i-MAX Industrial inverter air/water heat pump with axial fans

4

9.3 ALARM SIGNALIZATION........................................................................................................................................................ 18

9.4 HEAT PUMP LOCKOUT SIGNALIZATION ........................................................................................................................................... 18

9.5 ENABLEMENTOF DOMESTIC HOT WATER PRODUCTION (DHW) ......................................................................................... 18

9.5.1 MEMORIZATION OF THE SENSOR IN HEATING MODE ................................................................................................. 19

9.5.2 SANITARY MODE CALLING FROM DIGITAL INPUT ........................................................................................................ 19

9.5.3 HEATING MODE ON DOMESTIC HOT WATER TANK ..................................................................................................... 19

9.6 SUMMER/WINTER MODE ROMOTE COMMUTATION.......................................................................................................... 19

9.7 PLANT REMOTE SENSOR ...................................................................................................................................................... 19

9.8 AUXILIARY ELECTRIC HEATER ............................................................................................................................................... 20

9.8.1 PLANT CIRCUIT AUXILIARY ELECTRIC HEATER .............................................................................................................. 20

9.8.2 AUXILIARY ELECTRIC HEATER OF THE PLANT IN DEFROST CYCLE................................................................................. 20

9.8.3 ELECTRIC HEATER OF SANITARY WATER PRODUCTION ............................................................................................... 20

9.8.4 UNIQUE AUXILIARY ELECTRIC HEATER FOR BOTH PLANT SYSTEM/DHW PRODUCTION.............................................. 20

9.8.5 SELECTION MODE OF THE AUXILIARY ELECTRIC HEATERS ........................................................................................... 20

9.8.6 MANAGEMENT OF THE CIRCULATOR WITH ACTIVE ELECTRIC HEATER ....................................................................... 21

9.9 BOILER ENABLEMENT........................................................................................................................................................... 21

9.10 ACTIVATION OF AUXILIARY ELECTRIC HEATERS AND BOILER DURING JOINT AND SUBSTITUTION OPERATION TO THE

COMPRESSOR................................................................................................................................................................................... 21

9.10.1 OPERATION IN HEAT PUMP MODE .............................................................................................................................. 21

9.10.2 IN JOINT OPERATION (BAND I) ..................................................................................................................................... 21

9.10.3 IN JOINT OPERATION (BAND II) .................................................................................................................................... 22

9.10.4 SUBSTITUTION OPERATION.......................................................................................................................................... 22

9.10.5 OPERATION AREA - ACTIVATION OF THE AUXILIARY ELECTRIC HEATER AND BOILER (Plant circuit water temperature

sensor is not enabled) .................................................................................................................................................................. 23

9.10.6 AUXILIARY SYSTEMS OFFSET MANAGEMENT............................................................................................................... 26

9.11 DOUBLE SET-POINT MANAGEMENT..................................................................................................................................... 26

9.11.1 SETTINGS ...................................................................................................................................................................... 26

9.11.2 ADJUSTABLE SETPOINTS............................................................................................................................................... 27

9.11.3 COMMUTATIONS.......................................................................................................................................................... 27

9.12 SECONDARY CIRCULATOR MANAGEMENT (RELAUNCHING PUMP)..................................................................................... 27

10 HANDBOOK FOR SOME CONFIGURATIONS OF INSTALLATION.......................................................................................... 27

