MT1842 3 Rev. 06/18/08

MT1842 3/8" Wobble Drive Air Ratchet

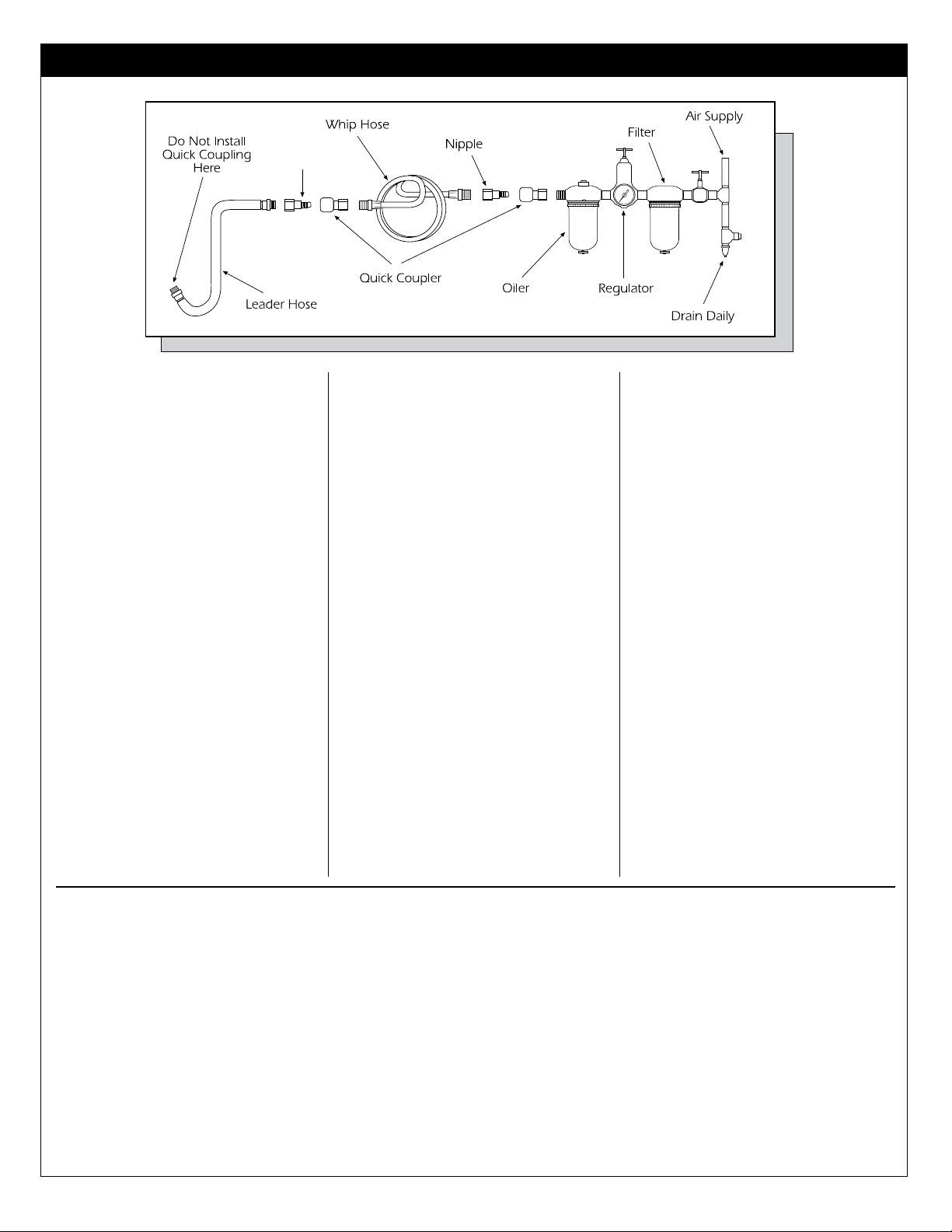

Toolsofthisclassoperateonawide

range of air pressures. It is recommended

that air pressure of these tools measures

90PSIatthetoolwhilerunningfree.

Higherpressure(over90psig;6.2bar)

raisesperformancebeyondtherated

capacityofthetoolwhichwillshorten

toollifebecauseoffasterwearandcould

causeinjury.

Alwaysuseclean,dryair.Dust,corrosive

fumesand/orwaterintheairlinewill

cause damage to the tool. Drain the air

tankdaily.Cleantheairinletfilterscreen

onatleastaweeklyschedule.The

recommended hookup procedure can

beviewedintheabovefigure.

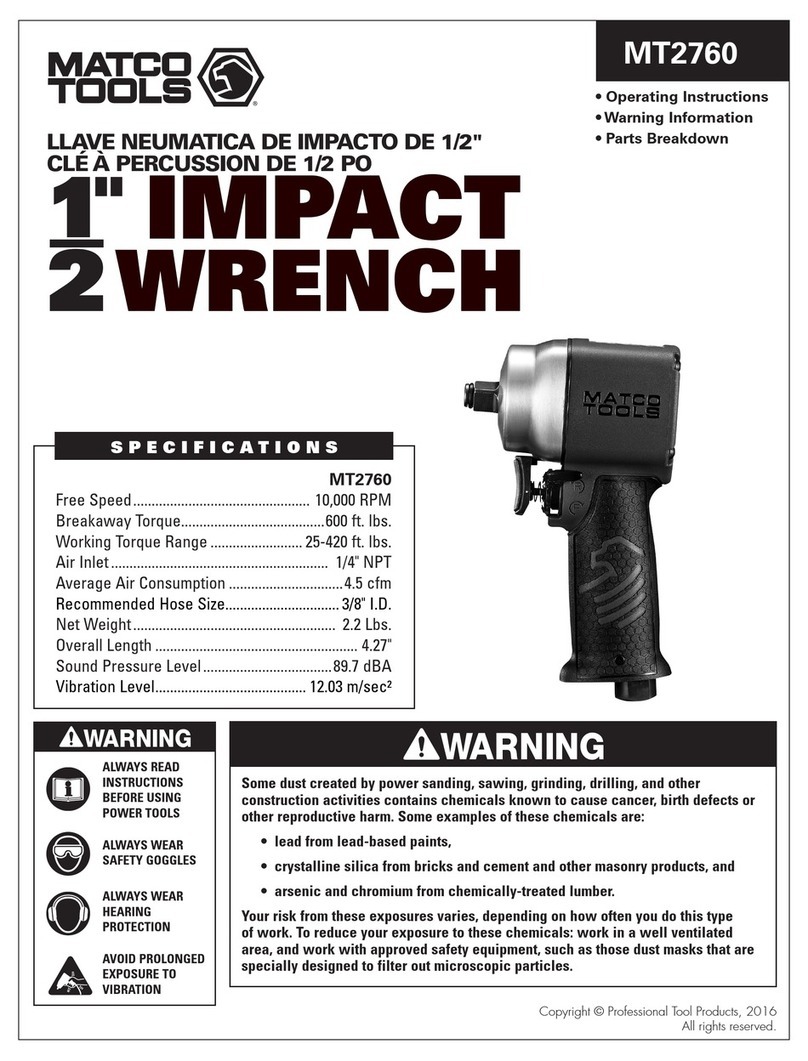

The air inlet used for connecting air

supply,hasstandard1/4"NPT.Line

pressure should be increased to

compensateforunusuallylongairhoses

(over25feet).Minimumhosediameter

should be 3/8" I.D. and fittings should

have the same inside dimensions and be

tightlysecured.

Thisratchetwrenchisratedat3/8"USS

boltsize.Ratingmustbedowngraded

forspringUbolts,tiebolts,longcap

screws,doubledepthnuts,badlyrusted

conditionsandspringfastenersasthey

absorbmuchoftheimpactpower.When

possible,clamporwedgetheboltto

prevent springback.

Soak rusted nuts in penetrating oil and

breakrustsealbeforeremovingwith

impactwrench.Ifnutdoesnotstartto

move in three to five seconds use a larger

sizeimpactwrench.Donotuseimpact

wrenchbeyondratedcapacityasthiswill

drastically reduce tool life.

Theforward/reversingbuttonisusedto

change the rotation of the tool. When the

buttonissettotheright,thetoolwillturn

in a right hand rotation. When the button

issettotheleft,thetoolwillturninaleft

hand rotation.

Actual torque on a fastener is

directlyrelatedtojointhardness,tool

speed,conditionofsocketandthetime

thetoolisallowedtoimpact.

Use the simplest possible tool-to-socket

hookup.Everyconnectionabsorbsenergy

andreducespower.

Otherfactorsoutsidethetoolmaycause

lossofpowerorerraticaction.Reduced

compressoroutput,excessivedrainon

theairline,moistureorrestrictionsinair

pipes or the use of hose connections of

improper size or poor conditionsmay

reduceairsupply.Gritorgumdeposits

inthetoolmaycutpowerandmaybe

correctedbycleaningtheairstrainer

andflushingoutthetoolwithgumsolvent

oil or an equal mixture of SAE #10

and kerosene. If outside conditions are

in order and tool continues to perform

erratically,disconnecttoolfromhose

andtaketooltoyournearestauthorized

service center.

Lubricatetheairmotordailywithquality

airtooloil.Ifnoairlineoilerisused,run

a teaspoon of oil through the tool. The

oil can be squirted into the tool air inlet

or into the hose at the nearest connec-

tiontotheairsupply,thenrunthetool.

The amount of oil to be used is 1 ounce.

Overfillingwillcauseareductioninthe

powerofthetool.Greasefittingonyoke

occasionallytoensureproperlubrication

of the ratchet mechanism.

Matcowarrantsitsairtoolsforaperiodof1yeartotheconsumer.

WewillrepairanyMTSeriesairtoolcoveredunderthiswarranty

whichprovestobedefectiveinmaterialorworkmanshipduringthe

warrantyperiod.Inordertohaveyourtoolrepaired,returnthetool

toeitheroftheMatcoAuthorizedWarrantyCenterslistedbelow,

freightprepaid.Pleaseincludeacopyofyourproofofpurchase

andabriefdescriptionoftheproblem.Thetoolwillbeinspected

andifanypartorparts arefoundtobedefectiveinmaterial or

workmanship,thetoolwillberepairedfreeofchargeandreturned

toyoufreightprepaid.

Thiswarranty gives youspecificrights. Youmay alsohaveother

rightswhichvaryfromstatetostate.

TheforegoingobligationisMatco’ssoleliabilityunderthisorany

impliedwarrantyandundernocircumstancesshallMatcobeliable

foranyincidentalorconsequentialdamages.

Some states do not allow the exclusion or limitation of

incidental or consequential damages so the above limitation or

exclusionmaynotapplytoyou.

MATCO AIR COMMAND

ToolRepairSV

1330 Commerce Dr.

Stow,OH44224

(800)433-7098

DISCOUNT TOOL REPAIR

3433 Losee Rd. #1

NorthLasVegas,NV89030

(702)657-6570