Max-Thrust Ruckus Balsa Pro-Build Series User manual

Other Max-Thrust Toy manuals

Max-Thrust

Max-Thrust Douglas A1 Skyraider User guide

Max-Thrust

Max-Thrust Ryan STA User guide

Max-Thrust

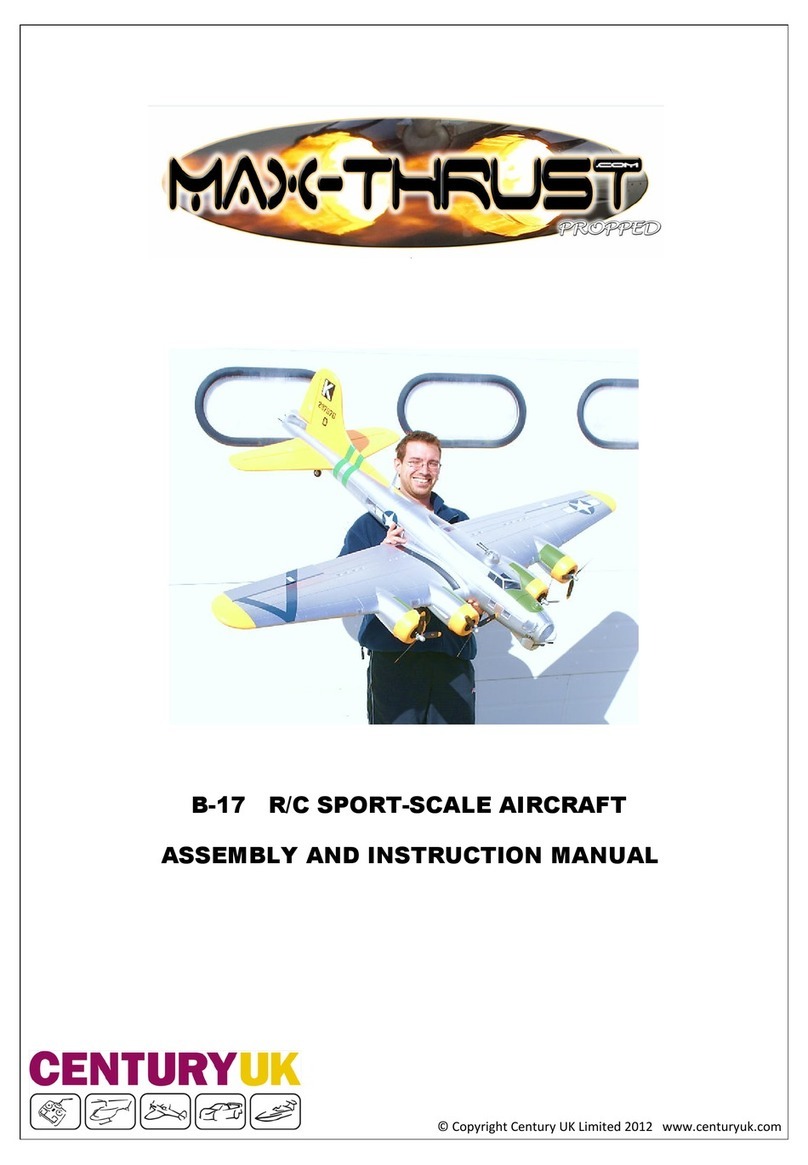

Max-Thrust B-17 User guide

Max-Thrust

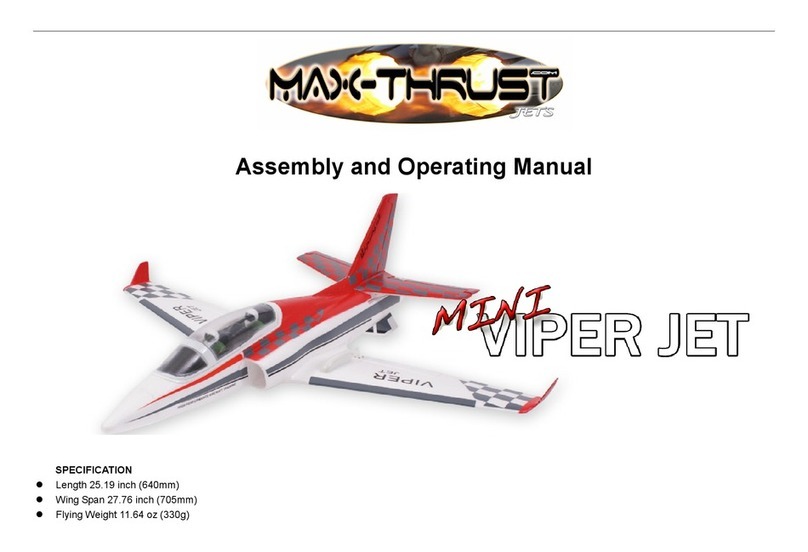

Max-Thrust Mini Viper Jet User instructions

Max-Thrust

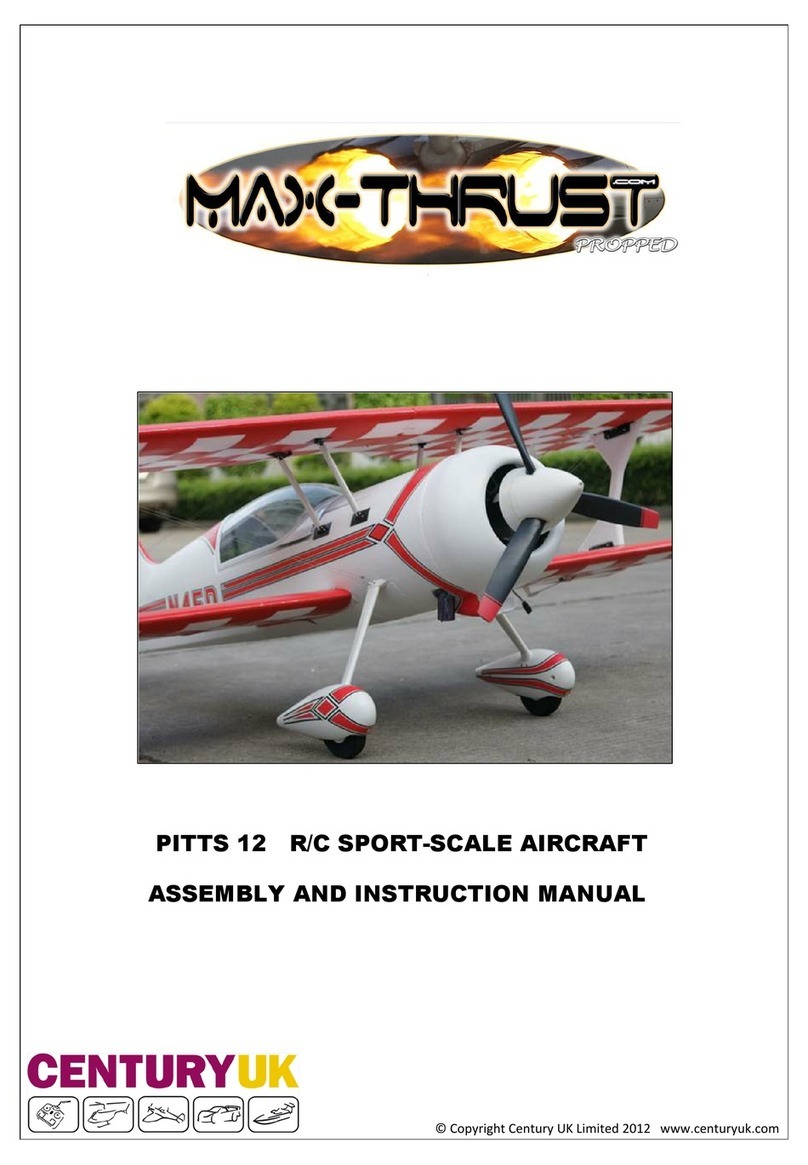

Max-Thrust PITTS 12 User guide

Max-Thrust

Max-Thrust MAX TRAINER Balsa Pro-Built Series User manual

Max-Thrust

Max-Thrust Double Trouble Balsa Pro-Built Series User manual

Max-Thrust

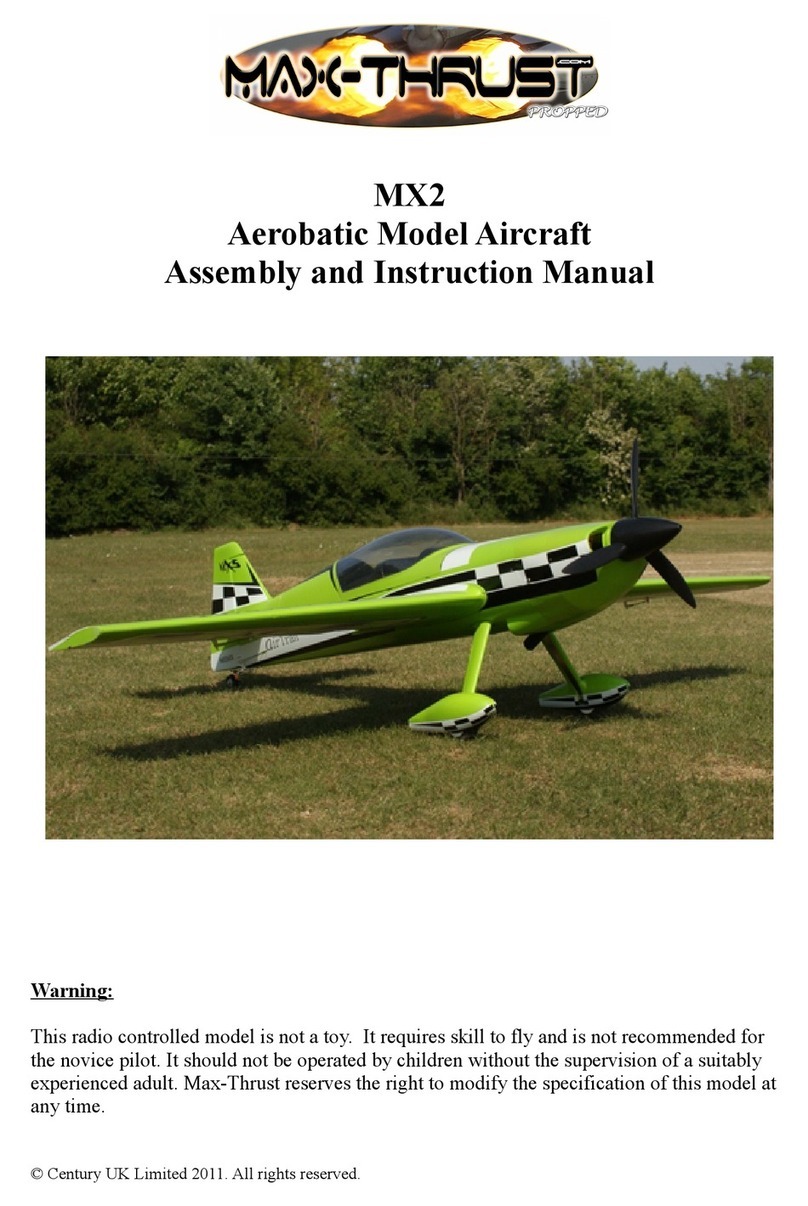

Max-Thrust MX2 User guide

Max-Thrust

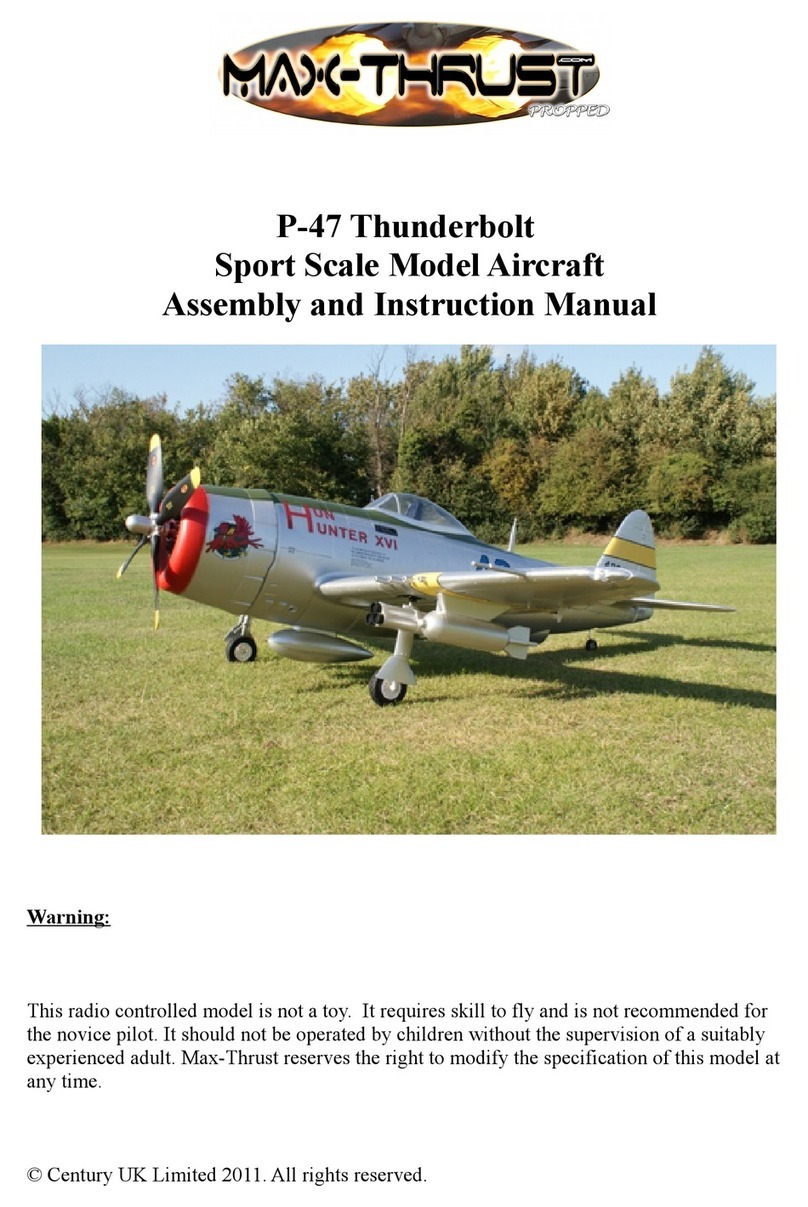

Max-Thrust P-47 Thunderbolt User guide

Max-Thrust

Max-Thrust APPRENTICE User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions