Murdock BF11 Series Installation and operating instructions

Other Murdock Water Dispenser manuals

Murdock

Murdock AI81.8 Series User manual

Murdock

Murdock A511.5 Series Installation and operating instructions

Murdock

Murdock BF1 Series Installation and operating instructions

Murdock

Murdock A171-UG-SO Series Installation and operating instructions

Murdock

Murdock BF2 Series Installation and operating instructions

Murdock

Murdock A171.8-UG-SO Series Installation and operating instructions

Murdock

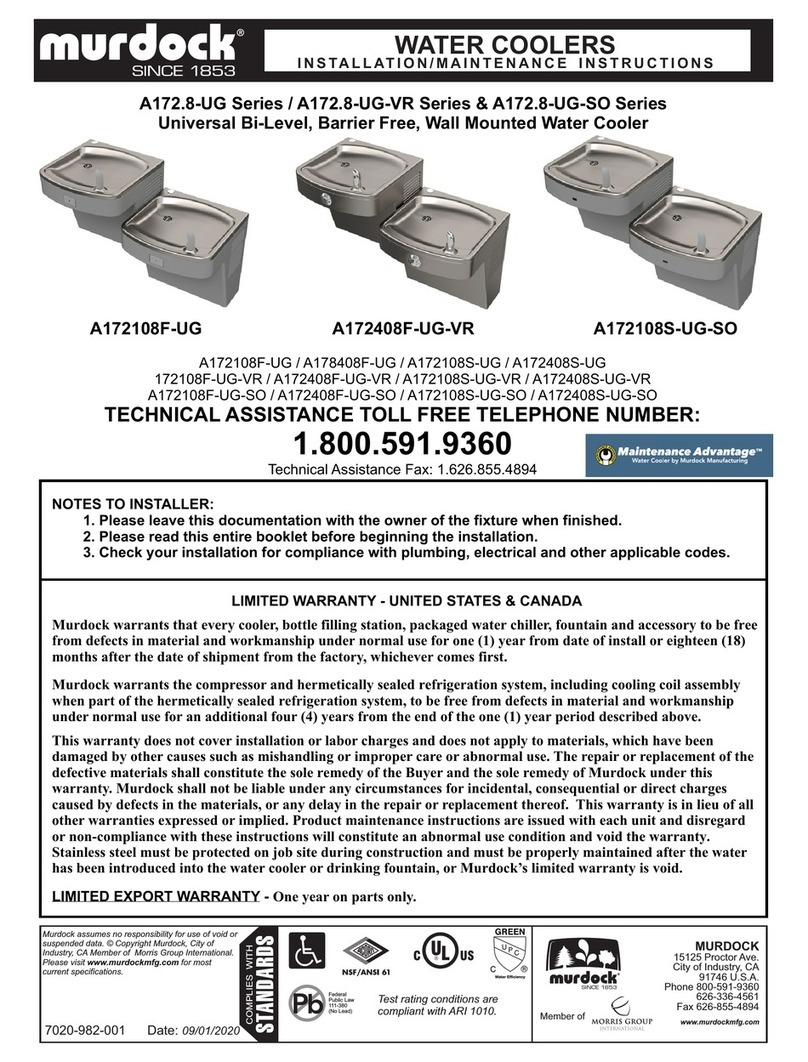

