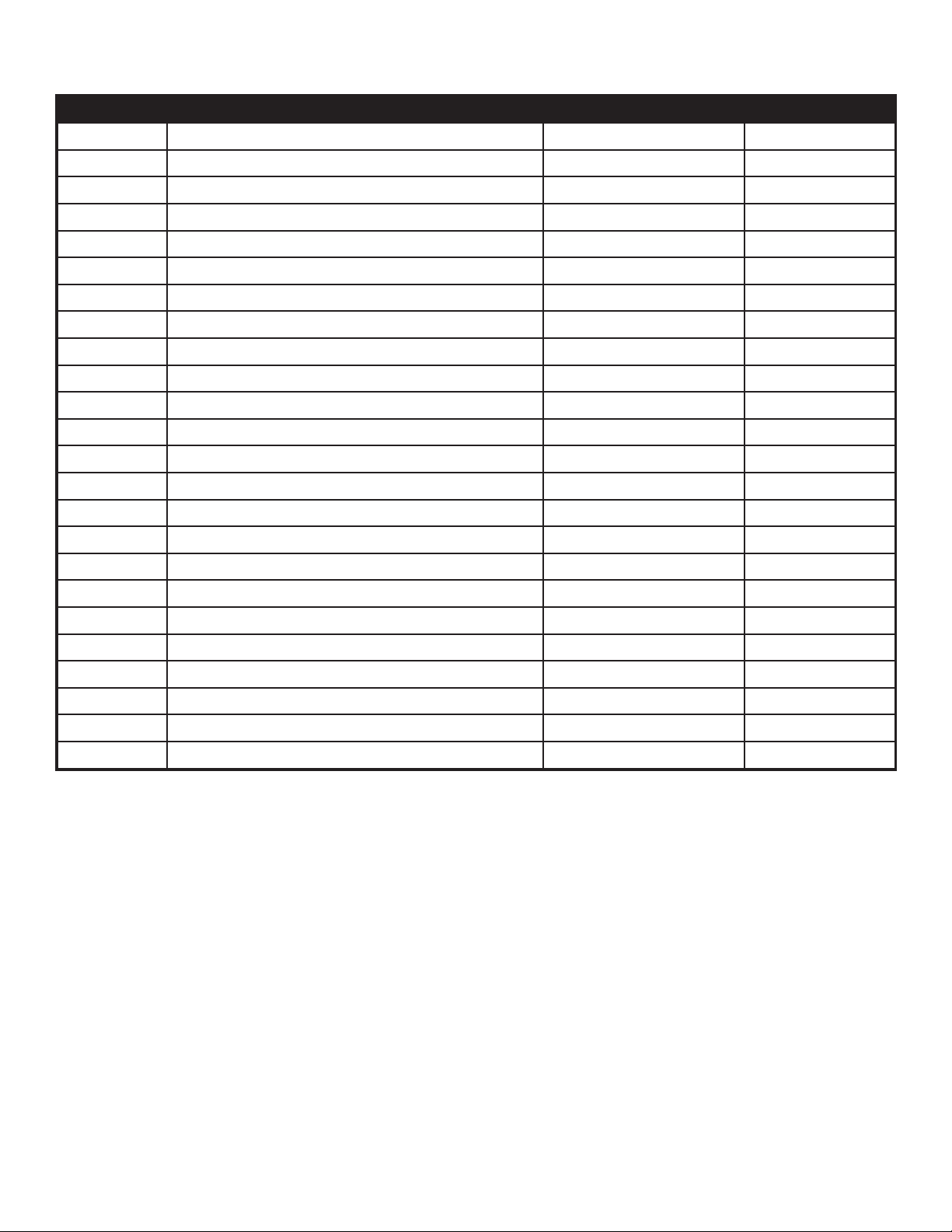

6

Regular Helical Spring Lock Washers(Inch Series)

WR364.ipt19

4

SCREW HEX HD 5_16-18X1

WR1007.ipt20

6

GREASE FITTING

WR1028.ipt21

23

HEX NUT 1/2-13NC

WR541.ipt22

2

KEY STOCK 5/16 X 1/4 X 1-1/4

WR1062.ipt23

1

TILT GEAR COVER-600CM

WX1860.iam24

2

LOCKWASHER 1/4 MED SP. REG HELICAL

WR633.ipt25

2

HEX HEAD BOLT 1/4-20 UNC 3/4 ZINC PLATED

WR973.ipt26

1

YOKE ASSM, 600CM-POWDERCOATED

WU592.iam27

1

1-1/4-12 UNF JAM LOCK NUT

WR1089.ipt28

1

Hex Bolt - UNC (Regular Thread - Inch)

