3

Check damaged parts. Before using this tool, check guards and other parts carefully

to determine if they operate properly and perform their intended functions. Check the

alignment of moving parts; check also for binding of moving parts, breakage or

damage of parts, incorrect mounting, and any other conditions that may alter the

operation of the tool.

Any part that is damaged, defective switches included, should be properly repaired or

replaced by a qualified service technician. Do no use the tool if the starter switch is

not functioning properly.

WARNING: The operation of any tool can result in foreign objects being

propelled into your eyes, resulting in severe eye damage. When operating power

tools, always wear safety goggles or safety glasses with side shields and a full face

shield when needed.

WARNING: If any parts are missing, do not operate the tool until the missing

parts have been replaced. Doing so could result in serious personal injury.

ELECTRICAL SAFETY

•Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will fit

in a polarized outlet only one way. If the plug does not

fit in the outlet, reverse the plug. If it still does not fit,

contact a licenced electrician to install a polarized outlet.

Do not change the plug in any way. Double insulation

eliminates the need for a three wire grounded power cord

and grounded power supply system.

•Avoid contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is grounded.

•Do not expose power tools to rain or wet conditions. A wet power tool will

increase the risk of electric shock.

•Do not abuse the cord. Never use the cord to carry the tool, or pull the plug

from an outlet. Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords increase the risk of

electric shock.

•When operating a power tool outside, use an outdoor extension cord

marked “W-A” or “W”. These cords are rated for outdoor use and reduce the

risk of electric shock.

•Replace damaged cords immediately. Use of damaged cords can shock, burn or

electrocute the operator of the tool.

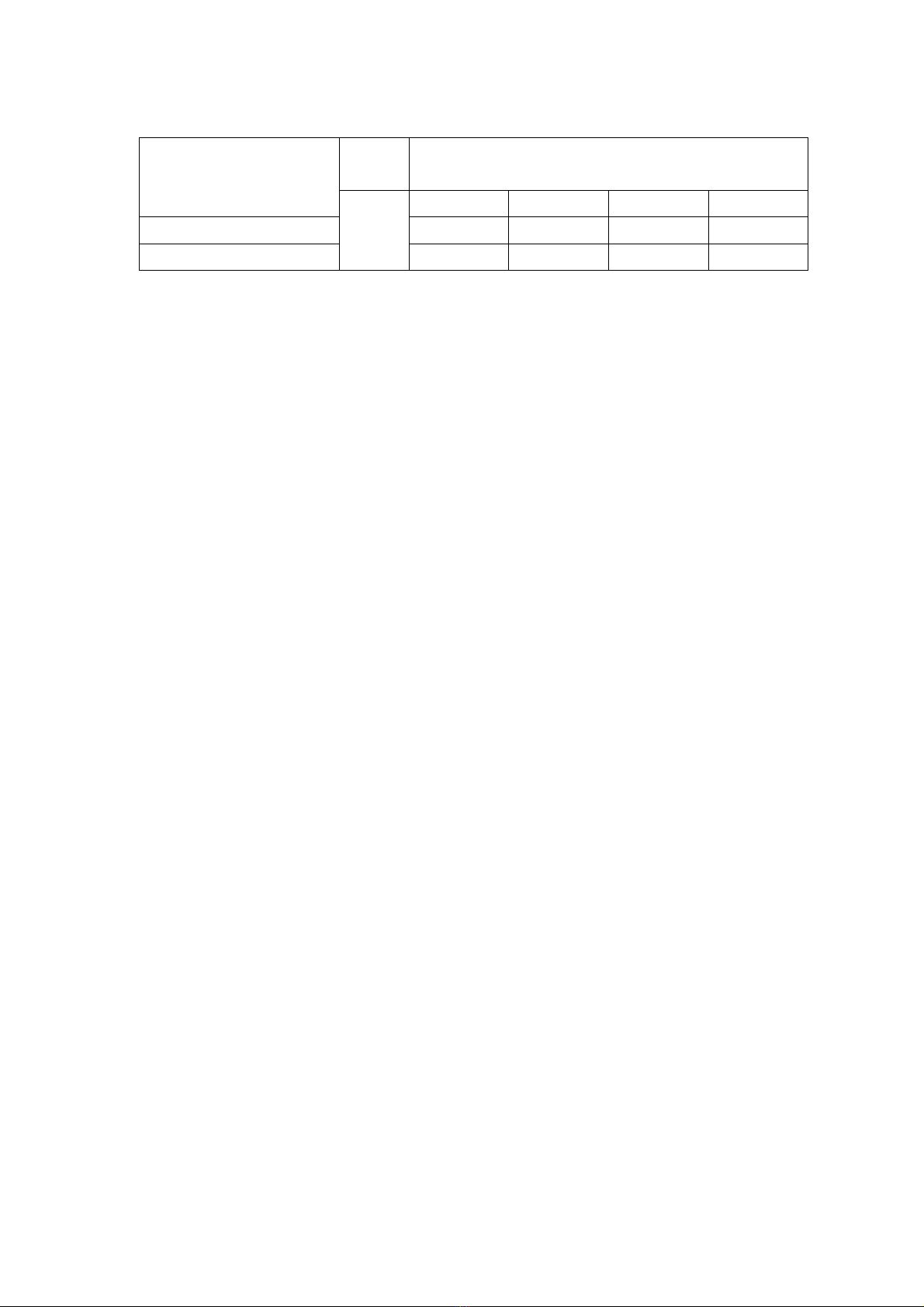

•If an extension cord is necessary, a cord with adequate size conductors should

be used to prevent excessive voltage drop, loss of power or overheating. The

table shows the correct size to use, depending on cord length and nameplate

amperage rating of tool. If in doubt, use the next heavier gauge. Always use UL

and CSA listed extension cords.