Safety - 1 UL 325 2018 Standard - MAX 1200 FS PRO/1700 FS PRO Matrix III Install Version 2.2G

2

UL 325 2018 Standard - MAX 1200 FS PRO/1700 FS PRO Matrix III Install Version 2c

Safety - 1

ul 325 compliant installation

requirements

a) Install the gate operator only when:

a) N’installez l’ouvre-barrière que si :

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

1) l’ouvre-barrière est approprié pour la structure et la classe d’utilisation de la barrière;

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 1.83 m (6 ft) above the ground

to prevent a 57.2 mm (2-1/4 inch) diameter sphere from passing through the openings anywhere in the gate, and in that portion of the

adjacent fence that the gate covers in the open position,

2) toutes les ouvertures de la barrière coulissante sont protégées ou grillagées du bas de la porte jusqu’à unminimum de 1,83 m (6 pi) du sol

si bien qu’une sphère de 57,2 mm (2 1/4 po) de diamètre ne peut passer par une ouverture au niveau de la barrière et de la portion de la

clôture adjacente que la barrière couvre en position ouverte;

3) All exposed pinch points are eliminated or guarded, and

3) tous les points de pincement sont éliminés ou protégés;

4) Guarding is supplied for exposed rollers.

4) des protections sont fournies pour les galets exposés.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The

pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will not come in contact with the

vehicular gate during the entire path of travel of the vehicular gate.

b) L’ouvre-barrière est destiné à n’être installé que sur des barrières utilisées pour les véhicules. Il faut fournir une autre voie d’accès aux

piétons. La voie d’accès pour les piétons doit être conçue pour favoriser le passage des piétons. Placez la barrière de sorte que personne ne

puisse entrer en contact avec la barrière pour les véhicules sur l’ensemble de sa trajectoire.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

c) Pour réduire les risques de coincement lors de l’ouverture et de la fermeture, la barrière doit être installée dans un endroit où la barrière et

les structures avoisinantes sont suffisamment éloignées l’une de l’autre. Les barriers battantes ne doivent pas ouvrir dans une zone d’accès

public.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-tighten the

operator clutch or pressure relief valve to compensate for a damaged gate.

d) La barrière doit être bien installée et fonctionner librement dans les deux directions avant d’entreprendre l’installation de l’ouvre-barrière.

Ne serrez pas trop l’embrayage ou la soupape de surpression de l’ouvre-barrière pour compenser une barrière endommagée.

e) For gate operators utilizing Type D protection:

e) Pour les ouvre-barrières qui utilisent des protections de type D :

1) The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving,

1) les commandes de l’ouvre-barrière doivent être placées de sorte que l’utilisateur voit l’ensemble de la zone de la barrière lorsque cette

dernière est en mouvement;

2) The placard as required by 62.1.6 shall be placed adjacent to the controls,

2) l’étiquette requise selon la clause 62.1.6 doit être placée à côté des commandes;

3) An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed, and

3) un dispositif de fermeture automatique (comme une minuterie, une boucle de détection ou un dispositif similaire) ne doit pas être utilisé;

4) No other activation device shall be connected.

4) aucun autre appareil d’activation ne doit être connecté.

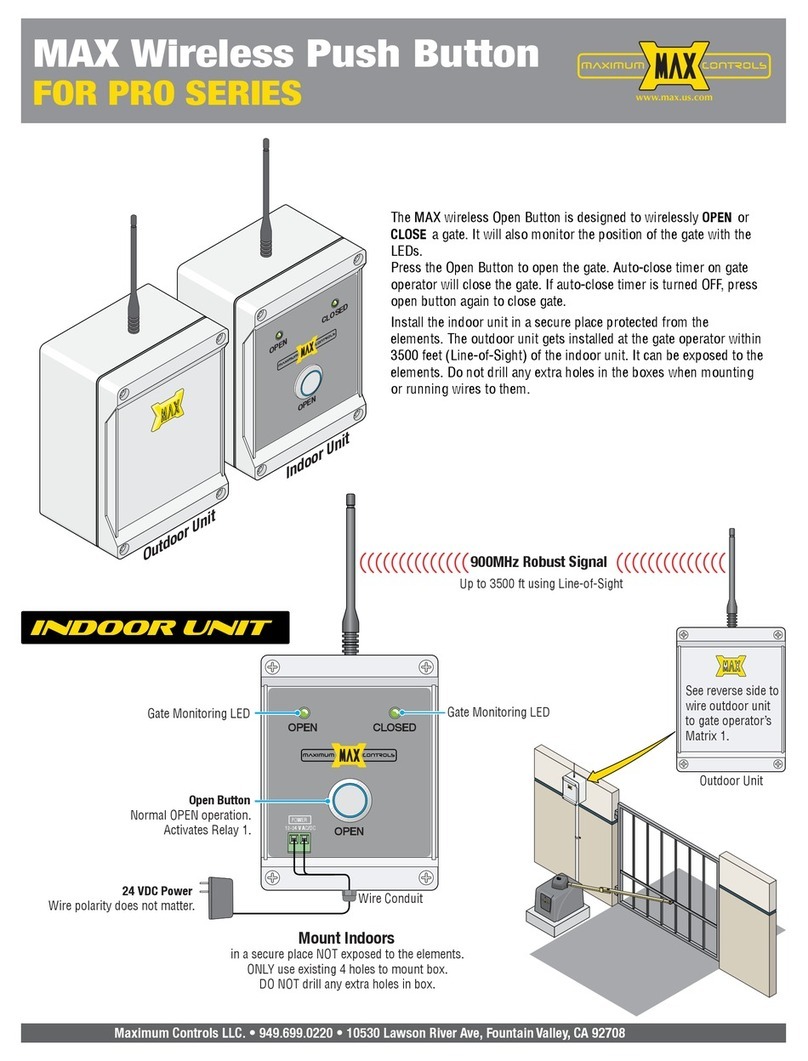

f) Controls intended for user activation must be located at least 1.83 m (6 ft) away from any moving part of the gate and where the user is

prevented from reaching over, under, around or through the gate to operate the controls.

f) Les commandes destinées à l’activation par l’utilisateur doivent être situées à au moins 1,83 m (6 pi) des pieces mobiles de la barrière et à

un endroit où l’utilisateur ne peut pas atteindre les commandes par le dessus, par le dessous, par les côtés et au travers de la barrière.

Exception: Emergency access controls only accessible by authorized personnel (e.g. fire, police, EMS) may be placed at any location in the

line-of-sight of the gate.

Exception : Les commandes d’accès d’urgence accessibles au personnel autorisé seulement (p. ex. pompier, policier, SMU) peuvent être

placées à tout endroit dans le champ de visibilité de la barrière.