Table Of Contents

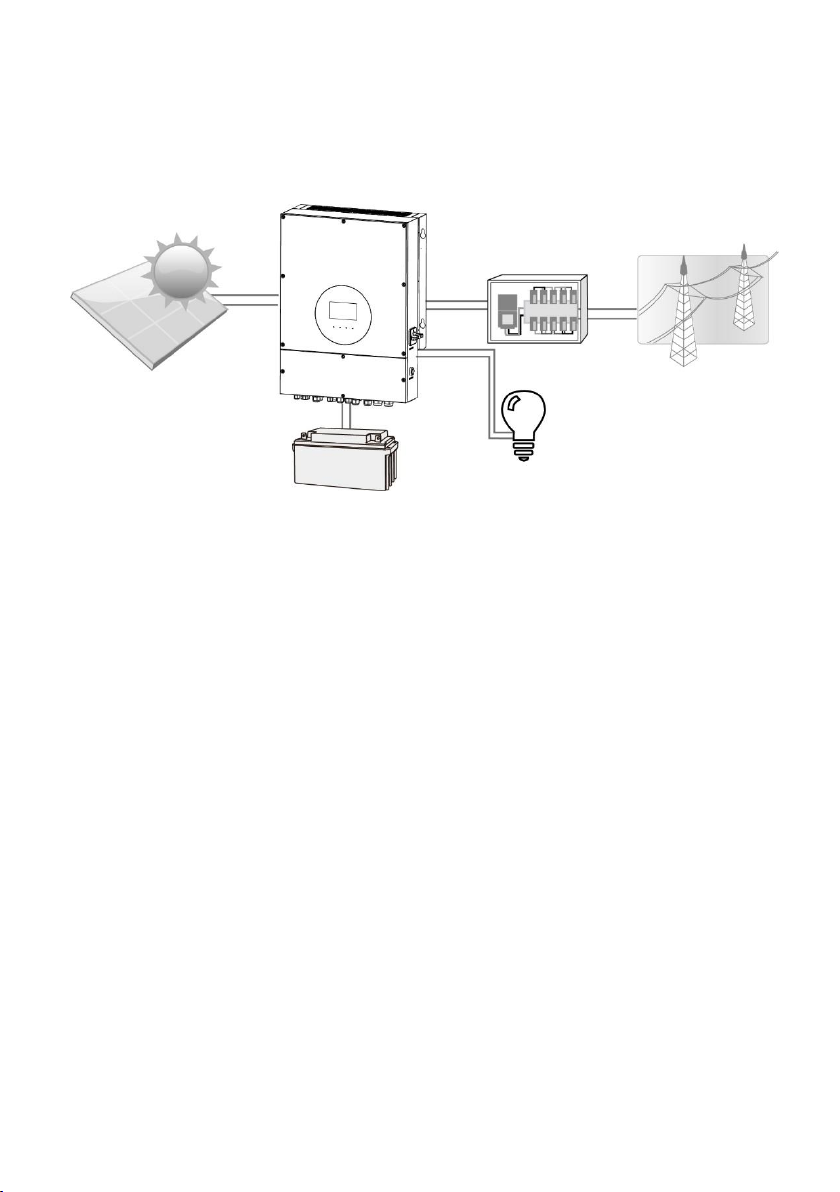

1. Introduction ....................................................................................................1

2. Important Safety Warning.................................................................................2

3. Unpacking & Overview .....................................................................................4

3-1. Packing List .............................................................................................4

3-2. Product Overview .....................................................................................4

4. Installation ......................................................................................................5

4-1. Precaution ...............................................................................................5

4-2. Selecting Mounting Location......................................................................5

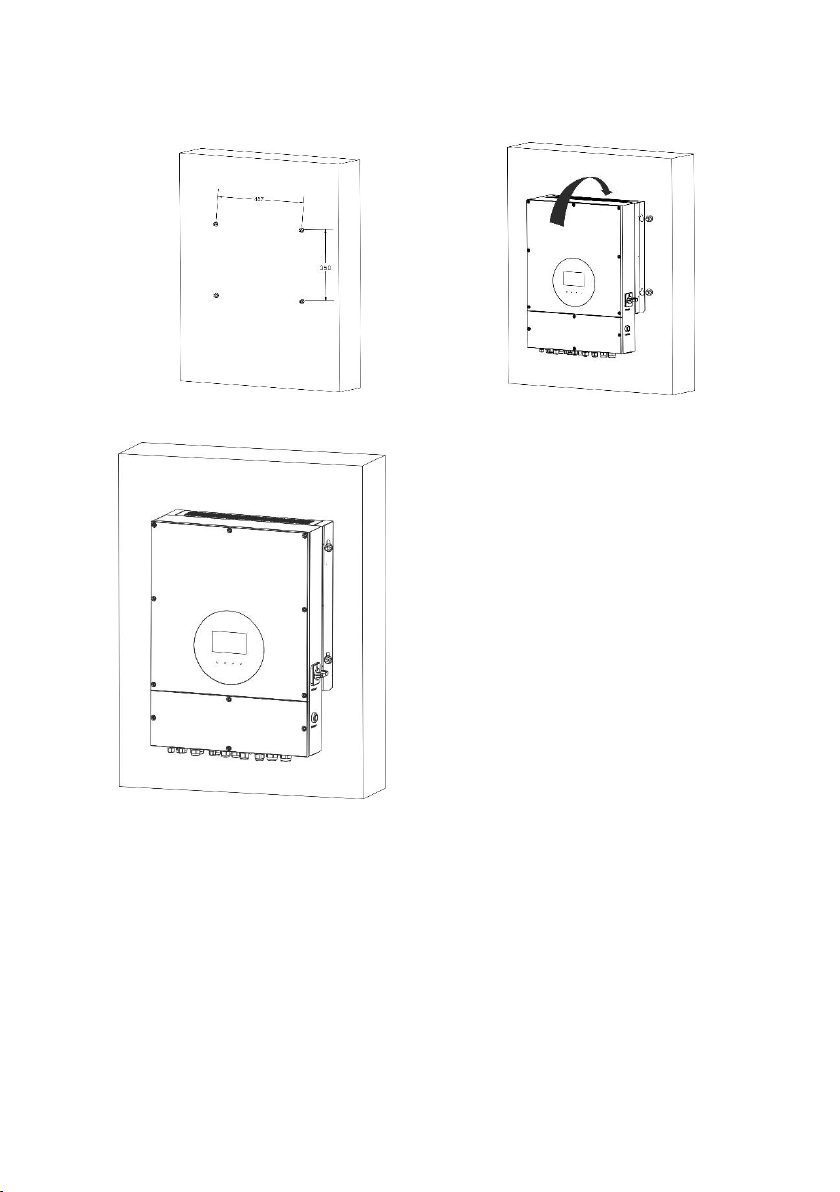

4.3. Mounting Unit ..........................................................................................5

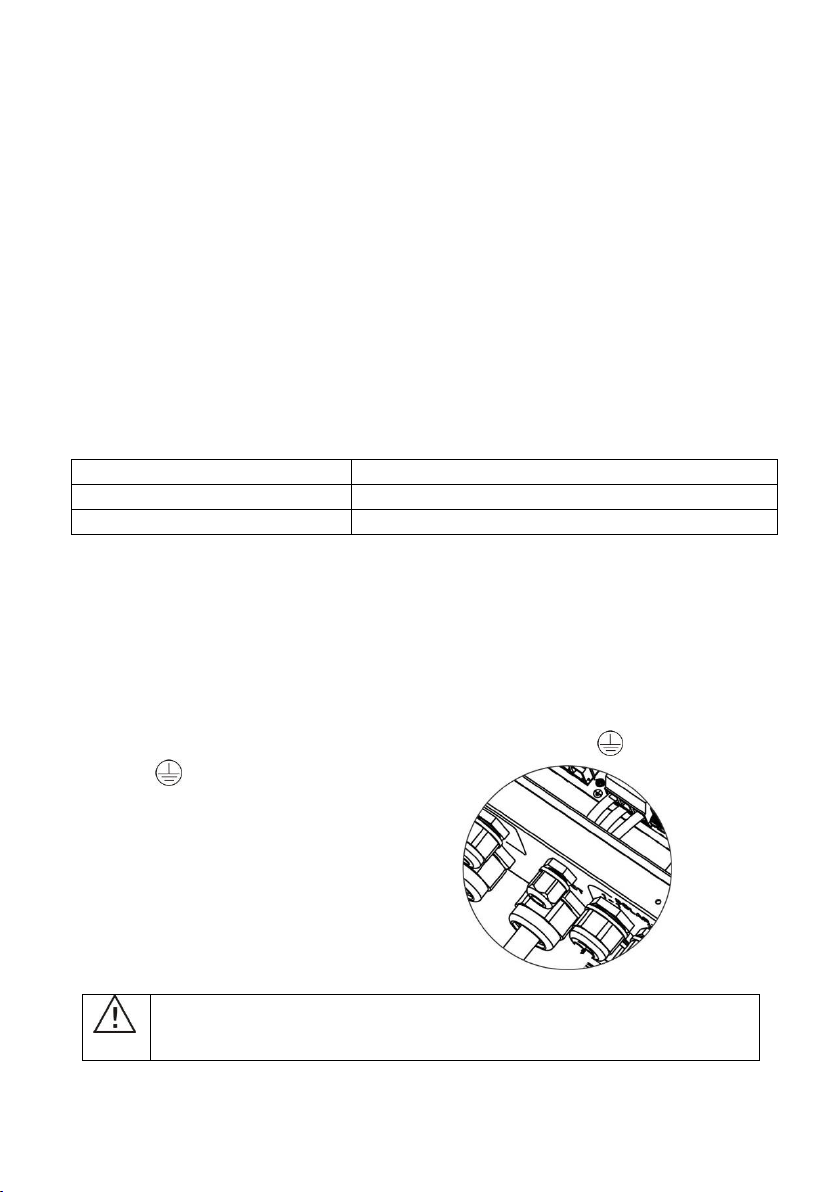

5. Grid (Utility) Connection ...................................................................................7

5-1. Preparation..............................................................................................7

5-2. Connecting to the AC Utility.......................................................................7

6. Generator Connection.......................................................................................8

6-1. Preparation..............................................................................................8

6-2. Connecting to the Generator Input.............................................................8

7. PV Module (DC) Connection ..............................................................................9

8. Battery Connection......................................................................................... 12

9. Load (AC Output) Connection.......................................................................... 13

8-1. Preparation............................................................................................ 13

8-2. Connecting to the AC output ................................................................... 13

9. Communication.............................................................................................. 15

9-1. Pin Assignment for RS-232 Communication Port........................................ 16

9-2. Pin Assignment for BMS Communication Port ............................................ 16

9-3. Dry Contact Signal.................................................................................. 16

10. Commissioning .............................................................................................. 18

11. Initial Setup................................................................................................... 19

12. Operation ...................................................................................................... 30

12-1. Interface.............................................................................................. 30

12-2. LCD Information Define......................................................................... 30

12-3. Touchable function keys ........................................................................ 32

12-4. LCD Setting.......................................................................................... 33

12-5. Query Menu Operation.......................................................................... 41

12-6. Operation Mode & Display ..................................................................... 46

13. Charging Management ................................................................................... 50

14. Maintenance & Cleaning ................................................................................. 52

15. Trouble Shooting............................................................................................ 53

15-1. Warning List......................................................................................... 53

15-2. Fault Reference Codes .......................................................................... 54

16. Specifications ................................................................................................ 56

Appendix I: Parallel Installation Guide...................................................................... 58

Appendix II: The Wi-Fi Operation Guide................................................................... 65