4 SW-07doc021023Table of Contents

Table of Contest Section-Page

SECTION 1 INTRODUCTION 1-1

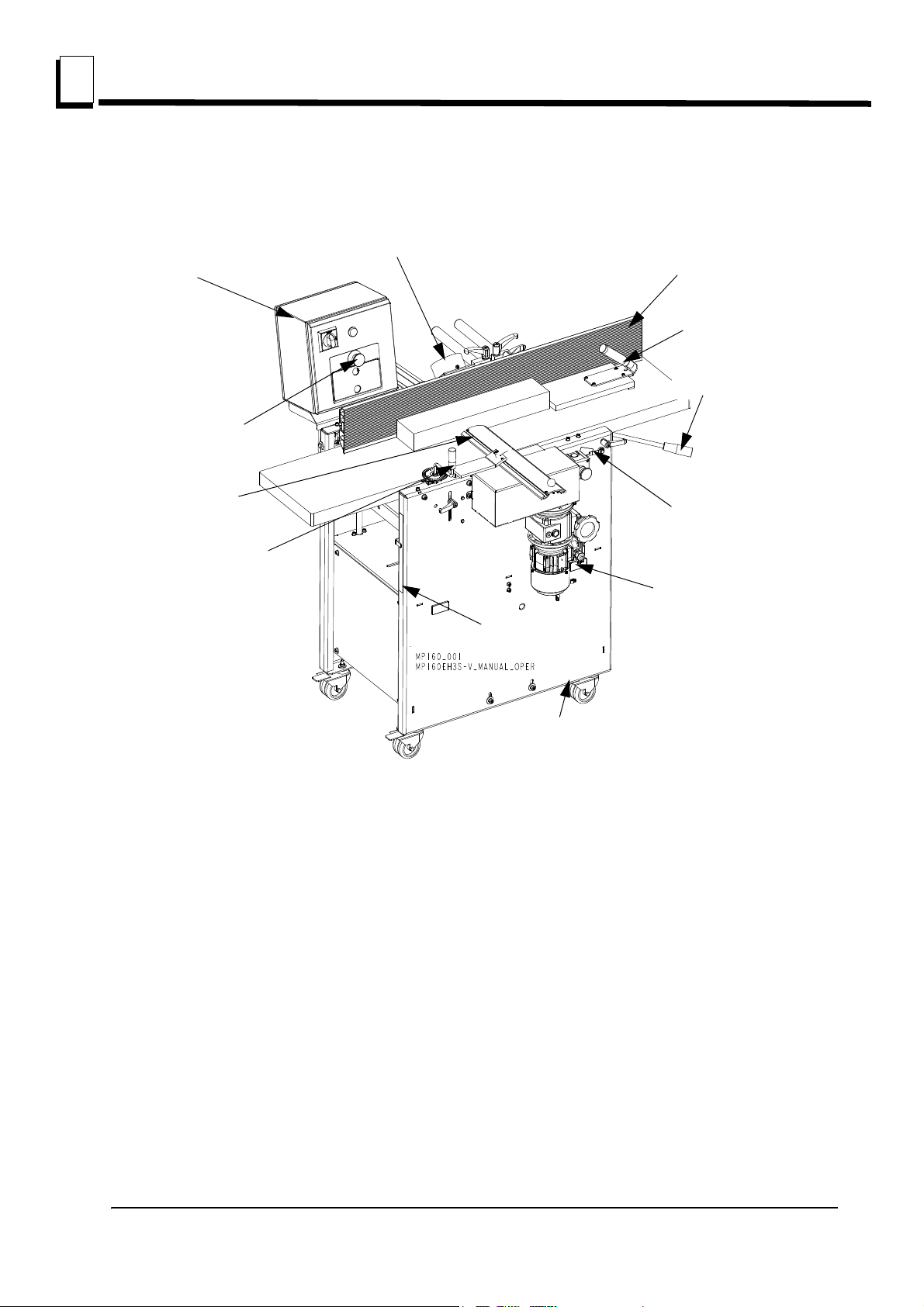

1.1 Machine description ...............................................................................1-2

1.2 Planer/thicknesser major components ...................................................1-6

SECTION 2 SAFETY 2-1

2.1 Safety Symbols.......................................................................................2-1

2.2 Safety Instructions ..................................................................................2-1

Planer/thicknesser operation

Safety Labels Description

SECTION 3 SETUP & OPERATION 3-1

3.1 Planer/moulder setup ..............................................................................3-1

3.2 MP200 planer/moulder operation...........................................................3-3

Control panel

Top cutter

Chain transmission with trapezoidal thread adjustment

Side cutter

Variable speed motor manual

Optional Table Assembling

Optional Table installation from the outfeed side.

Optional Table installation from the infeed side.

SECTION 4 MAINTENANCE 4-1

4.1 Wear life .................................................................................................4-1

4.2 Sawdust Removal ...................................................................................4-1

4.3 Miscellaneous Maintenance ...................................................................4-1

4.4 Drive Belt Tension Adjustment..............................................................4-2

Top cutter drive belt tension adjustment

Side cutter drive belt tension adjustment

Table chain tension adjustment

Roller drive chain tension adjustment

4.5 Long-term storage ..................................................................................4-6

4.6 Replacement of Inserts in Helical Cutterhead........................................4-7

4.7 Safety Devices Inspection ......................................................................4-8

SECTION 5 PLANER/MOULDER SPECIFICATIONS 5-1

5.1 Overall dimensions.................................................................................5-1

5.2 Specifications of the planer/moulder......................................................5-2