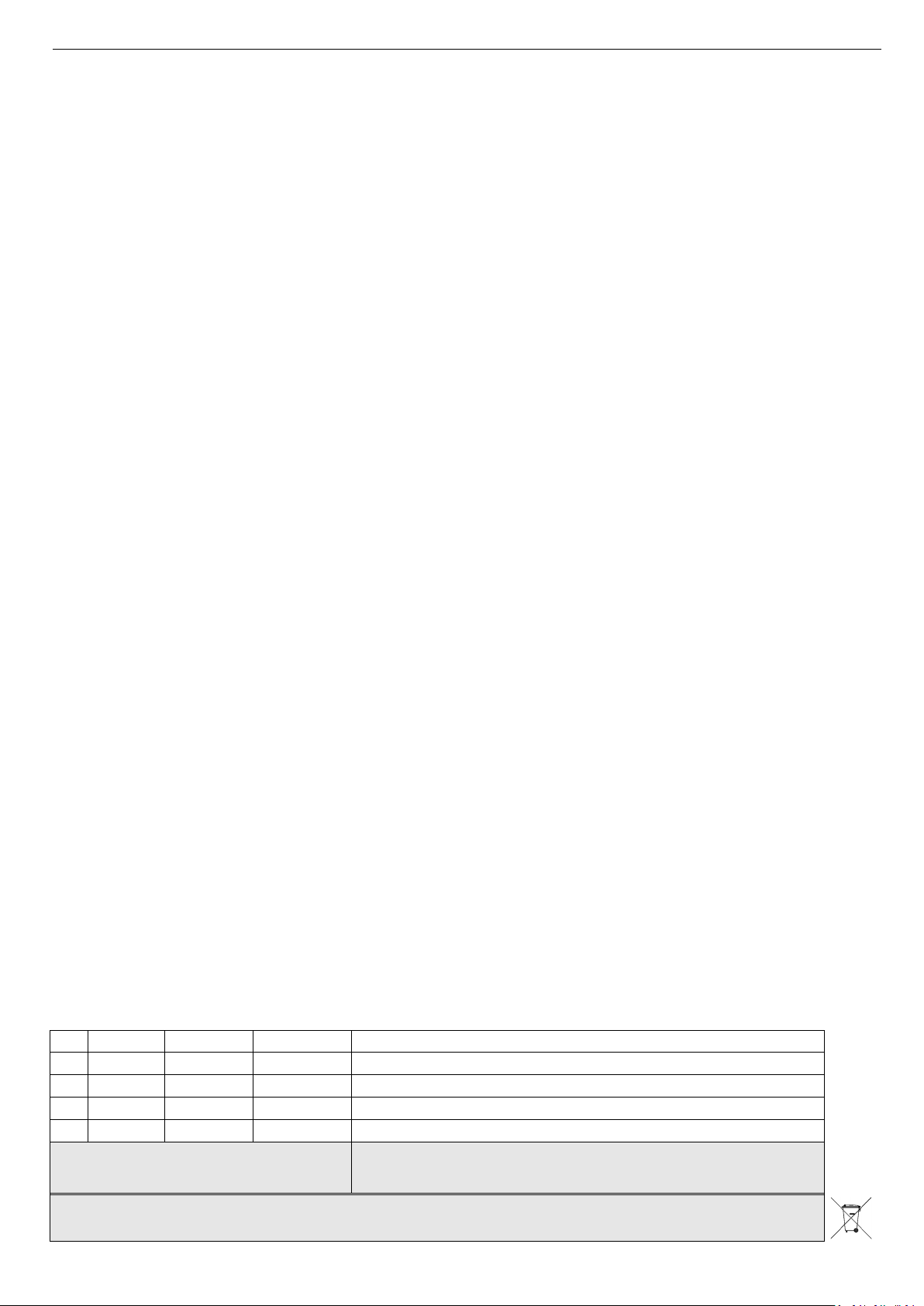

11 TABLES OF ALLOWED CONFIGURATIONS FOR THE USER AND INSTALLER......................................................................... 27

11.1 SETPOINT CONFIGURATION PARAMETERS .......................................................................................................................... 28

11.2 CONFIGURATION PARAMETERS........................................................................................................................................... 28

11.3 ALARM CONFIGURATION PARAMETERS .............................................................................................................................. 28

11.4 SETTING PARAMETERS ......................................................................................................................................................... 28

11.5 CONDENSATION PARAMETERS ............................................................................................................................................ 29

11.6 CIRCULATOR PUMP CONFIGURATION PARAMETERS........................................................................................................... 29

11.7 DEFROSTING PARAMETERS.................................................................................................................................................. 29

11.8 COMPRESSOR CONFIGURATION PARAMETERS ................................................................................................................... 29

11.9 CONFIGURATION PARAMETERS OF “GI” MODULE –PLANT MANAGEMENT –(OPTIONAL)...................................................... 29

