Matest B041 User manual

O P E R A T I N G M A N U A L

Gyratory Compactor

M A N U A L C O D E

B041

DO NOT TRY TO OPERATE THIS APPLIANCE BEFORE READING

AND LEARNING THIS MANUAL IN ALL ITS PARTS

USERS:

MACHINE MANUFACTURERS / DRAUGHTSMEN

/ OPERATORS MAINTENANCE / WORKERS

REV.

DESCRIZIONE

REDATTO/GESTITO

APPROVATO

COD. IDENT.

PAGINE

DATA EMIS.

0

6

Manuale Istruzioni

GN

UTEC

B041

.M01.

EN

48

07

/201

4

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 2/47 07/2014

GENERAL INDEX

Chapter

1

GENERAL INFORMATION

1.1

Warnings

1.8

Machine Identification Data

1.2

WARNING and DANGER indications - SIGNS

1.9

EC Stamp

1.3

Aim of the Instructions Manual

1.10

Usage

1.4

Structure of the Instructions Manual

1.11

Operators

1.5

Composition of the Instructions Manual

1.12

Storage

1.6

Modifications and enclosures of the Instructions Manual

1.13

Transportation and Movement

1.7

Constructor Identification

1.14

Packaging removal

Chapter

2

TECHNICAL CHARACTERISTICS

2.1

General machine description

2.2

Dimension and weight

2.3

Electrical supply

2.4

Noise

Chapter

3

GENERAL SAFETY NORMS

3.1

General norms

3.2

Machine Safety devices and protection

3.3

Passive safety devices

3.4

Active safety devices

Chapter

4

INSTALLATION INSTRUCTIONS

4.1

Location

4.2

Handling and movement

4.3

Assembling procedure

4.4

Electrical connection

4.5

Pneumatic connection

Chapter

5

MAN

-

COMMAND INTERFACE

5.1

Workplace

5.2

Commands and signals

5.3

Meters – Indicators

5.4

How to operate

Chapter

6

MACHINE

REGULATION AND TUNING

6.1

Regulations

6.2

Checking the safety devices work

Chapter

7

IN FUNCTION

-

USE

7.1

Machine calibration – Meters - Indicators

7.2

Switching on the equipment

7.3

Equipping – Sample positioning

7.4

Regulation

7.5

Switching the appliance on

7.6

Normal stop

7.7

Emergency stop

7.8

Start up after emergency

7.9

Stop commanded by Safety circuit

7.

10

Start up after stop commanded by Safety circuit

7.

11

Switching off

7.

12

Test Start Up

7.

13

EXAMPLE OF OPERATING

Chapter

8

MAINTENANCE

8.1

Periodical checks

8.2

Ordinary Maintenance

8.3

Extraordinary Maintenance

8.4

Authorised maintenance centres

Chapter

9

GUIDE TO RECOGNISING DAMAGE AND ANOMALIES

Chapter

10

SPARE PARTS

Chapter

11

INACTIVITY

Chapter

12

DECOMMISSIONING THE MACHINE

Annexes

I

PNEUMATIC SYSTEM DIAGRAMS

II

WIRING DIAGRAMS

III

ACCESSORY

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 3/47 07/2014

Chapter

1

GENERAL INFORMATION

1.01

WARNINGS

The manufacturer does not accept any responsibility for direct or indirect damage to people, things or animals and use of the

appliance in different conditions from those foreseen.

The manufacturer reserves the right to make changes to the documentary information or to the appliance without advance

notice.

Check the machine responds to the standards in force in the state in which it has been installed.

All operations necessary for maintaining machine efficiency before and throughout use are the operator’s responsibility

Carefully read the entire manual before operating the machine.

It is vital to know the information and limitations contained in this manual for correct machine use by the operator.

Interventions are only permitted if the operator is accordingly competent and trained.

The operator must be knowledgeable about machine operations and mechanisms.

The purchaser must ensure that operators are trained and aware of all the information and clarifications in the supplied

documentation. Even with such certainty the operator or user must be informed and therefore aware of potential risks when

operating the machine. Safety, reliability and optimum performance is guaranteed when using original parts.

Any tampering or modifying of the appliance (electrical, mechanical or other) which has not been previously authorised in

writing by the manufacturer is considered abusive and disclaims the constructor from any responsibility for any resulting

damage. All necessary operations to maintain the efficiency of the machine before and throughout use are the responsibility of

the user.

1

.02

WARNING AND DANGER INDICATIONS

-

SIGNS

The machine has been designed and constructed according to the current norms and consequently with mechanical and

electrical safety devices designed to protect the operator or user from possible physical damage. Residual risks during use or

in some intervention procedures on the device are however present. Such risks can be reduced by carefully following manual

procedures, using the suggested individual protection devices and respecting the legal and safety norms in force.

This manual includes “Warning” and “Danger” indications in relevant chapters. These indications are shown with the words

“Danger” or “Warning” in bold font and uppercase to make them highly visible.

WARNING

Il simbolo viene impiegato per indicare che la non osservanza delle indicazioni prescritte

potrebbe causare “Danno allo strumento”.

DANGER

Il simbolo viene impiegato per indicare che la non osservanza delle indicazioni prescritte

potrebbe causare “Danno allo strumento e/o infortunio al personale”.

INSTRUCTIONS

indicates the need to consult other documents before performing

operations.

“DANGEROUS ZONE” indicates any zone inside or in the proximity of the appliance in which a person is exposed to the risk

of injury or damage to health.

1.03

AIM OF THE INSTRUCTIONS MANUAL

This manual has been edited with the aim of providing all machine operators with all the necessary information on

installation, use and maintenance from production to scrapping in as comprehensive and clear manner as

possible.All the procedures useful for any foreseeable emergency situations have been listed by the manufacturer

and can be verified during use.

Operators, for whom this manual has been written, due to their competence must give instructions or operate the

machine themselves.The instructions manual must be carefully consulted by laboratory or site safety managers,

equipment operators and any internal and external maintenance workers.

The manual is integral to the product and refers to this appliance only.

The manual must be safeguarded and always kept near the equipment so that it can be easily consulted

whenever necessary.

IMPORTANT: The manual does not substitute the experience and technical training of the worker but must be

considered a guide for carrying out its functions.Furthermore all the norms and rules the operator should be

aware of or consult for correct use of the machine and/or test performance can be found in the manual.

This responsibility is entrusted to the installer and Laboratory or Site Manager where the machine is installed.

The Constructor is available to provide further informati.

1.04

STRUCTURE OF THE INSTRUCTIONS MANUAL

The manual can consist of a number of documents, as shown in the appropriate list.

Verify that all documents are present; otherwise request the missing parts from the Constructor before using the

machine.Instructions can be supplied with enclosures containing diagrams and designs, which are necessary for

interpretation of correct machine use and maintenance.

1.05

COMPOSITION OF THE INSTRUCTIONS

MANUAL

Description document

Instruction manual code

INSTRUCTIONS MANUAL

B041.M01

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 4/47 07/2014

1.06

MODIFICATIONS AND ENCLOSURES OF THE INSTRUCTIONS MANUAL

Il This manual reflects the state at the time of the launch of the machine on its market. If any modifications, improvements or

adjustments have been made since machine supply the Manufacturer does not have to intervene on the marketed machine

and will not consider the machine or the manual deficient or inadequate.

1.07

CONSTRUCTOR IDENTIFICATION

See the front page headline

1.08

MACHINE IDENTIFICATION DATA

On the identification nameplate of the machine are reported the

identification data and the electrical characteristics.

1.09

EC STAMP

SEE EC DECLARATION

1.10

USAGE

Machine or instrument usage:

This Gyratory Compactoris used to simulate and reproduce the real compaction conditions under actual road

paving operations, hence determining the compaction properties of the asphalt. Such compaction is achieved by

combining the rotary action and the vertical resultant force applied by a mechanical head.

Appropriate uses: Those defined in standard

( UNI EN 12697-10, UNI EN 12697-31 / ASTM D6925 / AASHTO T312).

This appliance is for the exclusive use which it has been conceived for. Any other use is considered improper and

therefore negligent. Machine use is allowed only in places free from danger of explosion or fire.

During operation check for conditions of danger.Immediately stop the machine should it be working irregularly,

and consult the authorised dealer’s Sales Service department. It is the Client’s responsibility to verify at the time

of installation and use that no conditions of use arise which are different to those indicated. Refer to the

Constructor when in doubt.

1.11

OPERATORS

DANGER

WARNING

The use, transportation, installation, maintenance, demolition and disposal of the

appliance are only permitted to “QUALIFIED PERSONNEL”. This

manual is exclusively aimed at “QUALIFIED PERSONNEL” and contains the

necessary information for machine use.

”QUALIFIED PERSONNEL” means people who, due to their training, experience and education, as well as

knowledge of the relevant standards, limitations and measures, have been authorised by the “PLANT SAFETY

MANAGER” to carry out any necessary activity and are able to recognise and avoid any possible danger.

The manufacturer recommends that the instructions, procedures and recommendations in this manual and the

work safety legislation in force be scrupulously adhered to, even with the use of appropriate protection devices

(whether individual or part of the machine).

Knowledge and respect of the instructions, safety warnings and danger in this manual are all necessary for

installation, operation, management and machine maintenance with a minimal risk.

