2

Item Subject Page#

1.0 Safety …………………………………………………………………………………………………………………………….. 3

2.0 General Information ………………………………………………………………………………………………………. 7

3.0 Installation of the Spacer Bolts ………………………………………………………………………………………. 7

Picture 1 Spacer Bolt Installation ………………………………………………………………………………………………….. 7

Figure 1 Spacer Bolt Configuration for 40”, 42” & 48” …………………………………………………………………. 8

Table 1 Spacer Bolt Part Identification ………………………………………………………………………………………… 8

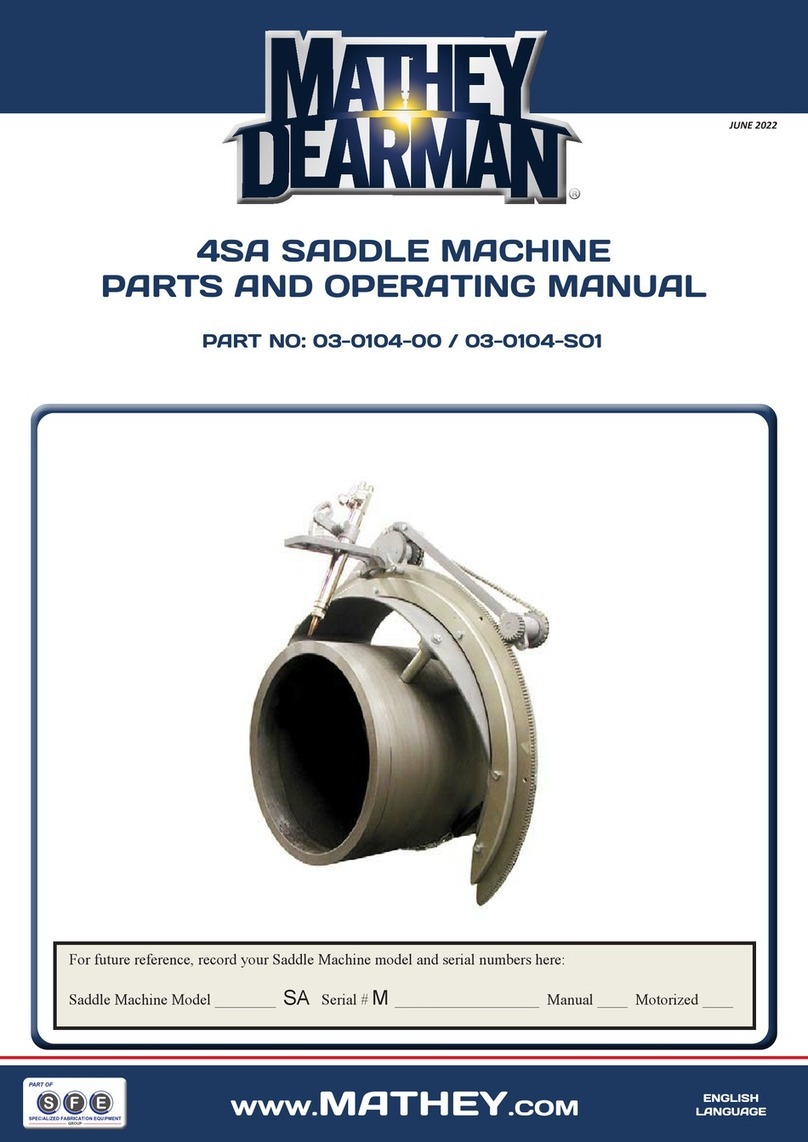

4.0 Installation of the Saddle Machine on the Pipe …………………………………………………………….. 8

Picture 2 Closing the Boomer Latch ………………………………………………………………………………………………. 9

Figure 2 Boomer Assembly Parts Configuration …………………………………………………………………………… 9

Table 2 Boomer Assembly Parts Identification ……………………………………………………………………………. 9

Figure 3Torch Arm & Torch Carrier Configuration ………………………………………………………………………. 10

Table 3 Torch Arm & Torch Carrier Parts Identification ……………………………………………………………… 10

5.0 Installation of the Torch Arm, Torch Carrier Assembly and Torch …………………………………..10

Picture 3 Installation of Torch Arm on the Threaded Stud …………………………………………………………….. 10

Picture 4 Installation of Wing Nut …………………………………………………………………………………………………. 11

5.1 Installation of the Extension Plate, Torch Arm, Torch Carrier Assembly, and Torch ………… 11

Figure 4 Extension Plate Configuration ………………………………………………………………………………………… 11

Table 4 Extension Plate Parts List ……………………………………………………………………………………………….. 11

Picture 5 Installation of Extension Plate Spacer …………………………………………………………………………….. 12

Picture 6 Extension Plate attached to Extension Plate Spacer ……………………………………………………. 12

6.0 The Manual Cutting Process …………………………………………………………………………………………. 12

7.0 The Motorized Cutting Process ………………………………………………………………………………………. 13

Picture 7 Motor Control Box Face View ………………………………………………………………………………………… 13

Picture 8 Motor Control Box End View …………………………………………………………………………………………. 13

Picture 9 Cable, Motor Control Box to Motor ………………………………………………………………………………… 14

A Note on Back Beveling ………………………………………………………………………………………………… 15

Figure 5 Manual 8SA Saddle Machine Parts Configuration …………………………………………………………… 16

Table 5 Manual 8SA Saddle Machine Parts Identification …………………………………………………………….17

Figure 6 Single Bearing Bracket Configuration ……………………………………………………………………………… 18

Table 6 Single Bearing Bracket Parts Identification ……………………………………………………………………… 18

Figure 7 Double Bearing Bracket Parts Configuration …………………………………………………………………… 19

Table 7 Double Bearing Bracket Parts Identification …………………………………………………………………… 19

Figure 8 Motorized 8SA Saddle Machine Parts Configuration ………………………………………………………. 20

Table 8 Motorized 8SA Saddle Machine Parts Identification ……………………………………………………… 21

Table 9 Trouble Shooting ……………………………………………………………………………………………………………. 22

8.0 Maintenance …………………………………………………………………………………………………………………. 22

8.1 Timing the Ring Gear to the Pinion Gears of the Manual Machine …………………………………. 23

8.2 Maintenance and Installation of the Double Bearing Bracket Assembly ………………………… 24

8.3 Maintenance and Installation of the Single Bearing Bracket Assembly ………………………… 24

8.4 Installation of a new Drive Chains on the Manual Machine …………………………………………… 25

8.5 Timing the Ring Gear to the Pinion Gears of the Stepper Motor Driven Machine …………… 26

8.6 Installation of a new Drive Chains on the Stepper Motor Driven Machine ……………………… 27

8.7 Installation of the Stepper Motor Kit ……………………………………………………………………………… 27

8.8 Storage …………………………………………………………………………………………………………………………… 28

9.0 Limitations ……………………………………………………………………………………………………………………… 29

10.0 Machine Safety ………………………………………………………………………………………………………………. 29

11.0 Condition of use ……………………………………………………………………………………………………………. 29

11.1 Condition of use ……………………………………………………………………………………………………………. 29

11.2 Use of the Saddle Machine not allowed by the manufacturer ………………………………………… 29

12.0 Disposal of the Saddle Machine ……………………………………………………………………………………… 29

12.1 General Information …………………………………………………………………………………………………… 29

12.2 Composition of Major Components ………………………………………………………………………………. 29

13.0 Warranty ……………………………………………………………………………………………………………………… 29

Table 10 Commercial Pipe Sizes …………………………………………………………………………………………………… 30