3

System Specifications

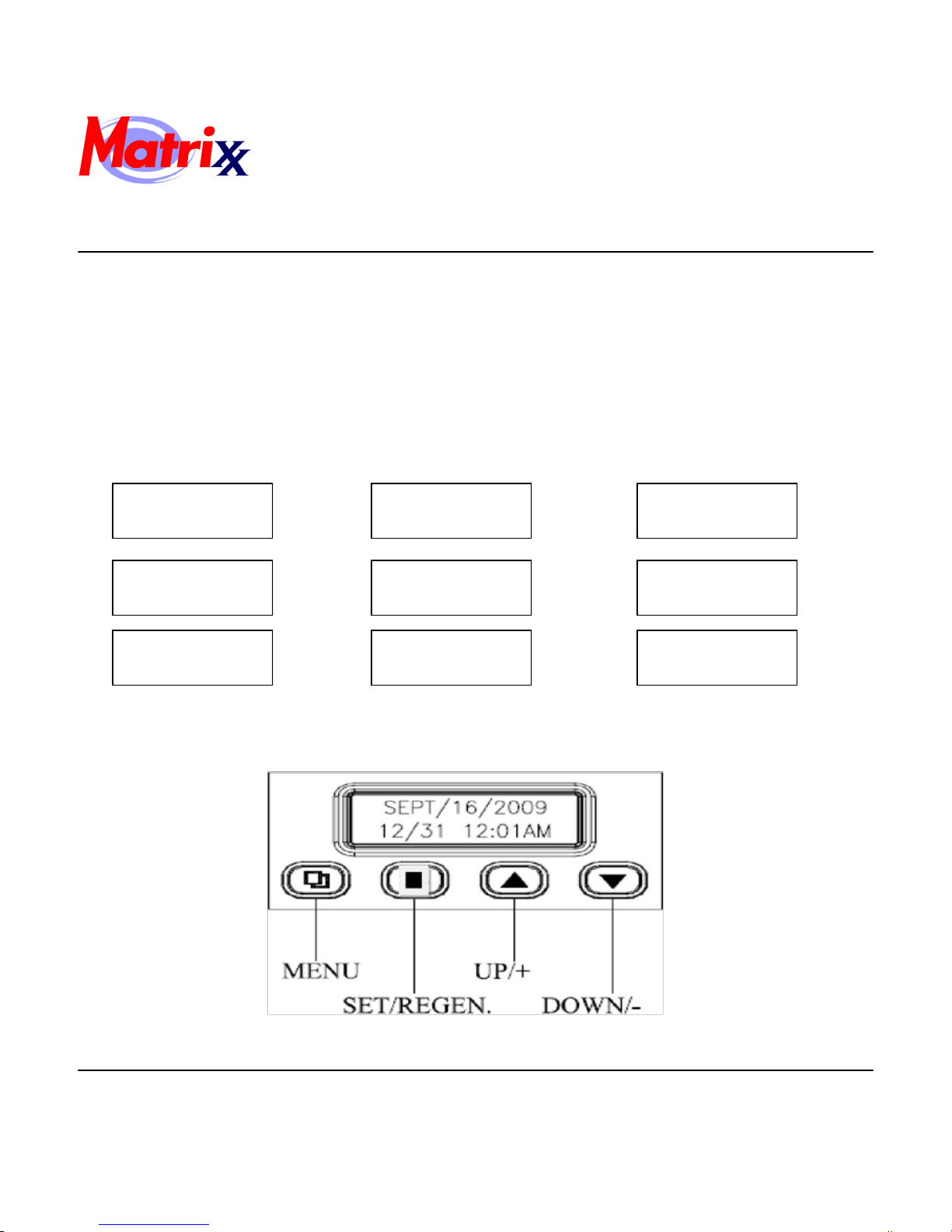

Figure 1. Specifications

US Water Systems classifies each softener according to the actual resin capacity. However, this is not the

regeneration capacity. The regeneration capacity will be lower than the actual resin capacity. This is due to

the resin ’ s regeneration salt curve. For example:

A 53,000 grain unit would require 30 lbs of salt during regeneration if the capacity was set to the actual resin

capacity ( 53,000 grains ) . If the unit is set at 37,000 grains it can be regenerated using only 10 lbs of salt.

The unit is much more efficient when it is set using the proper salt curve capacity and salt dosage levels. So

you can see that to get the final 16,000 grains from a 53,000 grain unit the salt usage will more than double.

Please use the chart below when setting you softener. This will ensure efficiency and longevity of your unit.

Maximum Water Temperature = 110°F (43°C)

Maximum Operating Pressure = 100

PSIG (689 kPa)

Voltage = 110 volts standard

Pipe Size = 3/4”

At the stated service flow rates, the pres-

sure drop through these devices will not

exceed 15 psig.

Changing salt settings from factory setting

may require changing injector sizes to

achieve stated capacities.

The manufacturer reserves the right to make

product improvements which may deviate from

the specifications and descriptions stated herein,

without obligation to change previously manufac-

tured products or to note the change.

Model # System Capacity Grains Flow Rate Regeneration Water Mineral

Tank

Size

Resin

Cu. Ft.

Brine Tank/

Cabinet

Size Inches

Salt

Capacity

(Lbs)

Ship

Weight

(Lbs)

@ 10

lbs/cu ft

@6 lbs/

cu ft

(Factory

Settings)

@ 3 lbs/

cu ft

Service

USGPM

Back-

wash

USGPM

Clean

Water

(Factory

Setting)

Problem

Water

085-MX-100 25,000 20,000 13,000 10.0 2.0 38.0 48.0 9 X 48 1.00 15 X 15 X

34.7

230 122

085-MX-150 37,000 30,000 18,000 12.0 2.4 48.5 60.5 10 X 54 1.50 15 X 15 X

34.7

230 155

085-MX-200 50,000 40,000 25,000 15.0 3.5 80.5 95.5 12 X 52 2.00 20.3 X 37.4 385 158

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

For the HTO systems use the following chart.

24,000 37,000 44,000

4.7 7.1 9.5