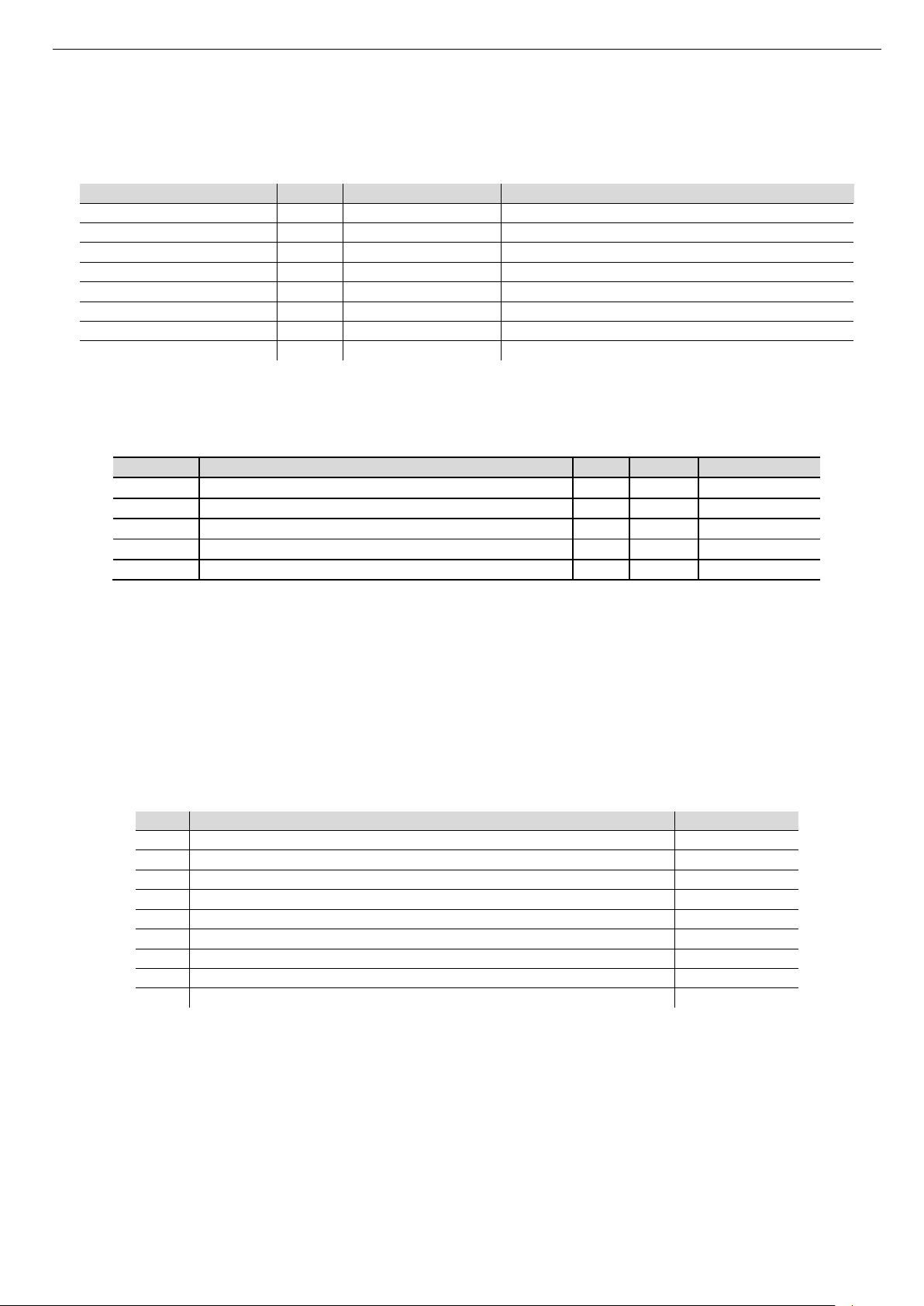

12 WATER WITH GLYCOL....................................................................................................................................................... 30

