2

Table of Contents

Section Page

Table of Contents ..................................2

Safety Instructions for

Thickness Planer ............................... 3

Safety Symbols ...................................... 3

Before Using The Thickness Planer ...3

When Installing Or Moving The

Thickness Planer ............................... 4

Before Each Use .................................... 5

To Reduce The Risk Of Injury From

Jams, Slips Or Thrown Pieces ..........5

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears .......................5

Inspect Your Workpiece ...................... 6

Whenever Thickness Planer Is

Running .............................................6

Before Leaving The

Thickness Planer ............................... 7

Glossary of Terms for Woodworking ..... 7

Motor Specifications and Electrical

Requirements .................................... 8

Power Supply and Motor

Specifications .................................... 8

General Electrical Connections .......... 8

110-120 Volt, 60 Hz. Tool Information 8

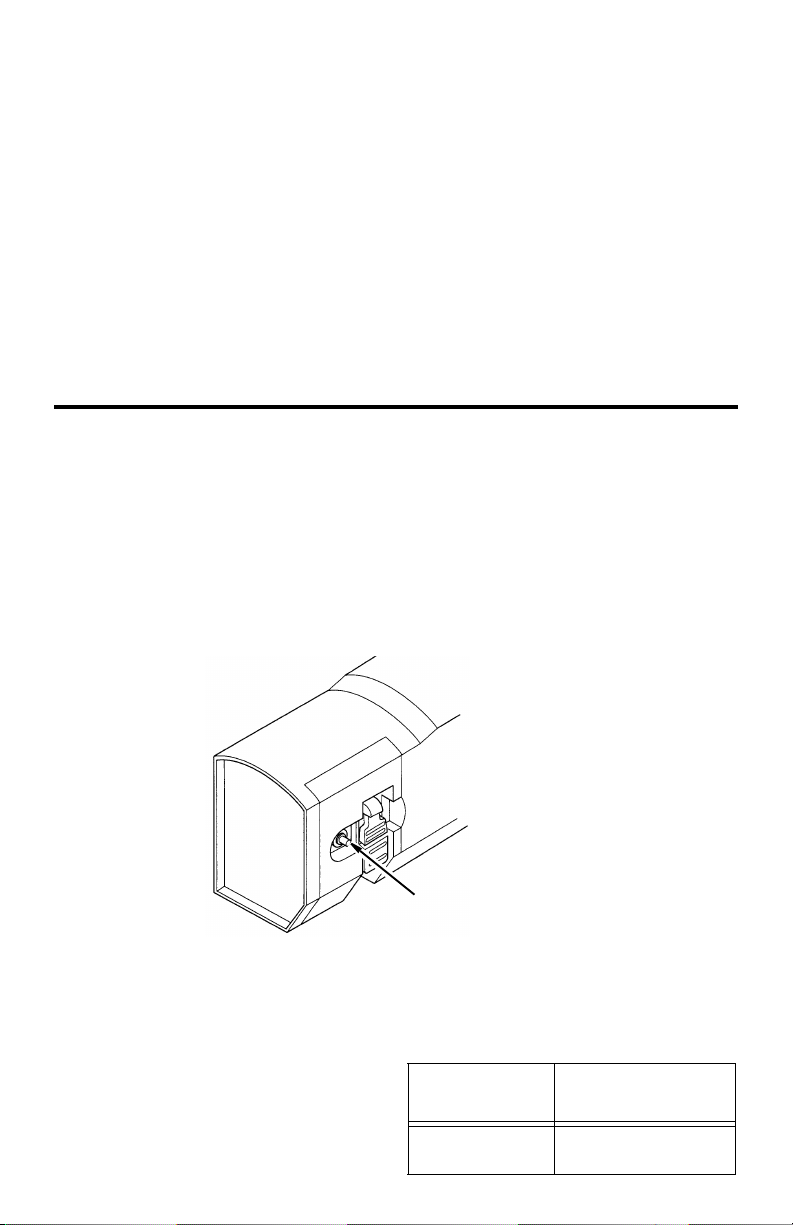

Motor Safety Protection ...................... 9

Thermal Overload Protector ............. 10

Wire Sizes .........................................10

Unpacking and Checking Contents .....11

Tools Needed ................................... 11

Unpacking ......................................... 11

List of Loose Parts ............................ 11

Assembling Legset ..............................12

Assembling Upper and

Lower Legs ...................................... 13

Assembling Lower Stiffeners ............13

Assembling Upper Stiffeners ............14

Mounting The Thickness Planer .......... 15

Mounting on Legset ..........................15

Mounting Thickness Planer on

Supplied Legset ...............................15

Mounting Thickness Planer on

Other Legsets or Work Benches ..... 15

Section Page

Portable Applications ........................ 15

Work Bench Applications .................. 15

Installing the Handwheel Knob ............ 16

Alignment (Adjustments) ..................... 16

Extension Assembly Alignment ........ 16

Adjusting the Thickness Indicator ..... 16

Getting to Know Your

Thickness Planer ............................. 17

Safety Instructions for Basic Thickness

Planer Operations ............................... 18

Before Using The Thickness Planer . 18

Before Each Use .............................. 18

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears .................... 18

Inspect Your Workpiece ................... 19

Whenever Thickness Planer Is

Running ........................................... 19

Basic Thickness Planer Operations .... 20

Before You Begin ............................. 20

Reduce Damage To Knives .............. 21

Preparing the Work ........................... 21

Carriage Lock ................................... 21

Carriage Lock Adjustment ................ 22

Elevation Handwheel ........................ 22

Feeding the Work ............................. 22

Material Removal Indicator ............... 23

Preset Thickness Stops

(Repeat-A-Cut) ................................ 23

Thickness Stop (Repeat-A-Cut)

Adjustment ...................................... 23

Checking for Worn Knives ................ 24

Maintenance ........................................ 24

Lubrication ........................................ 24

Cleaning the Knives .......................... 24

Cleaning The Feed Rollers ............... 24

Motor Ventilation ............................... 24

Changing Brushes ............................ 25

Replacing Knives .............................. 25

Accessories ......................................... 26

Wiring Diagram .................................... 26

Troubleshooting ................................... 27

Repair Parts ........................................ 28

Notes ................................................... 34