Ironwood P600 | User Manual 3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood P600 Planer. At Stiles

Machinery, our goal is to ensure that you are fully satisfied with

your purchase. This manual is provided so that you may properly

assemble, operate, and maintain your P600. Should you need help,

our team of dedicated service personnel are available to answer

your questions and provide any resource recommendations you may

need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

For specific information regarding the electrical system and

pneumatic supply, please refer to the data that is stamped on the

metallic plate.

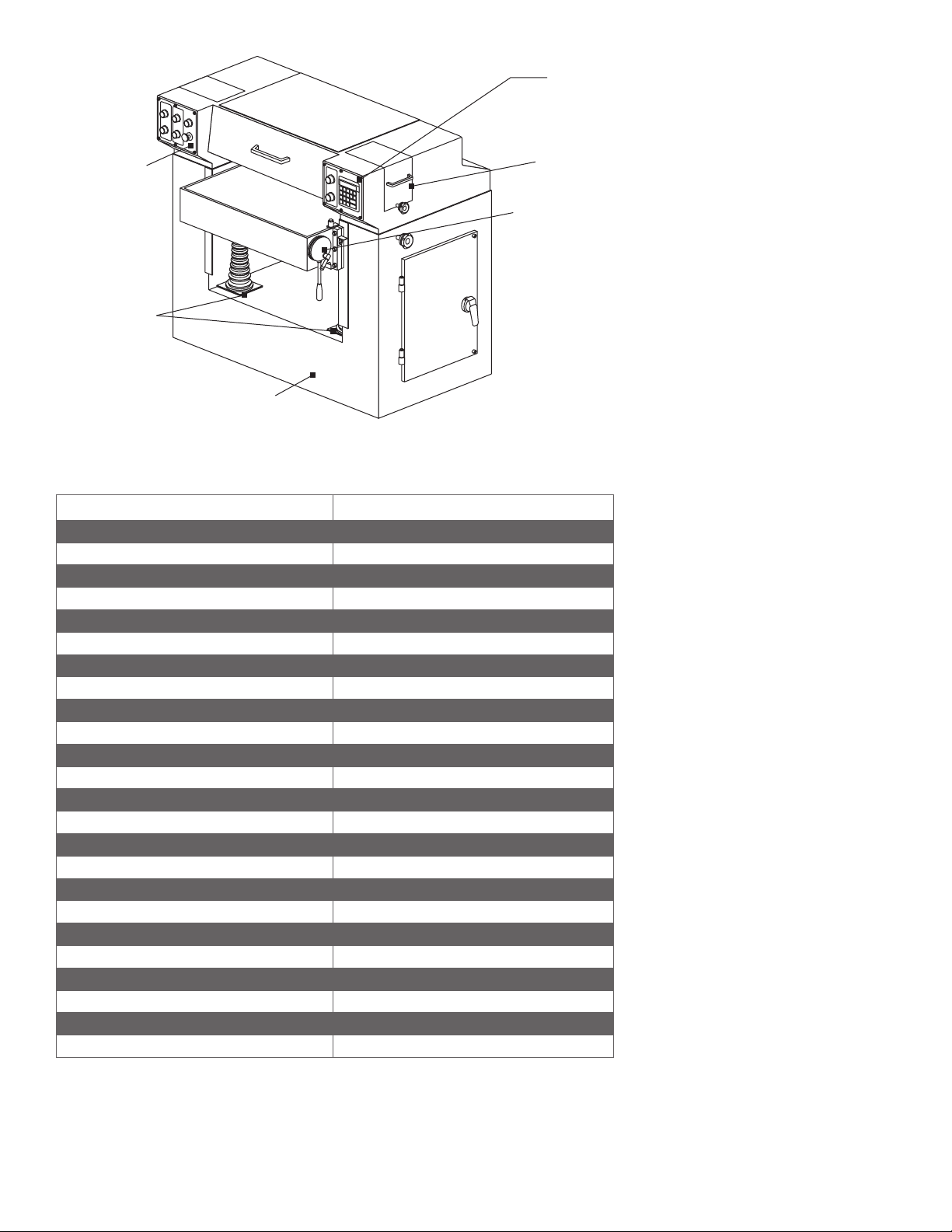

Machine information plate

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/p600

Machine Model ____________________________________________

Machine Serial Number _____________________________________

1.3 Features

• Iron machine base

• Four heavy-duty jack screws enable precise and vibration-free

performance

• Cast iron table is heat treated and precision ground for rigidity

and stability

• Digital controller has keypad entry for table positioning with

programmability to save 10 programs

• Conveniently located controls

• Segmented infeed roller and pressure shoe ensure positive

contact on workpieces of varying thickness

• Spiral cutterhead has six rows of 16 carbide inserts, providing

high chip-removal rate, superior surface finishing, and reduced

noise levels

• 1/2-hp motor raises and lowers table

• 2-hp feed motor with variable speed controls

• Variable feed speeds from 19-39 feet per minute

• Heavy-duty 10-hp cutterhead motor

• Enclosed micro-adjustment dial for accurate positioning of the

table

• Bed roller for planning of rough or finished lumber or glued

panels adjusts quickly from 0.0-0.5"

1.4 Intended Use

The Ironwood P600 is designed for planing raw stock to achieve a

desired thickness and/or remove defects. Planing typically follows

jointing (flattening and straightening) in the woodworking process.