WR1094.ipt29

1

SHAFT ASSM, DRUM, 600CM

R5358.iam30

2

CONE, BRG TIMKEN #13686 DRUM SH

WX1270.ipt31

1GASKET, DRUM HUB COVER 600CMWX1238.ipt32

1DRUM HUB COVER - 600CMWU660.iam33

4

WASHER FLAT 5/16WR236.ipt34

2NUT HEX 5_16 - 18WR149.ipt35

2SCREW HEX HD 5_16-18X2 1_4WR1053.ipt36

3SEGMENT, RING GEAR CLASS 30 - POWDERCOATEDWU589.iam37

21LOCKWASHER, 1/2" ZINC PLATED SPLITWR256.ipt38

3WASHER, 2.25 OD X 1-17/32 IDWR1103.ipt39

1SEAL, 20952 CRWX1262.ipt40

1Hex Nuts (Inch Series) Heavy Hex Slotted NutWR1038.ipt41

1TORSION AXLE ASSEMBLY, 2200#WX2079.iam42

4

HCS 1/2-13 X 1-1/2 Z5WR1018.ipt43

1DRUM ASSM, 600CM-PC-BLUEWU711.iam

44

2BLADE ASSM, 600CM TOP-PC-BLUEWU707.iam

45

2BLADE ASSM, 600CM BOTTOM-PC-BLUEWU706.iam46

1GEAR, INTERNAL TILT, 600CM-PC-BLACKWU713.iam

47

1BASE, MOTOR, 600CM, 600CM-PL, 1200-PC-BLACK

WU747.iam

48

2MOUNT, PIVOT-POWDERCOATEDWU717.iam49

23/8-16 FULLY THREADED TAP BOLT GRADE 8WR1233.ipt50

1CSTG, BRAKE BEARING-600CM 600CM-PL-PC-BLACKWU656.iam51

1BRAKE BAND ASSY-PC-BLACKWU709.iam52

1GRIPWL251.ipt53

2WHEEL & TIRE, 1300# CAP, ST175/80-13 ON 545WX2080.ipt54

1COTTER PIN 1_8 X 1 1_2WR1029.ipt

55

2Clevis Pins and Cotter Pins - Extended Prong Square Cut Type (Inch) - Cotter PinWR1074.ipt56

1Hexagon Socket Set Screw - Flat PointWR1041.ipt

57

17FENDER WASHER, 1-3/4 OD X 17/32 ID, ZN PLWR1070.ipt58

2KEY STOCK 3/8 SQ X 1" LONGWR1217.ipt59

1CSTG, HANDWHEEL BRG 600CM-PC-BLACKWU655.iam60

6WASHER-1/2" ZINC PLATEDWR411.ipt61

8HEX HD CP SCR 1/2-13 X 1 1/4WR1017.ipt62

9SCRW7-.500-13NC1.75 HHCS-PLNWR330.ipt63

4HEX CAP SCREW, 3/8"-16 2" GRADE 5 ZINC PLATEDWR264.ipt64

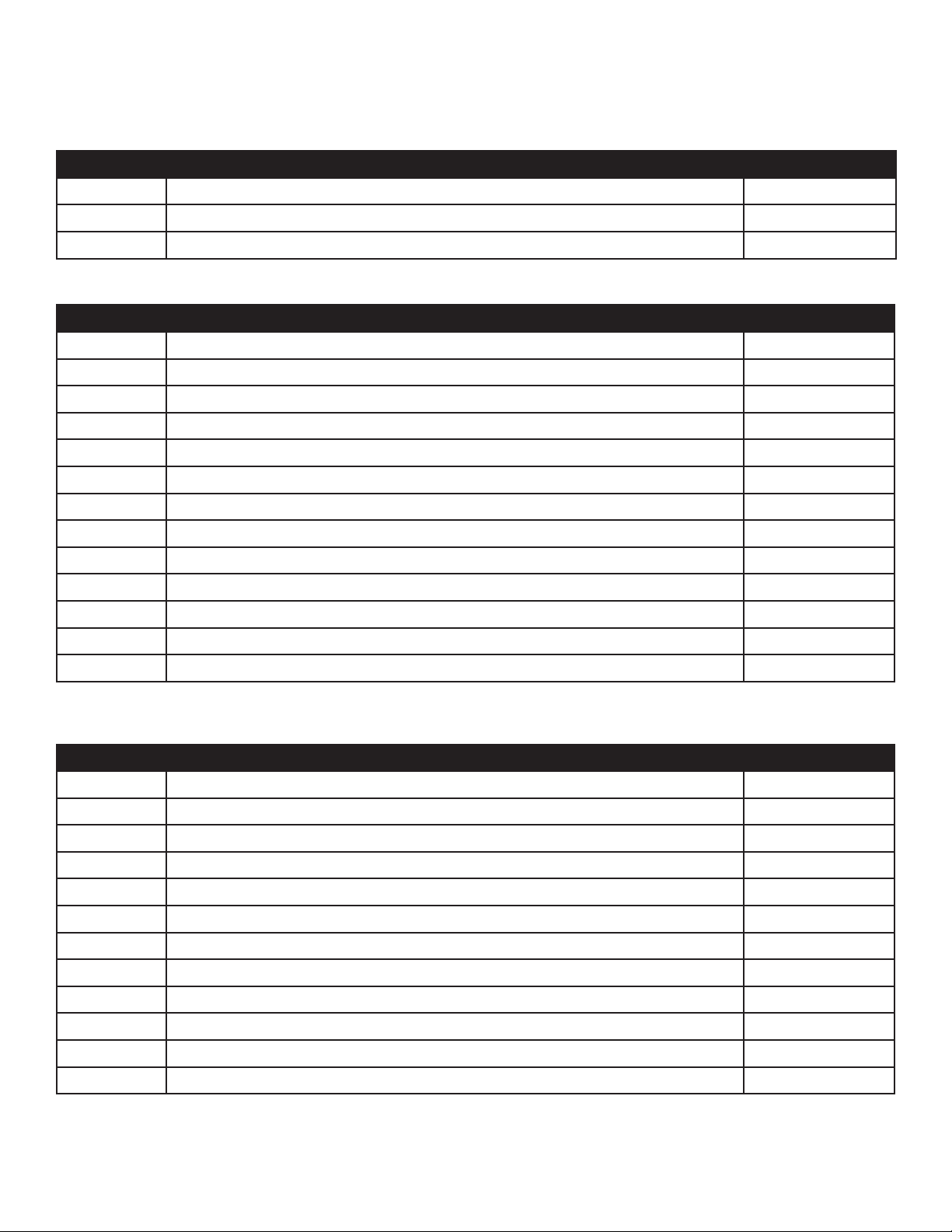

THIS PRINT DISCLOSES SUBJECT MATTER IN WHICH MARSHALLTOWN COMPANY HAS PROPRIETARY RIGHTS. THE RECEIPT OR

POSSESSION OF THIS PRINT DOES NOT CONFER, TRANSFER OR LICENSE THE USE OF THE DESIGN OR TECHNICAL INFORMATION SHOWN

HEREIN. REPRODUCTION OF THIS PRINT OR ANY INFORMATION CONTAINED HEREIN OR MANUFACTURE OF ANY ARTICLE HEREFROM,

FOR DISCLOSURE TO OTHERS, IS FORBIDDEN, EXCEPT BY SPECIAL WRITTEN PERMISSION FROM MARSHALLTOWN COMPANY.

HEAT-TREAT

MATERIAL

APVD.

BY

DATE

CK.

BY

DWN.

BY

DATE DATE

REV.DRAWING NO.

OF

NO.

PART

MACH. NO.

FIXT. NO.NO.

E.D.I. SCALE

DIE NO.

GA. NO.

SHEET

TITLE:

REV. REVISION DESCRIPTION DATE APVD

#

C

UNLESS OTHERWISE SPECIFIED:

ALL DIMENSIONS ARE IN INCHES [MILLIMETERS]

GENERAL UNSPECIFIED TOLERANCES

SUPPLIER VERIFICATION IS

REQUIRED PRIOR TO APPROVAL

CRITICAL DIMENSION / NOTE

FRACTION:

.5

ANGLE: 1/32

°

XXXX

XX

XXX

.020

DECIMAL: in. [mm]

.010

.005

.0005

- [.5]

X

-

[.013]

[.12]

[.25]

X

21487

MANUAL

ILLUSTRATIONS

-

1 3

-

rstone

9/16/2016

C:\Vault Local\Public\Product\21487 MANUAL ILLUSTRATIONS.idw

V49