Master Water Conditioning SIMPLUS 744 User manual

Other Master Water Conditioning Water Filtration System manuals

Master Water Conditioning

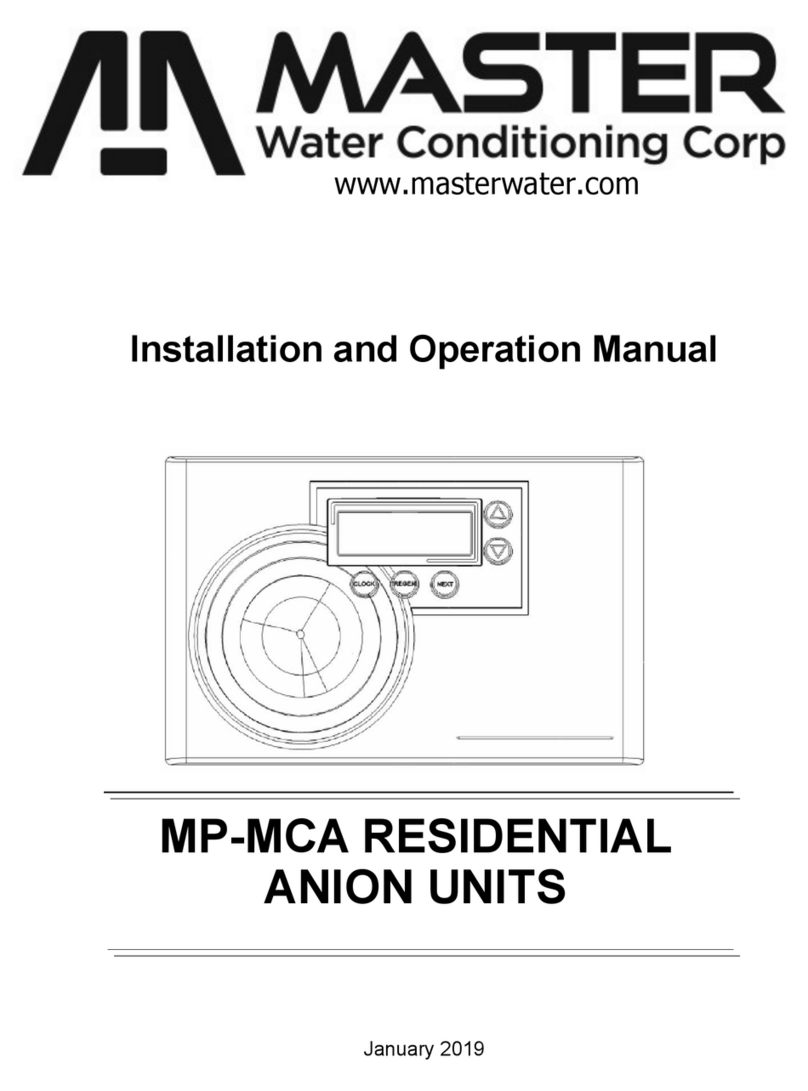

Master Water Conditioning MP-MCA Series User manual

Master Water Conditioning

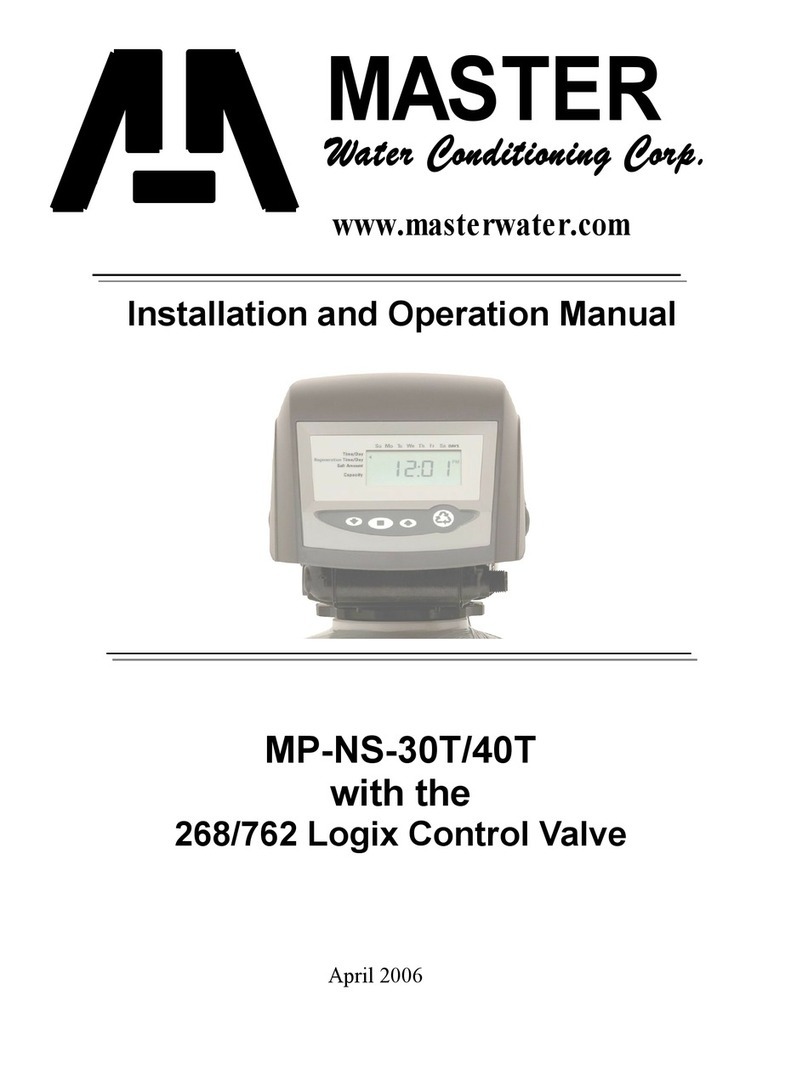

Master Water Conditioning MP-NS-30T User manual

Master Water Conditioning

Master Water Conditioning FES-30T User manual

Master Water Conditioning