Murdock A172.8-UG Series Installation and operating instructions

Murdock

Murdock H2O To Go BF15 Series Installation and operating instructions

Murdock

Murdock BF3 series User manual

Murdock

Murdock A171 Series User manual

Murdock

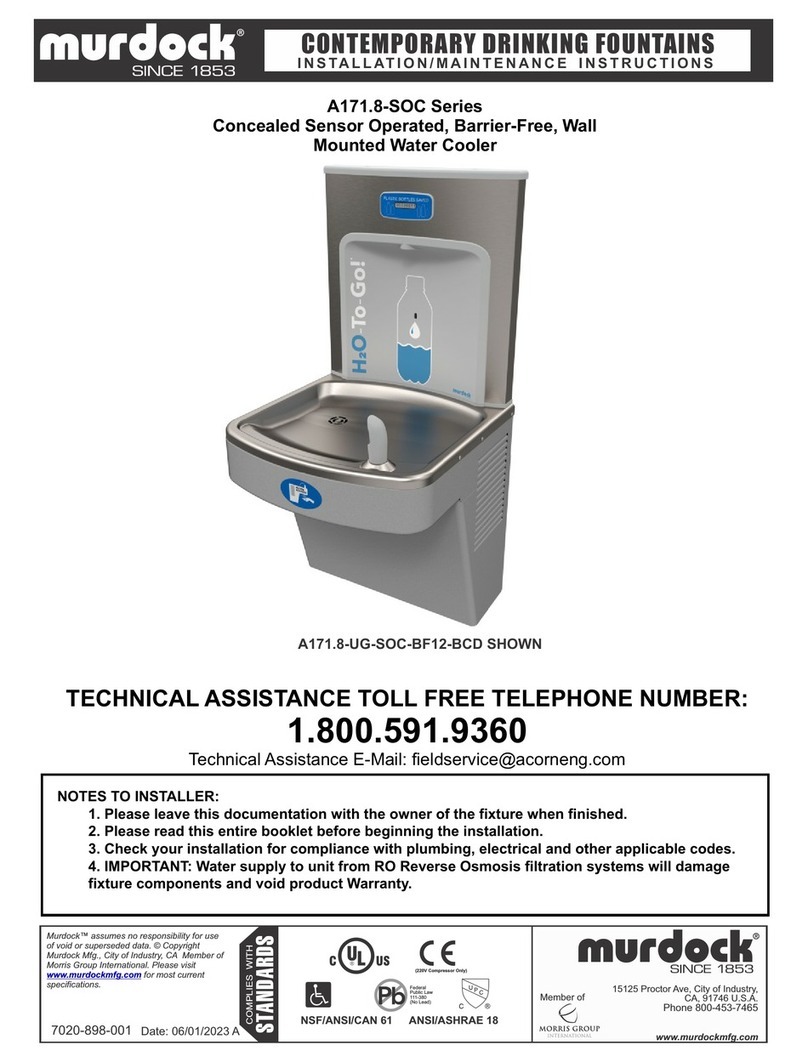

Murdock A171.8-SOC Series User manual

Murdock

Murdock H2O To Go BF12 Series Installation and operating instructions

Murdock

Murdock A171.8-UG-D1-BFS Series Installation and operating instructions

Murdock

Murdock BF158 Series User manual

Murdock

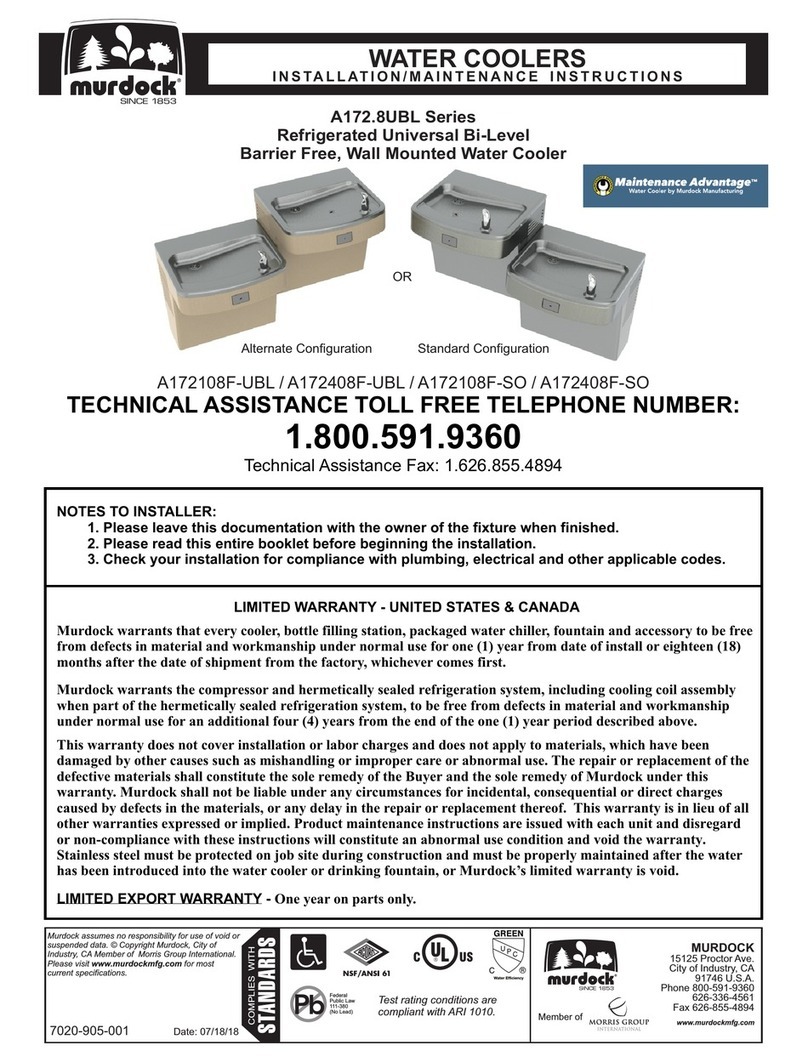