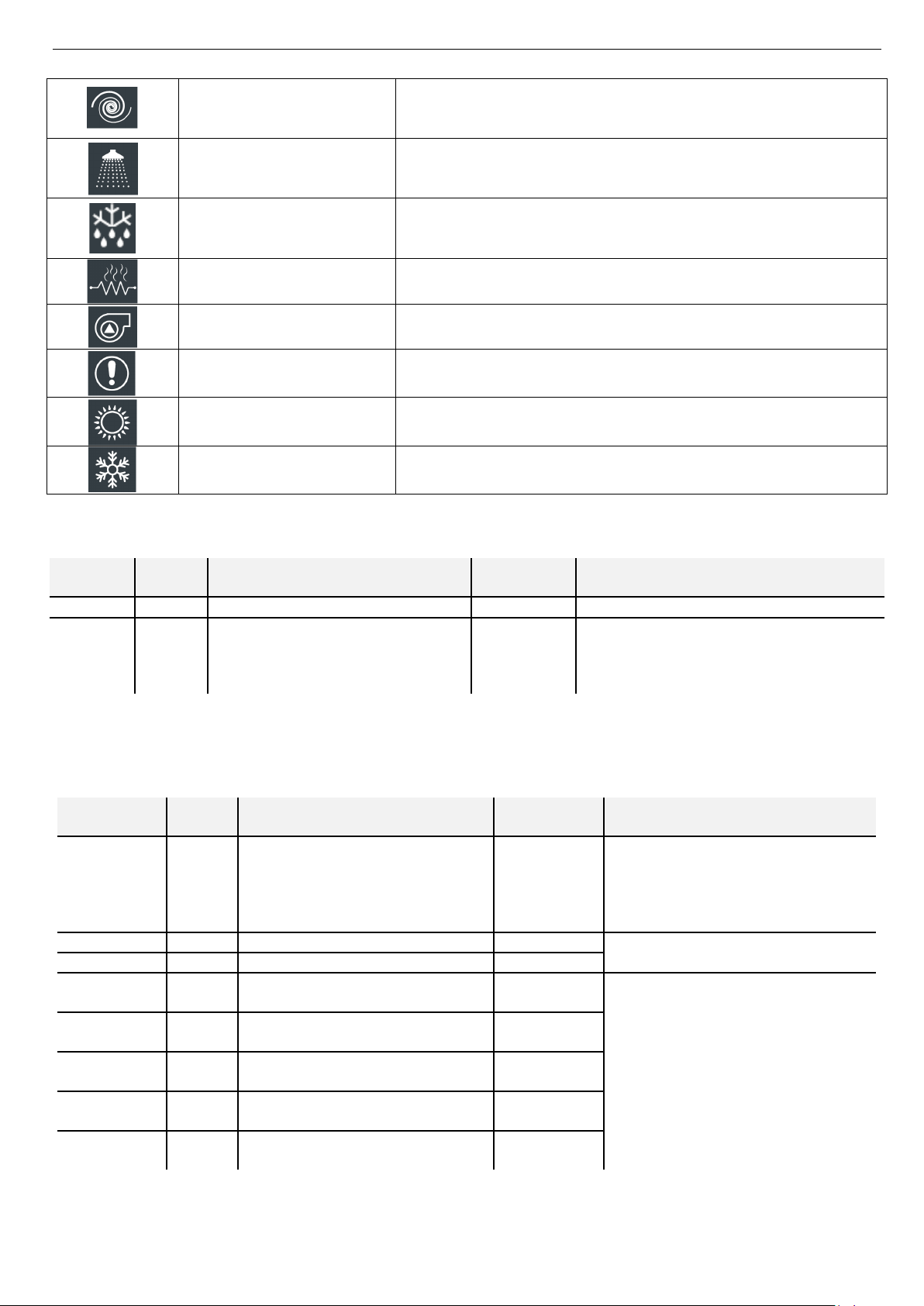

13 ALARMS MANAGEMENT .................................................................................................................................................. 31

13.1 E000 –REMOTE ON/OFF ...................................................................................................................................................... 31

13.2 E001 –HIGH PRESSURE ........................................................................................................................................................ 31

13.3 E002 –LOW PRESSURE ......................................................................................................................................................... 31

13.4 E003 –THERMAL PROTECTION OF FIRST ON/OFF COMPRESSOR IN BOTH CIRCUITS ........................................................... 31

13.5 E004 –FAN MOTOR ALARM ................................................................................................................................................. 31

13.6 E005 –ANTIFREEZE ALARM .................................................................................................................................................. 31

13.7 E006 –FLOW SWITCH ALARM .............................................................................................................................................. 31

13.8 [E008] DRIVER LIMITATION .................................................................................................................................................. 31

13.9 [E013] THERMAL PROTECTION OF SECOND ON/OFF COMPRESSOR IN BOTH CIRCUITS....................................................... 31

13.10 [E018] HIGH TEMPERATURE WATER SIDE ............................................................................................................................ 31

13.11 [E016] USAGE PUMP 1THERMAL PROTECTION ................................................................................................................... 31

13.12 [E641] HIGH PRESSURE ALARM SWITCH (IN SERIES TO THE COMPRESSOR DISCHARGE TEMP. SENSOR) ............................ 31

13.13 [E611÷E682] SENSORS’ ALARMS .......................................................................................................................................... 31

13.14 [E801÷E971] TIMEOUT INVERTER ........................................................................................................................................ 32

13.15 POWER FAILURE................................................................................................................................................................... 32

13.16 ALARMS LIST......................................................................................................................................................................... 32

13.16.1 HEAT PUMP LOCKOUT ALERT................................................................................................................................... 33