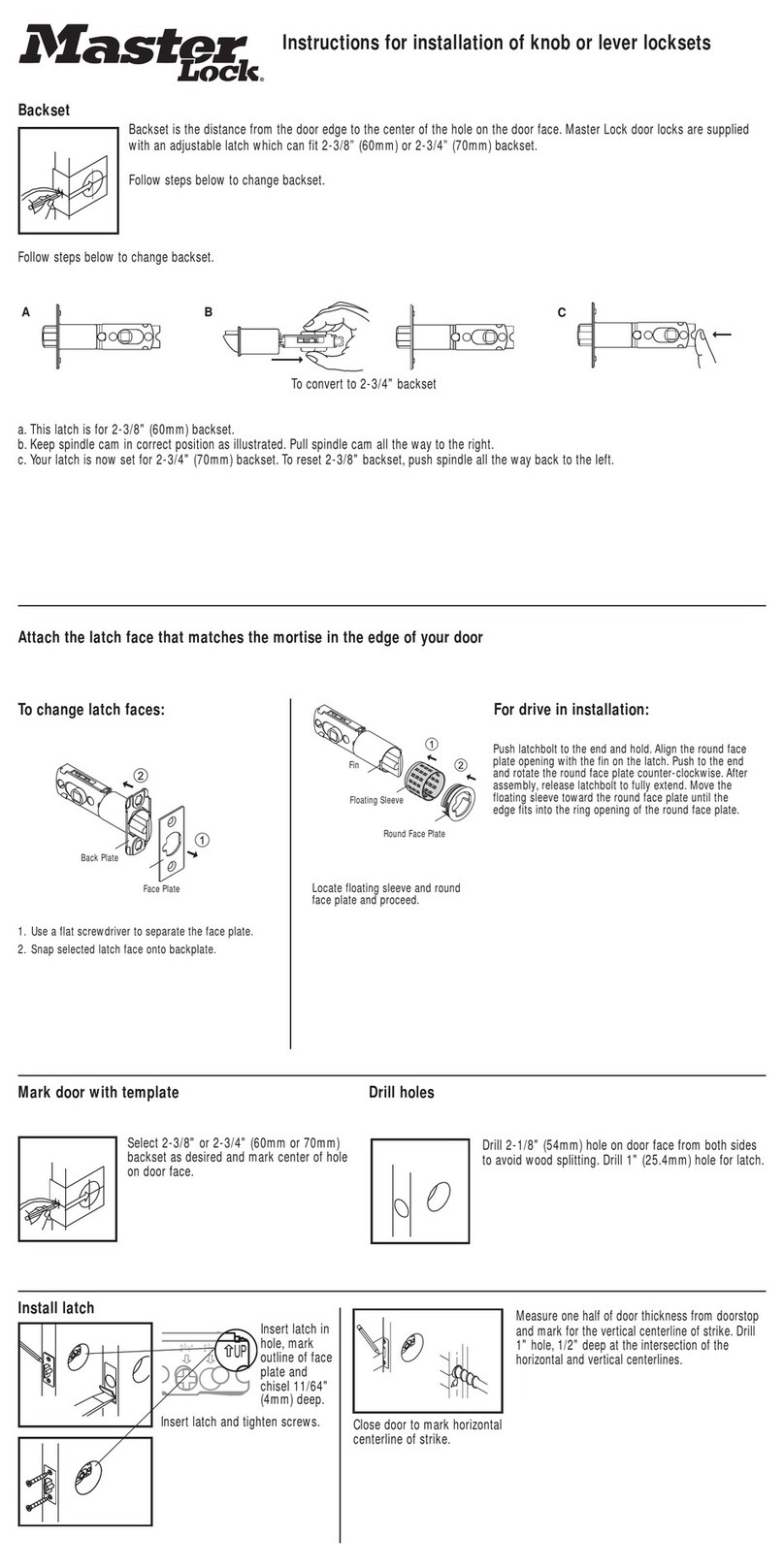

All of the ProSeries®locks have a generic construction technology that

allows for a uniform assembly and disassembly technique. Below is a step-

by-step procedure for disassembling one of these padlocks (refer to

diagram at right for parts and orientation). The only exceptions to this

procedure will be the Door Hardware and IC versions of the lock.

•Use the key to unlock the shackle, A. (If the key is unavailable you will

have to use another method to unlock the shackle).

•Use a 7/64" hexagonal wrench to remove the mounting screw located

inside the toe side shackle hole.

•Holding the trap door, D, in place, lock the shackle, A, into the padlock

body. (This relieves pressure on the extension, E).

•Remove the trap door, D, and the nut, F.

•Remove the cylinder, C.

•Remove the extension, E.

•Remove the locking ball bearings, B, and shackle, A.

The order may be reversed to reassemble the lock. A light application of

assembly grease may be used to hold the ball bearings in place during

assembly.

If the lock only needs to be rekeyed, it is not necessary to remove the

extension, ball bearings, or shackle.

Two functions are available in the locks, NKR (Non Key Retaining) and

NRK (Non Removable Key) and both functions are accomplished as a

design feature of the extension.

The NKR, non key retaining, function extension used in the lock has a

projection on one side. You should note the orientation of this projection

when removing the extension so that you can easily reinstall it during the

reassembly process. Extensions are supplied with different sizes and two

different styles have been used in the ProSeries®locks. Consult the

Extension section, page 17, of this manual for more detailed information.

The NRK, non removable key, function extension does not have a

projection to help with orientation and you will have to rely on the

position of the half-moon shaped actuator the tail of the cylinder contacts.

Again, different sizes and styles are available for use in the ProSeries®

locks, so consult the Extension section, page 17, of this manual for more

detailed information.

See component parts list on page 5.

ProSeries®Rekeyables Service Procedure

2

A

G

B

E

C

D

F