Murdock A172108F-UBL Installation and operating instructions

Murdock

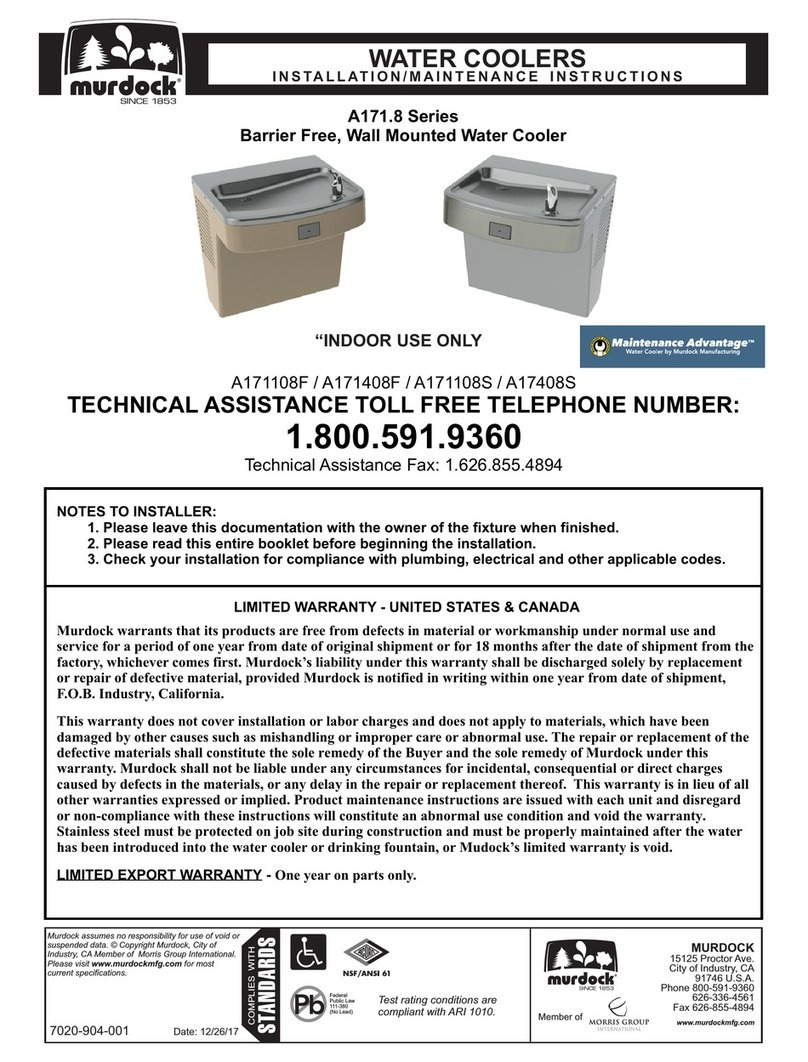

Murdock A171.8 Series User manual

Murdock

Murdock A171.8FGVR Series Installation and operating instructions

Murdock

Murdock A611.8 Series Installation and operating instructions

Murdock

Murdock A172.8FGVR Series Installation and operating instructions

Murdock

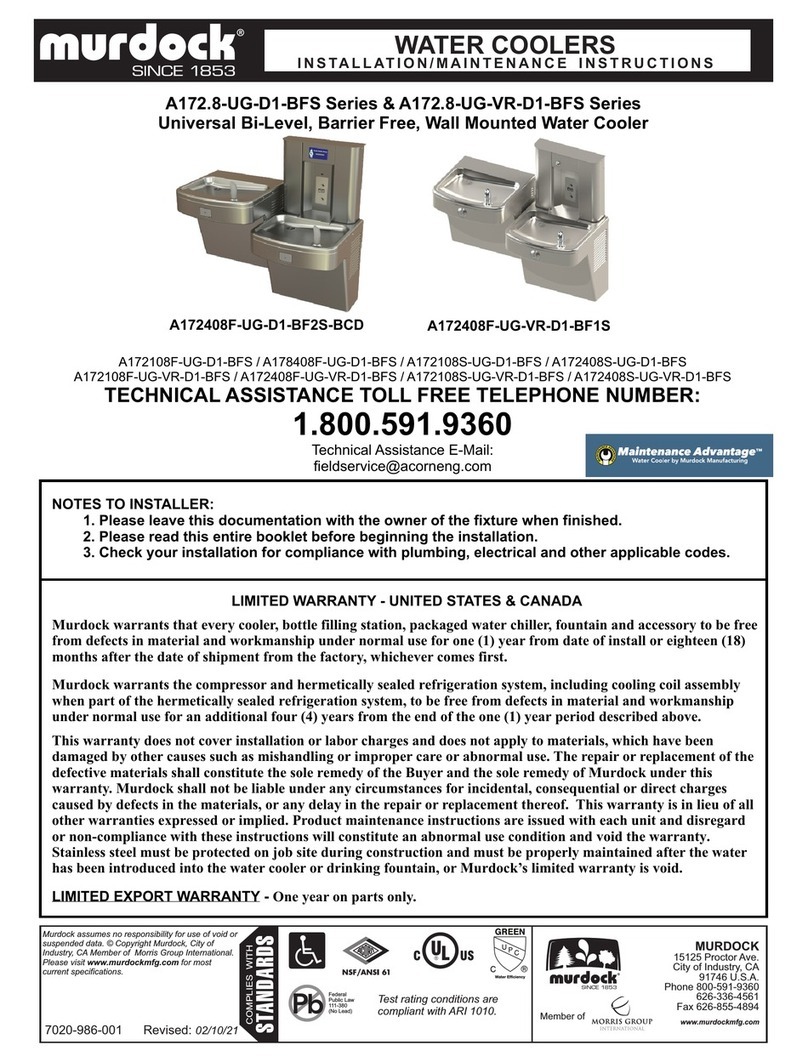

Murdock A172.8-UG-D1-BFS Series Installation and operating instructions

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual