Catalog

CHAPTER 1 PRODUCT INTRODUCTION..........................................................................................................................1

CHAPTER 2 TECHNICAL SPECIFICATION.........................................................................................................................2

2.1 MAIN SPECIFICATION............................................................................................................................................. 2

2.2 ADDITIONAL FEATURES..........................................................................................................................................2

CHAPTER 3 QUICK START..................................................................................................................................................3

3.1 FRONT/REAR PANNEL INTRODUCTION...............................................................................................................3

3.2 PRE-EXAMINE.......................................................................................................................................................... 5

3.3IF THE POWER FAILS TO START..............................................................................................................................5

CHAPTER 4 PANEL OPERATION....................................................................................................................................... 6

4.1 KEYBOARD ARRANGEMENT...................................................................................................................................6

4.2 FRONT PANEL OPERATION INTRODUCTION.......................................................................................................7

4.3 VOLTAGE SETTING OPERATION.............................................................................................................................7

4.4 CURRENT SETTING OPERATION............................................................................................................................ 7

4.5 SAVE/RECALL OPERATION......................................................................................................................................7

4.6 BATTERY CHARGING WARNING FUNCTION........................................................................................................7

CHAPTER 5 REMOTE OPERATION MODE....................................................................................................................... 8

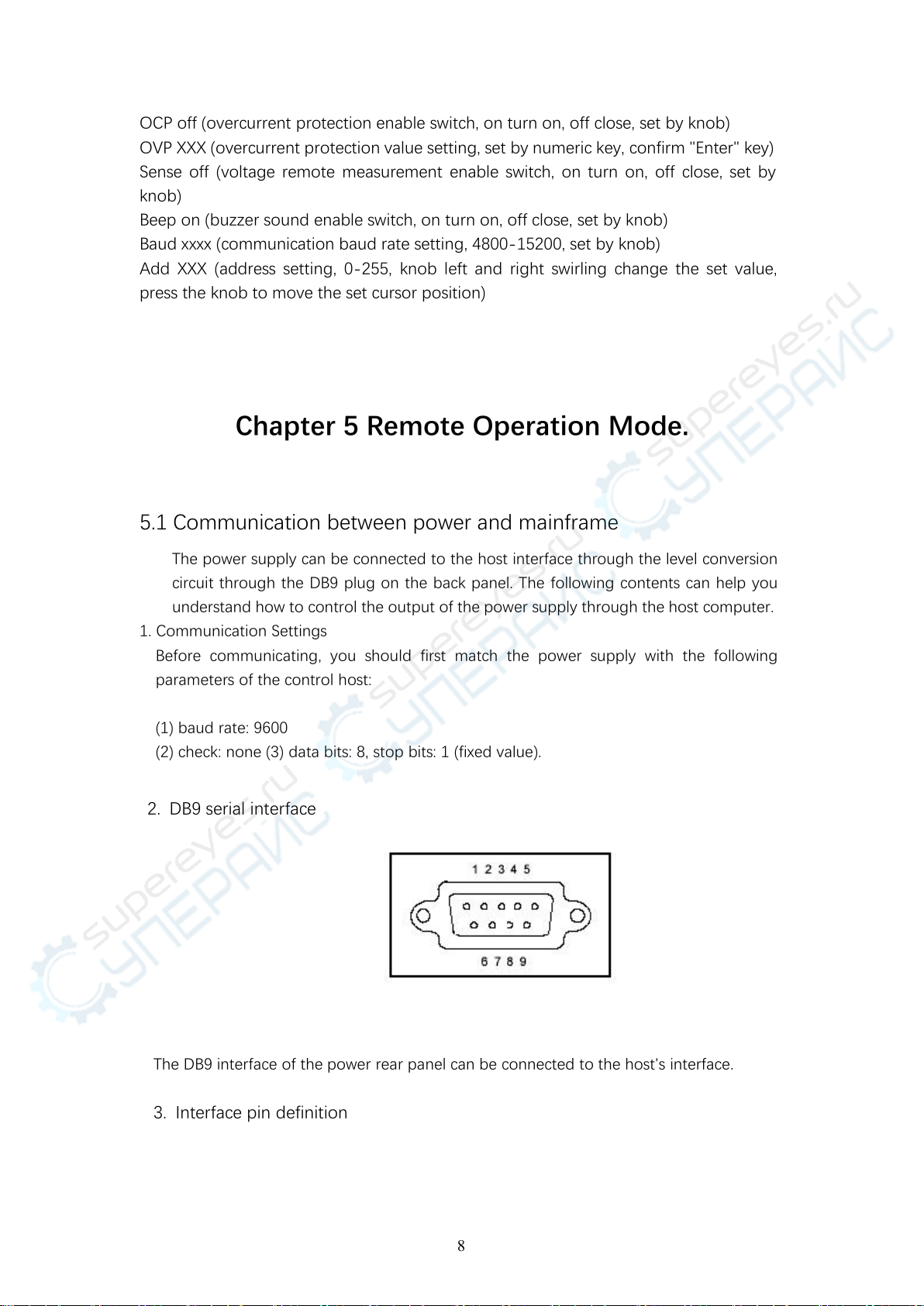

5.1 COMMUNICATION BETWEEN POWER SUPPLY AND MAIN UNIT..................................................................... 8

CHAPTER 6 SCPI COMMUNICATION COMMAND......................................................................................................... 9

6.1 SCPI COMMAND SUMMARY.............................................................................................................................9

6.2 COMMONLY USED COMMAND DESCRIPTION............................................................................................ 10

6.2.1 BASIC COMMAND......................................................................................................................................... 10

6.2.2 MPS-3600 SPECIFIED COMMAND..............................................................................................................10

6.2.3 MEASURING COMMAND.............................................................................................................................10

6.2.4 SETTING COMMAND....................................................................................................................................11

4.2.7 LIST 功能.........................................................................................................................................................

4.2.8 自动测试功能.....................................................................................................................................................

4.2.8.1 编辑自动测试列表..................................................................................................................................18

4.2.8.2 设置自动测试触发输出方式..................................................................................................................19

4.2.8.3 执行自动测试功能..................................................................................................................................19

4.3 输入控制.....................................................................................................................................................................

4.3.1 短路操作(SHORT)........................................................................................................................................

4.3.2 输入开关操作.....................................................................................................................................................

4.4 电子负载可操作范围.................................................................................................................................................

4.5 保护功能.....................................................................................................................................................................

4.5.1 过电压保护(OV