Master Water Conditioning PURO PRO 1800 SC Series User manual

Master Water Conditioning

Master Water Conditioning Clarifier MCA Series User manual

Master Water Conditioning

Master Water Conditioning MBA Series User manual

Master Water Conditioning

Master Water Conditioning Alliance MP-MCA Series User manual

Master Water Conditioning

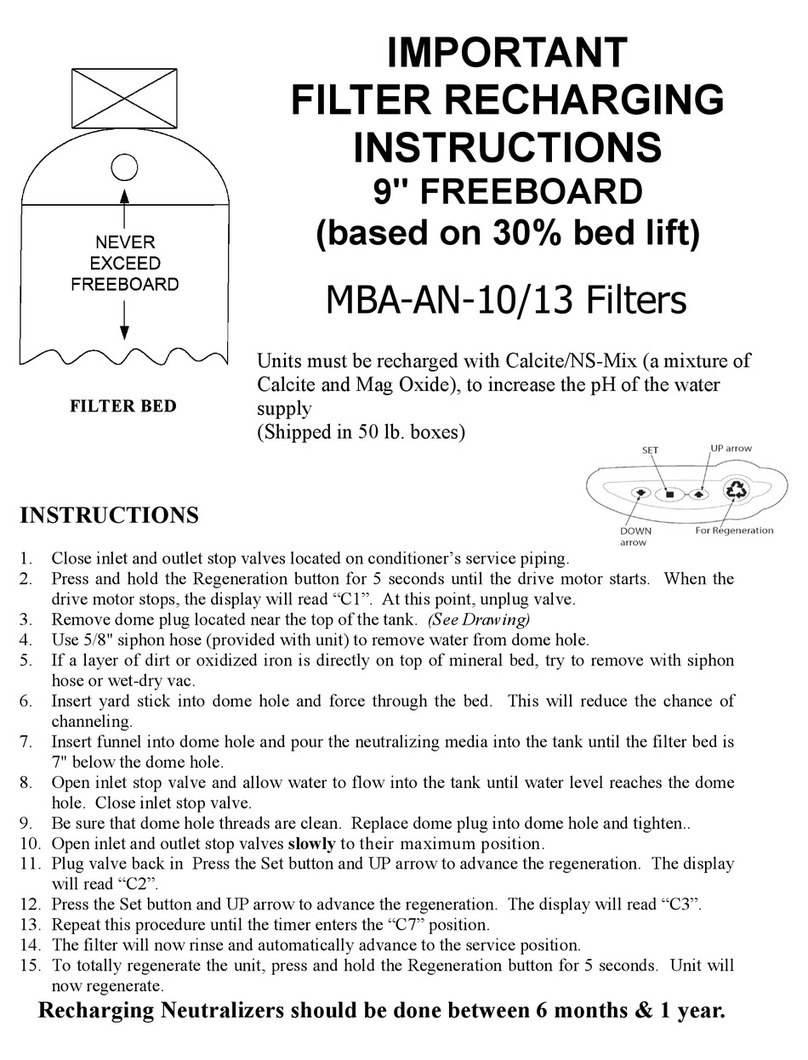

Master Water Conditioning MBA-AN-10/13 User manual

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual