Masalta MMD User manual

1

CONTENTS

SAFETYINSTRUCTIONS 1

HEALTH&SAFETY ... 2

OPERATING INSTRUCTIONS .2-5

SERVICE&MAINTENANCE 5-6

SPECIFICATION .6-7

SAFETYINSTRUCTIONS

Foryourownpersonalprotection and forthesafetyofthosearoundyou,pleasereadandensureyou

fullyunderstandthe followingsafetyinformation.It isthe responsibilityoftheoperatortoensurethat

he/shefullyunderstandshowtooperatethisequipmentsafely.Ifyouareunsureaboutthe safeand

correct useofourMMD, consult yoursupervisor.

CAUTION: Impropermaintenancecan behazardous. Readand Understand

thissection beforeyouperformanymaintenance, serviceorrepairs.

lEnsure, that all symbolson the machine, canalwaysbeclearlyread.

lDonot leaveanytoolsorpartslyingaroundon the workfloor, asthiscan causeaccidents.

lWatchwhereyou aregoing, the groundcan beslippery.

lTakecarethat you do notinjureyourselfon objects,suchasscaffoldingand reinforcementmaterials,

whichcan befound directlyorindirectlyintheworkingarea.

lBecarefulwhen liftingandcarryingtheMMD.Donotbend forwardswhen pickingupthe apparatus,

bend youknees.Ensurethattheworkingarea iswithinyourreach,thatyoudonothavetobend

forward.

lWhen cleaningthe machine,ensurethat no waterorcleaningdetergentsgetintothe motorhousing.

lWhen the machine isnotbeingused forlongerperiodsoftime,then itmustbestored inadryand

clean area.

lPayattention toyourownsafetyandthesafetyofyourcolleagues.

lRegularmaintenanceofthemachine promotessafeoperation.

Thefollowingsafety-aspectsspecificallyapplytothose machines equippedwithapetrol engine:

lDonotuseanMMD,fitted withapetrolengine,indoorsorinpoorlyventilated places,suchaspits

etc.

lMakesurethat thereissufficientventilation inspaceswhicharesurrounded bywalls.Neverinhale

exhaust gasses, theycandamageyourhealthandthat ofyourcolleagues.

lToavoidgettingan electricshock,do nottouchthe high-tension cableorsparkplugcapwhilethe

engine isrunning.

lCheck forfuelleaks beforerunningthe machine.

lDowearworking-gloves, safetyglassesandprotectingclothingduringrefueling.

lMakesurethatthereissufficient ventilation duringrefueling.

lRefuelingisonlyallowed afterthe engine hasbeen cooled offsufficiently.

lRefueling,whilethe engine ishot,might lead toaverydangeroussituation.Itisstrictlyforbidden to

refuel:

Inthe direct vicinityofopen fireorotherflammablematerials,

Whilesmokingcigarettesetc.

Inexplosion endangered spaces.

TROUBLESHOOTING GUIDE ... 7

WARRANTY .. 7

MAINTENANCERECORD .. 8

ECDECLARATION ...9

2

HEALTH&SAFETYS

WORKINGAREA

KEEPyourworkingarea clean andwell lit. Cluttered benchesanddarkareasinviteaccidents.

DO NOTOPERATEpowertoolsinexplosiveatmospheres, suchasinthepresenceofflammable

liquids, gases, ordust.

KEEPAWAYfromstanders, children, and visitorswhileoperatingapowertool. Distractionscan

causetoloosecontrol.

SpecificSafetyRules

Foryourownsafety,aswell asforthe othersone,and inordernot tocauseanydamagetothis

equipment, pleaseread carefullythe instructionsthat areexplained asfollows:

1.-Forthe properuseofthisdevice, pleaseassurethat theoperatorhasbeen correctlyinformed

ofthe contentofthismanualbeforeusingit.

2.-Thisscreedmust beused onlyundertheapplicationsforwhichit hasbeen designed and

accordingtothesesafetyinstructions.

3.-Donot touchanypart ofthevibratinggroupwhen the motorisrunning.

4.-Donot workinan area exposed toflammableliquidsorgases.

5.-Donotallowinexperienced ornottrainedpersonneltousethescreed alone.

6.-Alwayskeepthe vibratingscreed clean and dry.

7.-Pleasesecureall the threadsandboltsbeforeworking.

8.-Donot stopthe screed until theconcretemass isfullyvibrated.

9.-Donot workwiththe screed ifanytypeofdisfunction, even small, hasbeen observed.

10.-When workingwithapetrolscreed:

-Read the engine manufacturer'smanualbeforeworking.

-Donot workinclosed rooms, the exhaust fumesmaybetoxic.

-Wait 2minutesforthe petrolrefilluntil the motorgetscold.

PPE (Personal ProtectiveEquipment).

SuitablePPE mustbewornwhen usingthisequipmenti.e.SafetyGoggles,EarDefenders,DustMask

and SteelToecapped footwear(withanti-slipsolesforadded protection). Wearclothingsuitableforthe

workyou aredoing.Alwaysprotect skinfromcontact withconcrete.

OPERATING INSTRUCTIONSS

HowtoassembletheMMD

1. TheMMDissupplied in3components: theengine assembly, the blade andthehandle.

2. Theengineassemblyisequipped withaquick connectsystem,withwhichthe engine assemblycan

beassembled withhandleeasily.

3. Toconnecttheengine assemblytothe blade with2longboltsof160mm,until the twopartsare

bolted togetherclosely. Nowtighten the bolts.

4. Makesurethatthe MMDisproperlyassembled and that the ON-OFF switchisinthe ONposition.

5. Makesurethatthe fueltankisfilled withunleaded fuelonly.

Startand Stop ProcedurefortheEngines

3

HONDAENGINE

Pre-Operation Check

1.Engine oil level

Removethe oil fillercapand check the oil level: it shouldreachthetopofthe oil filterneck.

Ifthe levelislow, fill tothe topofthe oil fillerneck withthe recommended oil.

Add theengine oil slowlytoavoidoverflowing, asthe engine oil tankcapacityissmall.

Every10 hours, check the engine oil leveland replenishoil up tothe topofthe oilfillerneck ifthe engine

isoperated formorethan 10hourscontinuously.

UseHonda 4-stroke,oranequivalenthighdetergent, premiumqualitymotoroil certified tomeetor

exceed U.S.automobilemanufacturer srequirementsforserviceclassification SG,SF.Motoroils

classified SG,SFwill showthisdesignationonthecontainer. SAE10W-30 isrecommended forgeneral,

all temperatureuse.

CAUTION:

Usingnondetergent oil or2-strokeengine oil couldshorten the enginesservicelife.

Therecommended operatingrangeofthisengine is-5℃to40℃(23℉to104℉)

2.Aircleaner

CAUTION:

Neverrun the engine without the aircleaner. Rapidengine wearwill result.

Check cleanerfordirt orobstruction ofelement.

3.Fuel

Useautomotivegasoline (Unleadedorlowleadedispreferred tominimizecombustion chamber

deposits).

Neverusean oil/gasoline mixtureordirtygasoline.Avoidgettingdirt, dust orwaterinthe fueltank.

4.Retighteningboltsand nuts

Check forlooseboltsand nuts.Tighten the boltsandnutsproperlyandsecurely,ifnecessary.

Staringthe Engine

1.Turnthe engine switchtothe ONposition (on the equipment side).

2.Movethe chokelevertotheCLOSEDposition.

Note: Donot usethe chokeifthe engine iswarmorthe airtemperatureishigh.

3.Press the primingpumpseveraltimesuntil afuelflowinthe fuelreturntubeisvisuallynoticed.

4.Pull the startergriplightlyuntil resistanceisfelt, thenpull briskly.

Operation

1.Graduallymovethe chokelevertotheOPENposition.Warmupthe engine until it run smoothly.

2.Position thethrottlecontrolleverforthe desired engine speed (onthe equipment side).

Stopthe Engine

Tostopthe engine inanemergency, turntheengine switchtothe OFF position (on the equipment side).

Undernormalconditions, usethe followingprocedure:

1.Position thethrottlecontrolleverfullytoLOW(on the equipment side).

2.Turnthe engine switchtothe OFF position (on the equipment side).

Operation oftheVibrating ScreedMMD WARNINGS

1.Donotrun the engine inaclosedarea.Exhaustgascontainscarbon monoxide,anodorless and

deadlypoison.

4

2.Gasoline isextremelyflammableand can beexplosiveundercertainconditions.

3.Donot smoke. Makesurethearea iswell ventilated and free fromanysourceofflameorsparks.

4.Stopengine andallowthe engine tocooloffbeforerefueling.

5.Donotfill the tanksothefuellevelrisesintothe fillerneck orlevelsurfaceof the levelgauge.If the

tankisoverfilled,heatmaycausethefueltoexpand and overflowthroughthe ventsinthe

tankcap.Wipeoffanyspilled gasoline immediately.

6.Keeptheengine atleast1mtr.awayfrombuildings,obstructionsand otherburnableobjects.To

avoidgettingan electricshock,donottouchthe sparkplugorsparkpluglead duringengine

running.Toavoidaseriousburn,do nottouchahotenginemuffler.Beforeyou serviceorremove

partsstopengine andallowthe engine tocool.

7.Alwaysremovethe sparkpluglead fromsprakplugwhen servicingthe engine toprevent accidental

starting.

Read theinstruction manualofthe petrolengine.

HowToAdjustTheBladeAngle

Pleaseobservethefollowinginstructions:

lMakesuretorefill the fueltankintime.Donotletthe engine run soall the fuelisused.Thismight

causestartingproblems.

lPreventtheMMDof sinkingintotheconcrete.Afterthe engine hasbeen switched on, immediately

movethe MMDbackwards.

lWhen usingalowslumpconcrete, movethe MMDslowlyacross the surfaceofthe concrete.When

usingahighslumpconcrete,movethe MMDfasteracross the surfaceofthe concrete.

UsageRecommendations

Thescreedsareusedtothevibration and thefinishingof thefloors.Thisworkcan bemade directlyon

the surfacewithoutguides. Thanks toitslightweightand toitsmechanismproducingapowerfulvibration,

the screed isidealtosmoothrapidlyand easilythe floors(from6to18 cmthickness)dependingon the

concretetype.

Inordertoget agood finishingofthe concretesurface, werecommend tofollowtheseinstructions:

Turnin

gthehandletotheright,

the blade inclinesforward, pushing

and spreadingthe concrete.

Turningthehandletotheleft,

tomakethe blade incline backward,

pullingand spreadingthe concrete.

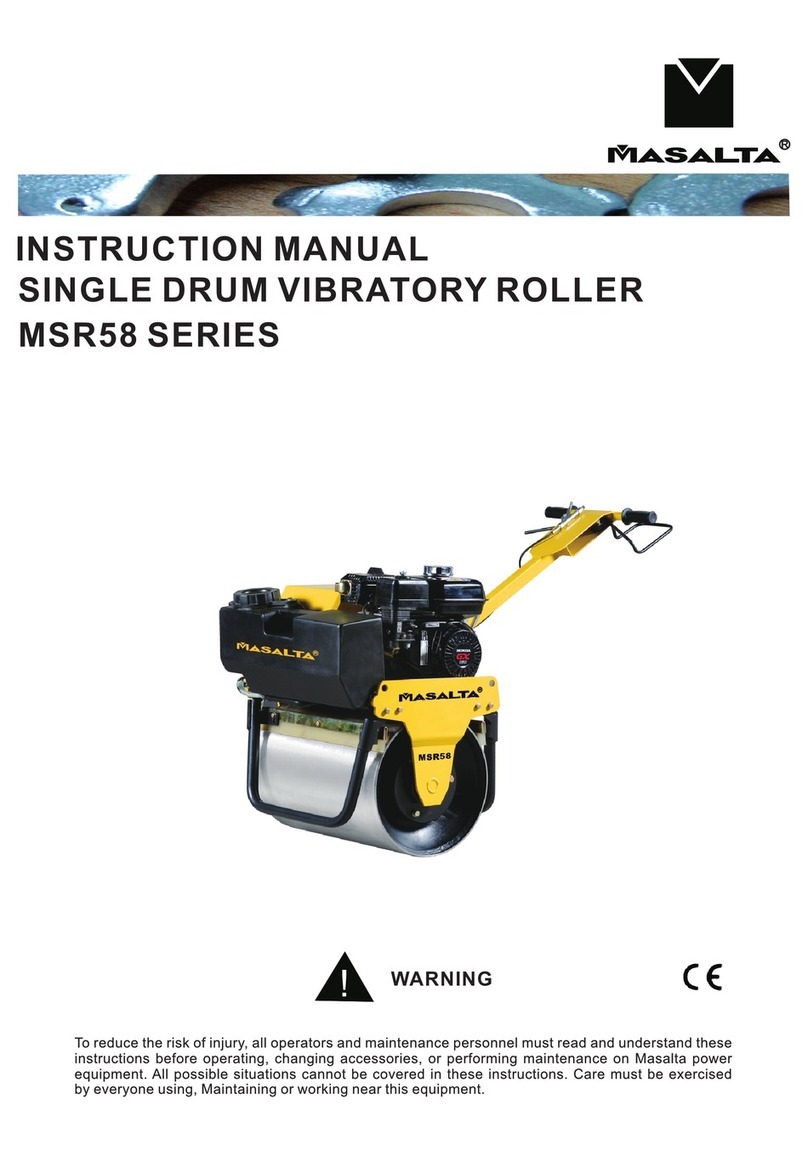

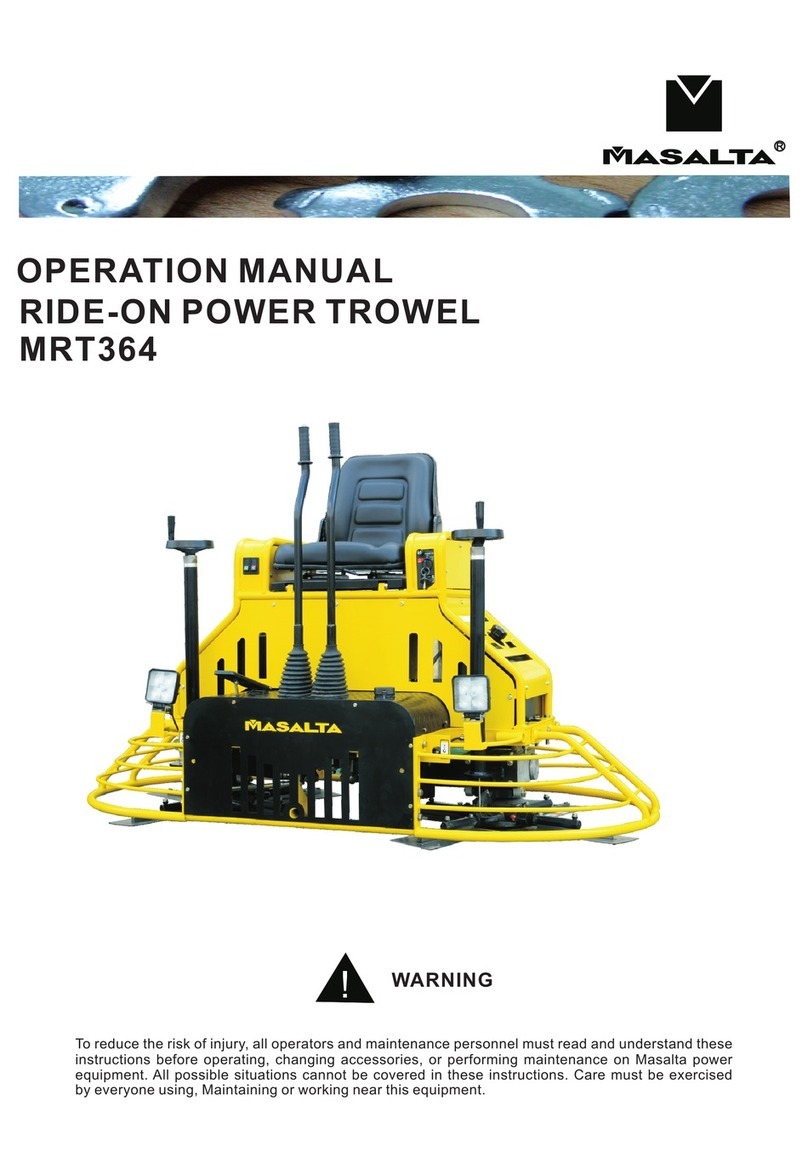

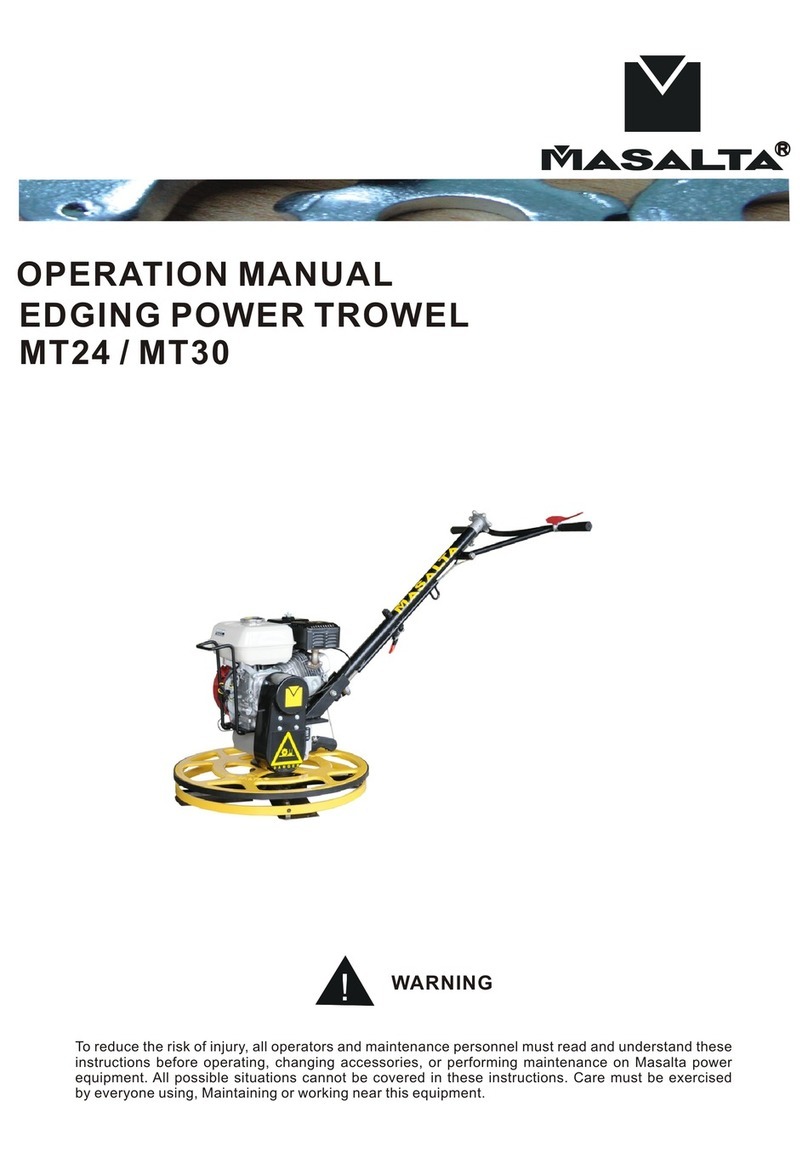

This manual suits for next models

3

Table of contents

Other Masalta Construction Equipment manuals