The “PLANT SAFETY MANAGER

” has the following responsibilities and duties:

- To know the machine functions, its commands, safety

and protection devices, possible dangers of use and all

the information in this manual in detail. This

knowledge can only be gleaned from detailed reading

of this manual.

- Correctly train and educate the “QUALIFIED

PERSONNEL” before allowing them access to the

machine. The personnel must also be exhaustively

trained with regards to the machine’s protection

devices.

- To know the safety legislation in force in detail in

order to operate the machine

- To recognise the “QUALIFIED PERSONNEL” for

transportation, handling, installation, use, maintenance,

disposal, etc.

- Ensure the machine’s safety devices are not

tampered with or removed and are checked on a daily

basis. Provide the operator appropriate individual

protection devices according to the laws in force.

- The constructor is available for clarification, assistance and training and declines all responsibility for damage to

things or people resulting from improper, incorrect and negligent use by untrained personnel.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 5/47 07/2014

1.12

STORAGE

WARNING

The appliance must be stored and conserved in the original packaging and in a closed

environment, protected from atmospheric agents with a minimum temperature of -15C°, and a

maximum of +60C°and a maximum humidity of 70%.

1.13

TRANSPORTATION AND MOVEMENT

WARNING

In order to avoid irreparable machine damage, move with care, do not overturn, protect from

rain, do not stack, protect the packaging and its contents from bumps and sources of heat.

Machine transportation and movement must be entrusted to Qualified Personnel who can ensure correct

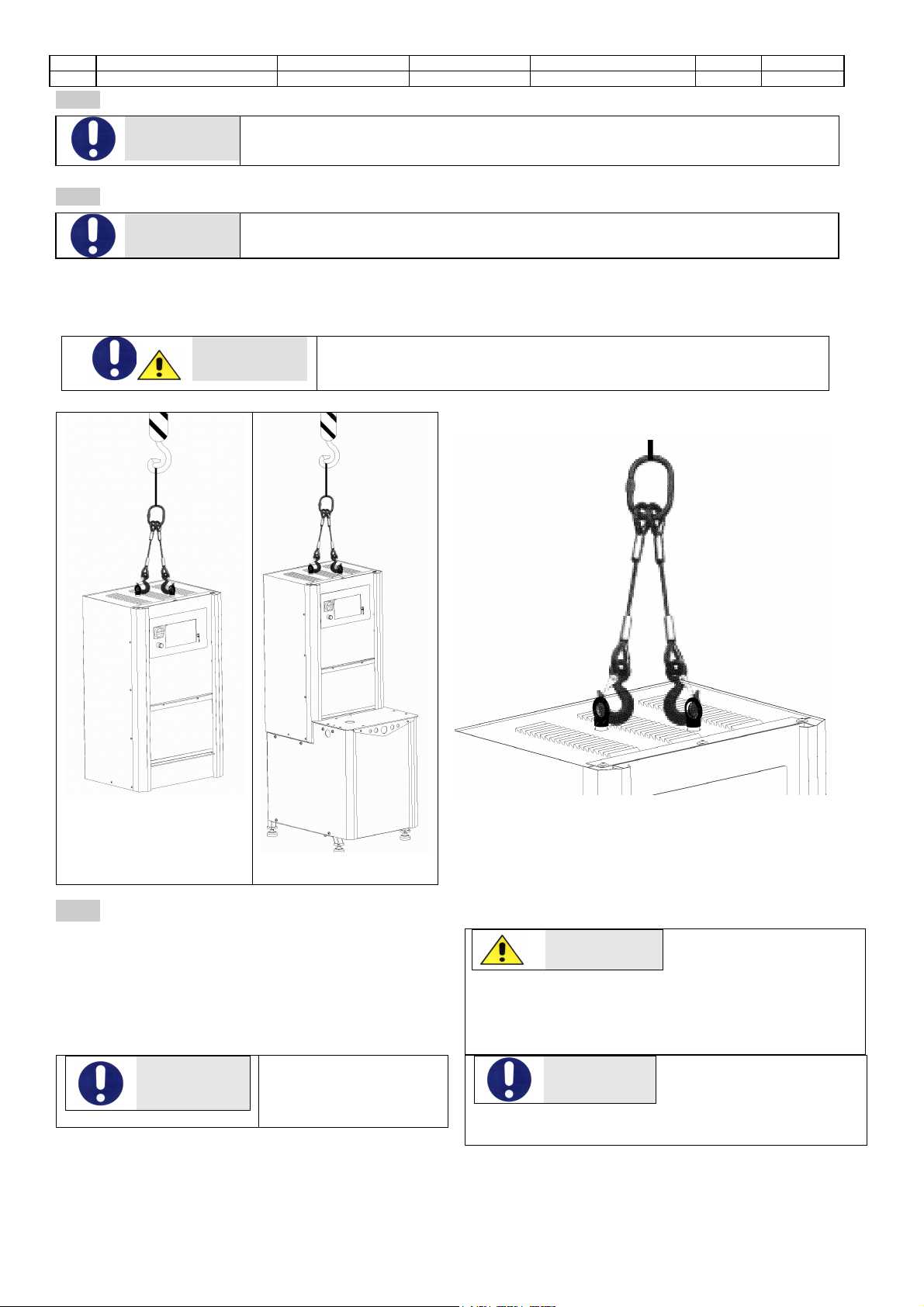

movement.

The machine is equipped of two steel eyebolts. (top side).

DANGER

WARNING

Do not transport or move the product should it be impossible to respect

the conditions on the packaging or there be any doubts. Request

information from the constructor.

260 Kg 350 Kg

1.14

PACKAGING REMOVAL

After removing the packaging check the machine is

complete and that there are no visibly damaged parts.

DO NOT USE THE MACHINE and refer to the

constructor when in doubt.

DANGER

The components used for

packaging (plastic bags,

polystyrene, nails, screws,

wood, etc)must

be kept out of reach of children, as they are sources of

danger. These components should be placed in the

appropriate containers.

WARNING

In order to avoid bumps

and overturn adopt the

normal and logical

precautions.

WARNING

Before disposing of the

packaging check all

machine components

such as accessories, utensils, instructions, documents

etc have been removed.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 6/47 07/2014

Chapter

2

TECHNICAL

CHARACTERISTICS

2.01

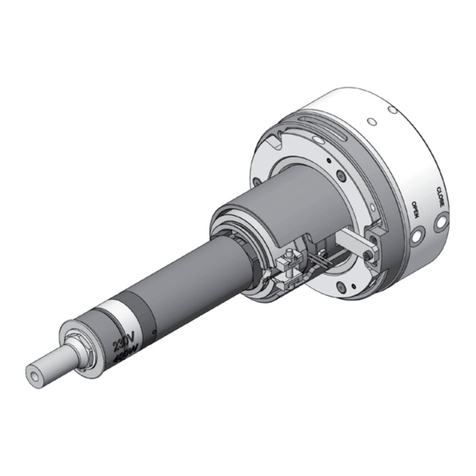

GENERAL MACHINE DESCRIPTION

This Gyratory Compactor, is used to simulate and reproduce the real

compaction conditions under actual road paving operations, hence

determining the compaction properties of the asphalt.

Such compaction is achieved by combining the rotary action and the vertical

resultant force applied by a mechanical head. The Compactor comprises a

highly rigid steel frame ensuring excellent angle control.

Load is applied by an electro-pneumatic cylinder, servo-controlled by a

precision pressure regulator; the height is measured by a linear transducer.

Gyratory motion is generated by an eccentric high precision system allowing

an easy set up with precision and constant angle of gyration.

The rotation speed is controlled by an inverter through on board computer

control. Using the proper perforated mould, the Compactor is able to run tests

also on cold emulsified asphalt mix.

The acquired results are also employed in the investigation of volumetric and

mechanical characteristics of the asphalt mix.

Picture.1

1

MAIN SWITCH

2

EMERGENCY

STOP

3 DISPLAY

4 USB / SD

5 SLIDING PANEL

6 TEST CHAMBER

7

REAR PANEL

8

AIR INTAKE

FITTING (pipe

Ø10)

9

ELECTRIC

POWER CABLE

Picture.2

ACCESSORIES

INSTRUCTIONS

Before the Assembly and use of the optional accessories,

please refer to the relevant instructions.

Hand operated specimen

Integrated worktop

Mechanical automatic specimen extruder

extruder

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 7/47 07/2014

LAYOUT :

Gyratory Compactor +

Integrated worktop + Extruder

Fig. 3

MOLD (accessory required for the

execution of the test)

1

MOLD BODY

2

RING OF ARREST

3

BOTTOM

There are different types. See for commercial catalogs

and specific encodings.

Two types of pistons

are available

(accessory necessary

for the execution of

the test) which differ

in the type of fixing.

The nominal diameter

must be chosen

according to the size

of the mold. Check the

catalog and find all

the specific

codes..

PISTON type 1

Fig. 4

1

PISTON

2

CLAMPING SCREWS

PISTON type 2

Fig.

1

PISTON

2

SCREW

3

TOOTH

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 8/47 07/2014

HARDWARE:

The main hardware features of the machine’s mother

board are described as follows.

ATTENTION

Even if designed and potentially available, some features

could be not be present on the control unit box.

•312 MHz processor that can be expanded up to 806 MHz.

