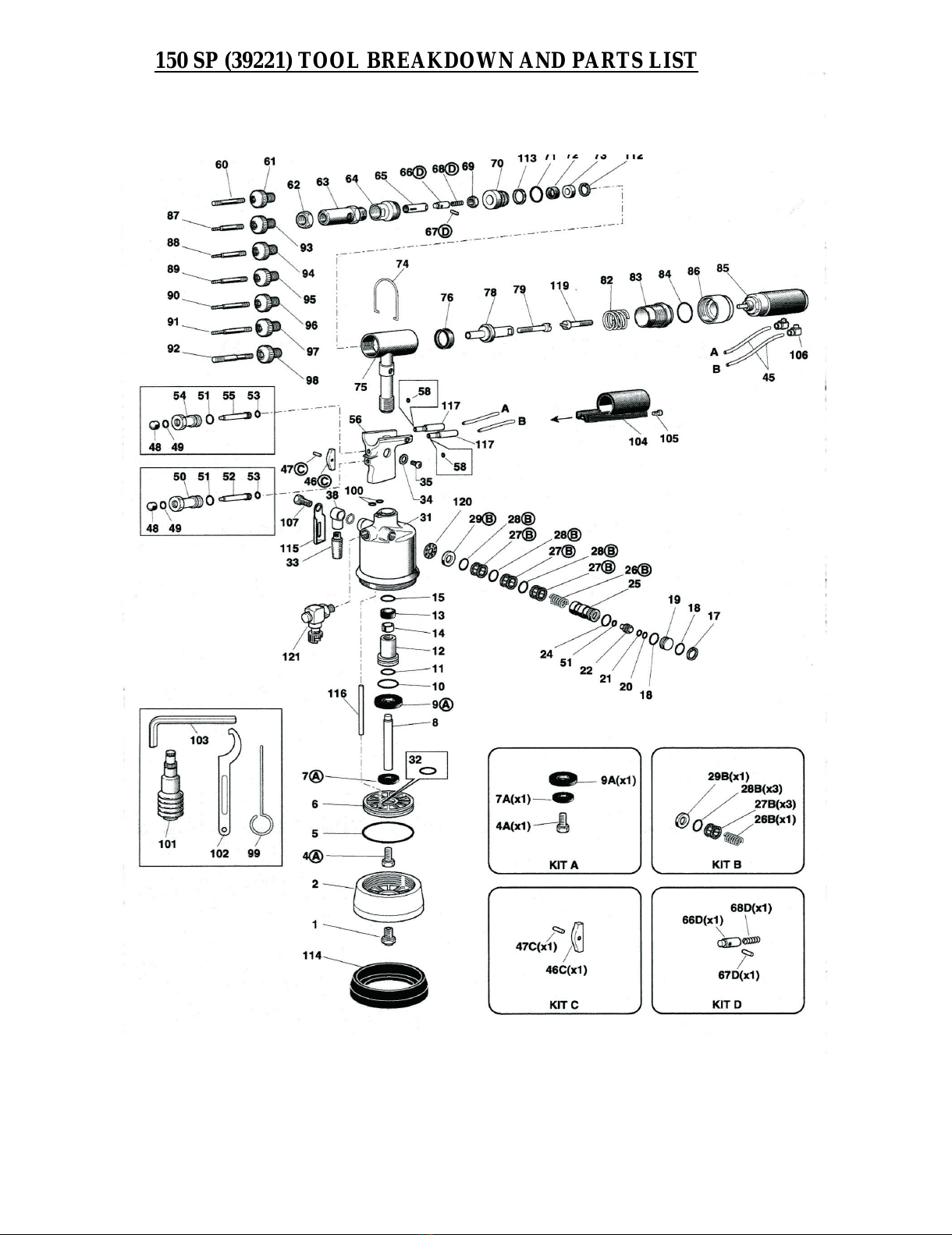

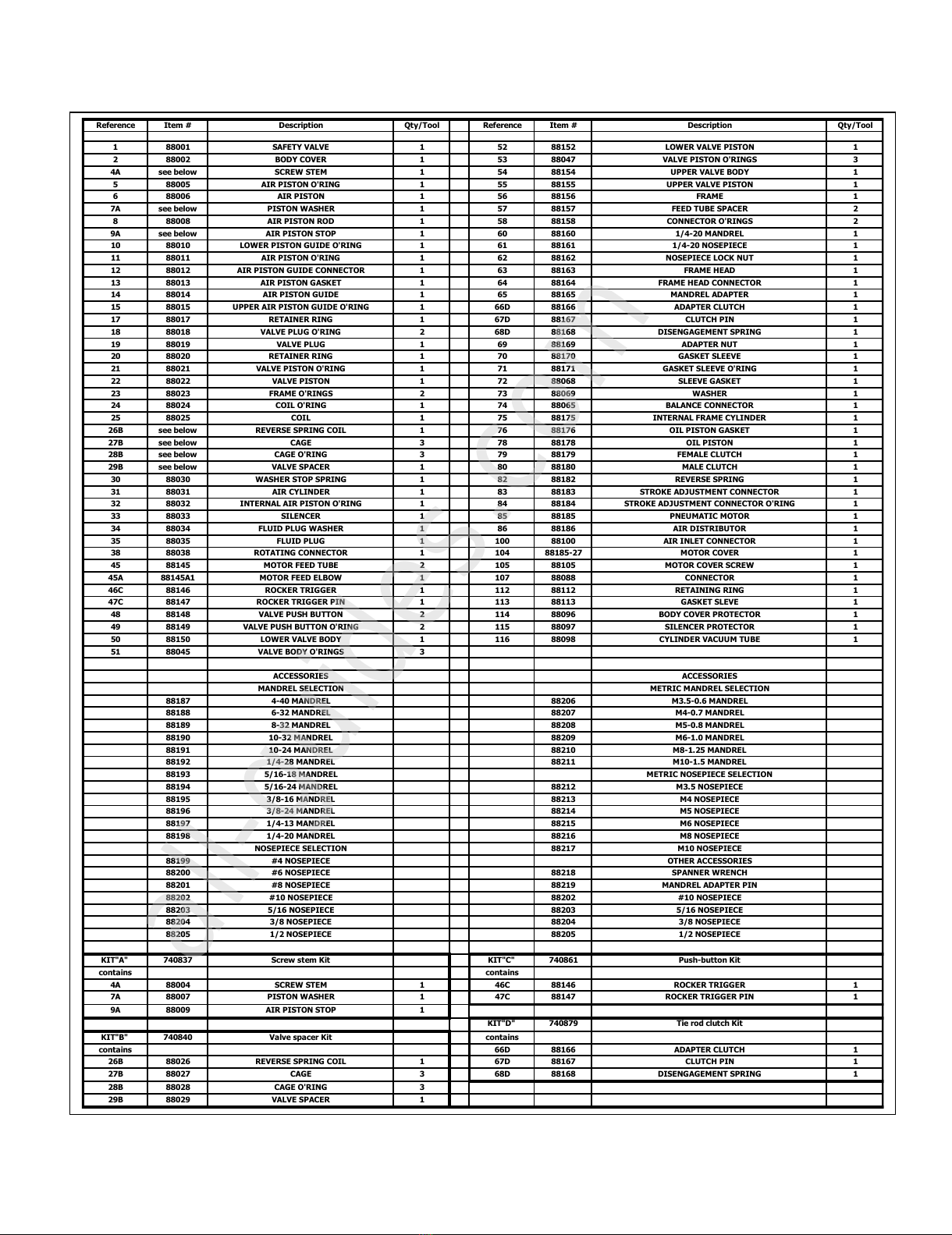

Reference Item # Description Qty/Tool Reference Item # Description Qty/Tool

188001 SAFETY VALVE 1 52 88152 LOWER VALVE PISTON 1

288002 BODY COVER 1 53 88047 VALVE PISTON O'RINGS 3

4A see below SCREW STEM 1 54 88154 UPPER VALVE BODY 1

588005 AIR PISTON O'RING 1 55 88155 UPPER VALVE PISTON 1

688006 AIR PISTON 1 56 88156 FRAME 1

7A see below PISTON WASHER 1 57 88157 FEED TUBE SPACER 2

888008 AIR PISTON ROD 1 58 88158 CONNECTOR O'RINGS 2

9A see below AIR PISTON STOP 1 60 88160 1/4-20 MANDREL 1

10 88010 LOWER PISTON GUIDE O'RING 1 61 88161 1/4-20 NOSEPIECE 1

11 88011 AIR PISTON O'RING 1 62 88162 NOSEPIECE LOCK NUT 1

12 88012 AIR PISTON GUIDE CONNECTOR 1 63 88163 FRAME HEAD 1

13 88013 AIR PISTON GASKET 1 64 88164 FRAME HEAD CONNECTOR 1

14 88014 AIR PISTON GUIDE 1 65 88165 MANDREL ADAPTER 1

15 88015 UPPER AIR PISTON GUIDE O'RING 1 66D 88166 ADAPTER CLUTCH 1

17 88017 RETAINER RING 1 67D 88167 CLUTCH PIN 1

18 88018 VALVE PLUG O'RING 2 68D 88168 DISENGAGEMENT SPRING 1

19 88019 VALVE PLUG 1 69 88169 ADAPTER NUT 1

20 88020 RETAINER RING 1 70 88170 GASKET SLEEVE 1

21 88021 VALVE PISTON O'RING 1 71 88171 GASKET SLEEVE O'RING 1

22 88022 VALVE PISTON 1 72 88068 SLEEVE GASKET 1

