Martin Engineering M3786-03/19 1Martin®Modular Slider Cradle

Introduction

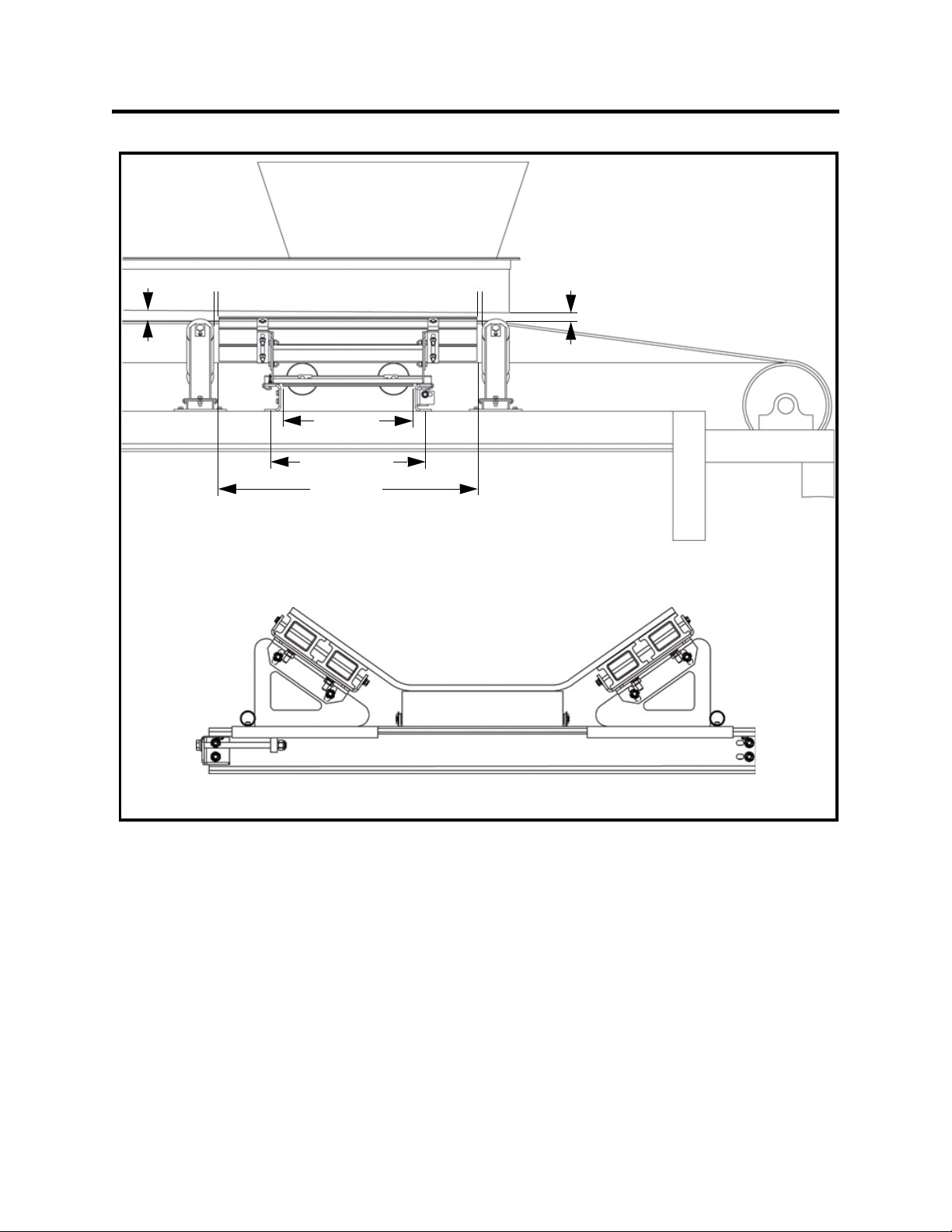

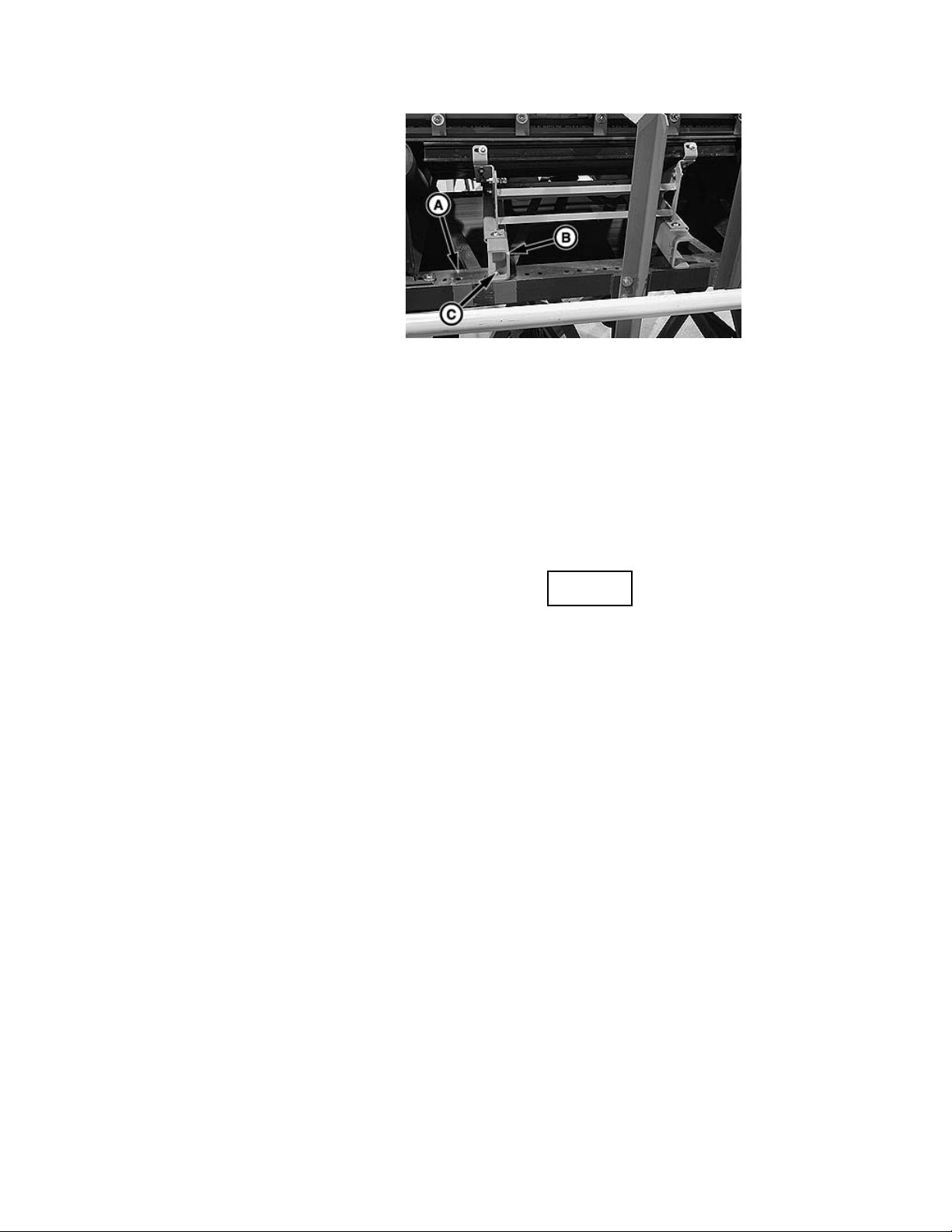

General The Martin®Modular Slider Cradle holds conveyor belts in a stable, sag-free

position to allow effective sealing. By minimizing belt vibration and sag, the

Martin®Modular Slider Cradle reduces escaping material and risk of damage

to the belt and conveyor accessories. Martin®Modular Slider Cradle bars

provide a low-friction, self-lubricating surface for conveyor belts to skim over

without heat buildup or undue wear on the belt surface or bars (see

specifications in Table I). The Martin®Modular Slider Cradle is not intended

to absorb impact.

Martin®Modular Slider Cradles are recommended for moderate- to severe-

duty belts from 36- to 60-in. (1000- to 1600-mm) wide. Cradles are not

recommended for conveyors operating at speeds over 700 fpm (3.5 m/s) or

that are less than 50 ft (15 m) in length. To improve belt support on short

conveyors or high-speed belts, contact Martin Engineering.

The Martin®Modular Slider Cradle conforms to CEMA Standard No. 502-

1980 Bulk Material Conveyor Troughing and Return Specifications (CEMA

Class D6).

Table I. Martin®Modular Slider Cradle Bar Specifications

References The following documents are referenced in this manual:

• American National Standards Institute (ANSI) z244.1-1982, American

National Standard for Personnel Protection - Lockout/Tagout of Energy

Sources - Minimum Safety Requirements, American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

• Federal Register, Volume 54, Number 169, Part IV, 29 CFR Part 1910,

Control of Hazardous Energy Source (Lockout/Tagout); Final Rule,

Department of Labor, Occupational Safety and Health Administration

(OSHA), 32nd Floor, Room 3244, 230 South Dearborn Street, Chicago, IL

60604.

Safety All safety rules defined in the above documents, and all owner/employer

safety rules must be strictly followed when working on the Martin®Modular

Slider Cradle.

Materials required Only standard hand tools are required to install and service this equipment.

Bar construction UHMW polyethylene

Bar dimensions 2.9-in. (72-mm) high

5.0-in. (127-mm) wide

48-in. (1220-mm) long

Coefficient of friction 0.5

Specific gravity 0.94

Tensile strength 6800 lb at 73°F (23°C)

Hardness 62 (Shore D)

Service temperature -20 to 140°F (-29 to 60°C)

Introduction