2/16 | Revision: | Revision Date: | Revised by: Matrix ITC

GENERAL TROUBLESHOOTING TOC

•UPDATE TO THE LATEST SOFTWARE VERSION, if possible.

oReference the Software Update topic if anything unexpected happens.

•Cycling power is recommended as the first attempt to fix most failures, and after major repairs are

implemented.

•If multiple, identical machines are available, swap suspected failed parts (console, cables, etc.)

and observe if the failure follows.

•If unsure where to begin with degraded console performance, disconnect everything from the

UCB (except for the console cable, as this supplies power). Verify expected operation; reconnect

parts one at a time until the failure is recreated.

•Before replacing any major part, inspect the cables to/from it. Disconnect and inspect the

connectors on both ends, as well as the terminals on the boards. If capable, perform continuity

tests to verify all the conductors are intact. If no damage/corrosion noted, carefully reconnect,

ensuring proper seating and connection. Request replacement cables if at all suspicious.

USING THIS GUIDE

Read & understand the General Troubleshooting section above.

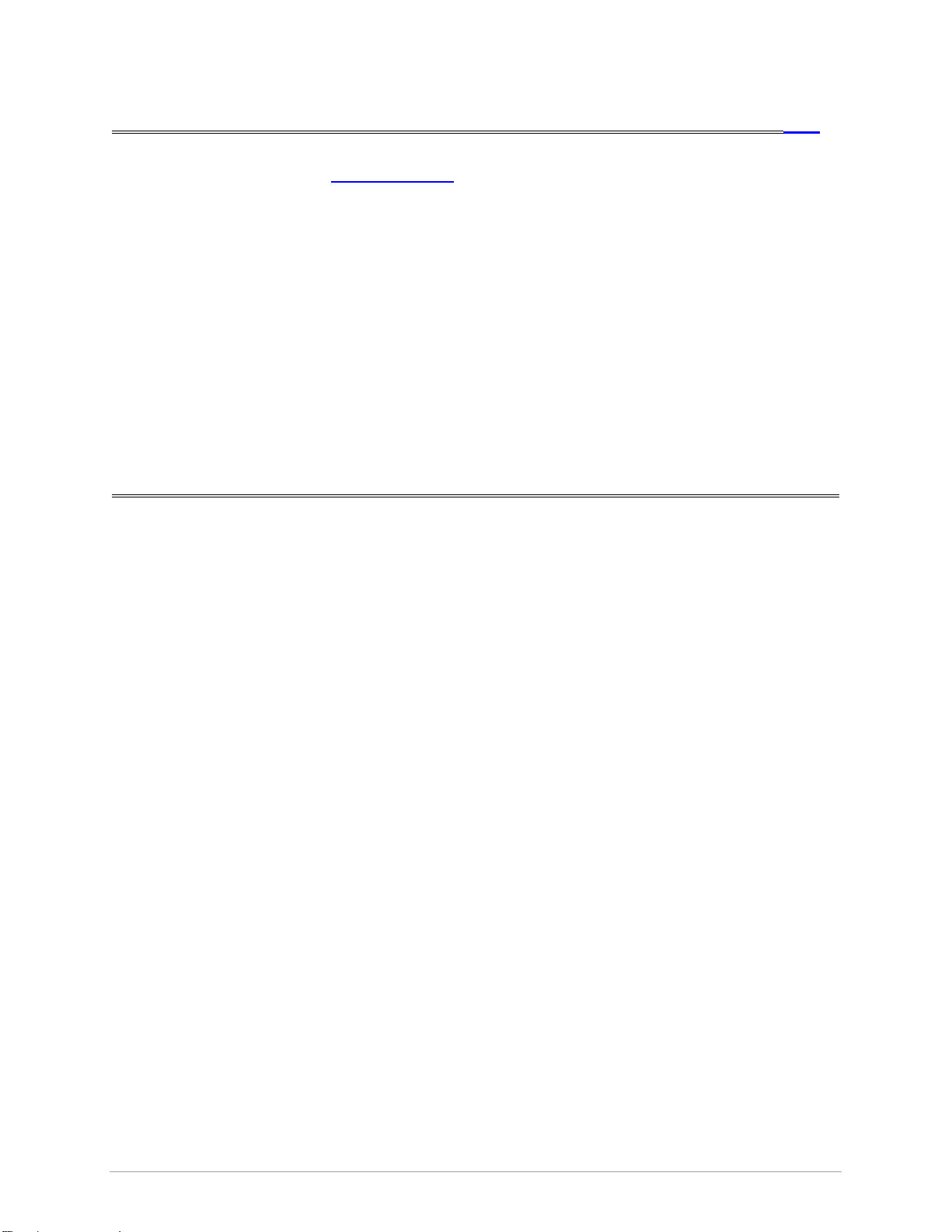

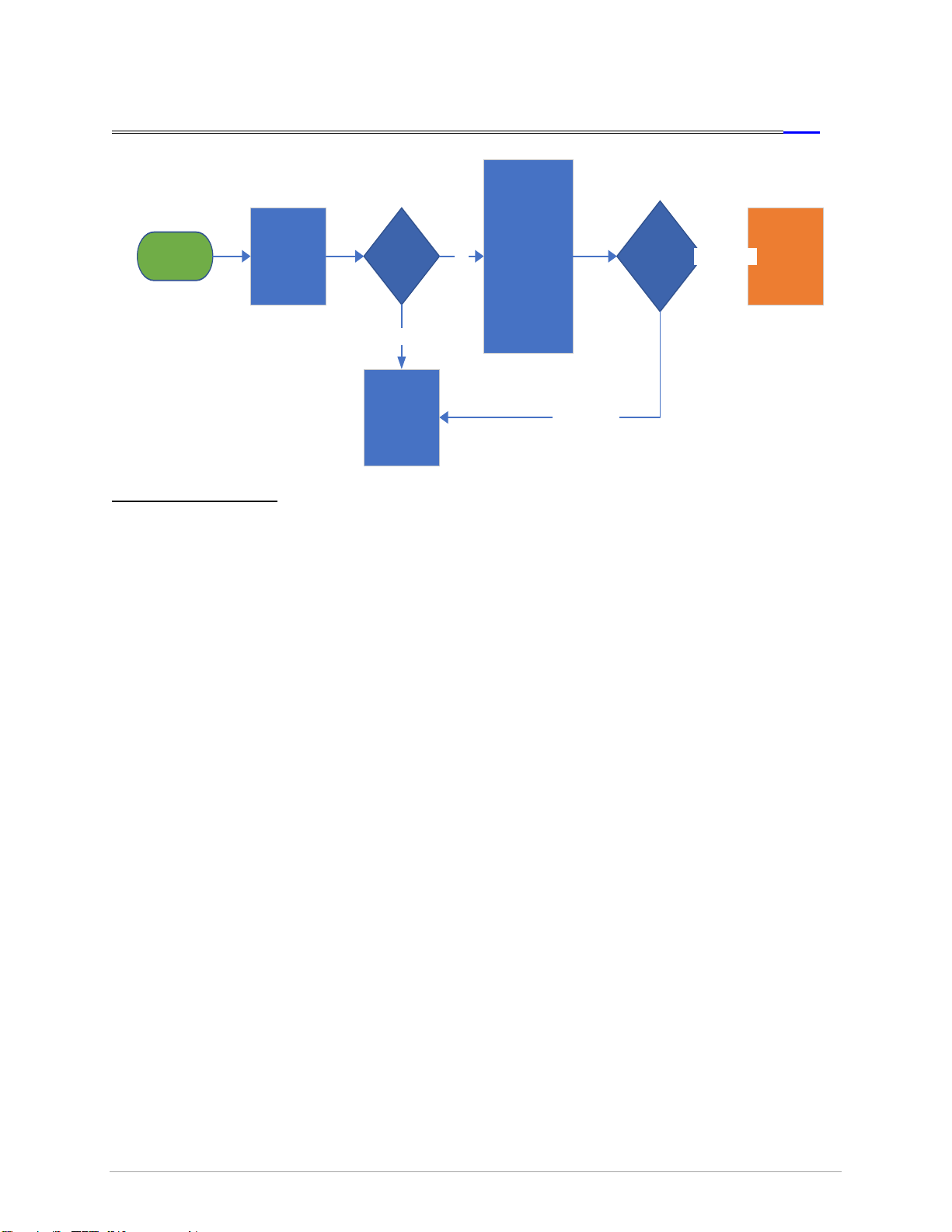

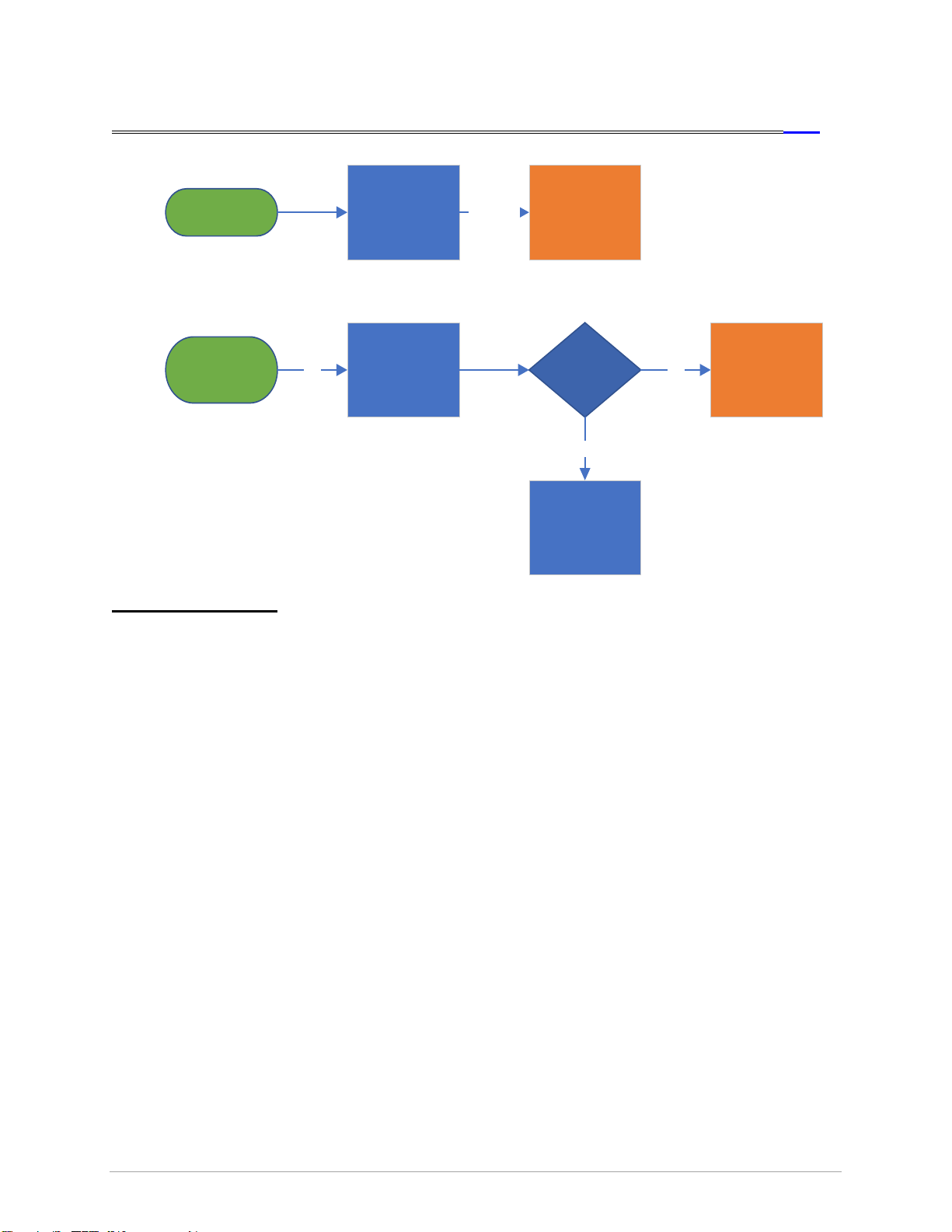

Given a problem description, link to the topic that appears most fitting from the ToC on the first page or

Find (ctrl-f) by keyword. Find the Green flowchart bubble that best describes the specific issue, and follow

the flow through asking questions, taking measurements, and suggesting corrective action. The

“Additional Information” section within each topic contains notes and details pertaining to that topic.

After each corrective action is taken, re-evaluate if the failure has been resolved. Some indications have a

straightforward order of attempts, and not all steps are always necessary if a lower-level fix resolves the

issue.