23 88023 FRAME O'RINGS 2 73 88069 WASHER 1

24 88024 COIL O'RING 1 74 88065 BALANCE CONNECTOR 1

25 88025 COIL 1 75 88175 INTERNAL FRAME CYLINDER 1

26B see below REVERSE SPRING COIL 1 76 88176 OIL PISTON GASKET 1

27B see below CAGE 3 78 88178 OIL PISTON 1

28B see below CAGE O'RING 3 79 88179 FEMALE CLUTCH 1

29B see below VALVE SPACER 1 80 88180 MALE CLUTCH 1

30 88030 WASHER STOP SPRING 1 82 88182 REVERSE SPRING 1

31 88031 AIR CYLINDER 1 83 88183 STROKE ADJUSTMENT CONNECTOR 1

32 88032 INTERNAL AIR PISTON O'RING 1 84 88184 STROKE ADJUSTMENT CONNECTOR O'RING 1

33 88033 SILENCER 1 85 88185 PNEUMATIC MOTOR 1

34 88034 FLUID PLUG WASHER 1 86 88186 AIR DISTRIBUTOR 1

35 88035 FLUID PLUG 1 100 88100 AIR INLET CONNECTOR 1

38 88038 ROTATING CONNECTOR 1 104 88185-27 MOTOR COVER 1

45 88145 MOTOR FEED TUBE 2 105 88105 MOTOR COVER SCREW 1

45A 88145A1 MOTOR FEED ELBOW 1 107 88088 CONNECTOR 1

46C 88146 ROCKER TRIGGER 1 112 88112 RETAINING RING 1

47C 88147 ROCKER TRIGGER PIN 1 113 88113 GASKET SLEVE 1

48 88148 VALVE PUSH BUTTON 2 114 88096 BODY COVER PROTECTOR 1

49 88149 VALVE PUSH BUTTON O'RING 2 115 88097 SILENCER PROTECTOR 1

50 88150 LOWER VALVE BODY 1 116 88098 CYLINDER VACUUM TUBE 1

51 88045 VALVE BODY O'RINGS 3

ACCESSORIES ACCESSORIES

MANDREL SELECTION METRIC MANDREL SELECTION

88187 4-40 MANDREL 88206 M3.5-0.6 MANDREL

88188 6-32 MANDREL 88207 M4-0.7 MANDREL

88189 8-32 MANDREL 88208 M5-0.8 MANDREL

88190 10-32 MANDREL 88209 M6-1.0 MANDREL

88191 10-24 MANDREL 88210 M8-1.25 MANDREL

88192 1/4-28 MANDREL 88211 M10-1.5 MANDREL

88193 5/16-18 MANDREL METRIC NOSEPIECE SELECTION

88194 5/16-24 MANDREL 88212 M3.5 NOSEPIECE

88195 3/8-16 MANDREL 88213 M4 NOSEPIECE

88196 3/8-24 MANDREL 88214 M5 NOSEPIECE

88197 1/4-13 MANDREL 88215 M6 NOSEPIECE

88198 1/4-20 MANDREL 88216 M8 NOSEPIECE

NOSEPIECE SELECTION 88217 M10 NOSEPIECE

88199 #4 NOSEPIECE OTHER ACCESSORIES

88200 #6 NOSEPIECE 88218 SPANNER WRENCH

88201 #8 NOSEPIECE 88219 MANDREL ADAPTER PIN

88202 #10 NOSEPIECE 88202 #10 NOSEPIECE

88203 5/16 NOSEPIECE 88203 5/16 NOSEPIECE

88204 3/8 NOSEPIECE 88204 3/8 NOSEPIECE

88205 1/2 NOSEPIECE 88205 1/2 NOSEPIECE

KIT"A" 740837 Screw stem Kit KIT"C" 740861 Push-button Kit

contains contains

4A 88004 SCREW STEM 1 46C 88146 ROCKER TRIGGER 1

7A 88007 PISTON WASHER 1 47C 88147 ROCKER TRIGGER PIN 1

9A 88009 AIR PISTON STOP 1

KIT"D" 740879 Tie rod clutch Kit

KIT"B" 740840 Valve spacer Kit contains

contains 66D 88166 ADAPTER CLUTCH 1

26B 88026 REVERSE SPRING COIL 1 67D 88167 CLUTCH PIN 1

27B 88027 CAGE 3 68D 88168 DISENGAGEMENT SPRING 1

28B 88028 CAGE O'RING 3

29B 88029 VALVE SPACER 1