III

Calder Brothers Corp

V 1.0

Serial Number Range:

874-S-86TCX5Y2*03874 to _____________

Model: 1860 Paver

1. Introduction............................................................................................. 1

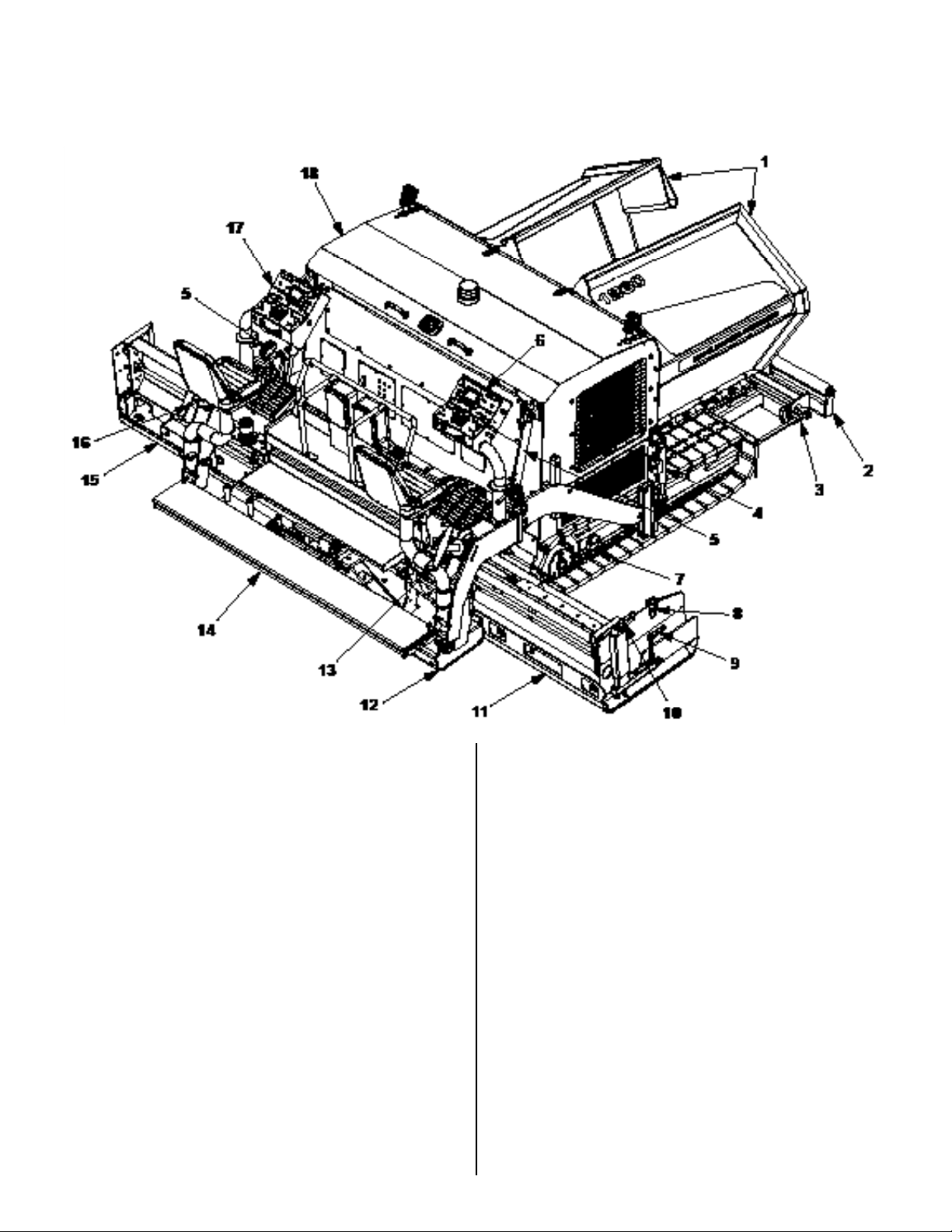

1.1 Machine Components ...................................................................................... 1

1.2 Serial Number Plate.......................................................................................... 2

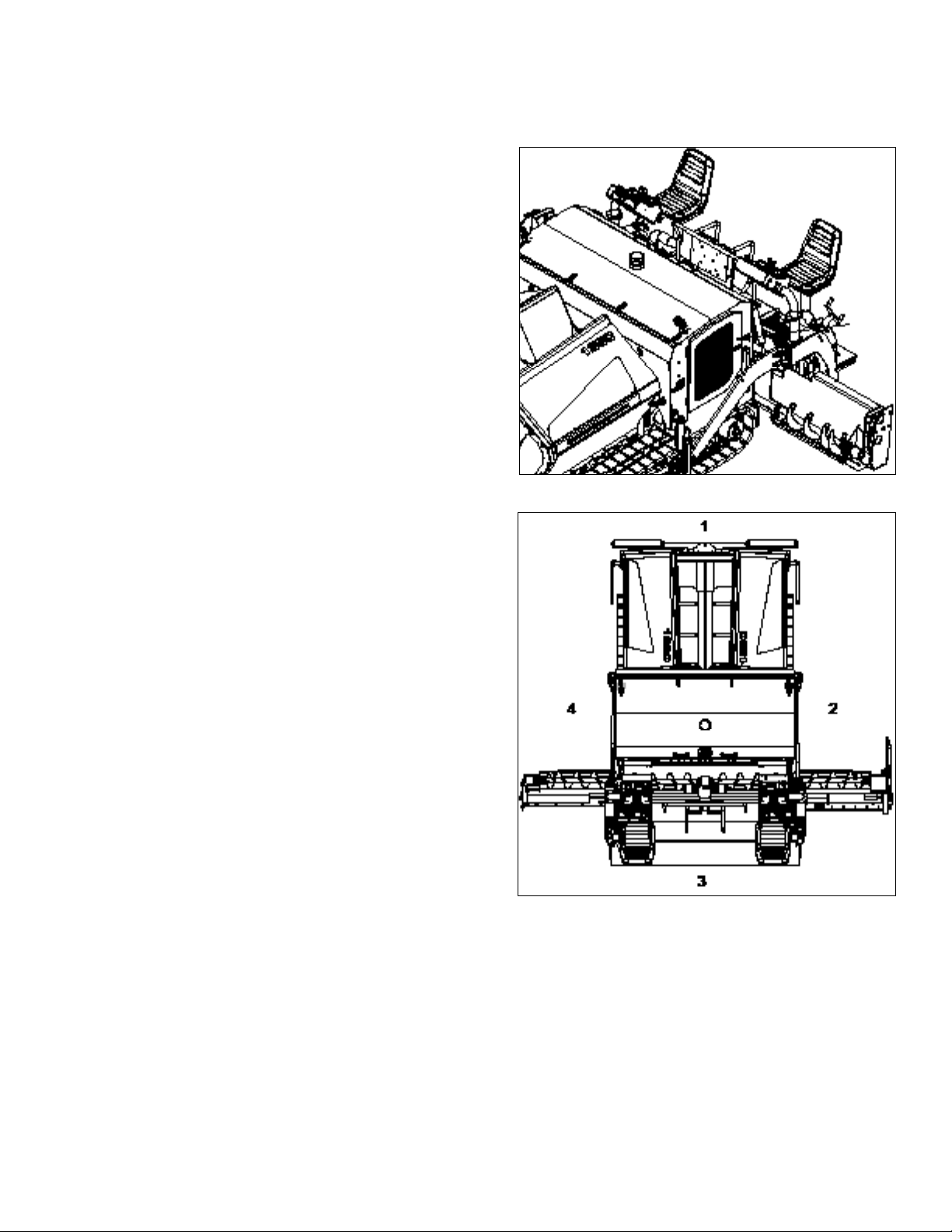

1.3 Operator Orientation ........................................................................................ 2

2. Safety....................................................................................................... 3

2.1 General Safety Information.............................................................................. 3

2.1.1 Safety Alert And Signal Words...........................................................................3

2.2 Operation Hazards............................................................................................ 3

2.2.1 ^ Pressurized Fluids..........................................................................................5

2.2.2 ^Hazardous Chemicals ....................................................................................6

2.2.3 California Proposition 65 Warnings...................................................................6

2.2.4 Hazards From Modifying Equipment .................................................................6

2.3 Maintenance Hazards ....................................................................................... 6

2.3.1 ^Maintenance And Service ..............................................................................7

2.3.2 ^Fire Or Explosion Prevention .......................................................................7

2.4 Safety Decals .................................................................................................... 7

3. Paver Operation.................................................................................... 10

3.1 Operators Station ........................................................................................... 10

3.2 Digital Display ................................................................................................. 12

3.2.1 Engine Warning Lamps.....................................................................................12

3.2.2 Engine Screen....................................................................................................12

3.2.3 Material Feed Screen.........................................................................................13

3.2.4 Screed Temperature Screen .............................................................................13

3.2.5 Password Screen...............................................................................................14

3.3 Prestart Checks .............................................................................................. 14

3.4 Start Engine..................................................................................................... 14

3.5 Idle/Pave And Engine Speed.......................................................................... 15

3.6 Emergency Stop ............................................................................................. 15

3.7 Active Station .................................................................................................. 16

3.7.1 Single Operator Mode ......................................................................................16

3.7.2 Dual Operator Mode .........................................................................................16

3.8 Driving ............................................................................................................. 16

3.9 Pause/Resume ................................................................................................ 17