N‐i‐HPInverterair/waterheatpumpchillerswithaxialfans

2

INDEX

1AIMANDCONTENTSOFTHISMANUAL...............................................................................................................................4

1.1HOWTOKEEPTHISMANUAL.................................................................................................................................................4

1.2GRAPHICSYMBOLS................................................................................................................................................................4

2SAFETYLAWS......................................................................................................................................................................4

3PERMITTEDUSES................................................................................................................................................................4

4GENERALSAFETYGUIDELINES.............................................................................................................................................5

4.1WORKERS’HEALTHANDSAFETY............................................................................................................................................5

4.2PERSONALSAFETYEQUIPMENTS...........................................................................................................................................5

4.3SAFETYSYMBOLS...................................................................................................................................................................5

4.4REFRIGERANTSAFETYDATASHEET........................................................................................................................................6

5TECHNICALCHARACTERISTICS.............................................................................................................................................7

5.1FRAME...................................................................................................................................................................................7

5.2REFRIGERANTCIRCUIT...........................................................................................................................................................7

5.3COMPRESSORS.......................................................................................................................................................................7

5.4AIR‐SIDEEXCHANGERS...........................................................................................................................................................7

5.5FANMOTOR...........................................................................................................................................................................7

5.6USER‐SIDEHEATEXCHANGERS..............................................................................................................................................7

5.7ELECTRICALCONTROLPANELBOARD....................................................................................................................................7

5.8CONTROLSYSTEM..................................................................................................................................................................7

5.9MONITORINGANDPROTECTIONDEVICES.............................................................................................................................8

5.10HYDRAULICCIRCUIT...............................................................................................................................................................8

5.11FANSPEEDCONTROL.............................................................................................................................................................8

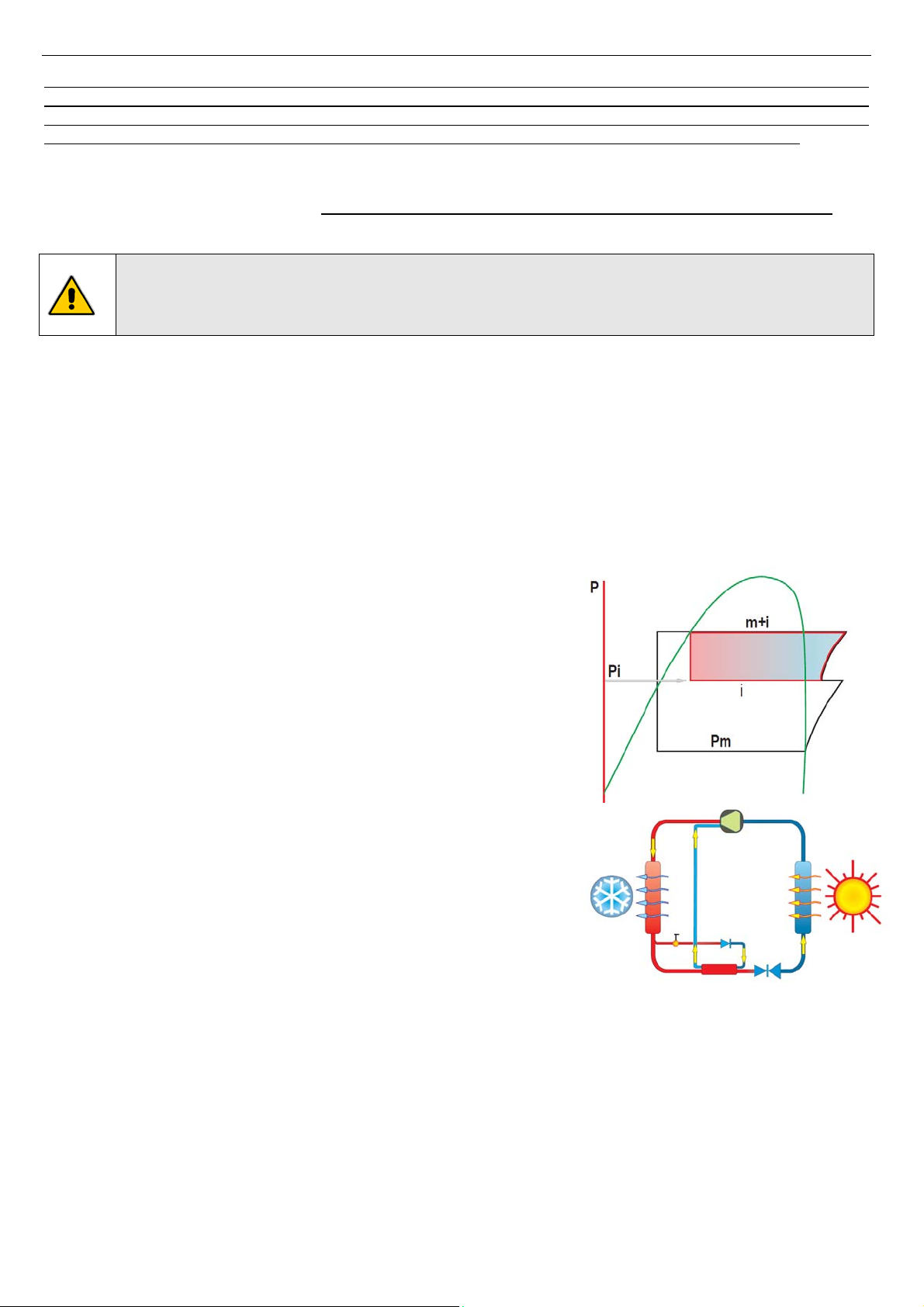

5.12ENHANCEDVAPOURINJECTION(EVI)TECNOLOGY...............................................................................................................8

6AVAILABLEVERSIONS,SIZESANDACCESSORIES..................................................................................................................9

6.1OPTIONALACCESSORIES......................................................................................................................................................10

7INSTALLATION..................................................................................................................................................................11

7.1GENERALITY.........................................................................................................................................................................11

7.2LIFTINGANDHANDLING......................................................................................................................................................11

7.3LOCATIONANDMINIMUMTECHNICALCLEARANCES..........................................................................................................11

7.4HYDRAULICCONNECTIONS..................................................................................................................................................12

7.4.1Drainageconnection....................................................................................................................................................12

7.4.2Servicevalve.................................................................................................................................................................12

7.4.3Plantdrainagesystem..................................................................................................................................................12

7.4.4Hydrauliccircuit...........................................................................................................................................................13

7.5REFRIGERANTDIAGRAMS....................................................................................................................................................13

7.5.1RefrigerantdiagramofthemodelN‐i‐HP0125...........................................................................................................13

7.5.2RefrigerantdiagramofthemodelN‐i‐HP0235‐0250..................................................................................................14

7.5.3RefrigerantdiagramofthemodelN‐i‐HP‐LT0125......................................................................................................14

7.5.4RefrigerantdiagramofthemodelN‐i‐HP‐LT0235‐0250.............................................................................................15

7.6ELECTRICALCONNECTIONS..................................................................................................................................................15

7.6.1Wiringterminalblock...................................................................................................................................................16

8STARTUP..........................................................................................................................................................................18

9POWER‐ONOFTHEUNIT..................................................................................................................................................19

10SHUTDOWNSFORLONGPERIODS.................................................................................................................................19

11MAINTENANCEANDPERIODICALCONTROLS.................................................................................................................19

11.1ENVIRONMENTALPROTECTION...........................................................................................................................................19

12WHENTHEUNITGOESOUTOFSERVICE........................................................................................................................20

13TECHNICALDATA(PRELIMINARIES)...............................................................................................................................20

13.1STANDARDVERSION............................................................................................................................................................20