Henan Master Machinery Co., Ltd

Tel:(+86)17737606271 www.mastermachinerys.com

cut. Meanwhile, sheet diamond could cut the steal beams in concrete. It

has simply, safety construction, easy and flexible operations.

SAFETY PRECAUTIONS

1. Before starting operation, the operator has to check that all control

and safety devices function properly.

2. To prevent fire hazards and to provide adequate ventilation for

stationary equipment applications keep the engine at least 3 feet (1

meter) away from building walls and other equipment during

operation.

3. Don't allow children to operate the engine. Keep children and pets

away from the area of operation.

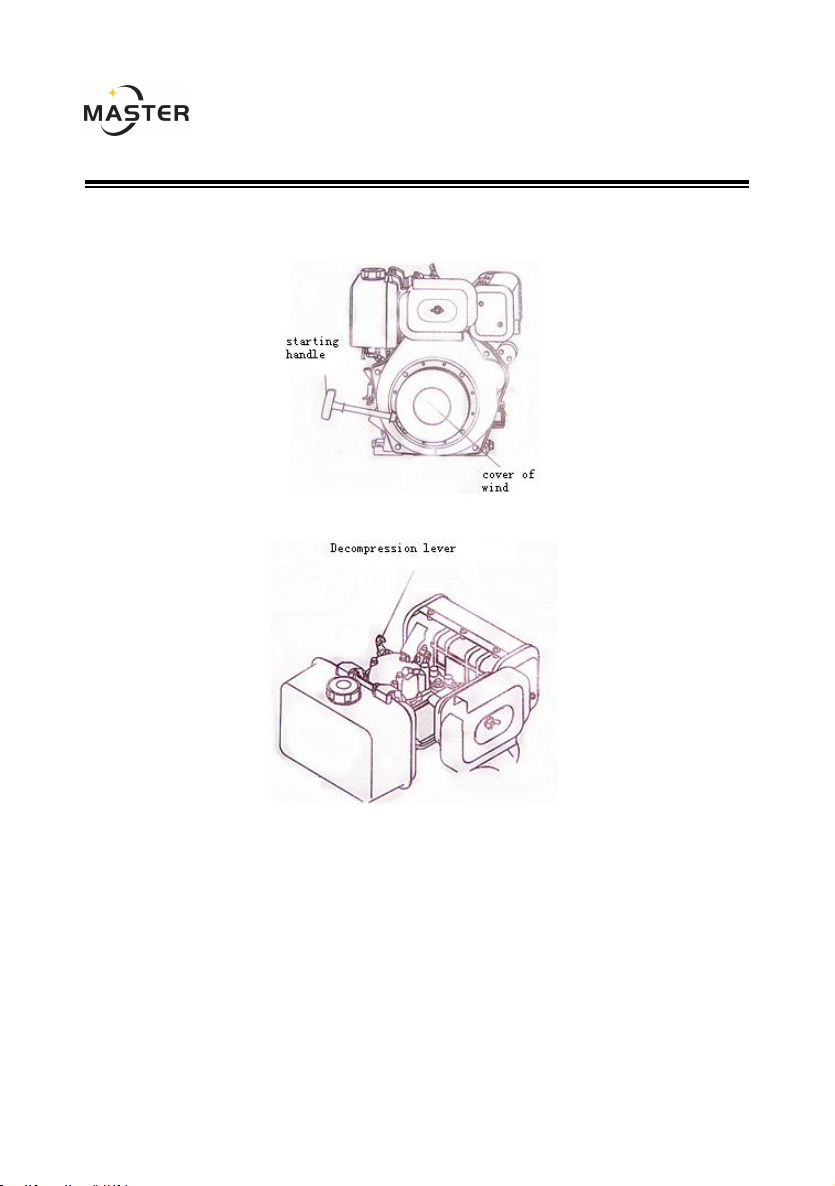

4. Know how to stop the engine quickly, and understand the operation

of all controls. Never permit anyone to operate the engine without

prior instructions.

5. Do not place flammable objects close to the engine.

6. The max gradient of 30° must not be exceeded.

7. Wear safety shoes, and eye protection glasses in case of trench

operation where falling sand stones maybe ejected.

8. Keep anyone away from the cutting sheet when the machine

working.

9. It is possible that this cutting machine exceeds the admissible

sound lever of 89 dB (A). According to the rules for the prevention of

accidents regarding emission of noise, the employees have to wear

protection if the sound levels reaches 89 dB (A) or more.

10. Be careful the handle can't keep away of the handle when operate

the machine.

11. Refuel the engine must always be stopped, using all necessary

safety precautions. When refilling fuel tank, do not allow fuel to

come into contact with the hot parts of the engine or spill onto the