•64 MB RAM that can be expanded up to 128 MB.

•32 MB flash memory that can be expanded up to 256 MB.

•LCD TFT QVGA (320x240 pixel) touch-screen.

•Keyboard with 5 crosswise keys.

•One audio channel.

•Buzzer.

•Clock.

•8 digital outputs.

•8 digital inputs.

•1 analog output (16 bit - 65536 points).

•8 analog inputs (two of them at high performances).

•Ethernet 100 Mbit for PC connection.

•2 USB-Host (to connect mouse/keyboard/pen drive).

•1 USB-Client.

•Slot SD-Card.

•1 RS232.

•1 RS485.

•2 controllers for step motors.

•Expansion slot for additional analog inputs.

•Expansion slot for motors control.

MAIN FEATURES:

•Gyratory angle: adjustable from 0 to 2,4°

•Gyration rate: adjustable from 5 to 60 work cycles/min

•Compacted specimen size: dia 100 and 150 mm; height

from 0 to 200 mm for both sizes.

•Vertical load on 150mm dia specimen: adjustable from 10 to

900 kPa

•Vertical load on 100 mm dia specimen: adjustable from 23

to 1500 kPa SOFTWARE:

The main software features of the machine’s mother board

are listed as follows

•Operating system: “Windows Embedded CE 6.0 R2”.

•More intuitive interface and a simplified management of

the machine (start up of the test with few and simple

commands).

•More opportunities for calculations and graphic

visualization (graphs on the machine and printing of the

results in a graphic mode).

•More opportunities for languages and International format

management (date and time, decimal separator, unit of

measurement…).

•Modular structure of the software in order to allow the

installation of new test modules later.

•The software on the machine can be easily updated.

•An unlimited memory provided by the SD-Card and USB-

Host slots.

Possibility to connect the machine to Internet in order to

activate the remote checking functions.

2.02

DIMENSION AND WEIGHT

A LENGTH

640 mm

B WIDTH

500 mm

H HEIGHT

1060mm

WEIGHT

250Kg

2.03

ELECTRICAL SUPPLY

On the identification

nameplate of the machine

are reported the

identification data and the

electrical characteristics.

Power supply:

230V

1ph

50/60Hz

1000W

Picture

. 5

2.04

NOISE

The air noise emission levels shown do not necessarily imply the levels of exposure to the worker.

The levels of exposure to the operator are obviously linked to the emission levels of the appliance; however other factors

influence the levels of exposure to the operator: length of exposure, environmental characteristics, the presence of other

machines etc. The appliance emission levels allow anyway an estimate to be carried out on the dangers due to noise.

If the daily personal exposure is equal to or more than 85 dB (A) it is advisable to use the Individual Protection Devices

(protective headphones, plugs, etc.). If the daily personal exposure is equal to or more than 90 dB (A) it is compulsory to use

Individual Protection Devices (protective headphones, plugs, etc.). For further information consult the standards in force in the

country of installation.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 9/47 07/2014

DANGER

Continuous use of the appliance and machines predictably present in the

installation environment could cause a heightened daily personal exposure to

noise.

Chapter

3

GENERAL SAFETY STANDARDS

3.01

GENERAL STANDARDS

To ensure the safety of machine operators:

· Any tampering with the appliance not pre-

emptively authorised by the manufacturer exempts

the manufacturer from any responsibility for

damage caused by or to it.

·The removal or tampering with safety devices

entails a violation of the safety standards.

· Machine use is only allowed in areas where

there is no risk of explosions or fires.

· Only the original fittings can be used. The use of

unoriginal fittings exonerates the manufacturer from

all responsibility.

• Check the appliance is in ideal working conditions

and that its parts are not worn or faulty before

Carry out all necessary maintenance

• Do not wear loose clothing, ties, chains or

anything else which could become caught in the

frame or other moving parts of the appliance.

• Be aware of the danger of electrical shocks from direct

or indirect contact due to unforeseen electrical faults.

• Do not subject the appliance to violent impact.

• Do not expose the appliance to fire, welding sparks or

extreme temperatures.

• Do not bring the appliance into contact with corrosive

substances.

• Do not wash the appliance with jets of water.

Check the workspace around the machine is clear from

potentially dangerous objects.

The machine operator must wear appropriate work

clothing such as protective glasses, gloves and mask in

order to avoid damage from, for example, harmful dust

projection. Wear a lower back support when lifting heavy

parts.

There should be no hanging objects such as bracelets

or otherwise, long hair should be protected with relevant

precautions, shoes must be appropriate for the type of

operation to be carried out.

DURING USE

When operating check there are no

conditions of danger. Immediately stop the

machine when it is functioning irregularly.

Contact the authorised Sales Service

department.

• For the operator’s safety do not touch any

part of the appliance when testing and use

the appropriate individual protection devices

in order to keep the operator safe.

RISK OR DANGER

PROTECTION DEVICES

FINGER

SQUEEZE

CUTS OR

ABRASIONS

REINFORCED

GLOVES

MATERIAL

FALL

ACCIDENT-

PREVENTION

SHOES

3.02

MACHINE SAFETY DEVICES

AND PROTECTION

DEFINITION: Protections are all the safety measures that consist of the use of

specific technical means (repairs, safety devices) to protect people from dangers

which cannot be limited reasonably in design.

DANGER

Tampering with the protections or any appliance

modification could cause risks to users or other

exposed people.

The manufacturer does not assume any responsibility for direct or in direct damage

to people, things or animals following tampering with the protections.

3.03

PASSIVE SAFETY DEVICES

Passive safety devices are the devices or solutions which eliminate or reduce the

risks to the operator without any active intervention by the operator.

The machine has got a protection door ,which prevents the opening during the test

so that the operator cannot come in touch either with the internal mechanisms .The

door opening causes an immediate interruption of the power feeding; in this way the

motor and the road wheel stop moving. The rotation can start again only after the

Picture

. 6

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 10/47 07/2014

closing of the protection door.

3.04

ACTIVE SAFETY DEVICES

Active safety devices are the devices or solutions which eliminate or reduce the

risks to the operator and require active and conscious intervention by the operator

for the preventive action to be carried out.

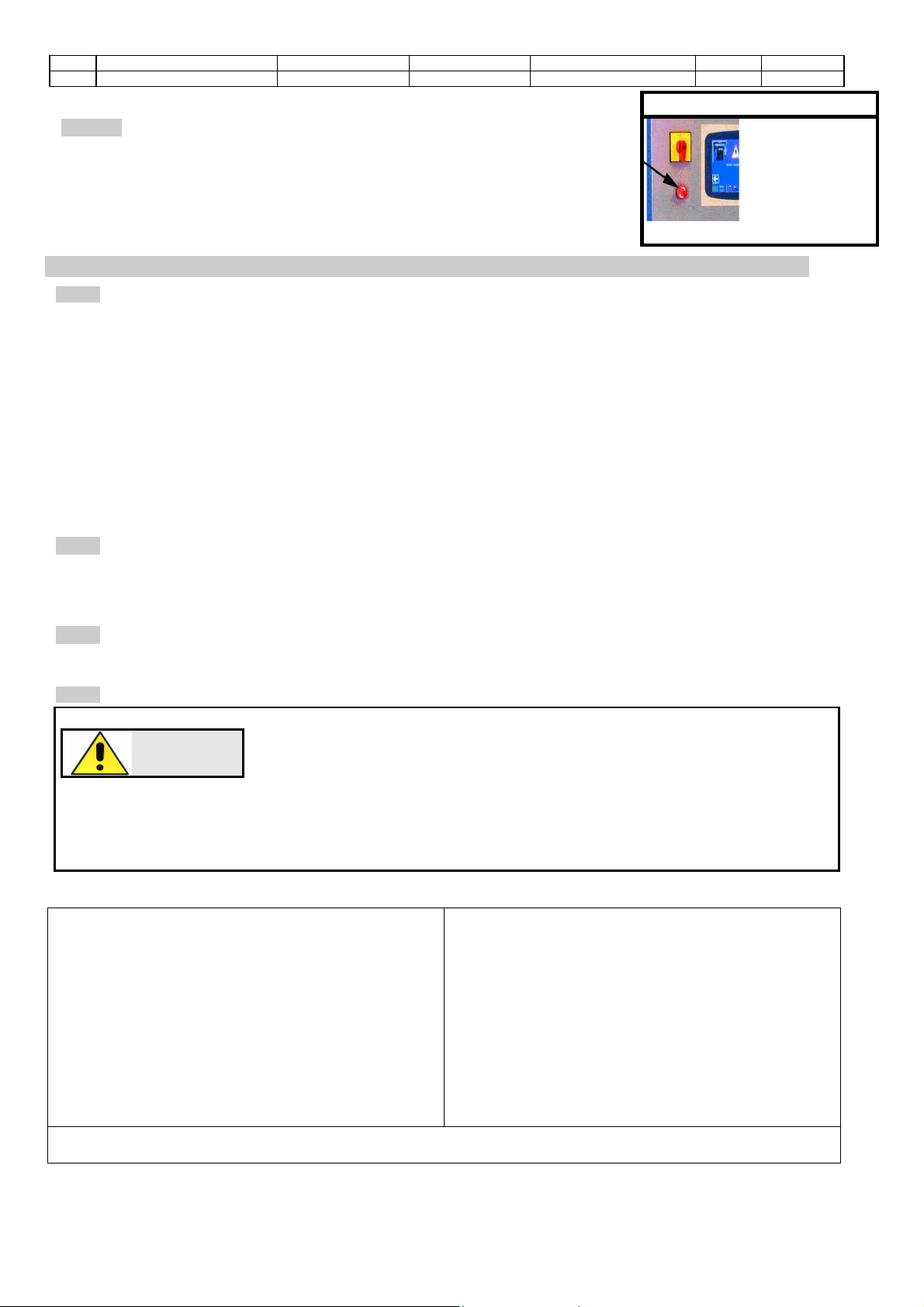

The appliance is equipped with a main switch acting also as emergency switch. By

activating it (Fig.7), stops moving.

Picture

. 7

Chapter

4

INSTALLATION INSTRUCTIONS

4.01

LOCATION

The equipment must be placed in an ideal position and environment for the use it has been conceived for

(laboratory use and protected from atmospheric agents) and that the machine is placed by a qualified operator.

ALLOWED TEMPERATURE:

+5°C / +40°C

ALLOWED RELATIVE HUMIDITY:

30% / 70%

GENERAL ADVICE

•The machine must be installed in an area which allows ease of access to all parts so that maintenance

may be carried out.

•Unauthorised people and objects which could be potential sources of danger must not be permitted in the

area surrounding the machine.

Do not position the equipment near instruments or appliances which could produce vibrations.

EN Standad requires the machine to be rigidly mounted on a firm and level concrete base. The levelling foot

supplied are considered acceptable for mounting on any firm and rigid level surface

4.02

TRANSPORTATION AND MOVEMENT

These instructions are applicable to the machine assemblers. Ensure the equipment is correctly supported at the

lifting point and that the machine does not slip. Do not remain in direct line with the application of force and do not

allow personnel where there are loads that cannot be adequately supported by mechanical means.

4.03

ASSEMBLING PROCEDURE

After removing the package, check that any parts of the machine are not damaged. In case of doubt, DO NOT

USE THE MACHINEand ask the manufacturer.

4.04

ELECTRICAL CONNECTION

DANGER

Wiring of the electrical system must be carried out by qualified personnel.

Before wiring consult the electric plan linked to the instructions manual and the

registration plate on the machine for information regarding supply, frequency and

nominal current. Connect the earthing system via the PE terminal (yellow-green)

before any other connection.

Apply a knife switch at the top of the connecting cable of the machine to the power system.

The knife switch must be combined with a safety device against the overload with a differential switch (safety

switch).The technical features of

the safety device must be in accordance with the standards in force in the

country where the machine has been installed.

ELECTRIC TOLERANCES:

•

Real voltage

±

10 % of the nominal one

•Frequency: ±1 % of the nominal one

in a continuous way

±2 % of the nominal one for a short period

•The harmonic distortion of the sum from the second

to the fifth harmonics not more than 10 % of the total

voltage as a real value between the conductors. A

further distortion of 2% is accepted for the sum from

the sixth to the thirtieth harmonics of the real total

value between the conductors.

•With reference to the voltage imbalance of the three-

phase voltage, the inverted sequence component and

the zero sequence component must not be more than

2% of the direct sequence component of the voltage.

•

The voltage pulses must not last more than 1,5 ms

with an up/down time between 500 ms and 500 ms

and a peak value not higher than 200 % of the real

value of the nominal tension.

•The electric supply must not be interrupted or

zeroed for more than 3 ms at any time. Between

two interruptions it must not take more than 1 s.

•The interruptions must not overcome 20 % of the

tension peak for more than one cycle. Between two

interruptions it must not take more than 1 s.

The manufacturer assumes no liability for any damages to people, things and animals caused by the non-

compliance of the above instructions.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 11/47 07/2014

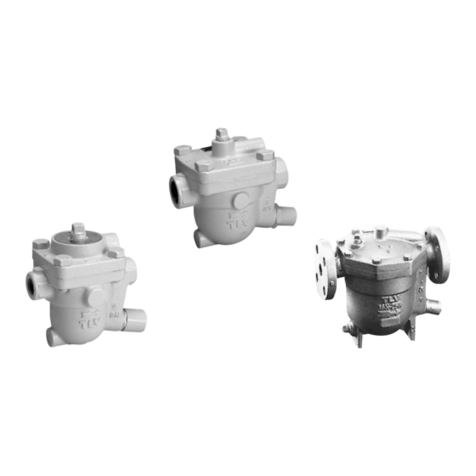

4.05

PNEUMATIC CONNECTION

Connect the Compactor to compressed air system; the pipe must be connected to

the AIR INLET FITTING located at the back of the compactor (pipe outer diameter

10 mm).

Compressed air requirement:

50lt/min (

occasionally

)

Compressed air pressure:

7÷10 bar

Air Compressor

(Optional)

ATTENTION

It is essential to mount an

adequate maintenance unit, air

filter-regulator

(FR) upstream of the air input.

Indicative features:

working pressure:

0.05÷0.09 Mpa ;

filtration degree:

40 µm ;

air filter

regulator

(necessary

accessory)

ATTENTION

Do not use a lubricator on the supply side of this product.

Chapter

5

MAN

–

COMMAND INTERFACE

5.01

WORKPLACE

The picture on the side shows the working area “3” where the

operator will be more frequently; it allows possibility to open the front

door to place moulds and to operate on the control panel and set test

parameters.

After placing the mould on the worktop “2” and closing the door, the

user must program test parameters by means of the control panel

“1” and start the machine.During compacting action the user can

observe the specimen through the transparent panels and supervise

test data on the control unit touch screen display.

Fig. 8

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 12/47 07/2014

5.02

COMMANDS AND SIGNALS

The man-machine interface pass

through the LCD TFT QVGA

(320x240 pixel) touch-screen

supported by a keyboard with 5

crosswise keys.All the machine

operating functions are

accessible through the touch-

screen and the keyboard as well.

Depending on the specific

contest the machine is working

in, some keys/functions can be

disabled or may assume a

particular meaning.

1 EMERGENCY

STOP BUTTON

2

MAIN SWITCH

3

DISPLAY

4

Keyboard

5

N°2 USB

-

Host

6

SLOT SD CARD

Consult the chapter related

to the screen you are

interested in to check the

exact use of the keyboard.

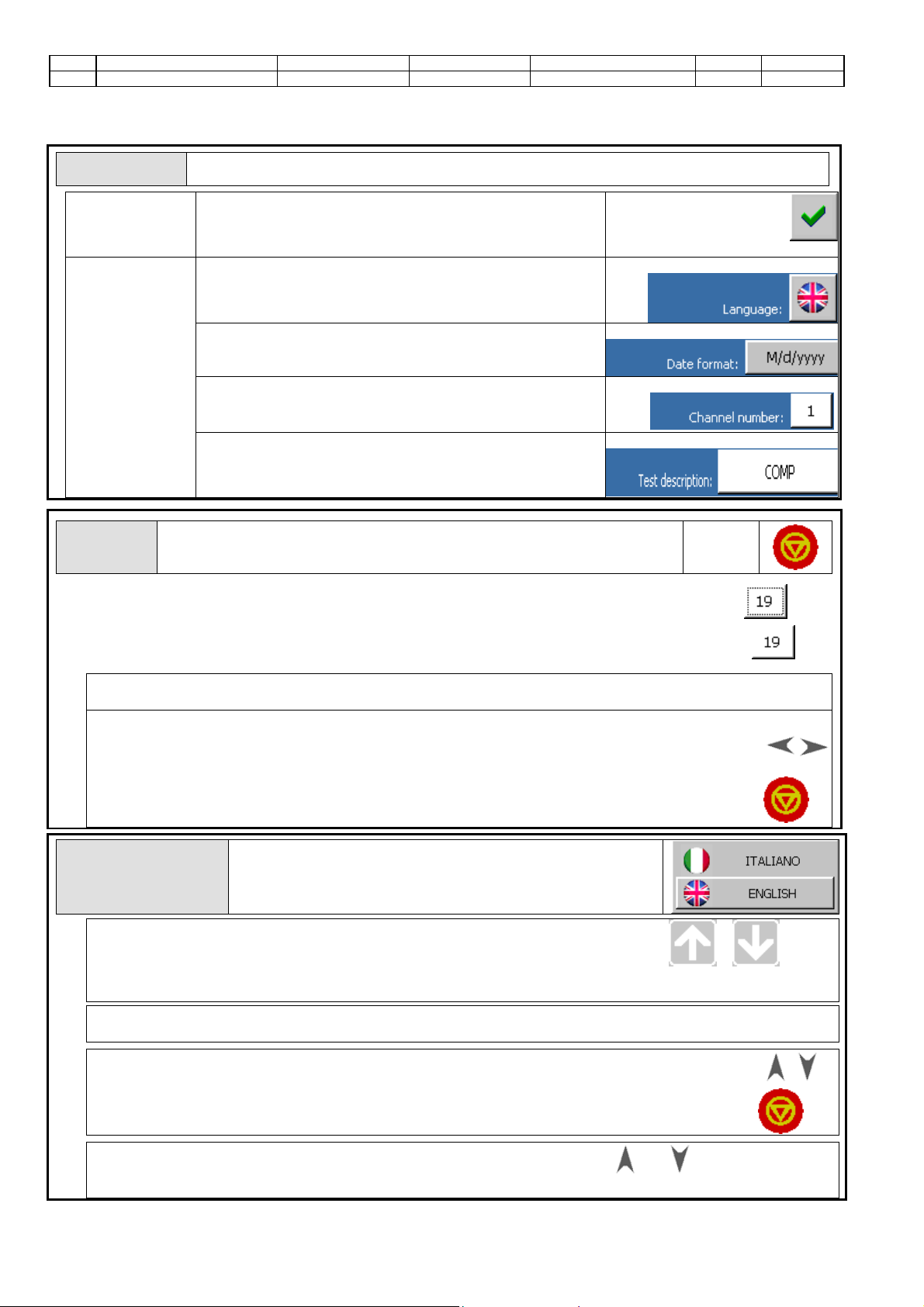

STRUCTURE OF THE SCREENS

1

Operating

area

It is the most important area of each screen

and it takes up the almost part of the display.

2

Status

Bar

It is divided into three parts and is placed in the

lower part of all screens. It provides with a

summary of the information concerning the

machine configuration and functioning.

Status Bar

Name and version of the machine

Status of the machine

Date and time

The central part is divided into four parts to highlight the following information:

Status of the machine

Alarm enabled or status

of the machine

It shows the presence

of one or more alarm

status ( ) ,or

configuration failure

( ) or the

operation status of the

machine

(following pages)

Configuration

profile

selected

State enabling legislation or active screen

State enabling legislation:

indicates whether the remote

execution is:

Enabled

disable

Screen enabled

:

It is represented by one of the following icons/pictures

to show the screen the operator is entering to. The list does not include

the icons that represent the Standards (see the relevant chapters). Some

screens can be entered only when using some specific machines

machine

calibration.

network

configuration.

password change.

software

maintenance.

visualization of the

enabled alarms.

configuration of the input analog channel

(the

icon also shows the number of the selected

channel).

configuration of the output

analog channel.

manual positioning.

calibration of the input analog channel

(

the icon

also shows the number of the

selected

channel)

.

calibration of the output

analog channel.

test archive

check of the input analog channel calibration

(the icon also shows the number of the

selected channel).

check of the output

analog channel

calibration

.

machine

configuration.

date and time set up.

International settings

.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 13/47 07/2014

MACHINE INTERACTION

BUTTONS:

All controls on the screens are shown as buttons and can be classified as follows:

:

1. command”

button:

Conceived for the execution of a machine function; this button

is usually shown on the right column of the operative area of

the display; on this button an image (such as the one shown

in the example) is visualized on a grey background Esempio:

2.“parameter”

button:”

This button is for the modification of a value through the

activation of a graphic scroll; an image on a grey background

is visualized on the button

Esempio:

This button is also for the modification of a value through the

activation of a text scroll; an alphanumeric text is visualized on

the button with a grey background

Esempio:

This button is also for the modification of a value through the

activation of a numeric scroll; a numeric text is visualized on

the button with a white background

Esempio:

.

This button is also for the modification of a value through the

activation of the virtual numeric/alphanumeric keyboards; a

numeric/alphanumeric text is visualized on the button with a

white background

Esempio:

FOCUS:

The Focus notion is used to point out which button of the screen will respond to

the pressure of the confirmation key

confirmation

key

A button has the focus active when it is visualized with dashed sides

example

A button has the focus inactive when it is visualized without dashed

example:

How to activate a button

through the touch-screen.

Touch the button and wait for the function execution (“command” button)

or for the change of the relevant value (“parameter” button).

How to activate a

button through the

keyboard.

Move the focus on the buttons visualized on the

screen (keys and ) up to the selection of the desired

button.

keys

Push the confirmation key and wait for the function

execution (“command” button) or for the change of

the relevant value (“parameter” button).

confirmation key

GRAFIC

SCROLL

It is visualized when a “parameter” button with an image on

a grey background has been activated. The below example

shows the graphic scroll for the language selection (screen

of the international settings).

How to select a graphic scroll

value with the touch-screen

Scroll the list up to the desired icon.

. ( or )

Touch the picture, wait for the closure of the scroll and for the update of

the relevant “parameter” button.

How to select a graphic scroll value

with the

touch-screen

Touch any point of the LCD display outside the scroll area

and wait for its closure.

How to select a value of a graphic

scroll with the keyboard

Select the desired image by skimming through

the list with keys. keys.

.

Push the confirmation key , wait for the closure

of the scroll and for the update of the relevant

“parameter” button.

confirmation

key

How to annul the selection of a value of a

graphic scroll with the keyboard

Push one of these keys, or and wait for the

closure of the scroll.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 14/47 07/2014

TEXT SCROLL

It is visualized when a “parameter” button with an

alphanumeric text on a grey background has been activated.

The below example shows the graphic scroll for the month

selection (screen of data and time setting).

How to select a value of the text

scroll with the touch screen

Scroll the list until the desired text is visualized. ( or )

Touch the desired text, wait for the closure of the scroll and for the update

of the relevant “parameter” button.

How to select a value of the text

scroll with the touch screen Touch any point of the LCD display outside the scroll area and wait

for its closure.

How to select a value of a text scroll

with the keyboard

Select the desired text by scrolling the list with

keys.

keys

Push the confirmation key , wait for the closure

of the scroll and for the update of the relevant

“parameter” button.

confirmation

key

How to annul the selection of a value of the

scroll with the keyboard Push one of these keys, or , and wait for the

scroll closure.

NUMERIC

SCROLL

It is visualized when a “parameter” button with a numeric value on a grey

background has been activated. The below example shows the graphic

scroll for the day selection (screen of data and time setting).

How to change the value of a numeric

scroll with the touch-screen

Decrease or increase the value until the desired

one is shown. ( oppure )

Touch the value (central area), wait for the scroll closure and for the update

of the relevant “parameter” button.

How to annul the change of the value of

a numeric scroll with the touch-screen

Touch any point of the LCD display outside the scroll area and wait for its

closure.

How to change the value of a numeric

scroll with the keyboard.

Decrease () or increase the value until the desired

one has been visualized. keys

.

Push the confirmation key, wait for the closure of the

scroll and for the update of the relevant “parameter”

button.

confirmation

key

How to annul the change of the value

of a numeric scroll with the keyboard.

Push one of these keys, or , and wait for the closure of the scroll.

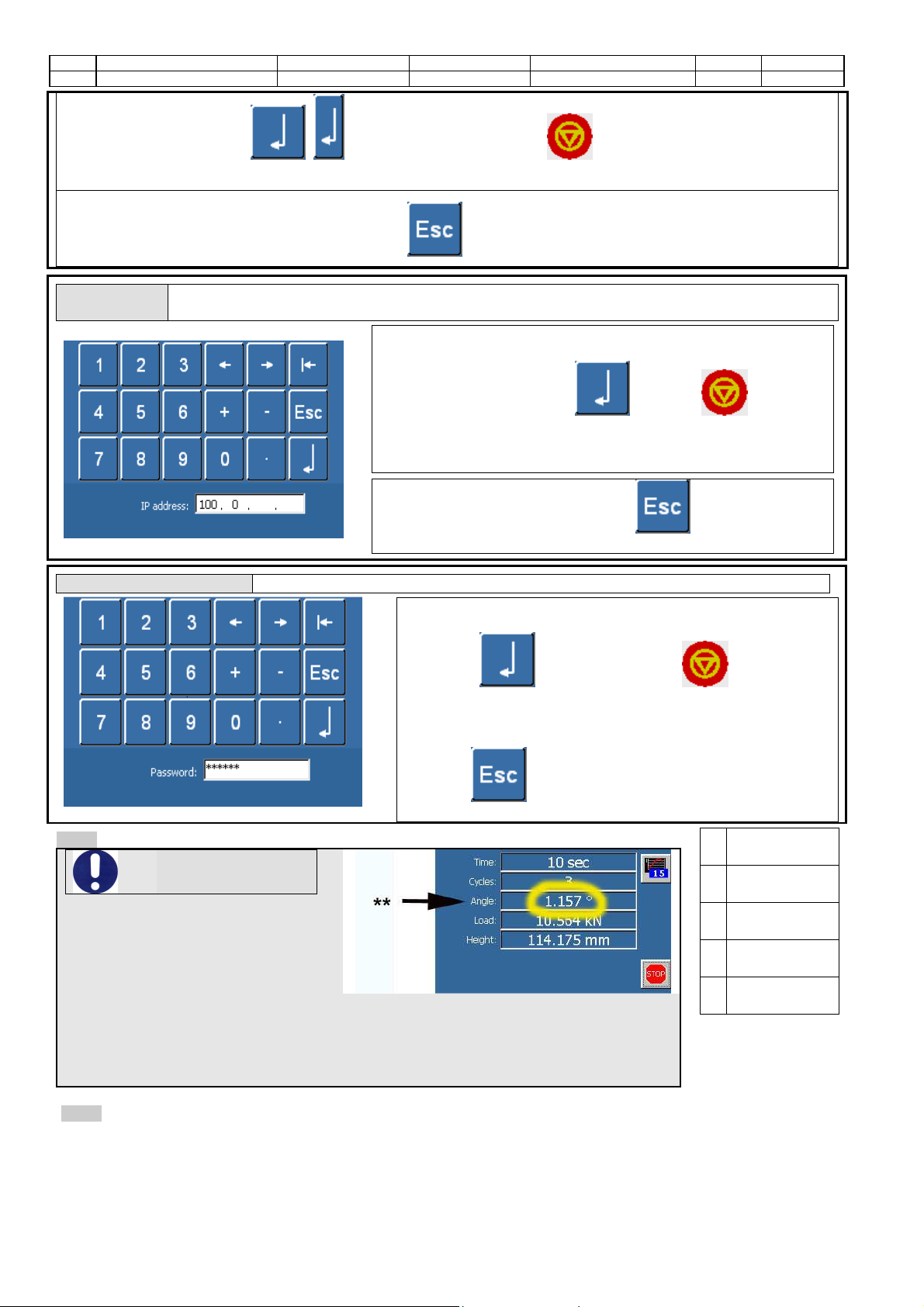

VIRTUAL NUMERIC/ALPHANUMERIC

KEYBOARD

It is visualized when a “parameter” button with a numeric/alphanumeric

value on a white background has been activated.

Virtual numeric keyboard

Virtual alphanumeric keyboard

How to change

Insert the numeric/alphanumeric value using the virtual keyboard.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 15/47 07/2014

a

numeric/alphan

umeric value

with the virtual

keyboard. Touch / or push the confirmation key to confirm the new value; wait for

the closure of the virtual keyboard and for the update of the relevant “parameter” button.

How

to annul the change of a

numeric/alphanumeric value with the

virtual keyboard.

Touch and wait for the closure of the virtual keyboard.

IP

ADDRESS

It is visualized when a “parameter” button is activated: the value is shown as an “IP address” on a white

background

How to change

an “IP

address” value

with the virtual

keyboard.

1. Insert the value as “IP address” using the

virtual keyboard.

2. Touch or press to confirm

the new value, then wait for the closure of

the virtual keyboard and the updating of the

relevant “parameter” button.

How to annul the change of

a value shown as ”IP

address” using the virtual

keyboard. Touch and wait for the

closure of the virtual keyboard.

PASSWORD

It is visualized when a function secured by a password is activated.

How to enter a password using the virtual keyboard

1. Enter a password using the virtual keyboard

2. Touch or press the button to confirm the

password. Wait for the activation of the secured function

(correct password) or for the visualization of an error message

(if the password is wrong).

3. Touch to annul the password entry and the activation

of the secured function

5.03

METERS

-

INDICATORS

ATTENTION

** N.B.: THE GYRATION ANGLE SHOWN BY

THE DISPLAY AND RECORDED BY THE

MACHINE DURING THE TEST IS THE

EXTERNAL ANGLE USED BY THE

MANUFACTURER TO CALIBRATE THE

MACHINE.

THIS ANGLE HAS A DIFFERENT VALUE FROM THE ONE OF THE INTERNAL ANGLE, AND

THEREFORE THE OPERATOR DOES NOT HAVE TO USE IT.

THE INTERNAL GYRATION ANGLE IS CALIBRATED AT THE FACTORY USING THE “DYNAMIC ANGLE

VARIATION KIT” IN ACCORDANCE TO THE INTERNATIONAL STANDARDS AND CERTIFIED BY A

DOCUMENT SUPPLIED WITH THE MACHINE.

SEE CHAPTER 7.01 CALIBRATION SPECIFICATIONS.

1

ROTATION

SPEED

2

NUMBER OF

CYCLES

3

SPECIMEN

HEIGHT

4

APPLIED

LOAD

5

ANGLE OF

ROTATION

5.04

HOW TO OPERATE

Modes of operation: - Compaction of specimen in accordance to the selected number of rotations.

- Compaction of specimen upon reaching the selected height.

- Compaction of specimen upon reaching the selected density.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 16/47 07/2014

Chapter 6

MACHINE SET UP

The first time these operations must be performed by qualified personnel in the presence of the operator

in charge. (Standard EN 292-2 art. 5.5 1d)

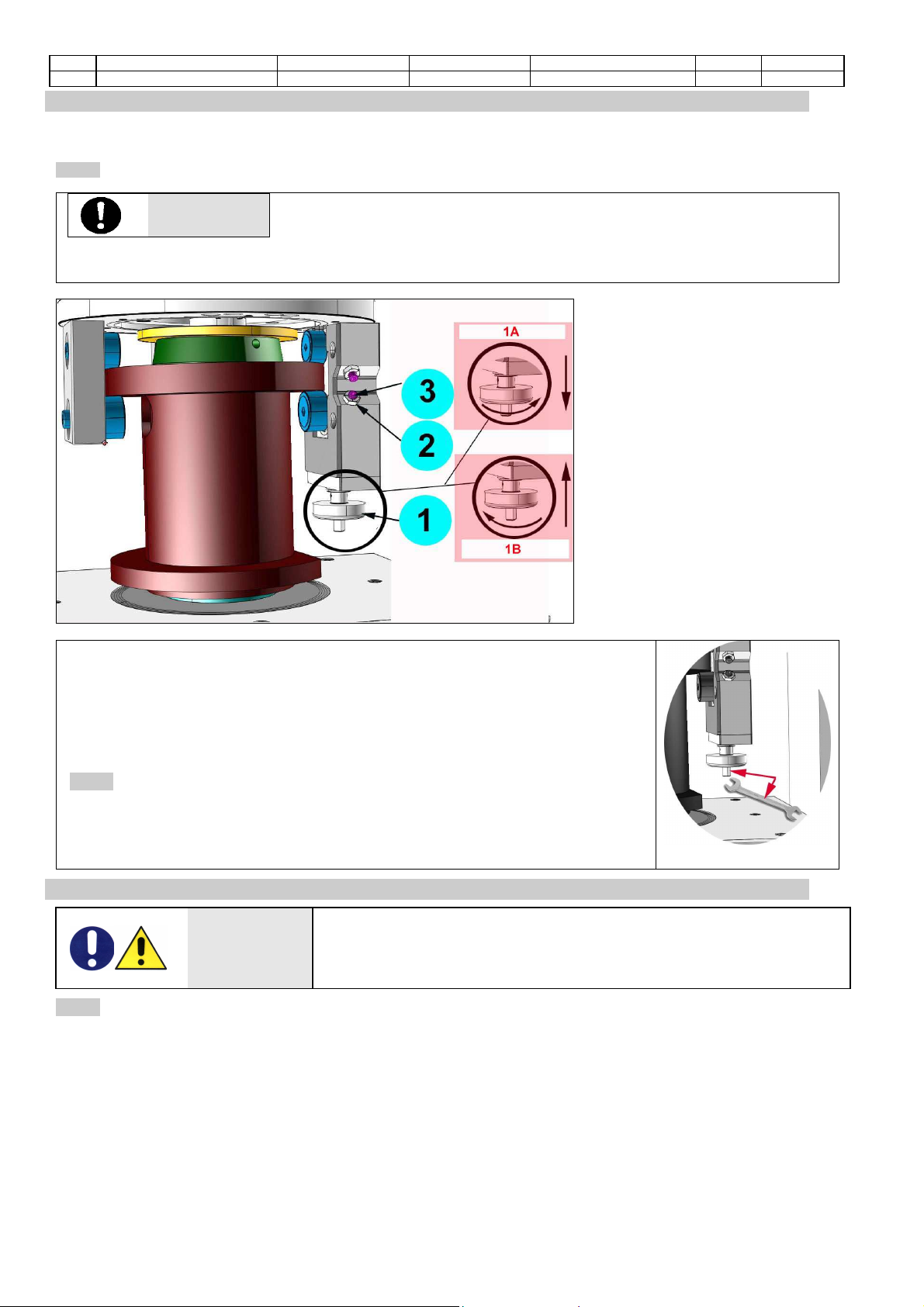

6.01

REGULATIONS

ATTENTION

The Matest Gyratory Compactor is calibrated at the factory to perform a set

gyration angle (lock position “1B”) and null angle (lock position “1A”). The

gyration angle can be changed within a working range acceptable for the

machine, adjusting the two dowels and nuts (“2” and “3”) placed on the selector. N.B.: THE MACHINE

CALIBRATION DECAYS IF THE FACTORY SETTINGS ARE CHANGED.

The gyration angle is set by the

hand grip selector that moves

vertically 2 of the 5 wheels

conceived to guide the mould.

The selector enables the operator to

set two working positions:

•the gyration angle

•the null angle

When the machine is off the

operator can set the gyration angle

by turning the hand grip “1” of the

selector clockwise up to the lock

position “B1” (the wheels moves

vertically upwards), or can set the

null angle at lock position “1A” by

turning the hand grip

counterclockwise (the wheels moves

vertically downwards).

Being the Gyratory Compactor calibrated at the factory, we recommend to set the

angle at lock position “1B” without introducing the mould into the machine. If this

condition is followed, the operators can insert the mould, perform the test and then

take out the mould from the machine without adjusting the selector.

If necessary, the operator can set the angle even after a pre-compaction of the

specimen using the null angle. In this case the rotation of the hand grip may be

difficult and a monkey wrench may be necessary to adjust the angle.

6.02

CHECKING THE SAFETY DEVICES WORK

Before proceeding to a regular and continuous use of the equipment, check the

emergency stop works correctly by: starting and stopping the machine through the

main switch, starting the machine and opening the doors, starting the machine and

pressing the emergency button.

C

hapter

7

IN FUNCTION

-

USE

DANGER

WARNING

Before setting the machine in motion it is essential that the Operator and

Safety Manager have read the Instructions Manual and understood all parts

of the machine and activities linked to it (Risks, Dangers, Functionality,

Operation, Protections, Commands, etc.)

7.01

MACHINE CALIBRATION

–

METERS

-

INDICATORS

The machine is checked in the factory, using sample equipment periodically checked by officially recognised

institutes. These checks cannot guarantee that the machine, meters and indicators will provide accurate values

and results conforming to the standards in force in the countries the machine has been installed and used in.

Normally such norms envisage calibration check after every movement. In order to obtain correct values and

results it is therefore VITAL that the operator, once the machine has been installed and set up and before official

tests, has an officially recognised body check the machine characteristics, its calibration and results/values

reliability. The manufacturer is exempt from all responsibility in the case of direct and indirect damage from use of

the machine without officially approval by the relevant bodies.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 17/47 07/2014

ATTENTION

It is

NECESSARY

to perform the following Calibration Checks, respecting the

provided deadlines, in order to comply with the instructions of the International

Standards in force related to the test (EN 12697-10, EN 12697-31 / ASTM D6925

/ AASHTO T312), and to control the possible settlements and run in wear conditions of the machine and its parts:

LILT TIME

→

MACHINE

INSTALLATIO

N

EVERY

MONTH

EVERY

THREE

MONTHS

Note

METERS ↓

ANGLE OF

ROTATION X X ** ** each 50 tests

until reaching

200 tests

APPLIED

LOAD X X

SPECIMEN

HEIGHT X X

ROTATION

SPEED X X

MOULD AND

PISTON See standards reference.

Follow the laws in force in the

country where the machine has

been installed for correct

calibration checks. Depending

on the instructions provided by

the law and by the Standard in

force, or depending on the main

goal of the tests, the operator

has to refer to an accredited

laboratory or to set up a

complete laboratory equipped

with appropriate equipment and

procedures.

7.02

SWITCHING ON THE MACHINE

Position the main switch on “I

7.03

EQUIPPING

–

SAMPLE POSITIONING

1.

RAM ASSEMBLING

1

TRANSDUCER

CHECKING DISC

2

PISTON

Assemble the transducer checking

disc and the piston on the terminal

part of the ram rod.

Lock the 3 dowels and make sure

that the piston is well-locked

without any clearance.

ATTENTION

During the

assembling

procedure it is very important the operator

handles carefully all the partsto avoid

damages (incisions or dents) that may

affect negatively the execution of the test.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 18/47 07/2014

Type 2

If your PISTON has 3 teeth

and 3 screws (see photo), fit

the piston with the rod, when

in lowered position. Then

enter the 3 teeth. Once lined,

insert the 3 screws and

tighten them with the Allen

wrench, making sure that the

piston is permanently

blocked.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 19/47 07/2014

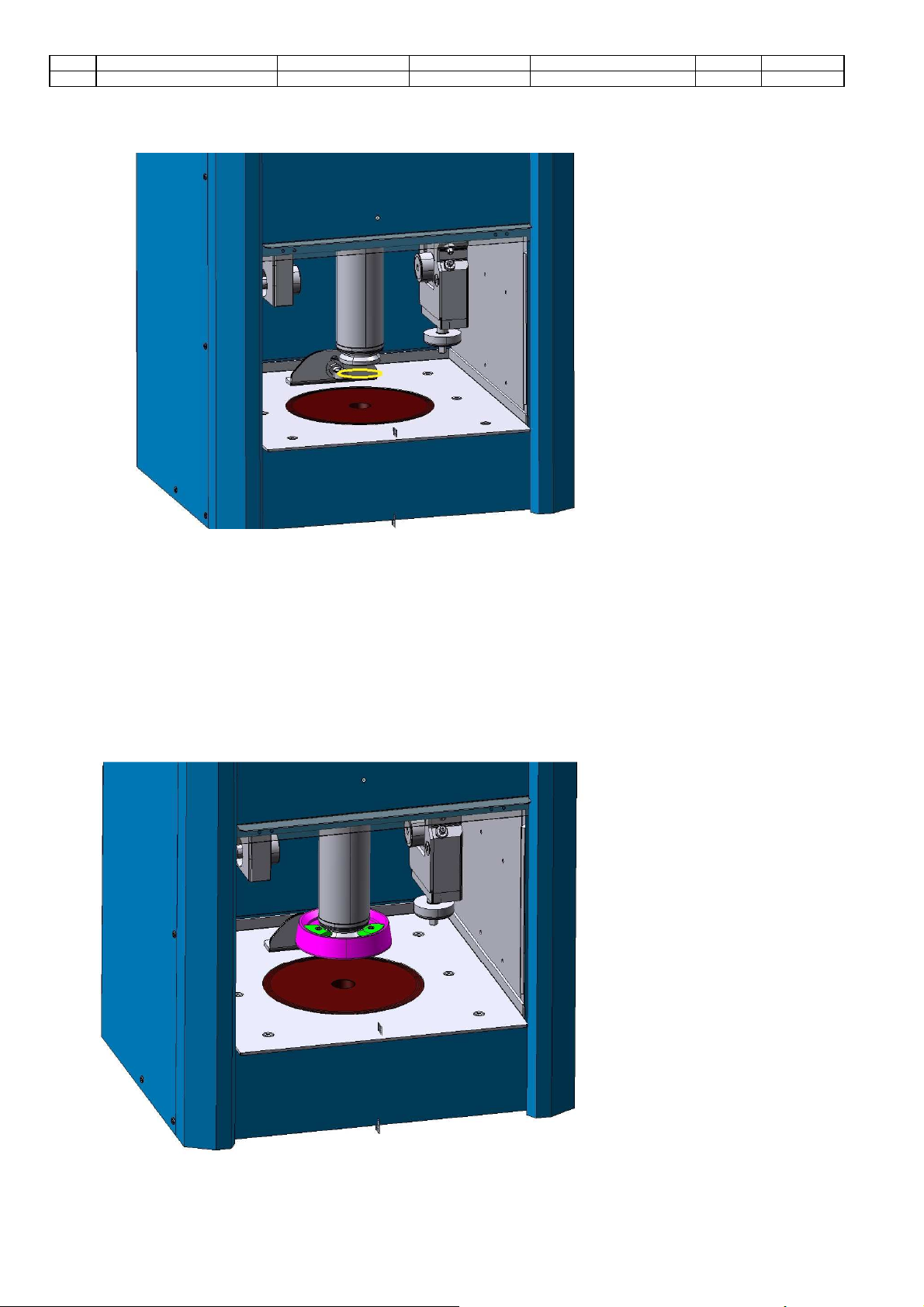

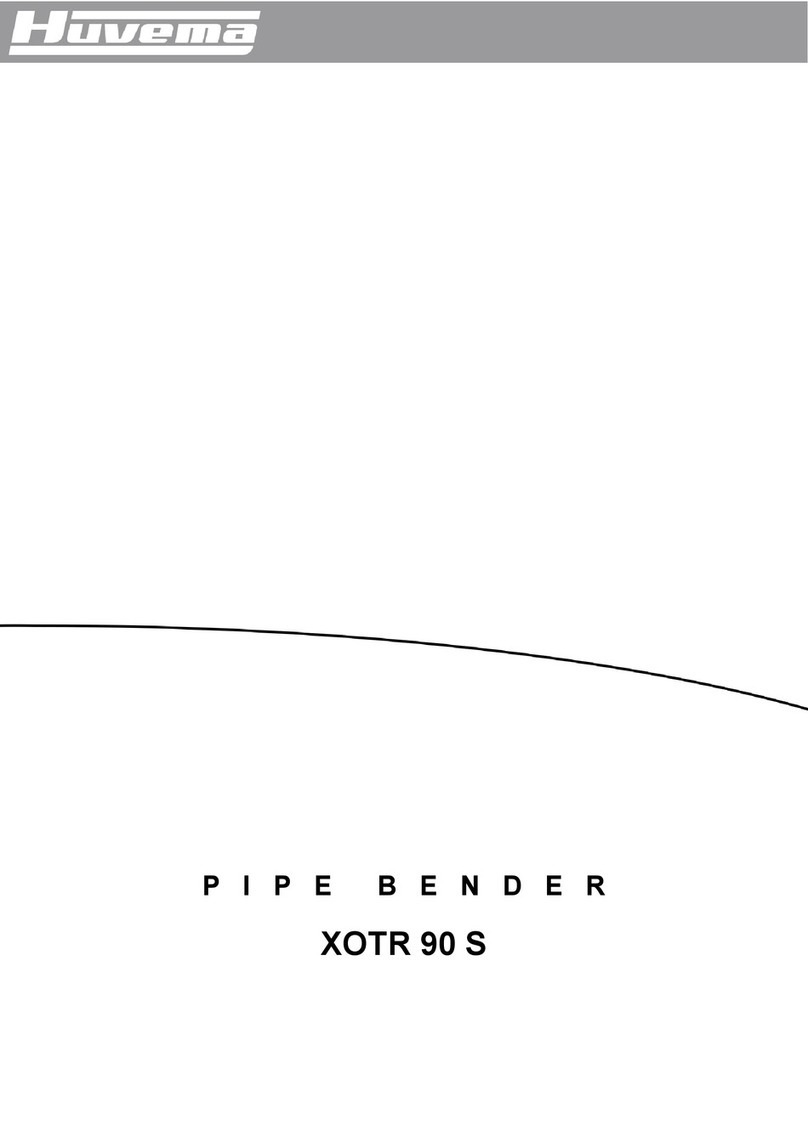

2.

CLEANING AND LUBRICATING

ATTENTION

An accurate cleaning of the

mould andall parts inside the

machine TEST CHAMBER is very

important for a good test

execution.

Failure to properly clean and

lubricate all the above mentioned

parts of the machine before each

use may result in compaction

errors, and premature equipment

wear.

After cleaning the machine, cover all

the parts with a thin layer of grease

or oil to protect them from rust.

1

WORKTOP A good cleaning condition must be maintained to avoid that impurities may be brought into

the test chamber when the operator drags the mould.

2

INTERNAL

PLATE

3

BASE DISC

The surface of the base disc is involved with the test execution and the mould bottom crawls

on with circular motion.

ATTENTION

For a correct test execution, it is very important that no

impurities are present between the bottom of the mould and

the surface of the base disc.

ATTENTION

It is of primary importance that a thin

layer of grease is laid on its surface to

avoid the seizing between the disc and

the bottom of the mould.

Use "Molykote ® Gn Plus" or

equivalent.

4

PISTON

It is very important that after each test the piston is cleaned properly to avoid incrustations.

5

TRANSDUCE

R CHECKING

DISC

The upper surface of the disc must be clean and without impurities as it works as checking

disc of the “T” sensor that reads the set angle.

6

WHEELS Their position and the circular motion generate the movement of the mould.

Their surfaces get in contact directly with the lubricated upper and lower collars of the

mould. No impurities must be present between these surfaces.

1

MOULD UPPER COLLAR SURFACES

These surfaces are in contact with the

machine wheels.

It is very important to keep them clean and

slightly lubricated with generic gear oil.

2

ANTI-ROTATION SLOT

This surface may be subjected to frictions

caused by the anti-rotation pin of the

machine. It is very important to keep it

lubricated with a thin layer of grease to avoid

noise and wear process.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 20/47 07/2014

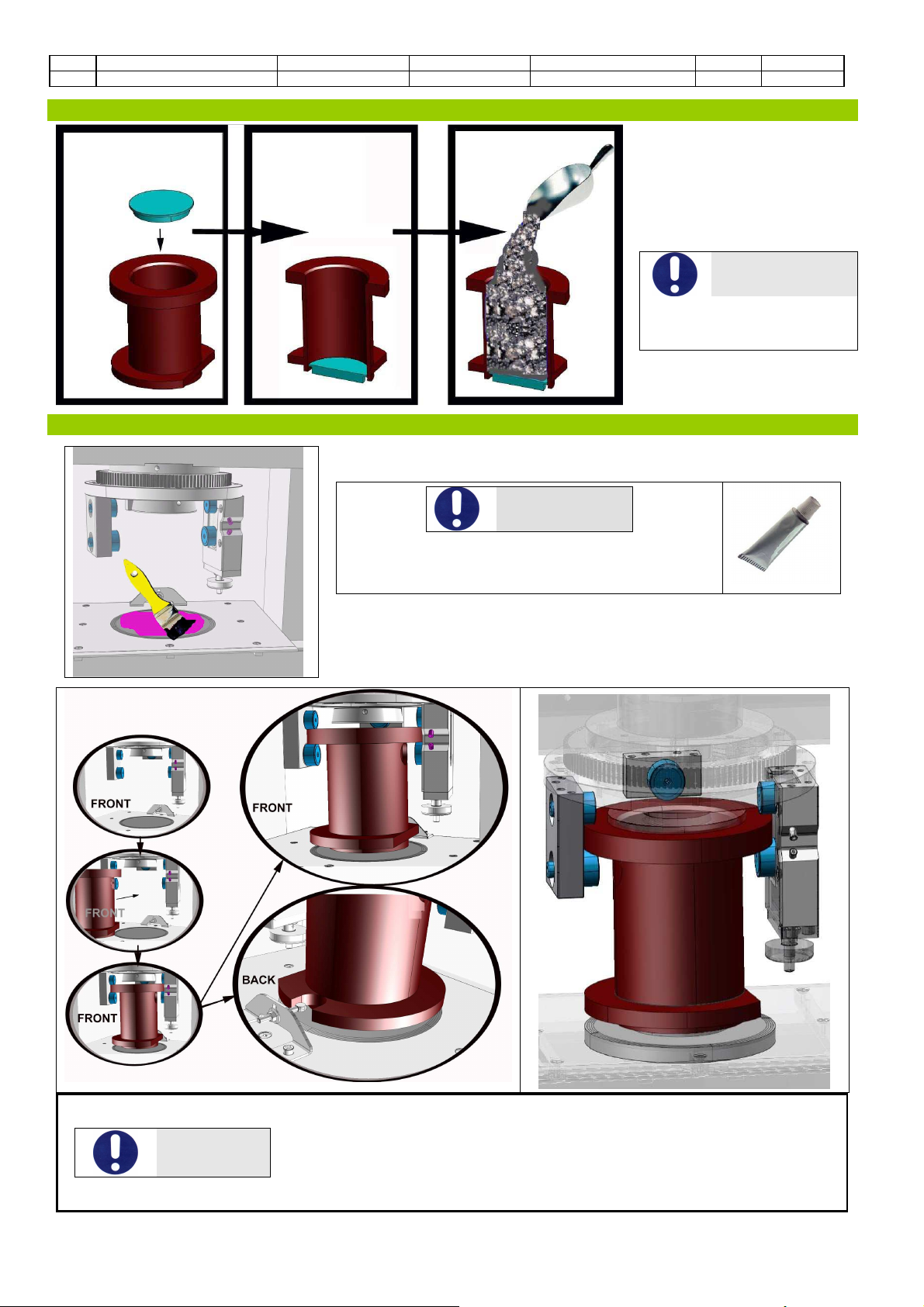

3.

SPECIMEN POSITIONING

•Insert the lower plate (puck)

into the mould (use the

extruder to make this operation

easier).

•Pour the asphalt mixture into

the mould.

ATTENTION

Make sure both sides of the

mould’s upper collar are

clean

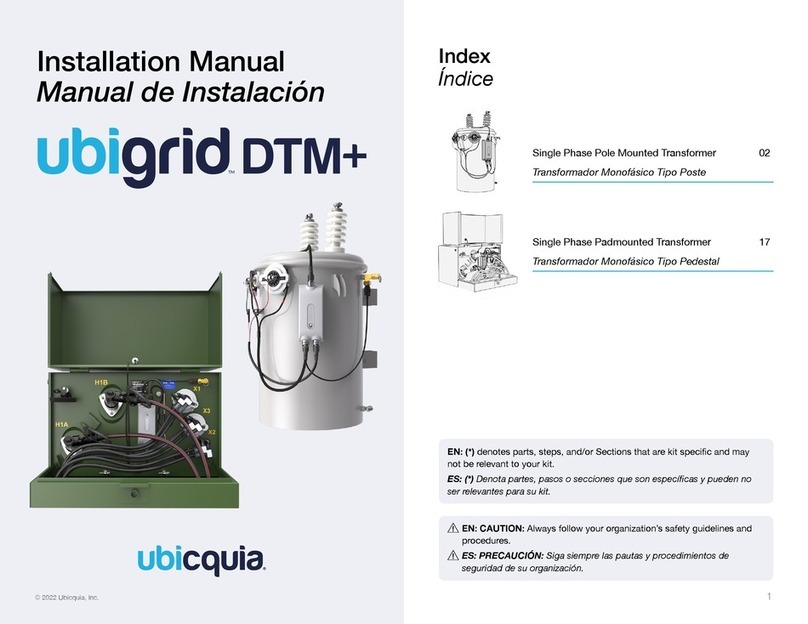

4.

INTRODUCING THE MOULD INTO THE MACHINE

ATTENTION

Spread a thin layer of grease on the base disc as

specified in paragraph "3" of the section "Cleaning

and lubrication."

Drag and put the mould into the machine test chamber, paying attention

to let the slot at the bottom of the mould turned towards the back.

ATTENTION

Make sure the anti-rotation pin is aligned with the slot placed at the bottom of

the mould. Make sure that the upper collar of the mould has been inserted

correctly between the lateral wheels and under the rear wheel; the mould must

be at the center of the machine base plate. This operation is very easy as the

base plate of the machine and the lower plate/puck of the mould have the

same diameter.

Table of contents

Other Matest Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TigerStop

TigerStop TigerFence user manual

WeighPack Systems

WeighPack Systems SPINDEXER 1800 Operator's manual

Powertrain

Powertrain WALTERSCHEID EK62/2S-L Repair instructions

Huvema

Huvema XOTR 60 S instruction manual

ubicquia

ubicquia ubigrid DTM+ installation manual

MachineryHouse

MachineryHouse SIEG SUPER X3 instruction manual